Research Reports/ Rapports de recherche

Lorenzen Pottery:

Fifty Years in the Making

1 Ceramics are one of the most durable and informative types of artifacts that archaeologists and historians interested in material culture routinely encounter. Potsherds from archaeological sites provide information not only on technology, provenance and age, but also on broader social interpretations such as the organization of production, exchange, use and consumption. Most of this material is derived from utilitarian wares produced on a relatively large scale.

2 Studio pottery differs from mass-produced ceramic wares in that it is made in small quantities by one individual or by small groups who handle all aspects of its manufacture. It includes both functional and purely decorative wares. In the Western world, studio pottery in the modern sense has its roots in the second half of the 19th century in Britain and western Europe. It was strongly influenced by the Arts and Crafts movement (ca. 1860-1910), which advocated traditional craftsmanship and designs. Like other aspects of our material heritage, studio pottery mirrors the interests and background of the artists who make it. Indeed, some contemporary studio potters make political statements through their wares, but this is a very recent phenomenon. Studio pottery remains a vibrant part of the material culture of the Maritime provinces owing both to private individuals making these wares and to institutions that have offered programs in the past (e.g., Mount Allison University) and/or continue to offer programs (Nova Scotia College of Art and Design [NSCAD]) in the clay arts.

3 In Nova Scotia, red-coloured earthenware is known to have been produced since the early 19th century (e.g., Powell 1999), if not earlier, but it remains to be demonstrated that pottery was made in this area during the French regime. Evidence for pottery being made in early 19th-century Nova Scotia, however, is presently being sought by archaeologists working near Grand Pré (Jonathan Fowler, personal communication, March 12, 2013).

4 The production of studio pottery in the Maritimes dates as far back as at least the 1930s, and, although many of these wares survive, little is known about the production practices of even the more prominent historical potters from this area. Against a backdrop of the studio pottery produced in the Maritimes, this paper addresses this issue by presenting a detailed history and description of the wares made by Ernst and Alma Lorenzen during their approximately fifty-year-long career as potters in New Brunswick and Nova Scotia.

Mid-Century Maritime Canadian Studio Pottery

5 Studio pottery comprises both functional and non-functional wares made by individual clay artists or small groups of artists. In this regard, it differs from wares produced on a larger scale by “industrial” potworks, although similar forms of ceramics can be made at both types of enterprise. Studio potters are of two types: those who ply their craft as a livelihood, and those for whom it is a hobby. The latter group greatly outnumbers the former. In New Brunswick, Erica (1913-2007) and Kjeld (1900-1963) Deichmann were probably the first to earn their living by making studio pottery. They settled in Moss Glen on the Kennebecasis River near Saint John in the 1930s, and, using local red clay, attempted their first firing in ca. 1935. Their kiln was a large, homemade, wood-fired affair that proved difficult to control. They attributed kiln losses to the alkali content of the local clay, but it has subsequently been shown that this material has good plasticity, undergoes normal amounts (10 rel. per cent) of shrinkage during both drying and firing and can be successfully fired at temperatures typically used for this medium (Owen and Boudreau 2008). The Deichmanns addressed this issue by using clay imported from Nova Scotia.

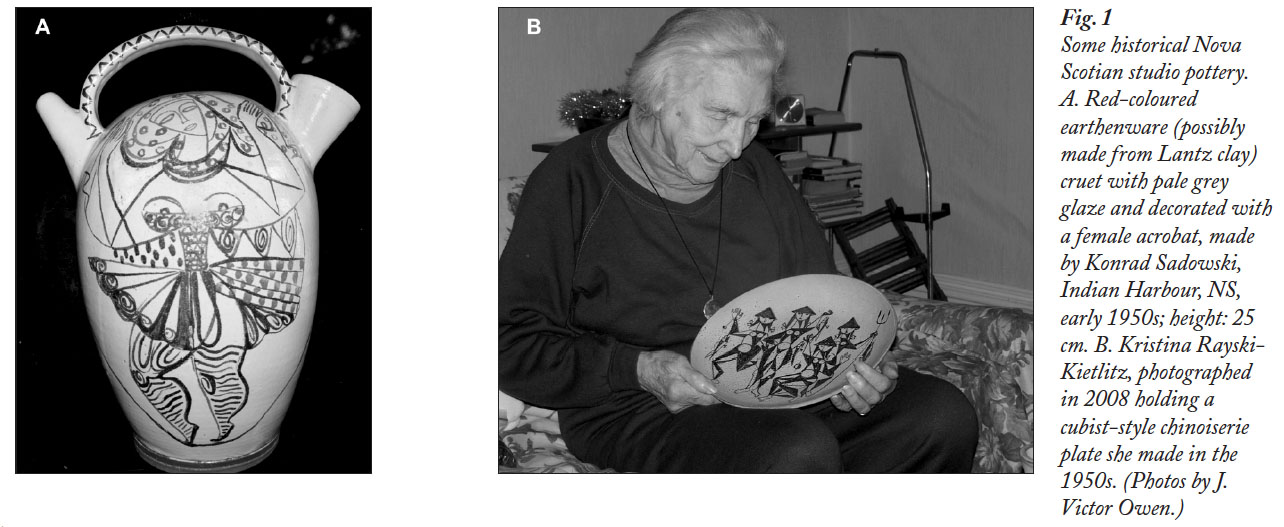

6 Ernst and Alma Lorenzen started making pottery as a hobby in the mid-1940s when they lived in Dieppe, New Brunswick, but soon produced it on a commercial basis, and relied on this craft for their livelihood by the time they were established in Lantz, Nova Scotia, in 1950. At this time, there were already many potters active in this province. Alice Hagen (1872-1972), who learned to throw clay on a potter’s wheel in the 1930s, had already learned to decorate existing pottery “blanks”—a popular hobby, particularly among women in the late Victorian and Edwardian era—and subsequently taught all aspects of pot-making at her home in Mahone Bay, Antigonish and Lantz (Crawford 2005: 28). Konrad Sadowski (1902-1960), a Polish immigrant who had a studio in Indian Harbour, taught pot-making in Halifax starting around 1949. With his wife Kristina, he produced functional wares with avant-garde designs (Fig. 1A). Nita DesBarres (ca. 1900-1976), another pioneer studio potter in the province, taught the craft to enthusiasts in Pictou County and also sold her wares. Many of the pots identified as having been made in Pictou that date back to the 1940s-1960s that were not made by DesBarres herself were probably made by her students. Grand Pré was another pottery centre in the 1950s and 1960s. It was here that a group of women, including Ruby Bleakney, Kristina Rayski-Kietlitz (Fig. 1B) and Helen Beals, worked, mostly on a noncommercial basis.

Display large image of Figure 1

Display large image of Figure 17 It was inevitable that Nova Scotia become a centre for potters, clay artists and brickmakers. The surface geology provides a wealth of raw materials used by these artisans—not only different types of clay, but many of the raw materials needed to make glazes. During the time of the dinosaurs, in the early Cretaceous Period, silica sand and kaolin clay—the kind used to make porcelain and other fine ceramics—were deposited in rivers and fault-bound basins now hidden by thick glacial deposits that blanketed the province during the ice age 125 million years later (Stea and Pullan 2001; Hundert, Piper and Pe-Piper 2006). Among the glacial deposits are layers of red clay that can be used to make various kinds of earthenware. Although they initially relied on commercial sources of clay and glaze ingredients, with time the Lorenzens increasingly made use of local materials to make their pottery.

8 Neither Ernst Lorenzen (1911-1990) nor his wife Alma (1916-1998) was from this province—he had emigrated from Denmark, whereas she hailed from the hamlet of Cocagne in southeastern New Brunswick. Out of this meeting of two cultures—one European, the other Acadian—emerged a unique style of pottery. The Lorenzens are world-famous for handcrafting exquisite clay models of Nova Scotian mushrooms, but they also created a wide variety of innovative and striking types of pottery during five decades of production. Although now inextricably associated with the small town of Lantz, some 20 km north of Halifax, the Lorenzens’ potmaking career started in New Brunswick in the mid-1940s.

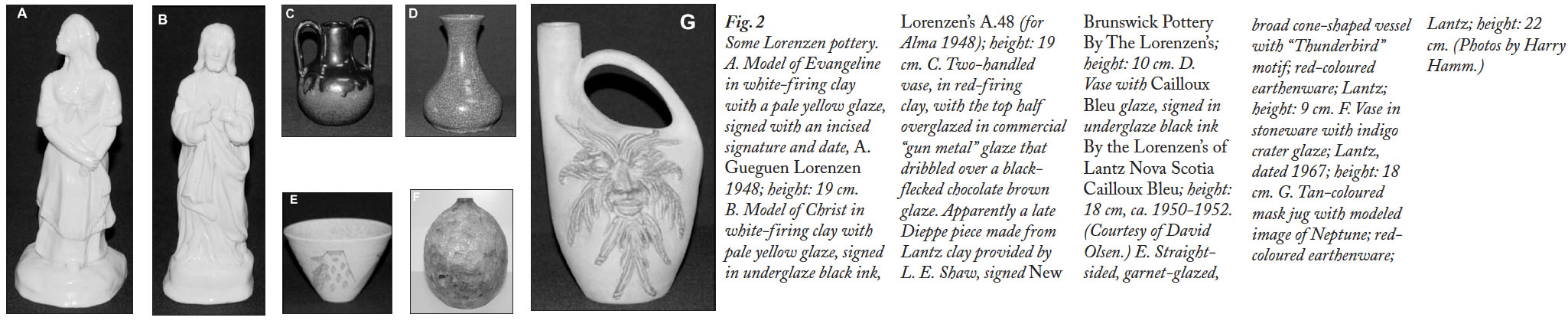

Lorenzen Pottery: The Early Days

9 Alma Goguen (also spelled Gauguin or Gueguen, the latter after her 18th-century ancestor, Sieur Joseph Gueguen) met Ernst in Antigonish, where she was enrolled at Mount St. Bernard College. To minimize her living expenses, she stayed with her widowed Aunt Marie, who owned the Bluebell Hotel in Antigonish. Alma had to withdraw from her studies to work at the hotel as concierge, cook and bookkeeper while her aunt was convalescing from an accident.

10 Ernst Lorenzen came to Canada to study forestry at the University of New Brunswick in 1930 when he was about nineteen years old. He was following a family tradition, since several generations of his forbearers were foresters. After staying with a Captain Gold (an anglicized spelling), a Dane who had a farm in Paradise, Nova Scotia, for three years, Ernst began his forestry studies. After two years of study, his forestry expertise took him back to Nova Scotia, fortuitously, as it turned out, to Cape George, near Antigonish, where he met and soon married Alma. The Lorenzens did not stay long in Antigonish. They moved first to nearby Cape George, then relocated to Rivière Verte, New Brunswick, before moving, in 1943, to Dieppe, a short drive to the Moncton airport where Ernst had found work. Alma pursued her artistic hobbies at home.

11 Since they started making pottery only as a hobby, the Lorenzens had no way of knowing that it would soon become their livelihood. At first, they modelled small pieces of pottery that they displayed,unfired and unglazed on window sills and in the living room of their flat on Légere’s Corner, a major intersection in Dieppe. A small room off the kitchen served as a studio. They soon became dissatisfied with their air-dried pottery and set out to find a kiln. They first used a small, electric kiln with an internal diameter of about 15 cm, the kind used for firing copper-enamelled jewellery and other small objects. To increase its capacity, they used unglazed, commercial refractory tiles as shelves, but, even so, they were restricted to firing small bowls, salt-and-pepper containers embossed with pinecones, buttons, cream and sugar sets, pin dishes, animal figures and novelty items such as miniature clogs.

12 So keen had they become about their new hobby that they fired up this little kiln almost daily. Inevitably, they soon outgrew it, and so they purchased a much larger, electric kiln from Amaco, which in the 1940s was the only company that supplied this sort of equipment in the area. Fortunately, they had a sympathetic landlord; Georges Bellefontaine allowed them to build a small shed behind the building where they rented a flat. As before, the Lorenzens used commercial glazes and white-firing clay, but when time permitted they also dug their own clay from the nearby village of Scoudouc. Unlike the sandy clay from the banks of Cocagne River which Alma had used as a child to make crafts, Scoudouc clay was cleaner and so was easier to prepare for making pots and models. Ernst would take a horse and skid through the woods to collect it. This clay is responsible for many of the white and tan-coloured bodied pieces the Lorenzens made while in Dieppe.

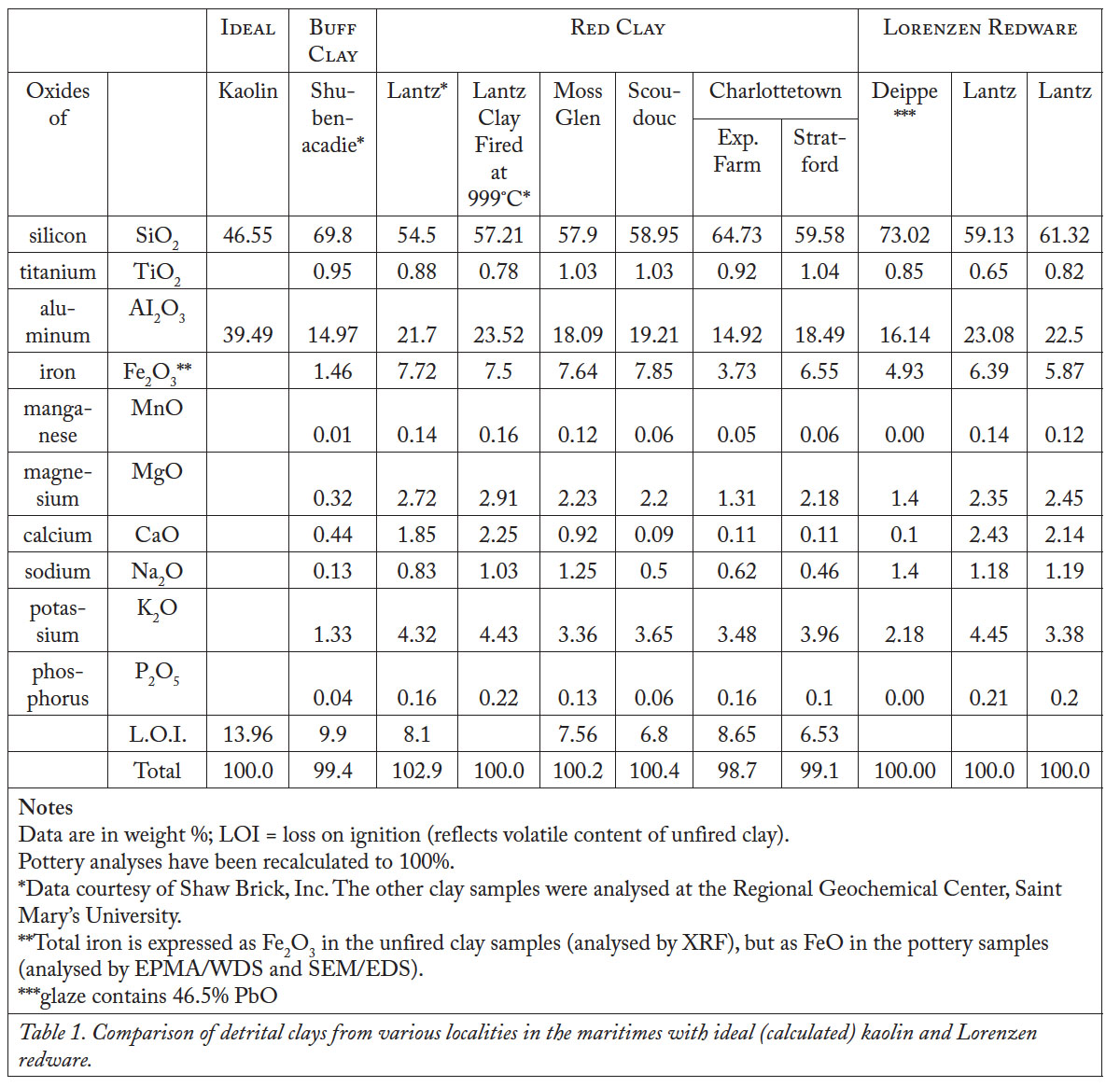

13 Alma did almost all of the design work. Except for a few small bowls, she did virtually no wheel work because she had trouble centring the glob of clay on the wheel. Modelling was her forte, and she often drew inspiration from both her Acadian and Catholic heritage while making figures (Fig. 2A and B). Ernst threw pots, modelled small figures of animals and also made plaster of Paris moulds so they could increase their output. Indeed, much of their production while in Dieppe involved slip casting and many of the salt-and-pepper containers and other small items were slip cast in molds. Despite this, Ernst steadily became more proficient at throwing pots. Alma shaped and applied handles to the cups, mugs and vases that Ernst threw. She also signed the base of all of their work.

Display large image of Figure 2

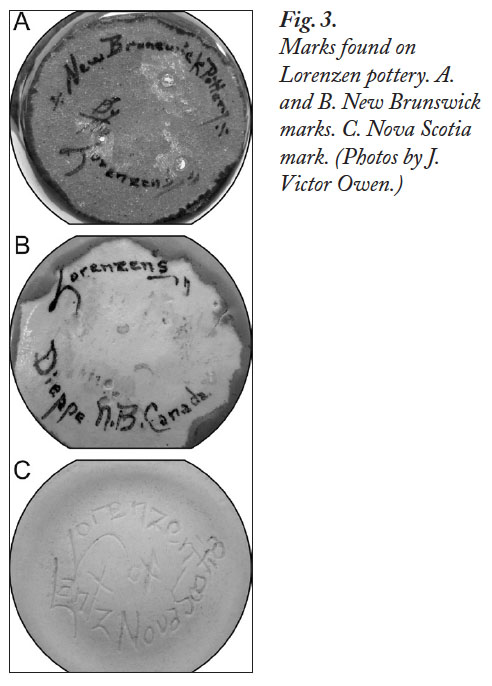

Display large image of Figure 214 New Brunswick Lorenzen pottery can easily be distinguished from the wares they subsequently produced in Nova Scotia because it is marked as such. At first, they used a stamp that left the impressed mark “New Brunswick Pottery Dieppe NB.” Later, they started labelling their pieces by hand in green or black ink under the glaze, either “Lorenzen’s Dieppe N.B. Canada” (Fig. 3B), or, by about 1948 when they started making pottery on a full-time basis, “New Brunswick Pottery By The Lorenzens” (Fig. 3A). Their Nova Scotia wares are simply marked “Lorenzen Lantz of Nova Scotia” (Fig. 3C), usually by being incised on the base. Typically, pieces signed with only the name “Lorenzens” corresponded to small, multiple items such as cups that would accompany a more fully signed, larger object such as a cruet. Both Alma and Ernst individually signed and dated some special pieces. Pieces made during the Canadian centennial year (1967) are commonly dated.

Display large image of Figure 3

Display large image of Figure 315 There are also differences in the manner in which they plied their craft. For example, for the first few years that Ernst threw pottery, he used a wire to cut each piece from the wheel-head. The base of these pieces is therefore flat. After being dried on a plaster of Paris surface (batt), the base was wiped smooth with a damp cloth. The base of their pots would be refined to a more elegant, recessed shape shortly after they moved to Nova Scotia. This move was instigated by the interest and generosity of Lloyd Shaw, a prominent brickmaker from Lantz. To entice the Lorenzens to the province, he gave them some of his red clay. Lorenzen red-coloured earthenware signed with a New Brunswick label evidently represents their successful experiments with this material while they still resided in Dieppe (Fig. 2C).

Lantz

16 During the winter of 1948-1949, the Lorenzens decided to move to larger premises. By the spring of 1949, they elected to move to Memramcook, where they had found some barns that they thought would be well suited for their growing business. Fate would intervene one more time.Being impressed with the Lorenzens’ work, Lloyd Shaw suggested that they move to Nova Scotia to take advantage of the red glacial clays his company used. He even offered to design and build a house and studio for them. The issue was settled. They moved to Lantz in September 1949, bringing along their large electric kiln, potter’s wheel, moulds and other pot-making tools. Shaw built their house next to the entrance to his brickworks. The location was excellent, for not only was the house built on suitable clay for throwing and modelling pots and other wares, but it was located on the main road between Truro and Halifax. Production started in earnest during the winter of 1950. Some dated pieces from this period are still extant.

17 Now that they were equipped with a professional studio, the Lorenzens had to consider the best way to market their wares so they could support their young family. They sold some of their wares directly to the public. This was not difficult. Until the Trans-Canada highway bypassed Lantz in about 1960, the road through the town was the main route to Halifax, the provincial capital. Large vases with colourful flower arrangements placed on the shelf behind the distinctive slanted picture window facing the street attracted the attention of passersby. The Lorenzens never sold their wares wholesale or consigned them. Apart from some pieces shipped to Banff, Alberta, retailers would come to their showroom and, like the general public, paid retail prices. They usually replenished their stock in the spring, before the tourist season. After the long, productive winter months during which the Lorenzens had produced large amounts of new material, retailers had a wide selection of wares from which to choose. Ernst and Alma benefited from this arrangement because they could receive feedback not only from the public directly, but also from the retailers who were moving their work. They soon learned which wares were marketable and which weren’t.

Mixing Clays

18 Nova Scotia has several types of clay suitable for making pottery, particularly those in the Musquodoboit and Shubenacadie areas. In addition to red ball clays at Lantz, these include stoneware clays, and kaolin at Meigher’s Grant and near Gay’s River. The Lorenzens made use of them all. The red colour of many ball clays such as that found at Lantz is due to the presence of iron oxide minerals, notably hematite. Unfired Lantz clay contains about 7.7 per cent iron oxide, 22 per cent alumina and 5 per cent alkalis (potash and soda). The buff-coloured stoneware clay from Shubenacadie has a much lower iron content (and lower alumina and higher silica) than Lantz red clay. Apart from differences in their lime (CaO) and soda (Na 2 O) contents, and higher alumina/ silica ratios (Al 2 O 3 /SiO 2 = 0.40 versus 0.23-0.33), Lantz clay is compositionally similar to the red clay deposits in southern New Brunswick and Prince Edward Island (Table 1). These red clays were exploited both by studio potters (e.g., the Deichmanns) and commercial potworks (Prince Edward Island Pottery, Charlottetown, 1880s; Owen and Rainey 2002). The composition of the orange-red body of an olive-green, lead-glazed (46.5 per cent PbO) Dieppe bowl most closely resembles clay from the experimental farm in Charlottetown (Table 1) in terms of its Al 2 O 3 /SiO 2 ratio (0.22 versus 0.23). Comparison of the body of this bowl with Charlottetown clay (recalculated to 100 per cent exclusive of LOI, and with total iron expressed as FeO) shows that the latter, however, is depleted in iron oxide (4.1 per cent versus 4.9 per cent FeO) and soda (0.7 per cent versus 1.4 per cent Na 2 O), enriched in potash (3.9 per cent versus 2.2 per cent K 2 O) and contains phosphate, a component not detected in the Dieppe bowl. Consequently, the source of the clay used to make this bowl is not known.

Display large image of Table 1

Display large image of Table 119 The Lorenzens found that red clay from Lantz could be used virtually as it was when taken from the ground. One deposit near Lantz was of particular interest. Ernst had heard a rumour in the village that layered, coloured clay locally known as “The Rainbow” could be found at Dutch Settlement, some 10 km from Lantz. It took him some time to locate it, and, for the most part, the Lorenzens relied on ordinary Lantz clay to produce their low-fired wares.

20 When he would start to run short on this material, Ernst would simply call Shaw’s brickyard and order a truckload, about two years’ worth. The clay would be dumped in their backyard. Ernst would move large chunks (approximately 10 kg) of the clay onto a long table in their basement to dry. Once it was dry, he would partly fill a big cast iron bowl with this clay and hammer it into smaller and smaller pieces, until they were at most the size of peas. He would then shovel the clay into buckets, place them next to a large galvanized steel washtub and then pour the ground, dried clay into a bucket of water into which some powdered nepheline syenite (a sodium rich rock that acts as a flux) had been dissolved. As he poured the clay pellets into the water, he would stir it until he had a mixture with just the right consistency, with the clay piled up forming a mound just above the waterline in the bucket. He’d then leave the slurry to settle and the mound of clay to slowly absorb the water. After a few days, he’d attach a coat hanger with a twisted end to a drill and agitate the mixture until he had a relatively homogeneous slip. This he would filter through a screen into the washtub to remove impurities such as pebbles or twigs. The washtub was almost always full of slip. If it was too thin, he’d skim off some water from the top layer.

21 Once or twice a week, Ernst would pour mugfuls of the slip onto large plaster of Paris batts that he had made using Mills Brothers (a Halifax retailer) dress boxes as moulds. He’d flip them after they had dried on one side and, while they were still pliable, would roll them up and cover them in plastic to keep them moist, storing them for future use. The clay destined for wheelwork had to be softer than that destined for modelling. When he or Alma needed some clay,Ernst would cut the rolled-up pancakes into 1 or 2 kg chunks and, using the Japanese method of wedging, would force air bubbles out and shape them into balls. This done, the clay would be ready for throwing.

22 The processing of Lantz clay was tedious, dirty work. Clouds of brown dust hung in the air in the basement. Over time, this adversely affected Ernst’s health. Even throwing the red clay had its consequences; late in his career, Ernst developed psoriasis, apparently because his skin became intolerant of the iron in this medium. As a consequence, he started making stoneware and porcelain instead. The more refined clays he used to make these wares were different from the Lantz clay he received by the truckload. Moreover, they would arrive already powdered, so he could avoid the arduous labour he invested in preparing the Lantz clay. He would nonetheless mix various refined clays together. Alma, however, still needed Lantz clay to make mushroom models, some of which used both red clay and kaolin. However, by this time, they were able to acquire this clay in powdered form from the Shaw brickyard. They still used the slip process that Ernst had developed, but sifted the dry clay first.

Potmaking

23 With a larger workspace in Lantz and clay close at hand, the Lorenzens’ output soared. No longer did they have to travel to Scoudouc to dig their own clay, so they had more time to experiment. Throughout their years at Lantz, the Lorenzens continued to make small objects as they had done in Dieppe, but, with access to larger kilns, they were able to make bigger and more elaborate pieces. Various refinements inevitably followed. For example, being dissatisfied with the flat, un-refined base of his thrown pots, Ernst discovered that if he turned a bowl with a wide rim, he could invert it on the wheel when it was leather hard, anchor it in place with small gobs of clay and, using a wire tool, coil off excess clay from edge to centre as it spun. For vases that were too tall to be inverted in this manner, Alma would use her paring knife to recess the base—a base that is both elegant and practical. It helped prevent their thrown pieces from wobbling and from scratching tabletops. This innovation characterizes Lorenzen pieces from the early days after their arrival in Lantz. Unlike their earlier pots and models, the base of these indented pieces was left unglazed.

24 Alma signed the base of all of their work, initially with “By the Lorenzen’s [sic] of Lantz NS” on the flat-bottomed pieces, but the first two words were eventually dropped (as was, in some instances, the “’s” on “Lorenzen’s” [sic]). Once this was done, the piece was ready for biscuit firing. Ernst was particularly efficient at stacking the kiln, an important task since if it was done improperly (e.g., if pieces were placed too close to each other) then undue kiln wastage would occur.

25 Ernst threw virtually all of his pots on the wheel. He would select a suitable amount (for the type and size of vessel he was creating) of prepared clay, say, a few hundred grams, and centre it on the wheel head. Not all clays are well suited for this purpose, however. Only clays with good plasticity are easily thrown on the wheel. However, Ernst threw all types of clay—red ball clay, stoneware clay and kaolin, as well as mixtures of clays. Some clay specimens he collected himself; others were brought by friends so he could test their suitability for making pots or models. Still other clays were purchased from commercial sources, including an Ontario outlet run by a Musquodoboit native who acquired truckloads of clay, including kaolin, from his hometown. So, directly or indirectly, the bulk of the clay used by Ernst originated in Nova Scotia.

26 There were, of course, some exceptions. Ernst’s notebooks mention, for example, Plainsman Clay, an Alberta clay he used in some of his stoneware. Most of his high-firing white clay and stoneware clay, however, were from Shubenacadie and Musquodoboit, where the Shaws had pits. Ernst also recorded recipes for paste mixtures including kaolin, ball clay, talc and other materials commonly used by ceramists. They show that he sometimes added specular hematite (a shiny, silver-coloured version of the iron oxide mineral that gives Lantz clay its red colour) to the stoneware clay body. This resulted in a mottling of the glaze colour and sometimes its texture as well.

27 Although of fine quality with good plasticity and a suitable firing range, unmodified Lantz clay can be difficult to use in the preparation of thin-walled or tall forms because of its tendency to warp or sag on the wheel. To avert this, Ernst would often add to the clay some grog (chamotte), ground ceramic material that gives the potter better control during throwing, and also adds a tactile texture to the paste. He commonly powdered soft, white refractory kiln bricks for this purpose. Ernst was able to throw delicate pots up until nearly the end of his career. Only the pots that he made around the time that he developed emphysema tended to become somewhat heavy, but, even after he took ill, he was still able to produce striking pieces.

28 With experience, collectors can easily distinguish the different types of Lorenzen pastes. Lantz clay fires a brick-red colour, which darkens to a chocolate brown when coated with a clear glaze. Coarse stoneware is a beige or pale grey colour, often with dark stipples. Ernst’s fine stoneware and porcelain, however, can resemble one another. In contrast to the snow-white or very slightly bluish white colour of porcelain, however, fine stoneware bodies have a slightly creamy or sandy tint. Their textures also differ subtly. Porcelain has a smooth, marble-like feel, whereas stoneware is slightly abrasive to the touch. Both are, of course, well vitrified, high-fired wares, a feature best seen where small pieces of the body have been chipped off the edge of the base.

Glazes

29 Glazes are used on most types of ceramics for both practical and decorative purposes. Because they consist of glass, they render impermeable porous-bodied wares that otherwise could not be used to hold liquids. Moreover, they can be surpassingly beautiful, and some ceramists specialize in this particular aspect of their craft. Charles Bezanson (Brother Thomas, 1929-2007), for example, a native Nova Scotian and friend and colleague of the Lorenzens for some thirty-five years, was one of the world’s most famous masters of porcelain glazes (see Nagano 1987). His influence on Ernst and Alma—and theirs on him—can hardly be overstated, and they each benefited from sharing glaze recipes and information concerning their firing.

30 Glazes are usually added to ceramic wares after an initial (bisque or biscuit) firing. They are applied either as a dusting of dry, powdered mixtures of minerals and metal oxides or as a suspension of these materials, usually in water that is quickly wicked away by the body of the ceramic object, leaving behind the glaze-forming powder. Often, potters will melt and regrind (“frit” or “calcine”) some of their glaze ingredients, rendering insoluble materials that would usually be soluble in order to counteract the toxic effects of some compounds commonly used in glazes, and to give them better control over the behaviour of the glaze as it melts in the kiln.

31 Glaze firings can be at high or low temperatures. Traditionally, alkalis (potassium and sodium, usually in the form of feldspars or of carbonate minerals derived from burning land plants and kelp) were used to flux high-temperature glazes, whereas lead was used in low-temperature glazes. More recently, compounds containing very light elements such as boron and lithium have been used as fluxes. Alumina is the most common stabilizer; lime can also be used for this purpose.

32 In addition to acting as a flux, lead also lends brilliance and smoothness to the glaze and gives it the ability to heal minute defects such as pinholes and blisters formed during firing. The Lorenzens used liquid glazes, and, until the early 1960s, these were invariably lead-based. While in New Brunswick, they used both commercial and homemade glazes. A notebook dated 1946, the first year they started making pots, records their earliest experiments making glazes. Instead of firing clear and colourless, their homemade glazes often had a slight yellowish tinge.

33 In Dieppe and shortly after they commenced operations at Lantz, the Lorenzens glazed the base of their pots. This can make it difficult to distinguish their early pieces made from white-firing, store-bought clay from those made from the pale beige-firing clay they themselves dug in Scoudouc. Regardless, a glazed, flat base on Lorenzen pots is a characteristic feature of some of their earliest work. In Dieppe, the only self-made glaze used by the Lorenzens was clear (colourless); the coloured glazes they used in New Brunswick were commercial glazes obtained from, for example, Amaco or Mercedes Ceramic Supplies. They had no spray booth in Dieppe; glazes were brushed on instead.

34 After moving to Lantz, they became more experimental and developed many novel glazes using local materials. To mix glazes, Ernst would consult his recipe book or a penciled plan for a new glaze he was developing. Everything except water was carefully measured. The powders were poured onto a sheet of newspaper and mixed with a spoon. The amount of water into which this mixture was poured was judged by instinct. If the glaze was to be brushed on, it had to be a different consistency than if it was to be sprayed. Only rarely did the Lorenzens dip pieces in glaze mixtures, although glazes were poured into biscuit-fired vases and other vessels and swirled around, and then the residue was poured out. The outside of the piece would be brushed or sprayed with the glaze. The pot would quickly absorb the water, leaving behind a residue that, when fired, would melt and subsequently be quenched during cooling, forming a glassy glaze.

35 To ensure uniformity, Ernst continued to use commercial silica sand and some sources of alkalis (e.g., Buckingham spar) for their glaze base, but he developed a penchant for using Nova Scotia minerals and ores to colour their glazes and create novel glaze effects. For example, they used locally found molybdenum ore to create a mottled, orange-coloured glaze. At least one of the glazes they used soon after they arrived in Lantz appears on someone else’s pottery. This glaze, a deep blue streaked by milky-green drips, appears on a small (15 cm wide), shallow dish signed “By the Lorenzen’s [sic] of Lantz Nova Scotia Canada” on its flat, glazed base. An identical glaze, however, coats an open vessel also made of red-firing clay, that is signed “HOS 1952” on its unglazed base. This suggests that either the Lorenzens shared this glaze with someone else, or that it is a commercial glaze used by many individuals.

36 Unlike the yellowish transparent glaze they used in Dieppe, while in Lantz the Lorenzens developed a completely colourless glaze with which they would often coat the interior of bowls. The clear glaze turns fired Lantz clay dark brown. They also experimented with metallic oxides and other minerals to colour their glazes. Unlike the relatively pure materials acquired from commercial enterprises, self-collected minerals had impurities that created unique glaze effects that enchanted Ernst and Alma. The novelty of many of their glazes can be attributed to their use of self-collected minerals not available from commercial sources, as well as to the novel mixtures of glaze ingredients and glaze firing schedules that they developed on their own.

37 Ernst acquired a list of abandoned mines and the minerals to be found there, and during weekends the family collected rocks throughout the province, visiting Advocate, Antrim, Economy, Londonderry, Meagher’s Grant, Sable Island, Sandy Cove, Walton, Yarmouth and other localities known to host prized minerals. These included apophyllite (a flaky silicate mineral), azurite (a copper carbonate), dolomite (calcium-magnesium carbonate), colemanite (a source of boron, which acts as a flux), galena (lead ore), barite (a barium mineral), iron-rich garnet (used in their garnet glaze, developed in 1955) and specular hematite. Ernst would crush these minerals to a fine powder for use in his water-based glazes. His experiments received recognition in the form of a Canada Council grant, awarded in 1965. This allowed him to visit Denmark to learn some of the methods employed by commercial potteries and to continue his own experiments with Nova Scotia minerals.

38 The Lorenzens used both low- and high-temperature glazes, depending on the type of ware they were producing. During the 1950s and 1960s, when most of their oeuvrewas made from red Lantz clay, they focused attention on low-fired lead glazes, all of which were fired in an oxidizing kiln atmosphere. Three colours ultimately proved most popular with the public: scarlet red (“Lorenzen Red”), malachite green and turquoise blue. They received the recipe for the latter glaze from Brother Thomas. Other glazes tended not to sell as well, even though Ernst and Alma preferred some of them. Their own favourite was a white-speckled navy blue glaze, which Alma referred to as “Cailloux Bleu” (pebble blue; Fig. 2D). The story behind Cailloux Bleu is fascinating. To safely spray glazes on his pots, Ernst constructed a spray booth with a fan, exhaust and light. The back was lined with a galvanized steel form to catch the excess spray, which would drip down into a dish. A powder was all that remained in the dish after the glaze mixture dried. After using this device for a year or so, Ernst decided to clean it out. Rather than simply discarding the powder residue, he decided to mix it in with water and try it as a glaze. Thus originated Cailloux Bleu, but once the powder was depleted, it was gone forever. Months later, Ernst prepared new glazes from the glaze residue that had accumulated in the glaze booth, but the effect was not the same. As a result, Cailloux Bleu, made from the residue of low-temperature glazes used on Lantz red clay, was history. Rare though these pieces are, they can be recognized by the dark blue colour of the glaze, its satin finish and the presence of white specks up to about 2 mm in diameter.

39 Another of Alma’s favourite glazes, used on stoneware, was referred to as “Old Faithful” due to its reliability. This glaze lost its opacity where it thinned over protrusions. It would pick up different tints (e.g., brown or blue) depending on the composition of the material it covered (clay or engobe). Another of her favourites was a soft yellow glaze with an orange peel texture, but pieces with these glazes sat longer on their display shelves, and so over time they made fewer and fewer of them.

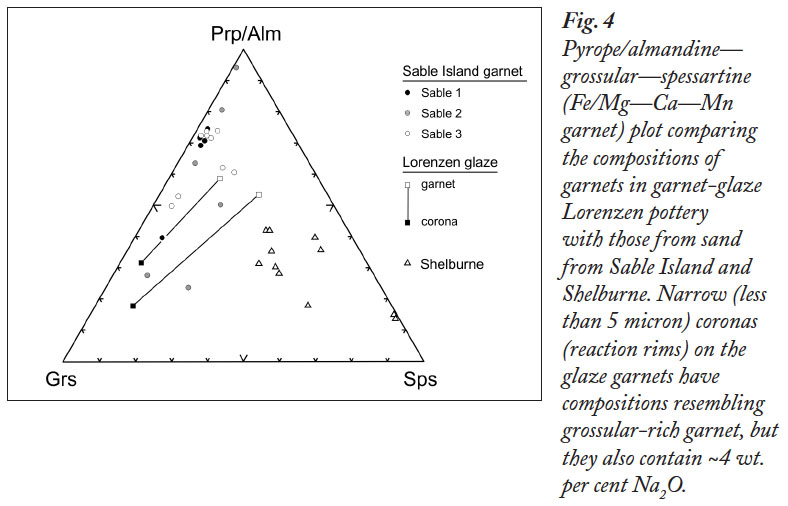

40 The Lorenzens’ well-known garnet glaze is white and stippled with tiny dark garnet grains. Analysis of the glaze itself shows that it is rich in silica, alumina, iron and lime and contains minute, angular grains of zircon (less than 15 microns in diameter) used as an opacifier. Two of the glaze garnets were analyzed. They are unusually iron rich; expressed in terms of garnet endmembers, they contain about 82 per cent almandine (iron garnet), 10 per cent pyrope (magnesium), 6 per cent grossular (calcium) and 2 per cent spessartine (manganese). Garnets of similar composition occur on Sable Island, although a wide compositional range of garnets occurs there (Fig. 4). Garnet sand also occurs near Shelburne, but those garnets tend to be enriched in spessartine compared to the analyzed Sable Island garnets. Garnet-glazed objects include salt-and-pepper shakers, creamers, sugar bowls and teacups and saucers. They are commonly decorated with black geometric shapes or theatrical motifs (e.g., Greek masks; Fig.2 E).

Display large image of Figure 4

Display large image of Figure 441 When the deleterious effects of lead glazes on consumers became known in the early 1960s, the Lorenzens started to use other, safer fluxes instead. Having mastered low-fired glazes, they turned to high-temperature glazes when Ernst started working with stoneware and porcelain pastes. He experimented with three or four types of reduction firings. His favourite glaze was a copper reduction red, a type subsequently used extensively by Brother Thomas. He also used a reducing kiln atmosphere to create soft, pale green celadon glazes. Crater glazes, characterized by lava-like bubbles, proved particularly challenging, because they were unpredictable. Some resulted in a thick, globby, slightly retracted surface akin to a crawling glaze, whereas, in other instances, the characteristic pock-marked cratering is better developed (Fig. 2F). Their records show that their crater glazes are highly feldspathic, consistent with the requirement that the glaze be highly viscous when molten to ensure that gas bubbles are trapped before the glaze can smooth out.

42 Some Lorenzen pieces have a two-toned effect. To achieve this, Ernst would spray a coloured clay slip (an engobe) over a piece in the bisque state. Then Alma would take the tip of a paring knife or a tongue depressor or whatever else was at hand and either scrape away the engobe to form a suitable pattern or add a wax resist to parts of the engobe to preserve it. The pieces were then sprayed with a semi-transparent or semi-opaque glaze, which would highlight the design and create the desired two-toned effect. The other method involved painting a design on a bisque piece with a watery oxide-wash solution. It was then left to dry, whereupon it was sprayed with a glaze. Two-toned pieces were also made by applying underglaze polychrome paint to bisque-fired pieces prior to glazing. This approach was used in their mushrooms but was rarely used on dishes. One particularly striking design Alma developed involved dotting a redware dish with red glaze and then applying an ivory-coloured, more fluid glaze between these patches, which would merge with the red, forming black streaks.

43 The Lorenzens experimented with hundreds of glazes. Their records, which are preserved by their descendants, list, for example, seven different celadon glaze recipes. Each glaze was given a different name. Some record the locality where key ingredients were found, such as the “Cap D’Or” glaze, which contained basalt (a dark green volcanic rock found near Nova Scotia’s Bay of Fundy coast), apophyllite, lead, barium, china clay and Cornish stone (altered granite). They described it as “very good” with a “rough texture but pleasant to the touch.” The Lorenzens always acknowledged in their notes the source of glaze recipes offered to them by friends and kept them confidential where requested. These, and some of their own most successful glazes such as Lorenzen Red, they kept secret.

Decoration

44 The Lorenzens employed many strategies for decorating their wares. Their designs have become so familiar that knowledgeable collectors can spot their work from a distance. Apart from making use of coloured glazes, Alma and Ernst decorated their pieces with hand-drawn or brushed geometric designs, by impressing various objects into the wet clay, or by applying shaped clay pieces to the surface of their pots. They also, of course, hand-moulded and carved clay to make models of mushrooms, birds and animals. One of their signature methods of decoration involved brushing a squiggly design with a wax resist on a dried, unfired pot before colouring it with, for example, a blue-firing cobalt oxide solution (as an engobe). The pot was then fired, glazed and fired again. Whatever translucent glaze they chose to use would show the pattern through it.

45 Alma used diverse household objects to make patterns in clay. These included plastic pieces from a pick-up sticks game, dental tools and even peach pits. She would often use these to incise patterns on the pendants and rings she made. She also commonly decorated with incised patterns footed trays that she shaped as a free-form slab and let dry in a sagged canvas form nailed to a rectangular frame. After letting the slab dry, she would apply feet to the corners and incise various patterns on the tray. Because of the shape of the canvas in which they were dried, these trays have a curved surface.

46 In contrast, Ernst would usually use woodworking tools and sharp knives to carve decorations on his pots, but, most times, it was Alma who instinctively knew the best pattern to apply to his work. In some instances, she would model a small decoration of, say, a face or animal, from which she would ask Ernst to make a mould. She would then cast several of these shapes, and fix them to one of Ernst’s pots, before destroying the mould. On other special pots, she would simply apply individually hand-shaped decoration. Some of these were specially ordered by clients, including the Nova Scotia government, which ordered a set of bowls bearing the provincial coat of arms. Another special order was placed by a Canadian medical society, which requested that a set of blue trays with the caduceus (sword with coiled snake) motif be produced for them. To ensure uniformity and speed up production, Ernst made a mould of the caduceus designed by Alma. The caducei were attached to hand-thrown trays. Ernst used a thick, viscous, nearly opaque glaze that retained a blue colour when applied thickly, but had brown edges where it thinned and showed the underlying red clay.

Mushrooms and Other Models

47 Europeans covet wild mushrooms; in contrast, many North Americans are taught since childhood to consider them all potentially poisonous. There was no history in the Lorenzen family of collecting mushrooms but Ernst developed his interest in these fungi while at UNB; the Lorenzens made thousands of models of mush- rooms, and they reside in private, institutional and museum collections worldwide. The story of the Lorenzen’s first foray into modelling mushrooms has been chronicled elsewhere (Barkhouse 1985), but is worth a brief retelling here. It all started one day in the fall of 1950. While searching for minerals useful for colouring new types of glazes, Alma nearly stepped on a small brown mushroom that Ernst immediately identified as a Coprinus micaceus. Already having considerable experience modelling figures, animals and birds while in Dieppe, Alma was more than willing to try her hand at creating some clay mushrooms. She started with the horn of plenty (Craterellus cornucopoides). Soon thereafter, a mycologist—a scientist specializing in mushrooms and other fungi—stopped by their Lantz studio, was enchanted by her model and immediately acquired it. Encouraged by this success, Alma started modelling other mushrooms, always identifying the genus and species by writing their Latin name on the base. Lorenzen mushrooms are true to nature in all respects, save for a slight thickening of the stems of some models to better support the most heavy-headed species and the omission of delicate veils or spiderweb like threads (corta) on some mushrooms such as Cortinarius and Mycena pura. Their very earliest mushrooms can be identified by the capitalization of both genus and species, an error soon pointed out by a mycologist friend. Until about 1960, these mushrooms were all modelled as flower frogs, each with a few small holes in the base to hold blossoms or a few sprigs of grass. Placed in a small Lorenzen dish to hold water, these adorned mushrooms made a delightful centrepiece for the dining room table.

48 The early models have the Lorenzen signature and mushroom genus and species inked on the base. Later mushroom models have unpierced bases, and writing on the base is incised in the clay, rather than inked on. The bases of both pierced and unpierced mushrooms are indented, not only to keep them steady, but also to minimize the chance that air bubbles might be trapped in what otherwise would be an overly thick clay model. Air bubbles would have caused the model to burst during firing.

49 To ensure accuracy, the Lorenzens prepared coloured sketches and photographed mushrooms in the field. Both made models, with Alma specializing in species with delicate gills. Each mushroom took about two weeks to create. The white porcelain parts of their mushrooms were painted with commercial polychrome paints. They were applied with a brush, a challenging task because the bisque-fired clay quickly absorbs the water-based pigment, and so it is an unforgiving medium to colour. Despite the challenges associated with colouring their models and wheelwork, the Lorenzens resisted the temptation to use an airbrush. In Alma’s words, “When we’re making mushrooms, we’re making little canvases” to be hand painted and glazed. These models are, in effect, miniature works of art, and so the use of an airbrush wouldn’t be appropriate.

50 The base of mushrooms made as flower frogs were daubed with a different glaze than that used on the top part of the model. The basic glaze was a clear dark green; the other was beige. When mixed and daubed on, they would mix haphazardly, giving a natural look. Sometimes the mixed glazes looked mossy—other times, less so. As with those used on their pots, these glazes were self-made. Only the holed mushroom models, the flower frogs, had to have their bases glazed underneath to render them impermeable. Many mushroom enthusiasts were purists, however, and appreciated these models simply as sculptures faithful to nature. They encouraged Alma to cease making them as flower frogs, and she was only too happy to comply, because having to glaze their bases made them vulnerable to sliding off their stilts during firing. Consequently, a higher proportion of the mushrooms survived kiln-firing once they were left unpierced and had unglazed bases. There were occasional accidents of course. Once, after Ernst died, Alma accidentally turned the temperature of the kiln too high, and, by the next day, all of the mushroom models had melted to puddles. Fortunately, this was a rare event.

51 In all, the Lorenzens made models of 245 different types of Nova Scotia mushrooms. The names of the mushrooms they made were compiled on a growing list soon after they started making them. By the late 1950s, collectors asked that an “official” list of Lorenzen mushrooms be made available to them, so they could see which ones they were missing. A handful of mushrooms, such as Lactarius indigo, were copied from illustrations in a book, when Alma, during the winter, was unable to seek new ones in the field. After Dr. Kenneth A. Harrison, a mycologist from Kentville, pointed out to her that some of these species were not indigenous to the province, she dropped them from the official Lorenzen mushroom list, and ceased making them.Others were dropped as a result of a name change instigated by mycologists or because of mistaken identity. For example, Alma made both Flammulina velutipes and Collybia velutipes, and gave each a slightly different colour. Since she preferred Collybia, it stayed on the list, whereas Flammulina was dropped. Ernst never produced more than a half dozen different types of mushroom models. Usually he produced some of the less attractive species such as the brain mushroom that Alma didn’t favour, but he still produced large numbers of his mainstay, the yellow finger mushroom Clavaria fusiformis.

52 Although anxious to document all of the Nova Scotia mushrooms they could find, the Lorenzens inevitably had to produce many duplicates of the most popular models. All were handcrafted, mostly by Alma. Certain species sold quickly, especially pink Russula maraie and, the most popular of all, Clavaria fusiformis. The latter was especially attractive as a flower frog, because the tall, slender yellow fingers stood high among the flowers. Ernst made them, along with a few others, at the beginning. Indeed, he was able to pay for flying lessons by making models of Clavaria fusiformis after-hours, reasoning that his extra work justified the expense of this endeavour. He obtained his pilot’s licence at the age of 45, and used a small plane to visit otherwise inaccessible locations, notably Sable Island, to seek garnet sand and other materials for his craft. Since there were restrictions on visiting Sable Island even in those days, Ernst would sign on as a co-pilot on an authorized flight, and simply took advantage of visiting the island to collect sand.

53 In addition to their mushrooms, the Lorenzens also made models of birds, cats, otters, amphibians, reptiles and even extinct synapsids such as Dimetrodon. Alma in particular had an interest in Eastern and Mesoamerican artifacts, and sometimes modelled deities from these and other cultures as separate models or as an applied motif (Fig. 2F).

Firing

54 In the late 1960s, the Lorenzens recruited the help of Tim Worthington, a Halifax potter, to construct a new, propane-fired kiln (Fig. 5). They used it for over twenty years for firing stoneware and porcelain thrown by Ernst. They used a smaller, front-loading electric kiln to fire redware, including redware-based mushroom models. It was also used for glazing these pieces. Eventually, this kiln was replaced with a top-loading model which was easier to stack.

Display large image of Figure 5

Display large image of Figure 555 The story of the Lorenzens’ gas-fired kiln highlights the contributions to kiln technology made by Luke Lindoe, a prominent Albertan geologist, ceramist and expert on the materials used by ceramists (he discovered and developed Plainsman Clay near Medicine Hat) and the methods by which they were fired (Crawford 2005). By the late 1960s, the Nova Scotia College of Art (subsequently renamed NSCAD) had outgrown its old location on Coburg Road in Halifax, and, indeed, its antiquated kilns had failed to meet safety standards. So, the Ceramics Department elected to send Homer Lord, a faculty member, and Tim Worthington, a student, to Banff to attend a kiln-building workshop being held by Luke Lindoe, so that upon their return they could oversee the construction of more modern kilns at their new address at the Historic Properties on the Halifax waterfront. The workshop was a practical affair: participants helped build new kilns from scratch to be used in a new ceramics studio at the Banff School of Fine Arts, which had been in operation since 1933.

56 Lindoe’s contribution to kiln technology involved changing the position of the entry point for the burners relative to the exhaust channel through the flue. He also modified the squat shape of kilns in favour of a higher, parabolic, beehive-shaped (“caternary arch”) structure more conducive to establishing an even heat flow within the structure. At the time, burners supplied heat to the kiln at a level above the point at which it was vented to the chimney. This, along with the squat shape of kilns, led to an uneven distribution of heat within the structure, such that the top part of the kiln achieved higher temperatures than the bottom. It also increased internal pressures when dampers were put in place, and so promoted a reducing kiln atmosphere. This led to a darkening of the body of redware (a malady known as “black core”) and a muddying of glaze colours. The thermal gradient within the kiln also meant that the results of firing were unpredictable. Moreover, the old kiln designs were inefficient, since a considerable amount of thermal energy was consumed simply in heating up the kiln structure itself, rather than directly heating its contents. By repositioning the burner intake below the vent and placing them parallel (rather than perpendicular) to the short brick wall (“bagwall”) traditionally used to deflect the flame entering the kiln, giving them a higher, beehive shape, and making use of light refractory bricks, Lindoe’s design gave potters more control over the kiln atmosphere (i.e., reducing versus oxidizing), more consistent kiln temperatures (and hence more predictable firings), and a less expensive alternative to traditional kilns. With the new design, when dampers were put in place, pressure within the kiln could escape through the flue opening rather than back up through the burner vents, so the burners fired in an oxidizing atmosphere. Potters could still achieve a reducing atmosphere by adjusting the burners themselves.

57 The new NSCAD kilns were built using these specifications. Homer Lord, a ceramist at the college, was sufficiently impressed with this design that he encouraged Ernst Lorenzen to have one built. This is the one that Ernst hired Tim Worthington to construct. It was housed in a shed behind their studio. It was a barn-shaped structure with a maximum exterior diameter of 175 cm, an overall height of 156 cm and depth of 100 cm. Its interior was 91 cm high, 56 cm deep (excluding the brick lining facing the door) and had a maximum width of 135 cm. A square brick conduit connected the kiln to a brick chimney. Modern kilns are equipped with a thermocouple so that temperatures can be closely monitored. Nevertheless, they still have a peep hole in the door so that ceramists can check their wares as they are being fired. Although thermocouples accurately measure high temperatures, use is still made of pyrometric cones (e.g., Orton cones) to determine when the desired temperature range has been reached, and that wares have been fired for a sufficiently long period of time. Orton cones are cone-shaped ceramic pieces that wilt at specific temperatures indicated by their Orton number. The redware produced from Lantz clay was fired at Orton cone 010 (approximately 920 o C, depending on cone size), so that, in the kiln, the pieces would glow orange. After this bisque-firing, the redware was glazed and refired at Orton cone 05 to 06 (approximately 1000 o C). The bisque-firing hardens the ware, exposes firing cracks before further time and effort is expended in the glazing process, and ensures that shrinkage is complete by the time the ware is glazed (Hamer and Hamer 1997: 24).

58 Stoneware and porcelain was, of course, fired at higher temperatures. Mushroom models were subjected to an initial, low-temperature (cone 010 or 011) bisque-firing, then painted and glazed and fired at cone 05. They took about a week to make, and, being small, many could be stacked in the electric kiln they used to fire these models. On rare occasions, these models were overfired and sagged in the kiln. Dozens of hours of work were lost as a result of these accidents. Nevertheless, with Ernst, Alma and their daughter Dinamarca (who helped her parents in their studio when her father’s health began to fail) all working in the studio, production peaked to the point that, between the two kilns, they undertook as many as three firings per week. After Ernst retired due to poor health, only mushrooms were produced at the Lorenzen pottery studio.

Legacy

59 How can the life and legacy of the Lorenzens be evaluated? In what ways did they contribute to the cultural milieu of Nova Scotia? Can their influence be detected in contemporary pottery? These are not easy questions to answer. Nothing anyone does is entirely new—we all build on the accomplishments of our peers and predecessors—so it can be difficult to assess one’s unique contribution to a discipline. Moreover, by necessity, artisans who develop their craft through their own experiments must guard the discoveries by which they create their signature pieces—otherwise anyone could easily reproduce them; this information nonetheless tends to be dispersed over time. Historically, potters have tended to be somewhat secretive about their work, so it is not surprising that the Lorenzens have been described as self-contained, even reserved individuals. Nevertheless, they maintained a lively and mutually beneficial correspondence with Brother Thomas and collaborated with him in making pieces during their visits to Weston Priory, Vermont, and equally during his visits to Lantz. They shared many glaze recipes with one another, the famous Lorenzen Red being a notable exception. In a very direct way, the Lorenzens thus contributed, as did some other Nova Scotia potters such as Eleanor (Sandy) and Foster Beveridge of Mahone Bay, to the professional development of Brother Thomas who, long before his recent passing (2007) was recognized as one of the world’s pre-eminent potters and glaze experts.

60 In the case of Western studio ceramics, it is easy to trace the influence that prominent artisans such as Bernard Leach had on other potters through his craft and publications, but he and his coworkers were in turn inspired by oriental ceramics, a tradition that can be traced back millennia. Like many of their contemporaries, such as Kjeld and Erica Deichmann, Ernst and Alma emphasized clean lines, simple decoration and novel glazes in their work.

61 Some of their innovations centred on unique glazes, particularly their scarlet-red glaze. Have others attempted to replicate their signature creations? Perhaps not, but their place as pioneers of Nova Scotia studio pottery is nonetheless secure. Moreover, Ernst was one of a handful of artisans who established the Nova Scotia Design Craft Council which today represents over three hundred individual artisans and craft enthusiasts through markets, exhibitions and other activities. Clearly, through sharing information and encouraging fellow potters, the Lorenzens had a major impact on their discipline.

62 The challenges facing modern studio potters are diverse. On one hand, the marketplace is more competitive now than it was in the Lorenzen’s heyday. On the other hand, it is easier to produce consistently predictable and satisfying results in the studio, because much more is now known about the methodology of producing fine clay art, standardized paste and glaze ingredients and recipes are widely available, and modern, programmable kilns allow potters better control over firing. As a result, less experimentation is required by those now entering this field, perhaps at the cost of creating novel and unique effects that the Lorenzens and their contemporaries who also used self-collected ingredients achieved.

63 Success in this trade, however, is measured by one’s ability to earn a living at one’s craft as much as the aesthetics of one’s work. On both counts, the Lorenzens succeeded in spades. Contemporary clay artists should reflect on the ability of the Lorenzens to support themselves—something very few artisans can now do—as much as on the merits of their wares. Their transition from hobby to livelihood is truly remarkable. Once they settled in Lantz, the Lorenzens focused on identifying their niche in the marketplace by offering wares that not only proved popular with the public, but were still gratifying and intellectually stimulating for them to produce. Ironically, at the time it was largely tourists who appreciated their work. These pieces are now being repatriated by Nova Scotia collectors back to the province where they were created. Ernst and Alma would be pleased.

We thank Tim Worthington for his reminiscences about building the propane-fired kiln at Lantz. Zoe Lucas kindly made available samples of garnet sand from three locations on Sable Island, and Randolph Corney assisted with sampling garnet sand from Shelburne. Shaw Brick, Inc. kindly made available the XRF analyses of Lantz and Shubenacadie clay reported in Table 1. Other analytical data were obtained through the support of Natural Sciences and Engineering Research Council of Canada Discovery and Saint Mary’s University Faculty of Graduate Studies and Research grants to J. Victor Owen. This paper is derived from an unpublished catalogue that accompanied an exhibition of Lorenzen pottery hosted by the Saint Mary’s University Art Gallery in 2012. This catalogue was largely based on the recollections of Dinamarca Lorenzen, who made pottery in her parents’ studio late in their career. Details about the ingredients of their glazes are recorded in notebooks preserved by the Lorenzen family. Thanks are extended to Robin Metcalfe, Harry Hamm and staff for their assistance with putting together this exhibition.