Research Reports / Rapports de recherche

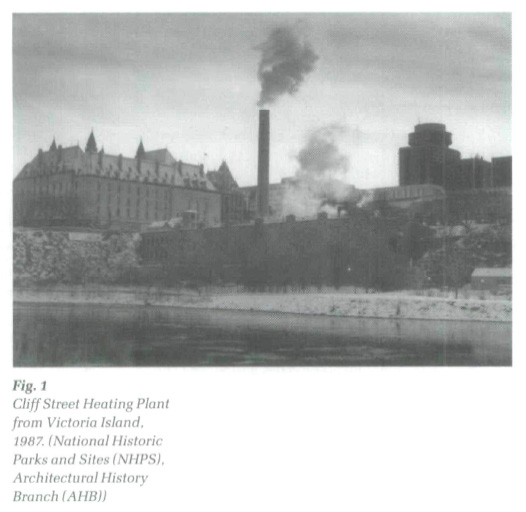

The Cliff Street Heating Plant, Ottawa

Introduction

1 The Cliff Street Heating Plant (Fig. 1) was built in 1918 to provide heat for the new Centre Block of Parliament and for several other government buildings. Likely the first federal building of its type, it incorporated recent advances in materials, mechanical systems, and design principles. It still supplies steam and cooling water to most federal buildings in central Ottawa through an extensive system of tunnels and buried pipes. It is one of the largest central heating facilities in Canada and has the largest air-chilling capacity of any central plant in the world.1

Historical Associations

Thematic

2 The Parliament Buildings and an increasing number of administrative, judicial and cultural structures have been symbolically or functionally central to the historic development of the Canadian state. While not in itself being a focus for this history, the Cliff Street Heating Plant has played an important auxiliary role. Through the supply of relatively clean, convenient and economical heat, it has facilitated the physical expansion of federal government operations in Ottawa.

3 Perhaps of greater interest is the Cliff Street Heating Plant's place in the history of architecture and heating technology. Improvements in this technology revolutionized building design and construction. Open fires were the primary sources of heat in early Canadian buildings. In the eighteenth century the closed stove became common in North America, offering more efficient combustion of fuel, radiation of heat, and dispersal of smoke. But stoves differed little from fires in that heat was still produced in the room in which it was required. In large buildings especially, this involved difficulties in the delivery of fuel, the cleaning and disposal of coal dust, ashes and soot, and the prevention of fires. Stoves, like fires, also consumed fresh air, which could only be replaced through open windows, an unsatisfactory situation in a cold climate.

4 By the nineteenth century builders had made further improvements. They transformed the common stove into a furnace by moving it out of the room to be heated but allowing the air it warmed to pass into the room. Almost simultaneously, builders harnessed steam technology for heating, first of factories, then of homes and offices. By mid-century, hot water heating had also become viable. Both these systems utilized boilers that could be fired in seclusion from the day-to-day functions of buildings.2

5 Like the elevator and electric lighting, central heating and ventilation systems were prerequisites for the development of modern architecture. Previously, building design had been limited by its dependence on lighting and ventilation from windows and on heat from fireplaces or stoves located in the actual spaces being warmed. Heating, lighting and ventilation supplied from a central source allowed for greater flexibility in grouping interior spaces. Structures could be more densely designed with less exposure to the exterior environment as interior climate control was no longer dependent on it. Hence taller, more massive buildings became possible. As Robert Bruegmann has written:

Display large image of Figure 1

Display large image of Figure 16 Canada's first Parliament Buildings in Ottawa, erected between 1859 and 1866, relied on a vault system of heating similar to that designed by David Boswell Reid for the new British Houses of Parliament. Boilers supplied steam to coils or pipes placed in vaults underneath the building. These coils heated fresh, cold air brought in from outside through tunnels. Forces of convection then conveyed this air through flues to all parts of the building. Vitiated air was extracted through a tall shaft. This system was apparently a failure. Fireplaces and steam coils in many rooms provided supplementary heat. A steam heating system was later installed in the Centre Block.4

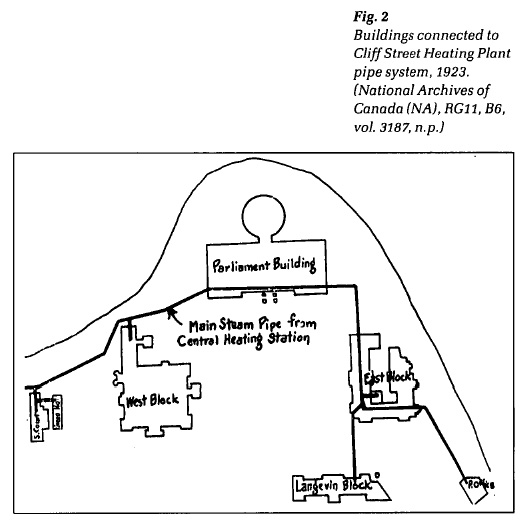

7 The first Parliament Buildings thus represent a transitional stage in the application of central heating technology to the architecture of a large public building. By 1916, when the Centre Block was destroyed by fire, both heating technology and architects' understanding had advanced significantly. While by no means a "sealed glass box," the new Centre Block was an essentially modern structure, its gothic surface features hiding a steel skeleton, electric lights and hot-water radiators. Later government buildings in downtown Ottawa conformed even in outward ways to the International Style.

8 The logic for constructing the Cliff Street Heating Plant, as opposed to individual systems in each structure, was simple. Heat distributed to all parts of one building from a central boiler could quite easily be distributed to several buildings. Heating and ventilation engineers in the early twentieth century touted this innovation, called district heating, as the wave of the future. Urban development was creating dense, commercial city centres, resulting in increasing pollution from smoke, soot and ashes produced by numerous small, inefficient heating plants. District heating might free city downtowns of this blight and spare building owners the high fuel and labour costs and the fire hazards also resultant from individual systems.

9 An experimental district heating system was opened in Lockport, New York, in 1877. New York City had its first district heating plant by 1883. The first such plant in Canada opened in Chatham, Ontario, in 1905-06. By 1927 there were over 200 district heating plants in North America, serving both individual commercial buildings and educational institutions, hospitals, and other unified complexes. Planners of the new Parliament Building also had the model of Washington, D.C., where a new plant opened in 1910 to serve the Capitol building and a number of other government structures.5

10 John A. Pearson, architect of the new Centre Block, was an advocate of district heating and had designed a plant at the University of Toronto.6 Designed under his supervision with the assistance of Consulting Engineer Melvern F. Thomas, the Cliff Street Heating Plant became an economic and functional success. In 1926 one observer was so impressed, he called it "one of the most complete illustrations on the American continent of the application of mechanics and physics to the problem of heating in a climate of Lat. 45°43' N, a series of large government buildings."7

Local Development

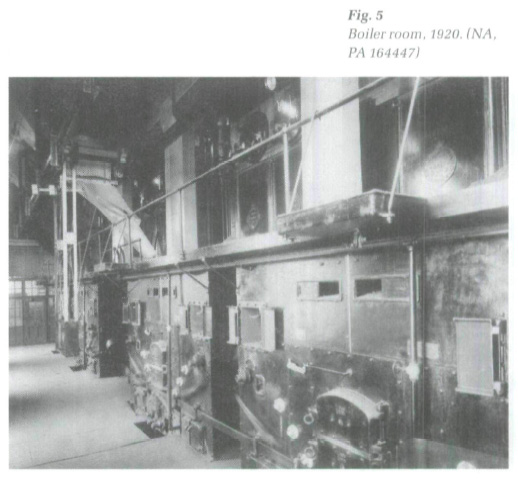

11 Ottawa's transition from lumber town to government city occurred in the four decades before 1940. While the city's population grew from 60 000 to 155 000, this 150 per cent increase was surpassed by a 1000 per cent increase in the number of public servants. Concomitant to this growth in government employment was the government's heightening profile on the urban landscape. From their crowded quarters on Parliament Hill, departments dispersed to various parts of the city, especially along the L- shaped axes formed by Wellington and Sussex Streets. The Royal Mint and the first Public Archives were among 11 new structures erected between 1896 and 1913. Most were in the downtown area. In the inter-war years, the Connaught, Justice, Confederation, Bank of Canada and Supreme Court buildings reinforced the government's physical presence in the centre of Ottawa. The construction on Parliament Hill of a larger Centre Block with a prominent tower, after the fire of 1916, was symbolic confirmation of this new prominence.8

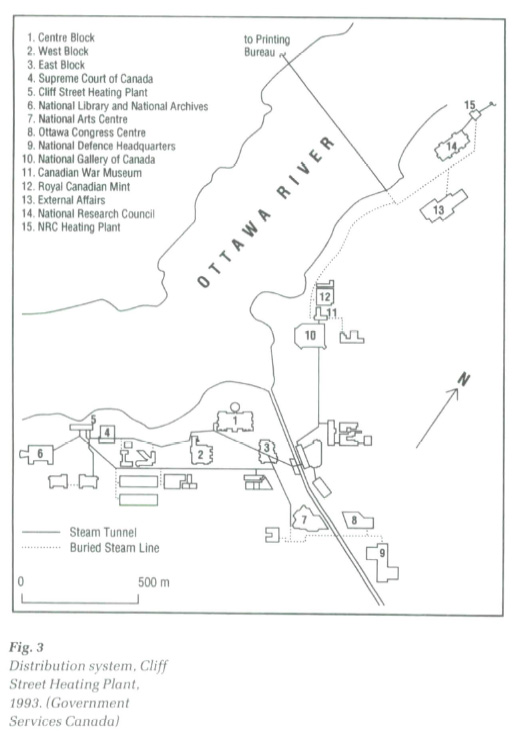

12 The far more prosaic task of heating these large public buildings fell to the Cliff Street Heating Plant, built in conjunction with the new Centre Block. Observing the success of district heating in other cities containing a high density of large structures, planners of the Cliff Street Heating Plant had designed it to be economically expanded as demand for its steam and hot water increased. By 1923 its system of tunnels and pipes provided heat to the Centre Block, East and West Blocks, Langevin Block, the old Post Office, the old Supreme Court, and a smaller building next door9 (Fig. 2). In 1987, the Cliff Street Heating Plant's distribution system extended from the National Archives and Library in the west, east parallel to Wellington Street, north as far as the Mint, the War Museum and the new National Gallery, and south to the National Arts Centre, the Congress Centre and the Department of National Defence Headquarters. Since that time the network has been further extended (Fig. 3; and, see Epilogue). Though all but its chimney are invisible to most Ottawans, the presence of the Cliff Street Heating Plantis felt throughout the core area of Ottawa.

Architecture

Aesthetic Design

13 The Cliff Street Heating Plant is a flat-roofed, rectangular structure approximately 90 m long, 18 m wide and 18 m high. Two one-storey extensions abut the north wall, and a 54 m brick chimney projects from the roof near the longitudinal centre of the building. Framed in reinforced concrete, the plant is almost devoid of ornamentation. In this sense it is similar to heating plants built later by the federal government in Ottawa. Like the plants at Sussex Drive (1931), Booth Street (1944-45), and the Central Experimental Farm (1960), the Cliff Street plant is a simple rectangular envelope enclosing a complex mechanical system. Architectural reference to the surrounding landscape or street-scape is found only in materials and some minor detailing. Cliff Street, as the first and largest of these structures, may well represent a model.

14 The Cliff Street plant was designed to harmonize with the rugged cliffs along the south bank of the Ottawa River (Fig. 4). In fact the building, originally only 38.4 m long, was inserted into an 18 m niche excavated from the cliff face. Its north wall, facing the river, was covered in rock-faced, uncoursed limestone salvaged from the excavation. Its roof was built flush with the summit of the cliff.10 The north elevation of this manmade escarpment was punctured by six tall, narrow, segmental windows along the length of the first floor. Two rows of four smaller segmental windows were placed at the second and third storey levels at the east end, where the pump house and offices were located. The windows and rough-hewn rock mimicked the textures and stratification of the natural rock face to the east. The only other exterior ornamentation was along the roof line, where a plain concrete cornice was placed and two projecting ash pit vents were faced with limestone and visually connected by a metal pipe railing.

Display large image of Figure 2

Display large image of Figure 2 Display large image of Figure 3

Display large image of Figure 315 This compact, austere, but attractive, structure was radically altered in subsequent years. In 1929-30 a 20.7 m, three-storey extension was built onto the west end in a style similar to the original but without second and third storey windows. A further western extension, also of similar facade, was built in 1951-52. At the same time a one-storey ash handling plant was tacked onto the front wall at about the midway point of the enlarged structure. In 1967 the building reached its current configuration with the construction of a one-storey pump house in front of the original portion of the plant.11 Both the one-storey additions are faced in the same uncoursed limestone as the main structure and have segmental windows vaguely reminiscent of the original main floor windows they now obscure. These exterior changes have combined to create a cluttered north elevation at the first storey level surmounted by a long, blank facade unbroken by windows. The original proportions of walls to windows have been destroyed, and the entire structure, now much larger, dominates the site in a way it never did originally.

Functional Design

16 As functional as was the external architecture of the Cliff Street Heating Plant, the original space enclosed by this rectangular envelope conformed even more rigorously to technological imperatives. The plant was designed to accommodate the state of the art in coal-fired boilers and hot-water circulation systems. Architect John Pearson and engineer Melvern F. Thomas used the cliff-bottom site to their advantage in designing these operations. The internal layout has been altered significantly as a result of more recent historic changes in the mechanical systems housed in the building. Despite major differences in technology, however, the plant has proven adaptable to these changes.

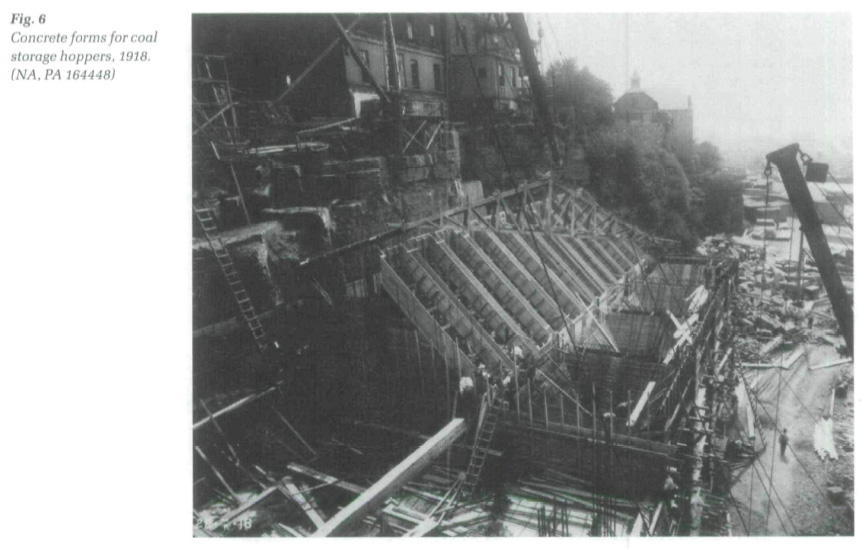

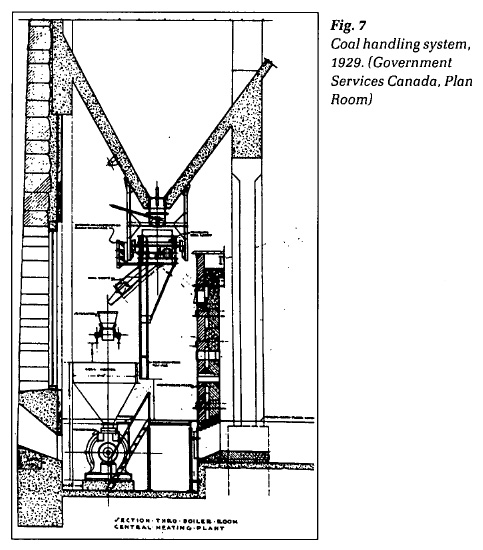

17 The western two thirds of the structure was originally occupied by four 500 horsepower Babcock-Wilcox horizontal water-tube boilers (Fig. 5) arranged in a line between two rows of reinforced concrete columns supporting the roof. Coal delivery was facilitated by the location of the entire plant below street level. Trucks or wagons delivered coal to the plant roof, where it was weighed and dumped into large concrete storage bunkers occupying the second and third storey levels above each boiler (Fig. 6). A travelling weigh hopper mounted on a track below the storage hoppers directed the coal to a stoker hopper located in front of each boiler (Fig. 7). Here it was separated and pulverized before being fed into the furnace. Ashes were conveyed to one end of the building, where a bucket conveyor elevated them to another overhead storage hopper, where they were periodically lifted to street level and discharged. Hence the movement of all coal within the plant was downward or lateral, relying largely on gravity for movement. Ashes, less bulky and lighter, were the only solid materials requiring hoisting. This effective design was complemented by provision for inexpensive expansion to the west in order to double boiler capacity. Additional boilers could be installed in extension of the building envelope without altering the internal layout.12 As noted above, this was done twice, in 1930 and 1951-52.

18 The eastern third of the Cliff Street Heating Plant housed functions distinct from the generation of steam. Often referred to as the pump house, this portion consisted of three levels. The first housed pumps that provided feed water for the boilers from the nearby Ottawa River. The second accommodated the plant engineer and the instruments necessary to monitor plant operations. The third housed water heaters and centrifugal pumps to generate and distribute hot water for the heating of buildings. Being nearest to street level, the third floor was chosen for this function in order to reduce static head on the pumping system, already obliged to push hot water through a tunnel several hundred metres long. But with the plant being situated lower than the buildings it served, water could return by gravity.13

19 The interior of the Cliff Street Heating Plant was gutted and rebuilt between 1965 and 1967 as part of the overhaul of its mechanical systems. Large oil and gas boilers replaced the coal-fired units, the concrete storage hoppers were removed, and four air-conditioning water chillers were installed in the locations of the original four boilers. While the pump house retained some pumping and electrical functions, a new pump house annex was added to the north wall. In addition, hot water generators and pumps were removed from the third floor. The plant henceforth provided no hot water, instead supplying steam to water heating units in individual buildings.14 The conversion to oil and gas obviated the need for structural concessions to coal and ash handling and therefore eliminated one of the principal design features of the Cliff Street Heating Plant. But aside from a lack of storage space, the building functions well in its present capacity. This attests to the adaptability of its original design.

Materials

20 Reinforced concrete was an appropriate choice for the structure of the Cliff Street Heating Plant. Though still a relatively new material in 1918, enough large buildings had been constructed throughout North America to recommend its qualities to the designers. Its fire resistance was a natural asset in a structure containing coal-fired boilers, and its economy was appropriate for a functional building constructed in wartime when steel was scarce. Its strength, finally, allowed for concrete bunkers capable of bearing heavy weights of coal and for a concrete slab roof that required a minimum number of columns interfering with the arrangement of complex mechanical systems.15

Designer

21 John Andrew Pearson was born in England in 1867, receiving his architectural training at Sheffield. He emigrated to Canada in 1888, and in 1893 formed a partnership with Frank Darling that lasted until 1923. Darling and Pearson was one of the most successful architectural firms in Canada, becoming best known for designs of banks and office buildings in the classical manner of the beaux-arts style. Among Pearson's best known works, aside from the Centre Block, are the Bank of Montreal, Toronto (1907), the Sun Life Assurance Building, Montreal (1914-17), and Trinity College, Toronto (1925).16 Perhaps most relevant to his responsibility for the Cliff Street Heating Plant, Pearson designed a central heating plant for the University of Toronto in 1913.

Display large image of Figure 6

Display large image of Figure 6Environment

Site

22 The Cliff Street Heating Plant stands on an isolated bank of the Ottawa River about 400 m west of Parliament Hill, just north of the open space between the Supreme Court and National Archives buildings. Located at the base of a steep cliff, the roof of the plant is on the same level as Victoria and Cliff Streets to the south. Access to the building, once from Cliff Street, is now generally from the west via the large parking area behind and below the National Archives.

23 No known buildings stood on this site prior to the construction of the Cliff Street Heating Plant. There was so little level ground that the plant had to be built on a spot largely excavated from the cliff itself. Photographs reveal the site was once used for lumber storage. No nearby evidence of this land use remains today, the development of the neighbouring parking lot and Victoria Island Park having obliterated any traces. The land south of the building was initially residential, later being occupied by World War II temporary buildings. Owned by the federal government, this land is now vacant.

Setting

24 The Cliff Street Heating Plant is an essentially industrial building. Planners of the building believed they had found in the obscure cove of the Ottawa River an ideal location for the plant. While close enough to provide heat to Parliament Hill, its noise, pollution, and inelegant architecture would not blight the government, commercial and residential districts of Upper Town.17 When built, it had less in common with the stately public buildings it served than with the mills, sheds and warehouses of nearby Le Breton Flats and Chaudière Falls. In fact, it stood almost at the point on the east-west line where the government city gave way to the lumber town.

25 Rapid development of the sawn lumber industry in this area began with the opening of American markets in the 1850s. Lumber became, with government, the twin pillar of the Ottawa economy. By the end of the century, mills, railway lines, and stacks of lumber dominated the area west of Parliament Hill along the Ottawa River. The 1900 fire dealt the lumber trade a blow from which it never recovered. But when the Central Heating Plant was built in 1918, the declining industry still had a major presence on Le Breton Flats, Chaudière Island and Victoria Island. Hydro-electric development of Chaudière Falls in the 1890s accentuated the industrial character of the Heating Plant's environs.18

26 The Cliff Street Heating Plant reinforced the industrial character of Le Breton Flats and the Chaudière district. Since its construction, however, industrial activity in the area has declined. In the late 1950s the Le Breton Flats community was bulldozed as part of an abandoned urban renewal scheme. By the 1970s, log booms had disappeared from the Ottawa River, and most of Victoria Island had been cleared for a park. But with the Chaudière Falls hydro-electric station and the E.B. Eddy plant in Hull, the Cliff Street Heating Plant forms part of a still-functioning industrial complex.

Display large image of Figure 7

Display large image of Figure 7Landmark

27 The Cliff Street Heating plant is, aside from its chimney, not visible from Wellington Street or locations to the east, west or south. Pedestrians and passengers crossing the Ottawa River on the Portage Bridge may glimpse it in passing. But its presence is only truly appreciated from Victoria Island or the foot and bicycle paths on the south bank of the Ottawa River. Few people seem aware of the plant's purpose, in no small part due to its negligible impact on the street-scape.

Epilogue

28 In the last five years, Public Works Canada (now Government Services Canada) has undertaken several modifications to the plant's systems and its steam network (Fig. 3). In the plant, two obsolete boilers were replaced by a single new boiler with more than twice their combined capacity. A control room overlooking the boilers and equipped with computerized controls was built on the second floor in 1993. A new steam tunnel to the National Archives was built, and a new tunnel along Wellington Street is scheduled for completion in fall 1994. From the National Gallery, a line of buried steam pipes now extends north to connect with a line serving the National Research Council (now National Research Council Canada (NRCC)) and External Affairs Department (now Foreign Affairs and International Trade) and a line from the Canadian Government Printing Bureau (now Canada Communication Group) heating plant in Hull. The Hull connection allows for greater flexibility in the use of both plants and enables more complete use of the Hull plant's boiler capacity. As a result, the boilers of the small NRCC heating plant on Sussex Drive have been taken out of service.19

This paper was originally written for the Architectural History Branch, Canadian Parks Service, in fulfilling its mandate under the Federal Heritage Buildings Policy (now Chapter Nine of the Government of Canada's Treasury Board Manual on Real Property Management). In order to acquaint readers with the assessment criteria for federal heritage buildings, I have retained, with minor revisions, the standard format and style of the original report. I would like to thank Joanne Bergeron, National Museum of Science and Technology, for redrawing the map in Fig. 3.