Creating a Past for the Canadian Petroleum Industry’s Technology:

The Drilling Rig

Bonar A. (Sandy) GowConcordia University College of Alberta

1 A study of the development, evolution and use of oil well drilling technology on the Canadian prairies, in the foothills and Rocky Mountains, the High Arctic and elsewhere from the early 1880s until the present day, might at first glance appear to present the researcher with a challenge because the relevant materials are scattered and not always catalogued or in a ready-to-use condition. Having said that, however, the materials are out there and the purpose of this research note is to point interested scholars in the appropriate direction.

2 While it is true that the Canadian oil industry had its start in Ontario in the early 19th century, and that at various times wells were drilled (usually dry holes) in New Brunswick, Nova Scotia, Prince Edward Island, the Queen Charlotte Islands and southern British Columbia, it was in western Canada that the industry took hold and rapidly began to produce tremendous wealth. This was most evident after Leduc #1 was brought into production by Imperial Oil in February, 1947; speculators, oil companies and governments at all levels benefited overnight from the Leduc bonanza and then from the discovery of a number of other significant fields scattered around the province. It was in western Canada that the newest American equipment, whether for cable tool or rotary drilling rigs, was tested, accepted or rejected, and often modified to better suit the local drilling conditions. By the 1970s Canadians—having done their apprenticeship in Canadian and foreign fields, and having worked with many of the leading American manufacturers—were at the forefront of technological innovation in the drilling industry, and were starting to pioneer techniques and equipment for use in the High Arctic, the offshore and elsewhere. Thus, any study on the technology used for oil or gas well drilling in Canada until at least 1970 will eventually have to focus on what happened in western Canada, especially Alberta, from the dry plains in the south to the muskeg bogs or “moose pastures” of the far northern part of the province.

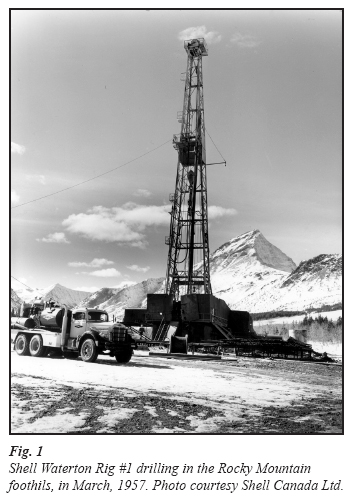

Fig. 1 Shell Waterton Rig #1 drilling in the Rocky Mountain foothils, in March, 1957. Photo courtesy Shell Canada Ltd.

Display large image of Figure 1

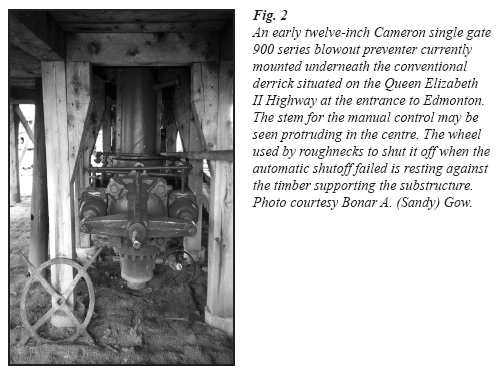

3 The good news is that there is no shortage of information on the evolution of oil well drilling equipment technology in Canada. In addition, there is an increasing amount of data and equipment available for studying developments since the 1970s in the High Arctic, the offshore and other fields. One of the industry’s greatest resources on this subject is the human one. Edmonton and Calgary are home for the greatest number of retired and active roughnecks, drillers, toolpushers, motor mechanics, geologists, seismologists, petroleum and chemical engineers and equipment supply-house workers and managers in all of Canada. They have organized themselves into formal “old-timers” associations and have included in their ranks persons currently working in the oil business. Among them are men who have worked in every oil field in Canada, the High Arctic, the offshore and around the world. Some of the older retirees have worked on the cable tool rigs (the last one was most likely used in Alberta around 1947); constructed full-scale models complete with many salvaged items of equipment; put together working miniatures which are on display at several locations in the province and in neighbouring Saskatchewan. Others have an intimate knowledge of steam power and wax eloquently on its virtues (“You could dry your clothes on the boilers and heat your food on the engines”). They can debate the strong points of a Detroit Diesel engine’s pulling power and overall reliability over that of a Cummins Diesel. These individuals can tell you what happens to metal in cold weather; how to thaw a frozen gas line; where to spot your rig; which light plant would give the best performance; and what life was like before blowout preventers came on the scene to hold down bottom hole gas pressure. Old-timers are a collective repository of information and, because of the nature of drilling, based as it is on a series of repetitive motions, they can recall in detail how machinery functioned. Their intimate knowledge of equipment, procedures, the causes of accidents and the like is truly impressive, and they are invariably eager to answer questions and to go with a researcher to the oil field museums or the drilling company yards to point out specific devices and to explain their operation. If they are unable to answer a question to their own satisfaction, they are quick to help the researcher connect with someone who can. No study on the technology behind oil well drilling equipment, past or present, will be a true success without the assistance of the old-timers.

Fig. 2 An early twelve-inch Cameron single gate 900 series blowout preventer currently mounted underneath the conventional derrick situated on the Queen Elizabeth II Highway at the entrance to Edmonton. The stem for the manual control may be seen protruding in the centre. The wheel used by roughnecks to shut it off when the automatic shutoff failed is resting against the timber supporting the substructure. Photo courtesy Bonar A. (Sandy) Gow.

Display large image of Figure 2

4 The ability to examine, collect information on, photograph and even operate items of oil well drilling equipment first-hand is essential. Equipment of all types has been—sometimes lovingly—preserved here and there across western Canada, but nowhere is it to be found in such abundance as Alberta, especially in Calgary and Edmonton.

5 Pieces of equipment can be located easily around Alberta, although some of them are doing yeoman duty in other capacities. For example, drill bits are sometimes found decorating gate posts, while casing and drill pipe have been turned into corrals and cattle guards. Local townspeople, farmers and ranchers around the province are usually willing to allow a researcher to look at abandoned drilling equipment and well sites, especially after permission has been asked to travel across private land. And remember the cardinal rule of the country—close and fasten the gate behind you! The company yards of drilling contractors are also the final home for pieces of obsolete technology and they are usually found at the back, often hidden by weeds.

6 Calgary has two significant repositories of drilling equipment. The first is the Glenbow Museum where smaller items are on display. Most are from the early days of oil exploration when cable tool drilling reigned supreme and thus they are rare. There are also some additional items in storage which have not recently been on display and they are of the same era. A second site that displays vintage drilling equipment—including a reconstructed cable tool rig—is the city’s Heritage Park. The rig is in running order.

7 Edmonton possesses two equipment museums. The first is in the hands of a private group, the Oilfield Technical Society. It is located just inside the city limits (www.edmonton-ots.com) in a rural setting. It has on display an impressive inventory of both drilling and production equipment. The drilling-related items are too numerous to mention in detail, but some truly unique items are: a spring pole drilling apparatus, a Failing 1500 drilling rig and a cable tool rig. The cable tool equipment was brought down from the northern part of the province where it had remained for decades, sitting over an abandoned hole. More recent rotary drilling displays include a complete shallow hole rotary rig donated by a major drilling company. The equipment is carefully maintained and there is a custodian on the site who is familiar with most pieces. A recreation facility is also at this location and inside there are pictures of oil field personalities. Anyone interested in the production side of things in the Canadian oil patch will also find a number of displays featuring equipment such as pumping units, production treaters and the like.

Fig. 3 These two roughnecks are changing a rock bit on a Shell rig, some time in the late 1950s. Photo courtesy Shell Canada Ltd.

Display large image of Figure 3

8 The second museum, a national historic site, is the Canadian Petroleum Discovery Centre (www.LeducNumber1.com), a 5.2 hectare park, at Devon, just south of Edmonton. The Centre has just completed a multi-million dollar renovation which enlarged the library as well as the archival and display areas. On the top floor, the Centre features pictures and a few words on the members of the Canadian Petroleum Hall of Fame, which is bigger every year. The executive publishes an annual booklet featuring full biographies on each of the individuals. There is also an excellent library (see below). On the floor below is a sizeable display area filled with innumerable pictures, pieces of equipment, models of various types of drilling rigs, seismic and geological displays, drill bits, core samples and a gift shop which carries books on the oil business not likely to be found outside of Alberta. On the grounds there is a collection of drilling-related vehicles and an operating shallow depth rotary drilling rig. It sits over a hole that is no longer producing, in this case Leduc #1, the discovery well which ushered in the real “age of petroleum” in Alberta. The Edmonton area old-timers occasionally start up the diesels on this rig and show the public how drilling with this type of technology took place. A conventional steel derrick of the type used from the 1930s to the early 1950s is on the grounds as well. The most recent addition to the rig collection is a restored and operating cable tool derrick with a gasoline engine. It was built and equipped by retired drillers and volunteers from Edmonton and Calgary. There are also displays featuring smaller pieces of equipment—casing, drill pipe, tubing, bits, whipstocks, bailers, fishing tools, geological samples, and other such things—which are strategically located around the grounds. It should be noted that the production side of the oil industry is also on display: an early service rig, a pump jack and tank, bottom hole pumps and smaller pieces of oil field apparatus. The Centre is open year round and the staff and volunteers are always willing to assist visitors.

9 Information explaining how equipment was designed, how it functioned, common operational problems—anything critical to an understanding of the evolution of drilling equipment—can be found in a number of locations. The Glenbow Museum and Archives has a collection of taped interviews conducted with old-timers from the earliest days of the oil business in Alberta. Some of the interviewees are now deceased, but their knowledge has been captured on these tapes. Many of them talk at length about equipment and procedures. Some of the interviews have been transcribed and are available in manuscript form. There are also newspapers from Turner Valley, Wainwright, Lloydminister and several smaller centres where drilling took place in the 1920s, 1930s and mid-1940s. (They can also be found on microfilm at the Alberta Legislature Library.) These newspapers are sprinkled with bits and pieces of technical information on drilling passed on to the public in lay terms by local reporters. They document drilling progress, the careers of the drillers, accidents, fires, major technical problems and often contain detailed comments on new equipment or problems with old gear. A careful harvesting of the articles in these newspapers will yield a rich crop of information.

10 Technical information is abundant at the Discovery Centre. The custodians there have used their personal contacts with old-timers to preserve for posterity an impressive collection of pamphlets, brochures, books, manuals, handbooks, blueprints and drawings dealing with every aspect of drilling. These equipment manuals and procedural handbooks are all but impossible to find outside of the Centre. Moreover, the library has a series of files which contain technical documents produced by manufacturers and they appear to be unavailable elsewhere in Canada. The documents section has been organized by a professional archivist, and new material arrives regularly for inclusion in the collection. Staff members cannot catalogue and organize it as rapidly as they would like.

11 Unfortunately, the financial failure of a number of early drilling companies, and the amalgamation of others, sometimes make it difficult to follow the path of technical change with ease because many records were discarded. Furthermore, the smaller companies often neglected to document their adoption and use of different technologies: many decisions were made by one or two individuals on the rig floor and much was done by word of mouth. Comments and evaluations often wound up on the inside of a cigarette package which, when it had outlived its usefulness, was tossed in the mud at a well site or ground into pieces on the floor of a company pickup truck. Fortunately, this was not the case with Imperial Oil (Esso Resources), Shell, Royalite (absorbed by Imperial Oil) or Chevron. The first three had their own drilling departments and they were good at record keeping. Imperial’s was the largest and it has an excellent archives. There is also a good library with up-to-date publications that deal with the full range of topics relating to oil and gas exploration, production, pipelines, processing and refining. The files and ledgers are bulging with company-based research and in-depth reports on equipment testing, as well as the background to key decisions relating to the ongoing use of individual pieces of equipment.

12 The recent move of Imperial Oil from Toronto to Calgary has resulted in a $4 million donation to the Glenbow Museum, making the Glenbow the home to the country’s third-largest corporate archives collection. The Imperial Oil Review, which is very important source of data up until the 1960s when its format began to change, is also in this collection that comprises more than 125 years of Canadian heritage. It includes in excess of 150,000 photographs, hundreds of motion picture films, thousands of letters and countless artifacts chronicling Canada’s petroleum industry. Shell, too, has a good library and a fine collection at its Calgary office, as well as a helpful staff. Older copies of its company employee publication are significant because in it there are snippets of information on the drilling program. Chevron’s holdings are useful but tiny, and consist mainly of background information on the drilling of certain wells. The employee publication has some helpful technical data in it. Lastly there is the Royalite Oil Company, originally an Imperial Oil subsidiary created in the 1920s, whose drilling department was directed to drill wells in the Turner Valley area for the mother company in Toronto. Some of Royalite’s drilling records, which are cared for by the Glenbow, contain significant amounts of information, especially on the Turner Valley and Redwater fields. Royalite company officials commented in depth on the equipment they tested and adopted and these documents made it safely to the Glenbow where they were catalogued and properly preserved. An invaluable set of the company’s staff magazine, The Royaliter, which is crammed with technical data on both the exploration and production side of things, is in the hands of a former company employee who transferred to Imperial Oil in the years after Leduc #1 was brought in. He resides in Calgary. These magazines contain information which was extracted from now long lost company files, put into lay language and passed on as items of interest to employees and their families.

13 Photographs are critical to a study on drilling technology. There is an excellent collection at Imperial Oil and Shell. Not to be outdone by the oil companies is the Glenbow, which concentrates on southern Alberta. All three collections are catalogued. However, the largest and most outstanding collection of photographs of vintage drilling (and production, pipeline, refining and processing) equipment up to the early 1960s is to be found in the Alberta Provincial Archives, now housed in a state-of-the-art facility on Edmonton’s south side. Finally, there are the photographs taken by the old-timers, which often capture the unusual, as well as images missed by the professional photographers.

14 Canada’s oil and gas drilling technology is an area that historians of technology have not investigated in depth, and although this writer has published a general work on the subject, there is still much research to be done on specific areas of drilling technology, particularly from the 1970s onward. Furthermore, the history of the technology behind petroleum production, as well as oil and gas pipe lines, refining and processing, are almost untouched. These aspects of the Canadian petroleum’s technology also beg for the researcher’s attention.