Research Reports / Rapports de recherche

Documenting the Small Craft Collection of the Canadian Canoe Museum:

The Development of SmartScan and the Visual Archiver

1 The Canadian Canoe Museum has recently implemented two state of the art systems, the SmartScan 3-D small craft measuring device and the Visual Archiver records management database system, to assist with the documentation and management of information on the watercraft in their collection. This project was feasible through a partnership with Steve Killing Yacht Design and Commonwealth Heritage Planners, with financial assistance provided by the Museum Assistance Program of the Department of Canadian Heritage and the Antique and Classic Boat Society, Toronto Chapter.

2 The SmartScan system was designed by Steve Killing Yacht Design. It is a new device used to record the hull shape of small craft. This apparatus runs a computer-controlled carriage beside the craft and records the cross section shape of the hull at regular intervals. The system is optical, does not require any contact with the vessel and runs autonomously once the vessel is in place. The recorded shapes are transferred to the computer where they are stored as a permanent record of the shape and can be used to create traditional line drawings of the hull.

3 The Visual Archiver system is new archival software that provides a flexible and comprehensive means of cataloguing, organizing and exploring image collections, archives and inventories. It features a viewer package that allows researchers or the general public the opportunity to access information from a kiosk site without being able to alter any of the data. The viewer is designed to allow the creation of CDs that can then be used as a cost-recoverable way to store and retrieve information. Information packages can be made available in kiosk systems both on and off the museum site.

4 This paper focuses on the museum collection and the development and use of the SmartScan 3D imaging apparatus. The background and operation of the Visual Archiver is covered in general terms but its specifics are not dealt with in this paper.

The Evolution of the Canadian Canoe Museum

5 The collection of the Canadian Canoe Museum was originally assembled by Kirk Wipper, Physical Education professor at the University of Toronto and founder of Camp Candalore, a boys camp located in Dorset, Ontario. He began collecting watercraft in the late 1950s. In 1968, he founded the Kanawa International Museum of Watercraft.

6 In 1995, nearly thirty years after he began collecting, Mr. Wipper transferred ownership of the collection to a volunteer board of trustees representing a non-profit organization known as the Canadian Canoe Museum. At this point in the museum's history, all that physically existed was the collection itself. The board had the challenge of finding a location and a facility to house the massive collection. In addition, they set out to hire the necessary staff and to raise the funding needed to establish the museum.

7 During the five years that followed, the museum experienced a series of major events fueled by the energy and dedication of hundreds of volunteers and museum financiers that would transform it into an entity unto itself.

Highlights of the Museum's Development

- 1996 Staff members hired to manage and administer the museum and its collection.

- 1996 Two buildings and eight acres of land donated by the Outboard Marine Corporation.

- 1996 The entire collection of 550 water-craft moved from Dorset, Ontario, to Peterborough, Ontario.

- 1996-2001 Over a five year period corporate donations and partnerships with all three levels of government reached approximately five million dollars.

- March 2001 Museum opened 370 square metres of permanent exhibits in the Weston Heritage Centre.

- June 2001 Launch of three travelling exhibits currently circulating across Canada.

- June 2001 Design and development of educational and artisan programs celebrating Canada's unique cultural heritage.

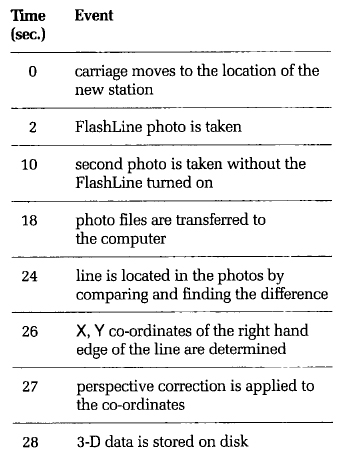

Display large image of Figure 1

Display large image of Figure 1Collection Profile

9 The Canadian Canoe Museum holds the largest collection of watercraft in the world, consisting of over six hundred canoes, kayaks and other self-propelled watercraft. It is nationally significant and features a diverse collection of vessels ranging from a 59-foot (18-metre) Salish racing dugout to a 5-foot (1.5-metre) canoe constructed of paper. Approximately one-third of the collection consists of Aboriginal watercraft, each vessel serving as an example of a unique balance between form and function. These craft range from numerous styles of bark canoes representing cultural regions throughout Canada to massive cedar dugout canoes from the west coast. This collection also features several examples of skin kayaks from the eastern, central and western regions of the north.

10 A significant portion of the collection features a historic collection of wood plank, wood strip and wood canvas canoes manufactured by well-known companies throughout the Peterborough region. This includes the Ontario, Peterborough, Lakefield, and Rice Lake canoe companies and vessels built by the predecessors of these large companies including examples from Dan Herald, William English, and Thomas Gordon. There are also fine canoes representing major canoe manufacturing centres from the east coast of Canada and from the United States.

11 Modern examples of watercraft, which reflect the use of new materials and design techniques, are found in the collection. In this section are canoes that represent a particular story or journey, such as the famous red Chestnut canoe used by Canadian canoeing legend Bill Mason, the bark and canvas covered canoes used by former Prime Minister Pierre Elliot Trudeau, and Orellana, the canoe used by Dan Starkell and his son Dana to paddle an unprecedented 19 300 km from Winnipeg to the mouth of the Amazon River.

12 Specimens from around the world are present in the collection. Some of these unique craft include dugouts from Papua New Guinea, Taiwan Klong boats, Senegal plank canoes, Quechen reed boats, a Welsh coracle, and a Chumash sewn plank canoe.

13 The museum has amassed an impressive array of associated objects including paddles, tripping equipment, clothing and many exceptional scale models. The archives, currently located at Trent University, comprise approximately twelve linear metres of documentation, related to all facets of Aboriginal history, European exploration, and local canoe manufacturing.

The Challenges of Collections Management

14 In any museum, there are challenges in managing and caring for the artifacts, but the sheer size of this collection and the scope of the work to be completed presented a serious challenge in meeting museum standards of collections' management and conservation. It was remarked by one museum professional that "It would likely take one hundred museum staff one hundred years to complete the work needed on the collection." Obviously there remained serious constraints on the ability of only one staff person to carry out the work on the collection, while meeting other demands of the job in a growing national museum.

15 Perhaps the most frustrating problem for staff, researchers, and the interested public was the lack of documentation for the collection. Although there were efforts by previous staff of the Kanawa Museum to maintain a registry of artifacts, much of the valuable detailed information relating to provenance, origin, history, and so on was not documented or was interpreted incorrectly. To add to the challenge, the collection was in limbo for approximately three years while arrangements were being made to find it a new home. During this period, there was no trained staff working with the collection, or overseeing it. Out of necessity, the collection had to be moved several times. Although efforts were made to record the movement of the collection and to track each item on the register, in many cases watercraft were inappropriately identified, or identification tags became lost.

16 In addition to the challenges of collections' records management, the condition of the collection itself was suffering. After spending almost all of its life in an uncontrolled environment, many of the craft suffered physical distortion as a result of fluctuating temperature and humidity levels. The constant moves, and improper support over long periods of time, made it inevitable that many of the craft had become hogged and twisted and had suffered physical and structural damage.

17 To address the issues facing the collection, a plan was developed to systematically approach each issue and to deal with it accordingly as resources became available. For the Canadian Canoe Museum, timing was everything.

Partnerships for Progress

18 In 1999, Dawn McColl, collections manager at the Canadian Canoe Museum, learned of a device being designed by Steve Killing, which was used to record the shape and document the lines of watercraft. With the specialized collection of watercraft at the Canadian Canoe Museum, it seemed logical that the museum could benefit immensely from such an apparatus. A proposal for a partnership was presented by Steve Killing and his son Jonathan to further develop the prototype to serve the specific needs of the museum.

19 At the same time, McColl was introduced to a project being developed by Commonwealth Heritage Planners. It was a state-of-the-art archival management database called the Visual Archiver. This comprehensive data management system would allow users to manage a variety of types of data including images, documentation and even the data recorded by the SmartScan device. Selected information could then be downloaded into a kiosk system for audiences to retrieve and view.

20 In 1999 funding was acquired from the Department of Canadian Heritage's Museum Assistance Program to set up the SmartScan and Visual Archiver Programs. As a result of funding acquired in 2000 to develop permanent exhibits, teams of researchers were brought on board, bringing a wealth of specialized knowledge and research skills to the museum. A conservator was also hired to work specifically towards preserving the craft. Fortunately, at the Canadian Canoe Museum there has never been a lack of skilled volunteers and the dedication needed to successfully meet any challenge. Finally all of the resources were put in place to work towards meeting the goal of achieving the highest standards of collections management and conservation.

Goals and Objectives

Small Craft Research

21 The installation of integrated technology of the SmartScan and Visual Archiver systems has enabled the Canadian Canoe Museum to document and reproduce detailed technical information from watercraft. It allows the Museum to improve on its existing collections management system by expanding its current database capabilities to include line drawings, video, images and documentation, and combining them in a user-friendly viewer package. Of great importance is the increased ability to provide access to information to facilitate research on a national scope. Finally, this new technology will assist the museum to foster relationships with other museums and institutions to work towards preserving our watercraft heritage.

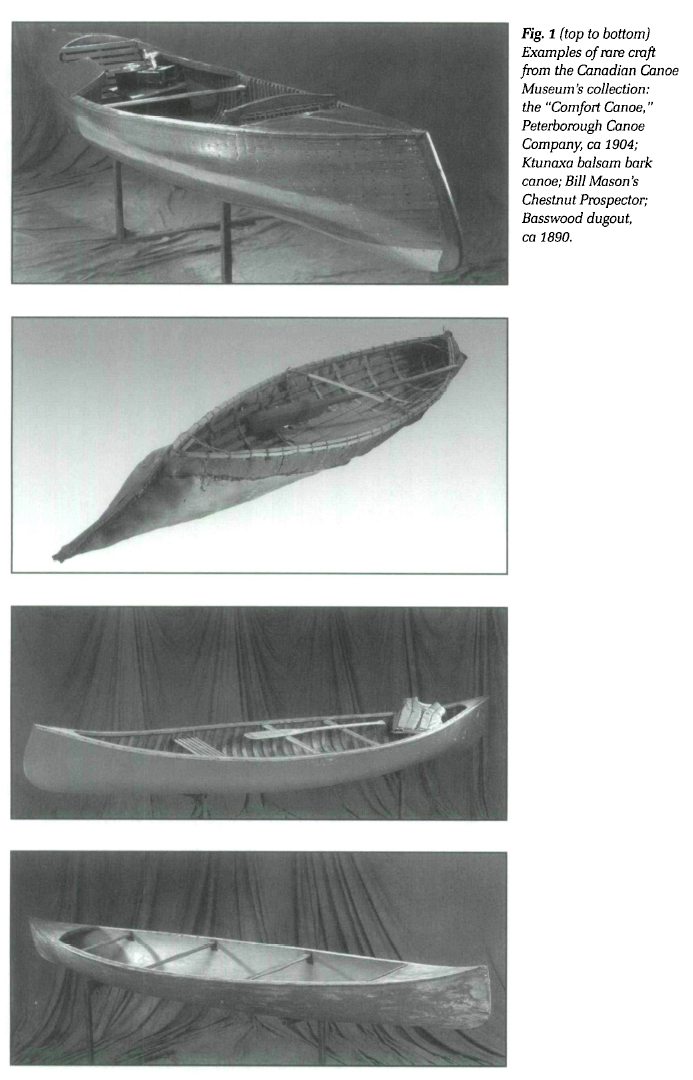

Small Craft Preservation

22 The data collected from the SmartScan system will be used to obtain an accurate three dimensional representation of the craft in a timely, efficient manner. This ability allows the museum to readily monitor and study any changes or distortion in the hull of the craft over time and to make the appropriate restorative action.

23 Currently the drawings produced by SmartScan have enabled museum staff to fabricate specialized supports and mounts for each of the craft on display, as well as those being shipped in travelling exhibits. This will have major implications when the museum begins to plan for the development and manufacture of permanent storage facilities for the collection.

24 The present condition of certain craft are of grave concern to the museum. Many of the skin kayaks and bark canoes are rare and extremely fragile, and in some cases badly damaged. The SmartScan device requires minimal manipulation or handling of the vessel and its non-intrusive nature lessens the risk of additional damage to the craft.

25 SmartScan will provide accurate measurements of any hull's current condition with a record of any areas of damage. Taking the data one step further, drawings can be modified with faired lines, depicting a close approximation of the original shape of the hull. This information will be fundamental in making decisions about conserving a hull in its present state or reproducing the craft using the original as a template. The museum will then be able to determine the degree and method of treatment. The ability to produce this type of information will play a valuable role for determining future conservation treatments.

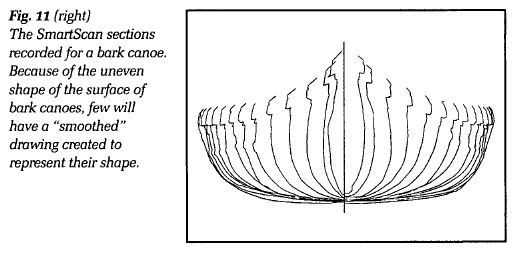

26 It is expected that the information collected regarding the preservation of watercraft will be of great benefit to conservation specialists, restorers and builders who are interested in boat restoration. It will foster a greater degree of documentation, monitoring and research, and will result in studies on approaches to conservation, treatment and preservation of small craft. In effect, this will promote collaboration among professionals from both the restoration and the preservation fields to work together toward finding solutions to the challenges specific to canoes, kayaks and other paddled watercraft. This information will also be a useful resource to exhibit designers and curators when planning for the exhibition of such objects.

Public Access and Educational Programming

27 As with other museums, the Canadian Canoe Museum is under increasing pressure to provide outreach opportunities, information and research with limited resources and limited staff. With these new tools the Canadian Canoe Museum will find itself in a good position to be able to respond to requests for information and documentation on canoes and kayaks. This will be of particular value for First Peoples, who are involved in studying and reconstructing canoe and kayak designs pertinent to their own individual heritages.

28 Access to increased documentation will also contribute to enhanced public education in providing a timely response to inquiries and generating more detailed information. This is imperative due to the increasing reality of global inquiries. The multi-user, multi-platform, multi-access aspects of the Visual Archiver expedite the storage, retrieval and updating of information. Most of all it promotes efficient access to information about the collection to a variety of users.

29 The SmartScan device and Visual Archiver will be able to provide visitors with watercraft information in a progressive and dynamic fashion. The database of canoe and kayak designs with accompanying images and information will define the Canadian Canoe Museum as a leading centre of canoe and kayak research. The multi-media kiosk will allow visitors an opportunity to visit the museum's collection in far greater detail and depth than possible through more conventional displays and exhibitions. This will be possible both on and off the museum site.

Products and Services

30 The Canadian Canoe Museum has recognized that over the last ten years, there has been a substantial increase in the interest in redeveloping and reconstructing traditional canoe and kayak designs for the commercial market. It is our hope that canoe and kayak builders will be able to depend upon the museum for accurate offsets and line drawings that can then be built as reproduction watercraft. In this fashion, the Canadian Canoe Museum will play a leading role in the preservation and continuation of our Canadian watercraft heritage.

31 With the nostalgia surrounding the canoe and the rising interest in preserving and learning about canoe culture, there lies a market that is virtually untapped. Using the resources of the Canadian Canoe Museum archives and artifact collection, combined with that of the new technologies of SmartScan and the Visual Archiver, there lies endless possibilities in the area of product and service development.

Project Development and Costs

32 In light of the constantly growing demands on the staff of the museum and the limited resources available, it was unrealistic to think that the small staff could meet its extensive goals in a timely manner without importing some new technology.

33 The SmartScan system provided a simple, straightforward, and timesaving opportunity to document the craft in the collection. Trained volunteers could complete much of this work in a space located within the museum. This enabled visitors to observe the process, making it a dynamic exhibit in itself. The results were consistent and accurate and yet the time required to measure a hull, and potential for operator error, were greatly reduced.

34 A second major issue was to justify the initial costs to implement the new systems. This level of sophistication would have been prohibitively expensive only a few years ago, but fortunately the lowering costs of new technology made it feasible to pursue this project. The ability to co-operate with two private sector partners (Killing and Commonwealth) allowed the museum to gain considerable knowledge, skills and technology in a cost-effective fashion. In fact, when costing out this project, taking into consideration the development of new technology and the scale and scope of the end product, the overall cost seemed quite reasonable.

35 When looking at the cost savings and benefits over the long term and comparing it to other processes of manual documentation the benefits of the SmartScan device became clear. In a feasibility report produced for the museum by students of the Computer Technology Program of Sir Sandford Fleming College, research was completed to examine the cost of operating both the SmartScan and Visual Archiver systems and to compare these systems with other similar methods of documentation and information management.

36 The report stated that once training of volunteers had been completed and all processes and procedures of documentation were established, the long-term savings of using the SmartScan device to document the craft would be substantial. In calculating the potential savings the report researched and assigned an hourly average rate for an experienced layman to manually document the canoes in the collection. This figure was then multiplied by an average length of time it would take to document a sixteen-foot (5-metre) canoe to the same level of detail as SmartScan. It is noted that this detail is greater than would normally be done by most documenters using a manual technique. (For example: one skilled measurer at $50/hr x 20 hours/canoe = $1,000 per canoe.) The SmartScan can document both sides of the same sixteen-foot canoe in approximately forty minutes, operated by one trained volunteer. This, combined with the additional time required for the processes of set up of the craft, equals an approximate time of seventy minutes to record the shape of the hull in great detail.

The Development and Operation of the SmartScan 3-D Measuring System

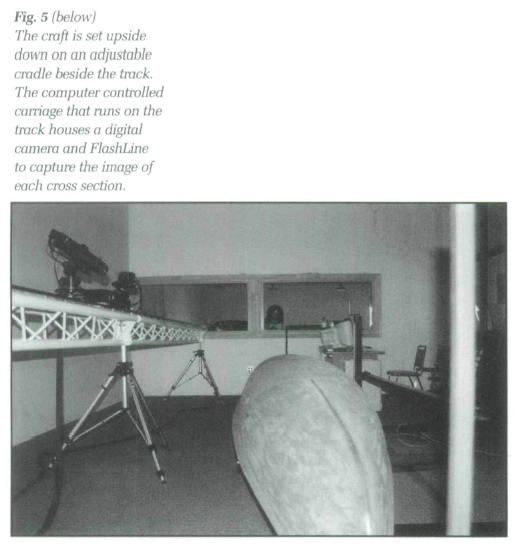

37 In order to fully appreciate the benefits of the SmartScan measuring device, it is useful to briefly review the manual procedures used to record the shape of small craft hulls.

Manual Hull Shape Documentation

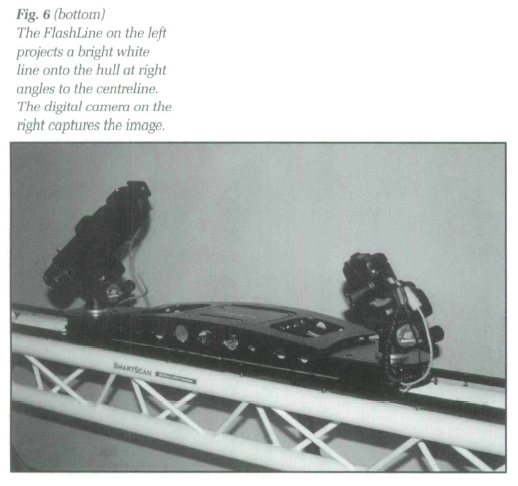

38 The manual recording of the hull shape of small craft is well established and there are almost as many systems for taking off fines as there are documenters. The techniques vary from crude, quick and simple to clever and sophisticated. The book Boats — A Manual for Their Documentation by the Museum Small Craft Association gives a description of ten different methods for taking the lines from a hull. One group of techniques records the offsets directly from the hull. That is, measurements from a vertical, horizontal or angled reference line to the hull surface are recorded in a table. Later those dimensions are plotted either full scale or at reduced size to re-create the original shape.

Display large image of Figure 2

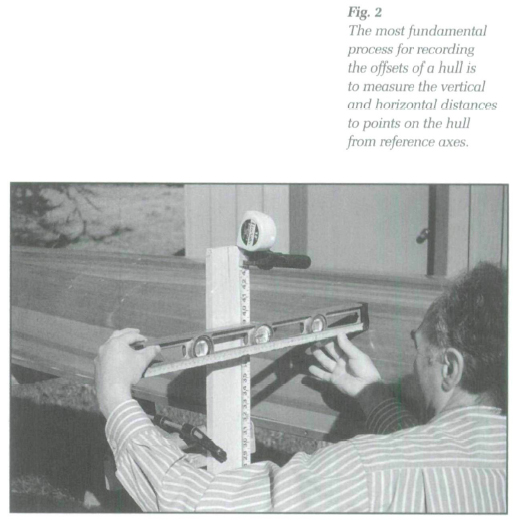

Display large image of Figure 2 Display large image of Figure 3

Display large image of Figure 339 Other procedures use customized tools with pointers or templates to record the physical shape, which can then be transferred to paper without the use of offsets. Fig. 6 shows one such device built in 1999 at the Canadian Canoe museum.

40 Manual documentation can be exact, but is seldom swift. One of the time-consuming steps with manual systems is the establishment of reference base lines and confirmation that the stations' locations are precise and square to the reference line. In order to be able to reconstruct the shape of a vessel, the relative position of the sections is required. That means they must be referenced both horizontally and vertically to a common baseline. They must also be square to that line as viewed from above. Those that have documented boats by hand know the challenge of creating reference lines in a shop with an uneven floor or perhaps no floor at all. Additionally, the operator is always trading off the desire for more points to define the station well, with the reality of time constraints.

41 Once the reference lines are set up and the station locations determined, there is a further challenge in deciding what points to record. If they are taken at regular intervals along the station line, perhaps every two inches, then there is the potential that certain irregularities in the hull shape will be missed. Historic vessels are not as smooth as most technicians would like. The usual bumps and hollows require extra offsets to be added to precisely record the shape. The manual processes, although they can be made to give good results, are time consuming and leave the potential for significant errors.

42 Because of the intensive, time-consuming nature of the process, many small craft documenters will take sections at twelve inch intervals and will record one side of the vessel only, assuming the other is close to a mirror image. In some cases, if the vessel is symmetrical bow to stern and port to starboard, only one of the four quadrants will be measured. Even so, the time required for this type of "casual" shape reference of a small vessel is about four hours.

43 At the Canadian Canoe Museum it was decided that this large collection required a system that was more time efficient, but perhaps more importantly, offered the chance for very consistent results no matter who was taking the offsets. Also of great importance is the ability of SmartScan to record in detail any imperfections on the hull of the boat. It allows the museum to record all of the hull shape characteristics of a craft that make it unique. This is particularly true in bark and skin craft. Significant with the repetition in documenting day after day is the tedium that can set in and the tendency to cut corners during the shape documentation process. If this were to happen, the accuracy and the confidence in the results would drop. The Canadian Canoe Museum made the decision that a more automated system was required to record the shape of its small craft collection.

Other Automated 3-D Systems

44 In the quest for a system to measure the Canadian Canoe Museum collection, the entire array of available 3-D shape recording systems was researched. Other museums were polled to learn of their techniques and experiences. They are summarized here as discrete point, station and point cloud recording systems.

45 Discrete point systems are a partially automated version of the manual system of taking offsets. For small half models, a standard computer digitizing wand can be used to record the shape. Anywhere the wand is moved, the X, Y and Z co-ordinates of a point in space can be collected. The reach of a typical wand is a one metre sphere and therefore is not applicable for canoe-sized vessels. Other discrete point systems have been developed for larger vessels that use surveying theodolites and require a reflective target to be held on the craft while the operator of the instrument aims at the target and pushes a button to record the point. The existing technology for discrete point systems is limited by three significant factors: the requirement to touch the often delicate historic craft; the rather lengthy time required to record the points, and the somewhat inconsistent density of points and therefore varying accuracy of the recorded shape.

46 Station Recording devices document in fine detail the sections of a vessel at intervals selected by the operator. The SmartScan system developed and described in this paper is a station recording device. There are other station measuring devices that are extremely accurate, in the order of .03 mm, but most are limited to objects the size of a human body. For small craft measuring up to one by six metres a new approach was required.

47 Point Cloud devices are laser based and measure distance by timing the delay of a laser signal as it reflects from an object. Point cloud refers to the density of the data obtained from these devices — the points cover the entire face of an object and although the location of the points seems somewhat random, the 3-D co-ordinates of each point are known. The area that can be scanned is limited to what can be seen, although by moving the laser other areas can be viewed. Some architectural firms use these devices to record the shape of the front of an existing building. They are fast, accurate enough for the purpose, and expensive.

48 The limitation of point cloud devices for small craft is the one-centimetre accuracy that does not improve even if the laser is moved closer to the object. This accuracy is just beyond the acceptable range for small craft documentation. The Canadian Canoe Museum set as their target 1/16 inch (1.5 mm) as a desirable accuracy.

The Requirements for SmartScan

49 Like any museum, the Canadian Canoe Museum has restrictions in the handling of their artifacts. In many cases a vessel is the only example of a particular craft that the museum owns and, in some cases, the only example of that craft in existence. It is therefore imperative that the boats be handled with care and as little as possible. One of the early requirements set by the Canadian Canoe Museum was that the actual measuring of the vessel's shape could not involve physical contact. The boat could be moved to the scanning location and carefully set in place, but in order to protect the canvas, bark, wood or skin exterior, touching of the vessel was discouraged.

50 Although these vessels will change shape slightly, even as they are transported, there was a desire to accurately discern cross section shape changes within 1/16 inch. This was the target set for SmartScan. Repeatability was set as an important goal and in particular, repeatable results with various operators. Since the museum is volunteer based, they needed to be able to follow a series of simple steps to document the craft and get consistent results. The safety of operation was a concern, as the museum wanted to operate the scanning in a public space. They saw the process as an excellent opportunity for an exhibit within the museum floor plan. But this public display added new restrictions: if laser light was to be used it must be eye-safe and moving equipment needed to be away from visitors. Ensuring the safety of museum staff and volunteers who work with the machine was a key consideration.

How Was the System Developed?

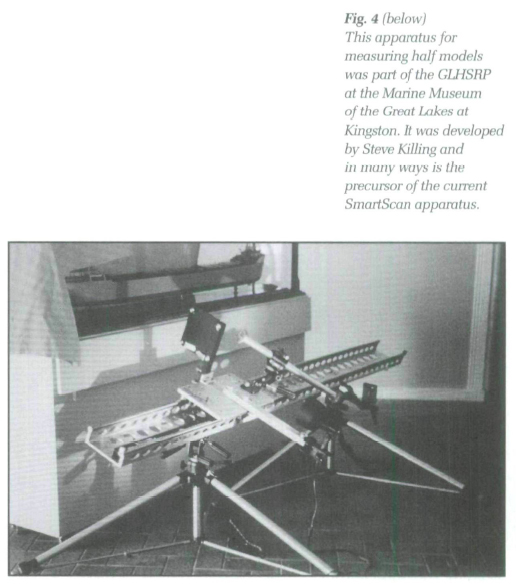

51 In 1987 the Marine Museum of the Great Lakes at Kingston commenced the Great Lakes Historic Ship Research Project (GLHSRP) (see, Boats — a Manual for Their Documentation, chapter 16, by Garth S. Wilson) and required a device to record the shape of half models. The device had to be portable, and like the current requirements for SmartScan, could not require contact with the models. Some devices, they noted, would leave small indentations in the model after the lines were recorded.

52 The project involved recording and drawing the lines of these vessels and performing calculations on the hull shapes. Steve Killing developed a device that has some similarities to the SmartScan system. A 35-mm camera was mounted on a track approximately 1.2 m long. Beside the camera was an unfrosted light bulb which cast a crisp shadow onto the model in the plane of a station line. The camera recorded this station line with a standard square target in the background of the photo. To create useful data from this photo, the transparencies from the camera were processed and mounted in a projector above a digitizing tablet (digital cameras were not commonly available in 1987). The shape of the shadow line in the photo was digitized along with the standard reference grid and entered into the computer. That shape was then corrected for perspective and the result was a true representation of the station shape of the vessel.

Display large image of Figure 4

Display large image of Figure 4 Display large image of Figure 5

Display large image of Figure 5 Display large image of Figure 6

Display large image of Figure 653 This system was workable, but the three-step process (photographing, digitizing and drawing) was tedious and there was a large potential for error. Nevertheless the system was used successfully to record the shape of one hundred half models.

54 In 1997 Jonathan Killing, one of the eventual co-developers of SmartScan, took this concept a step further in his grade ten science project. He showed that the automatic scanning of small craft was valid. The process is described in more detail below, but it used all the elements that would become part of SmartScan — digital camera, flash line, computer controlled carriage, and custom software. The objects being scanned were small half models and the accuracy was good but not excellent, mainly limited by the use of a low resolution digital camera.

55 This project proved that the science and practicality of the process could be merged. One could get reasonable accuracy from the process and it could operate autonomously. The name of the science project was transferred later to the new device — SmartScan.

56 The Canadian Canoe Museum became aware of this device and recognized the potential for documentation of the collection at the museum. In 1999 the SmartScan project was officially launched and the work began to enlarge the prototype and increase its accuracy.

The Science Behind SmartScan

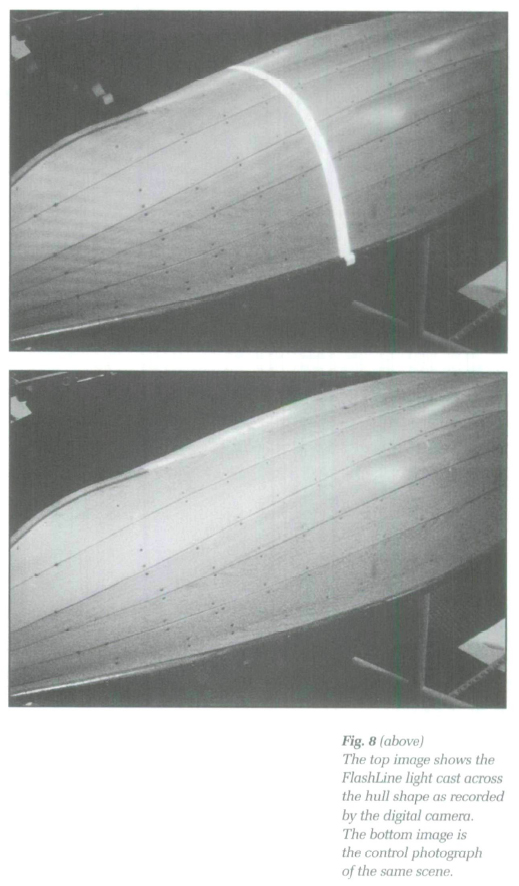

57 The concept of SmartScan is very simple: it records the station shape of an object by taking a photograph of a line cast across the hull.

58 The SmartScan apparatus consists of a 7.3-metre-long track set up semi-permanently in a space dedicated to the scanning process. For large or delicate craft the track is portable enough to move to the boat rather than the normal arrangement of bringing the small craft to the track. A carriage is mounted on the track and can travel its length under computer control. It is moved by a stepper motor to an accuracy of .05 mm, well within the requirements of small craft measurement. Mounted on the carriage is a digital camera to record the photographs and a FlashLine, which projects a bright white line onto the craft.

59 The digital camera must be of a type that permits total control by a computer and as camera manufacturers increase resolution and decrease cost, it is contemplated that the camera will continue to be upgraded. In the first six months of operation the camera has already been upgraded with a fifty percent improvement in resolution. The current camera at this writing is an Olympus 3040 zoom with a resolution of 3.34 megapixels.

60 The FlashLine utilizes an external flash unit made for the camera that is affixed to the rear of a custom line-focusing unit. The light from the flash is restricted to pass through a narrow slit and then focused by a lens to project onto the hull. The width of the line on the hull is about three-quarters of an inch, but only the crisp right hand edge is used for measurement. For ease of maintenance the flash unit can be removed from the FlashLine and replaced or repaired if necessary.

Display large image of Figure 7

Display large image of Figure 7 Display large image of Figure 8

Display large image of Figure 861 The carriage is connected by cable to the power supply for the motor, camera and FlashLine. This cable bundle also contains the signal controls from the computer for the camera functions and stepper motor. On the computer resides the SmartScan software running under Windows 98. The software permits the camera functions (exposure length, f-stop, picture resolution, white balance, zoom and focus) to be adjusted to suit the set-up in the room. These typically will be fine-tuned only once and need not be changed for each boat.

62 Since the shape recording done by SmartScan is optical and depends on the accurate shape defined by the FlashLine cast across the hull, a robust procedure for locating the line in the photograph of the hull was required. During the development phase of the project, experiments were done using eye-safe lasers to cast a bright red line. However, it was found that the red laser line, although straight and easily distinguishable to the naked eye, was not bright enough to be reliably recognized by the computer. And even though the laser was eye-safe it did cause some irritation to persons near the scanning unit. A focused, bright, white light was found to be many times more visible and had the added benefit of low risk when operated in a public space.

63 A digital camera image is composed of individual pixels (small squares of colour) that when viewed in a normal photograph compose the picture. The camera records a large array of numbers that define the colour in each pixel. When the computer has access to that photograph it can interrogate each pixel to determine its colour. One of the original thoughts during the development of the apparatus was that a line of a specified colour could be shone on the boat and then recognized by its colour in the photograph. However, the colour of the line varied with the colour of the boat and the ambient light, which led to many misinterpretations of the location of the station line. It quickly became evident that a new approach to locating the line within the photograph was required.

64 The software now uses a comparative technique. Two photographs are taken for each station — the first with the FlashLine turned on and the second, used as a base, without the FlashLine. It is a simple task for the computer to compare the two photographs and determine the difference between them. As the software compares each pixel of the two photographs it creates a third photograph. If the two original pixels are the same colour it puts a black pixel at that location in the new image; if they are different colours it inserts a white pixel. The resulting photograph displays the white line on a black background.

Display large image of Figure 9

Display large image of Figure 9 Display large image of Figure 10

Display large image of Figure 10 Display large image of Figure 11

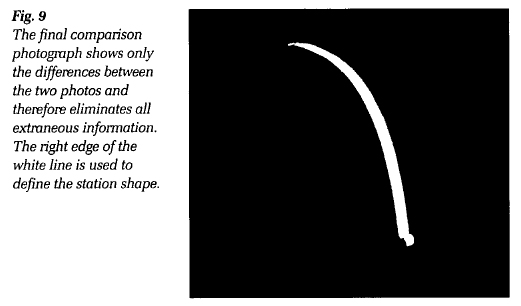

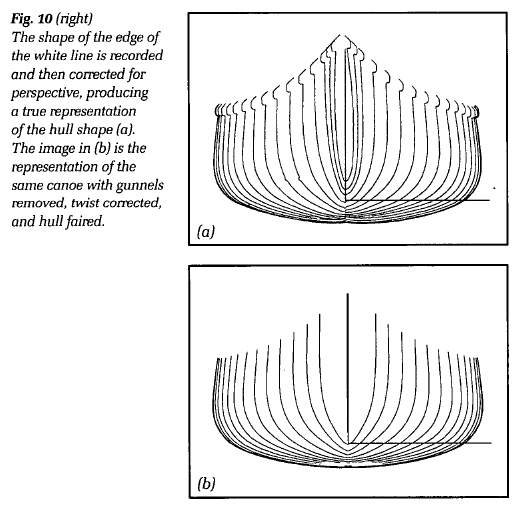

Display large image of Figure 1165 Although the line is now defined, the information is not yet useful for drawing the station shape of the craft. There are two more steps for the computer to take. The wide white line is too coarse to give us exact information on the hull shape. The software locates the right edge of the line and records the X and Y co-ordinates of those points from the black and white image. The last step of the process is to remove the perspective from the photograph. This is a standard mathematical procedure, but requires a knowledge of the exact orientation of the camera — its distance and angle from the object. The camera orientation is calibrated at the start of the day by taking a picture of a standard calibration target permanently set at the end of the track. With known dimensions of this target, the software calculates the perspective correction that must be made to the camera's image to produce an undistorted image.

66 Using the perspective correction routine, the SmartScan software can calculate the X and Y offsets for a given section. These are stored along with the station's position along the track in a standard 3-D dxf format that can be read into Rhinoceros 3-D, AutoCad, or any older 3-D drawing software. SmartScan has a command button on the computer screen that launches the Rhinoceros 3-D software and automatically loads in the most recently scanned file. A typical station of a small vessel with a girth length of 66 cm from the centreline up to the gunnel will have seven hundred points defining each line.

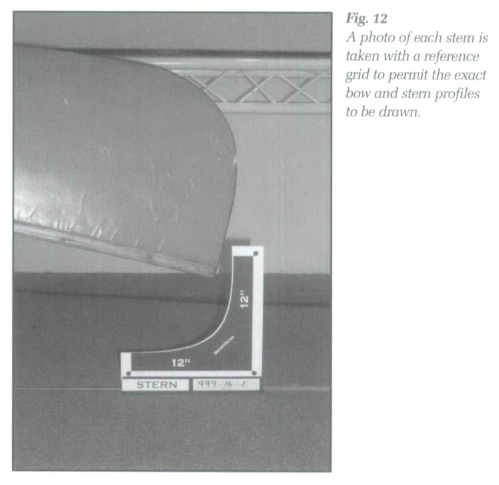

67 It was initially thought that scanning closely spaced stations near the stem would provide the best definition of the bow profile. It was soon discovered that it was much more accurate and simpler to take a precise digital photograph of the bow and stern profiles and simply scale and trace them in the 3-D software. These two photos are taken while the vessel is in the SmartScan cradle.

68 Two secondary files are saved at the same time as the 3-D dxf file of all the stations. One is a text file that lists all the calibration factors and camera settings that were used along with the location of all the stations scanned. The operator is prompted for other details which can optionally be included in the file, such as accession number, boat type, construction style, donor, colour, gunnel dimensions, measured beam (used as a confidence check on the scanned file), stem thickness dimensions and operator name. The second file is a Microsoft Excel spreadsheet file that contains a list of all boats scanned. Each time SmartScan saves a new boat a line is added to this file with select details from the text file. This Excel file can be sorted and printed to show all boats scanned.

Limitations and Accuracy

69 The SmartScan system is an optical system — it cannot see through an object. Consequently, if the camera cannot see part of a boat, it will not be able to scan it. Typical canoes and kayaks with keels, gunnels and tumblehome or flare present no problem. They are scanned one side at a time and the two halves married together in the 3-D software.

70 The visual system requires some small adjustment to camera setting when scanning the extremes of colour. A white canoe and a black canoe will display the FlashLine quite differently and an adjustment in either the camera settings or the analysis settings may be required.

71 There are several issues that determine the accuracy of the results and most are in the setup of the apparatus, not the daily set-up of the small craft. Critical are the straightness of the track, the calibration of the carriage, the alignment of the FlashLine perpendicular to the track and the resolution of the camera. The camera resolution determines the number of pixels that will represent the line on the hull. The number of pixels in the image is built into the camera and has been upgraded from 640 x 480 (science project system) to 1792 x 1200 (initial installation at the Canadian Canoe Museum) to 2048 x 1536 (current camera). This resolution gives us a pixel size that represents approximately 1 mm full size.

72 The set-up of the canoe has a small effect on accuracy and there are only a few items that require the operator's careful attention. The boat is set on the adjustable stand and should be parallel to the track. A line on the floor and plumb bob stands make this a rather straightforward procedure. The most significant factor for the set-up of the boat is to ensure that the locator arrows (see description in next section) that define the imaginary centreline of the boat are in exactly the same location on the stems when scanning the port and starboard sides of the boat. This ensures that when the two halves of the boat are "assembled" in the software that no width is added nor subtracted from the centreline.

73 It takes about eight seconds to take each of the two pictures used to define the station shape. The speed of operation of the device is limited by the storage time of the photograph on the internal disk of the camera. The analysis time and moving the carriage to the next location increases the total time for each station to 26 seconds. A typical 18-foot (5.5-metre) craft documented every six inches (15 cm) will take about 18 minutes to complete one side. In practice this seems very fast, since handling the canoe and recording the initial information usually takes longer than the scanning.

Display large image of Figure 12

Display large image of Figure 1274 Scanning vessels with bark, painted, varnished, or unfinished surfaces has not posed any problems to date. The results appear accurate and consistent. It is anticipated that decks can be documented as easily as hulls although the Canadian Canoe Museum has not scanned any at this point.

The Daily Operation of SmartScan

75 The operation of SmartScan from startup to shutdown has been designed with simplicity and accuracy as the two prime goals. Simplicity, so that there is the least amount of room for error, and accuracy, so that researchers using the data from SmartScan will gain confidence in its usefulness.

76 The computer in the scanning room is dedicated to the SmartScan task It is a moderate speed (700 Mhz Pentium) PC running Windows 98 (as of this paper). In the morning the computer is turned on, the software launched, and then the carriage power and camera turned on.

77 Daily calibrations are recommended to be confident that no changes have occurred since the last scan, although the last stored calibrations may be used again if desired. The track is calibrated for length and the camera for perspective correction. These are automatic functions and a click of the command buttons sets them in motion. Total calibration time is about three minutes for the track and thirty seconds for the camera.

78 The canoe is then set upside down on the arms of the adjustable cradle. Crank handles on top of the cradle permit each end to be adjusted in height. To maintain consistent bow up or down attitude when the vessel is turned around to scan the other side, height blocks are placed under the stems and the arms adjusted so that the vessel is just clear of those blocks. When the vessel is turned around the blocks stay with the boat so that the same level attitude can be achieved. The end locator arrows are set to just touch the longest extent of the vessel (often the stem band) and are set at exactly the centre of the width of the stem band. The plumb bobs on the arrows help to position the vessel ends directly over a line on the floor and therefore ensure the canoe will be parallel to the track.

79 Because the centreline of many historic vessels is not straight, SmartScan uses an imaginary straight line from bow to stern to permit the re-assembly of the port and starboard sides into a whole boat. Any deviation of the centreline of the craft from straight will still be present in the computer file, but the boat's keel may show up to one side or the other of the imaginary centreline. This permits the amount of distortion of the hull's centreline to be recorded.

80 SmartScan will document anything in the room and consequently it needs guidance as to where the artifact is placed. The plumb bobs on the arrow locators hang above a tape measure affixed to the floor. This tape reference is used to locate the hull within the track and the co-ordinates of the extreme ends of the boat are entered into the software.

81 The last task before scanning begins is the determination, by the computer, of the position of the imaginary centreline of the boat. It moves to the location of the arrow targets and scans the target face at each end of the boat. The distance of the target face from the track is used as the centreline.

82 The location of the stations to be scanned is totally at the operator's discretion. The options given are equal spacing (for example 30 cm), number of stations (perhaps thirty), individual stations (for example 15 cm forward of centre) or a user defined default layout. For most craft the Canadian Canoe Museum has found that a standard default spacing works well. They have settled upon 15 cm spacing in the middle 95 percent of the hull and 7.5 cm spacing from there to the ends of the hull. While this is the standard used at the Canadian Canoe Museum, SmartScan will scan at any spacing from .5 mm and up.

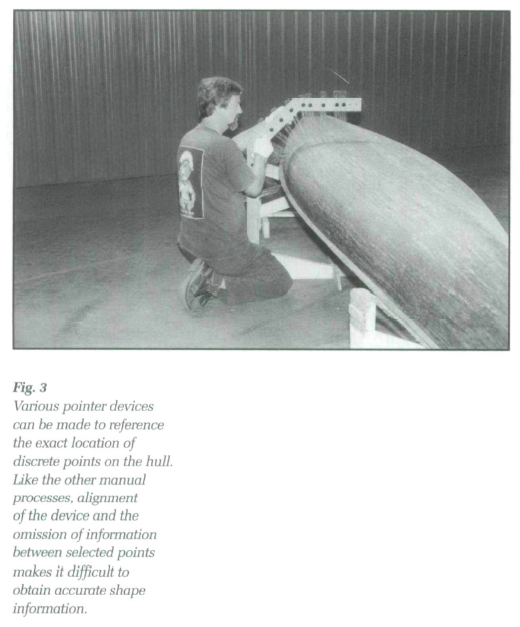

83 With the station spacing set, the software takes over and the scanning proceeds uninterrupted. For a typical station me sequence of events is:

84 This is repeated for each station without operator involvement. During the scanning process the operator often will spend time discussing the procedure with museum visitors. When one side of the hull has been completely scanned the boat is turned around, the locator arrows reset, the centreline located and the scanning recommenced.

SmartScan Output

85 There has been much discussion of the format of output from the scanning process. Different users have different goals for the scanning. Those who wish to document the artifact and record its bumps and hollows are happy to stop with the scanned sections. For this reason the primary output of SmartScan is the raw un-smoothed station shapes. For some boats this will be the only output. It will permit others to analyse the shapes and interpret the data in any fashion they wish. It will also permit a comparison with future scans to see if storage techniques and environmental factors within the museum are working as planned.

86 For other boats in which the artifact is relatively smooth and fair, there may be a desire to produce a traditional lines drawing of the vessel. It is understood that this process involves some subjective decisions and therefore is not a true representation of the shape of the artifact. A twisted hull, broken frame or curved centre-line, for example, would not be desired if the purpose of the drawing is to construct a new vessel. During the next phase of the drawings therefore the goal (in most cases) is to smooth, with restraint, the shapes recorded by SmartScan and cover the virtual boat in the computer with a surface. From boats completed to date, the largest deviation from the scanned data to the faired surface is about 1/8 inch (3 mm). It is important to realize that the amount of smoothing is to be kept to a minimum.

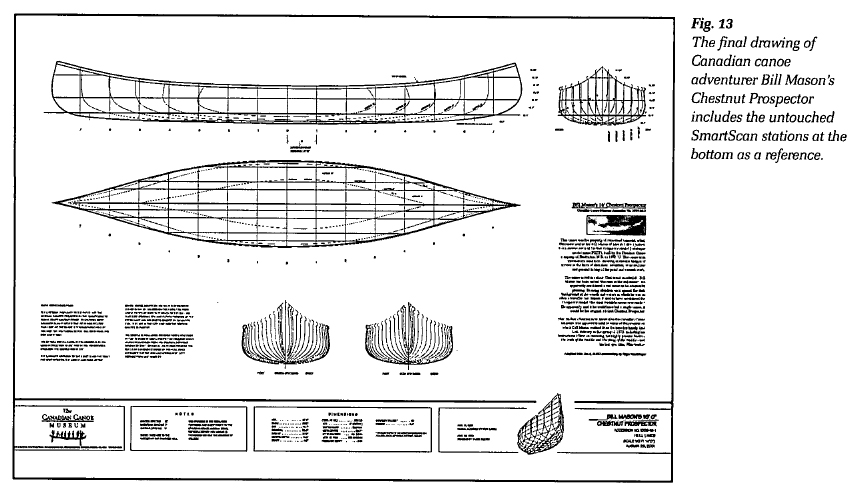

87 The lines drawing process at the Canadian Canoe Museum is done in Rhinoceros 3-D and involves first trimming the gunnel and keel from the ends of the sections, putting a fair curve through the seven hundred points on each station, tracing the stem profiles from the photos, averaging the port and starboard sides and then having the software essentially shrink-wrap a surface through these station curves. Each of these steps is fairly automated and a skilled operator may take four hours, which includes decision making time, to produce a smoothed hull from a set of scanned lines. The gunnels and keel are then added back on the smoothed hull. This hull can now be rendered and rotated for viewing on the screen.

88 The shape created in Rhinoceros 3-D can be sliced to create new stations, buttocks and waterlines — a traditional lines drawing. When complete with notation and some measure of artistic flair, this drawing can be used in research or as an artistic item for display.

Display large image of Figure 14

Display large image of Figure 1489 A secondary but valuable use of the images from SmartScan was in the development of cradles for the shipping of boats in travelling exhibits. The boats were scanned at the location of the foam supports and those exact shapes cut to match the boat. The fit, complete with bumps and defects, was an exact match and therefore gave excellent support to the boat.

90 For boats that merit full lines drawing there are added benefits. Once the shape of a hull is numerically defined the potential for further analysis and development is increased. With a press of a button on most marine design software packages, values relating to performance and stability can be calculated. The displacement of a hull on a given waterline will indicate the capacity of a boat for cargo and the freeboard remaining when loaded. The prismatic coefficient (measure of the fineness of the ends of the boat) combined with the surface area of the hull under the water is a good indicator of the low and medium speed resistance of the hull. Stability calculations can be made to compare with other boats and help relate the design to its use. The full 3-D hull shape definition can be used to supply a numerically controlled milling machine with the data required to cut a model of the boat from wood, plastic, or aluminum. These drawings, models and artifacts will prove interesting to audiences when used for interpretation and display.

Further Developments: Digital Cameras, Speed, Automatic Surface Fitting

91 Prior to 1999 the availability of low cost high-resolution digital cameras was scarce. More importantly for this project, there were no cameras available that could be totally controlled by the computer. Even now, the current camera does not permit total control, but with slight modification it was set up so that the scanning can be done without operator intervention. The current development in digital cameras is very rapid and the increase in resolution offered is rising quickly as vendors try to match the quality of film cameras. As this resolution improves, so does the opportunity to image small craft with higher accuracy. If the resolution doubles, then the smallest detail that can be detected through this process halves in size. It is expected that the camera will be further upgraded in the future, although there is little reason to go beyond double the current resolution for this application. The detriment to increased resolution is increased file size and extra time required to analyse the data. Computer time is only a small limitation on the speed of operation. With the current advancements in computer processor speed, the scanning process will only become faster.

92 At this time the SmartScan unit at the Canadian Canoe Museum is the only one is existence. With such a specialized machine for a small market, the number of units predicted to be built will be small. Other museums with small craft collections may find it useful to either bring a limited number of craft to the Canadian Canoe Museum for scanning or to install a machine of their own.

93 Currently the Canadian Canoe Museum is working to optimize the presentation format of data from the SmartScan and Visual Archiver systems. This is largely dependent on the development of procedures, processes and policies that are to be incorporated into the volunteer training program. As we continue to document a variety of craft within the museum, we continue to discover new applications for the data provided by the device. The museum is presently working on a number of specially selected watercraft from the collection to develop comprehensive packages of information on each artifact. These viewer packages will be placed on a kiosk system within the museum for audiences to access. As new information on the craft is collected, we anticipate a greater interest from researchers, anthropologists and historians and builders who are anxious to learn from the wealth of knowledge that the artifacts contain.

94 Part of the long-range plan for collections involves keeping staffing and operating costs to a minimum. Exhibit development, education and a focus on researching the collection will form the foundation of the museum in the long term. The museum must meet the challenge of developing revenue streams developed through a variety of means including extensive partnership with the private sector and an entrepreneurial approach to managing the collection. This must be accomplished without compromising the integrity of the collection, the mandate of the museum or the people of the past, present and future, who the museum represents.

The Canadian Canoe Museum would like to thank the following people and their organizations for lending their support to this project: Antique Classic Boat Society, Toronto Chapter; Charlie Adams, Serpent Mounds Park Manager, Hiawatha First Nation; Thomas D. Andrews, Subarctic Archaeologist, Prince of Wales Northern Heritage Centre; David E. Baker, President, Wooden Canoe Heritage Association; Department of Canadian Heritage; Hallie E. Bond, Curator, The Adirondack Museum; Derek James Cooke, Curator, Furniture, Fine Arts Conservation and Curatorial Services, Canadian Heritage, Parks Canada; Brian L. Desbiens, President, Sir Sandford Fleming College; Richard Gerrard, Registrar, Collections Management, Toronto Historical Board; Rebecca Hopfinger, Curator, The Antique Boat Museum; Kenneth R. Lister, Assistant Curator, Anthropology, Royal Ontario Museum; James Raffen, PhD., Associate Professor and Coordinator, Outdoor and Experiential Education, Queen's University; Harold D. Shield, Chairman, Museum Relations, Antique and Classic Boat Society; Mark Starr, DuPont Preservation Shipyard Documentation Office, Mystic Seaport Museum Inc.; John Summers, Curator, Coronet Project, International Yacht Restoration School; Garth Wilson, Curator, Marine and Forestry, Canada Science and Technology Museum.