Research Reports / Rapports de recherche

Change and Diversity Within Traditional Cooperage Technology

1 The barrel made from wooden staves and bound by hoops was a very common object throughout history. Today, it has become a veritable symbol of continuity and a tangible link to the past. In fact, it exists as a container largely because of its symbolic value. From suburban flower pots to easily understood museum offerings, barrels serve mainly to invoke a sense of an idealized past. Even in the production of wine and spirits where the wooden cask is still used, its historical function for maturing and storage is largely obsolete, but its use is an instant hallmark of mastery and tradition.

2 It appears, however, that popular perceptions of continuity in cooperage technology have impeded analysis of its historical importance. Few researchers of material culture have approached the "staved container" in a historical manner, despite its embarrassing profusion in some archaeological sites.1 Certainly, the barrel as a form of container is ancient and continuous, but this paper will examine cooper-age technology in terms of diversity and change over time.2

The Meaning of Cooperage

3 We may first define "cooperage," for which three usages are noted. Cooperage may describe the work of making and repairing staved containers by people broadly designated as "coopers." It may also describe the objects themselves, such as tubs, barrels, pails, buoys and the like, all of which may be called cooperage, both singly and collectively. In the study of cooper-age, the artifacts also include evidence of related activities, such as handling, stowage, inspection, and even forest trades. Finally, a cooperage designates the place where coopers work, whether in fabricating, repairing, reassembling or filling barrels.

4 In some ways the idea of cooperage is parallel to that of "pottery," a comparison which serves well in the search for relevant models to apply to the study of cooperage in archaeology where most of the artifacts used in this study are encountered. Among the immense body of scholarly literature on pottery, various approaches to the study of Mediterranean amphorae seem particularly applicable to the study of cooperage. Most archaeological finds of cooperage are in underwater sites related to maritime commerce (although they may be found in other waterlogged environments, among which are finds of old barrel cases used to support the walls of shallow wells).3

5 The study of cooperage diverges from that of pottery in some important respects. It has a strong documentary aspect, based upon the laws, regulations and contracts surrounding the commerce in casks of numerous staple commodities in the early modern period. As well, the cooperage particular to trades is often shown in meaningful detail in iconography depicting the conduct of various staple trades. The variety of sources for the study of cooper-age implies the need to establish concrete points of reference between documentary and artifactual data at the least abstract level possible; once this has been accomplished, however, the amount of information available for analysis is increased exponentially.

6 Enquiry into cooperage technology is divided into four kinds of evidence implicit in the artifacts and documents: the material of staves; the materials of the hoops; the contents of a barrel; and the division of cooperage labour. In studying diversity and change in these four variables, we begin to approach a history of cooperage "technology," or how cooperage was done.

Stave Materials

7 As with any composite artifact, the various materials contained in a barrel are also indicators of the complexity of the society and the industry that made it. Because barrels were made near to where their contents were produced and not near the source of a cooper's materials, the choice and collection of these materials represents a special aspect of study. Leaving for the moment the trades implicated in the production and transport of raw "staves," or the pieces of wood which form the case and heads of a barrel, the reasons governing a cooper's choice of wood species will be briefly discussed.

8 The choice of oak, particularly the species comprising what are known as "European oak" and the "white oak" of America, indicates a need for great strength during handling or stowage, or a need for liquid tightness. The need for strength, as in the case of a cargo of whale oil barrels found on the sixteenth-century Red Bay, Labrador, site, arose from the practice of using the same barrels over and over again, in the same manner, every year for one or two decades. Because whale oil is viscous, tightness for these barrels would have been less important than strength in the choice or European oak. This also helps to understand the thinness of the staves - about 1.0 to 1.5 cm. of these barricas. For precious liquids such as today's spirits or wine, white and European oak ensure nearly absolute tightness because of the tylosis which clogs the pores of the heartwood. By comparison, staves from the American species which comprise the "red oak" trade appellation are more porous and have therefore always been undesirable for wet cooperage although they are just as strong as die American white oak or die European oak.4 For the purposes of sixteenth-century Basque whalers, American red oak might well have sufficed had it been available to them. It was not until the early seventeenth century that English colonists began to export American oak staves, and the Quercus rubra was not planted commercially in Europe until the seventeenth century.5

9 Another European hardwood, the chestnut (Castanea sativa), is frequently found in relatively durable, liquid-tight cooperage used in the production of local, everyday wine. The use of chestnut indicates a complex choice. The custom of oak maturation for costlier export wines arose in the late middle ages when the flavour of oak in wine was an effect of seaborne transport in sturdy oaken casks. It was the transport rather than the resultant flavour that raised the price of this commodity. In today's trade, wine is not transported in wooden casks, but because an oaky flavour remains associated with wine of exportable quality, die distinction between oak and chestnut casks continues.6

10 The use of softwood staves indicates yet another departure from the highest standards of liquid tightness and strength. Most archaeological finds of Roman barrels are softwood and softwoods are well-represented in modern finds as well. Documentary sources indicate that softwood barrels may have been prevalent in cooperage of the early modern period. The laws of Virginia governing the staple export trade of milled flour did not specify any wood species; naval stores consisting of pitch, tar and resin were put in pine casks; turpentine could be put in anything except "pine-sap" timber (presumably sappy pine), and only salt pork and beef required the use of white oak hardwood containers for export. Similarly, in the naval stores trade of Les Landes (Aquitaine) and the Baltic countries, hardwood barrels were not readily available.7 The mixed archaeological collections of cooperage from naval ships, such as the Amsterdam (Dutch, 1748), the Invincible (British, 1758), the Machault (French, 1759), "44Y088" (American, 1781) and the Defence (United States, 1776) confirm that naval stores and provisions tended to be packed in softwood casks.8 In summary, the choice of stave and heading material in historical cooperage appears to be an important index, regulated on the one hand by needs of tightness and strength in the vessel's intended function, and on the other by economy. However, as can be seen in die wine and spirits trades of the twentieth century, ideological considerations might also play a role in the choice of stave materials.

Hooping Materials

11 The study of the barrel's hoops may be approached separately because the production of materials and finished hoops comprised trades separate from those involved in the production of raw staves. Hooping materials were produced as one of a wider range of commodities by such trades as coppicing, pollarding, the plantation of osiers, the gathering of timber off-cuts and iron-working. Each of these trades was subject to its own technologies and available species.

12 A question which often arises is the significance of iron hoops. The earliest studied examples of metal hoops are medieval and the contexts in which they were found suggest that they may have carried some ideological significance. Social status may have been conferred by the metal hoops found in domestic cooperage from a noble Carolingian site, and ritual value may be associated with those found in a Saxon burial ship at Sutton Hoo in England.9 The masses of metal hoops found on the 1622 wreck of the Nuestra Senora de Atocha off Florida were associated with a colonial treasure cargo, although the Iberian iron trade in this period was certainly capable of producing low-cost iron hoops.10 Based on these few examples, the finding of metal hoops appears to imply some complexity in coopering needs and technology which was not general before the nineteenth century. In this context, the metal hoops on an isolated well barrel from the Andalusian colony of Santa Elena, South Carolina, ca 1565-85, would indicate a trade connection with the metropolitan Spanish empire. This 480-litre pipa may well have served as a water barrel on a ship for the Carrera de las Indias.11

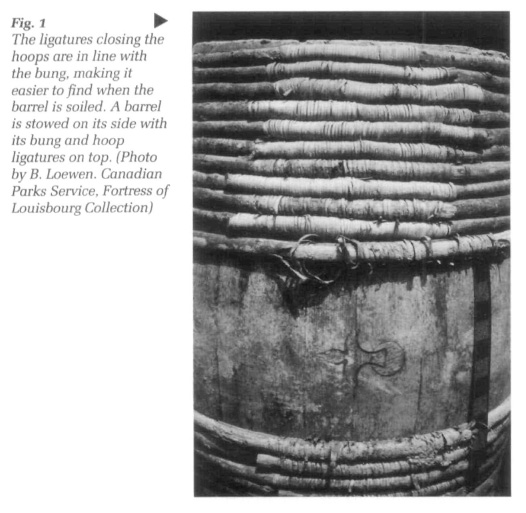

Display large image of Figure 1

Display large image of Figure 113 The problem of hoops made from vegetal material is at once more common and more complex. Vegetal hoop finds from before the twentieth century are the rule in archaeology, a rule attested by numerous photos of wharves from the nineteenth and early twentieth centuries. Two main types of vegetal hoops may be identified by their closure technique. The first utilized a kind of ligature made of osier (Salix sp.) or a comparable material, wrapped around the ends of a split pole so as to form the hoop. The second type was closed or locked by notching each end of a similarly split pole, hooking the ends together, and twisting the "tails" between the hoop and the case of the barrel. The first method presupposes an osier industry which could be developed wherever willow-like species were found, but in fact was concentrated along the banks of Loire and the Gironde, and in Flanders and Picardy. The osieries of these regions, it appears, were able to marginalize their competitors in England and Iberia by the quality and low cost of their osier. In North America, osieries apparently never developed. The ca 1565—85 Santa Elena barrel appears to have ligatures made of a vine-like material, while at the French fortress of Louisbourg, Cape Breton, in the eighteenth century, the trailing roots of birch trees were harvested for ligature material.12 These attempts to continue European hoop-making technology without the benefit of a supporting osiery trade were abortive. By far the commonest American method of hoop closure was the hook. The ligature method allowed the hoop itself to be made from weaker materials such as chestnut or alder (Alnus sp.). The hook method weakened the hoop and tended to tear it as well; to compensate for this weakness, the stronger ash (Fraxinus sp.) and American hickory ( Carya sp.) were chosen instead. Another commonly used hooping material was hazel (Corylus sp.), apparently used in both techniques of closing a hoop. This short list of species is by no means exhaustive.

14 As with osier, poles for hooping were usually harvested on plantations, bundled and sold in markets.13 As with osier, the cultivation of poles was largely a European phenomenon. The ash, hazel and chestnut were widely coppiced or pollarded, although there appears to have been a tendency to cultivate the ash in northern Europe and the chestnut south of the Loire.

15 The relationship between species and closure technique may be illustrated by the 1799 account of an English osier planter near Ely during the French wars. Before embargoes of osier were imposed on England, the English basketry trades had come to rely on osier imported from the Low Countries. Rather than purchasing inferior English osier to bind their hazel hoops, English coopers evidently adopted the hook technique popular in America, but in order to do so they had to switch to the more durable ash. Among British coopers today there seems to be a tacit acceptance that the hook method belongs to them and the ligature method to the continent.14 In conclusion, the specialized nature of hoop production, whether vegetal or metal, seems to afford as much opportunity for historical analysis as does the production of raw staves.

The Contents

16 The question which intrigues the most is a barrel's content, usually long disappeared in archaeological sites. The question is not utterly insoluble, but can only be approached circuitously by understanding capacity and dimensions, provenance, tightness and use-cycle evidence in terms of what is known of various staple trades. The early modern period, especially in the north Atlantic theatre, had significant staple economies in which certain commodities were associated with specific regions.15 Many of these economies developed cooperage practices particular to a region and a commodity, for example, the West Indies sugar staple or the Chesapeake Bay tobacco staple. Eventually these practices were regulated for purposes of customs and excise, so that norms of barrel size, number of hoops, stave thickness and wood species may be learned from documentary sources. Such regulations also signal the decline of self-regulating bodies among coopers, such as guilds. The development of coopering norms involved practices of packing, inspecting, stowage and cycling, and the norms eventually grew to be quite inflexible. Two of the most important norms may be observed for the Bordeaux wine trade16 and the Dutch herring trade,17 both of which came to influence other trades and other regions. The ca 225-litre Bordeaux barrique was adopted for the whale oil trade, presumably when the Basques that dominated the transport of Aquitaine wine began outfitting whale-hunting voyages to Terranova, and the decks of Basque-built ships were customarily spaced so as to accommodate this size of barrel, called by them a barrica.18 When the Basque monopoly over the whale oil trade was broken in the seventeenth century, the Dutch at Spitsbergen continued to use a similar barrel which they called a kwarteel.19

17 Documentary evidence on cooperage appears to suggest a linkage between the capacity of a barrel and its contents. Yet, literature and archaeology indicate that capacities were intentionally imprecise, and that repairs and reassembly might result in even greater imprecision of capacity. In looking at archaeological examples, the question "what is a size" is perplexing, but a few observations can nonetheless be made. First, a cooperage "capacity" was perceived as a minimum quantity, which in practice was exceeded by some two to five per cent.20 Norms of capacity appear to have become more rigid the more times a barrel was sold with its contents, since with each exchange it was further removed from the producer who was responsible for its gauge. At the other extreme are the barricas from Red Bay, which range from about 190 to 240 litres in capacity due to their frequent re-use and repair and to the fact that they were retained by the initial producers of the oil, while the eighteenth-century Virginia salt meat barrels were supposedly made to a seven per cent tolerance.21 Second, the great profusion of local barrel sizes that has been recorded, for example in France,22 does not appear to be representative of the main staple trades of the early modern period in which a few regional capacities dominated the majority of trade in a given commodity. Thus it appears, given the nature of staple trades, that capacity can be used as an indicator of the contents and possible provenance of a cask.

18 Tightness was also related to the barrel contents. Tightness may be achieved in contemporary cooperage by several means: wood species, as already discussed; the number and distribution of hoops; stave thickness; and the "cambre" or amount of bend in the staves of the barrel. Today, a stave thickness of 3 cm is common in whisky barrels which are required to store liquid over long periods of time but require little handling compared to historical barrels used for shipping.23 Even in this century, beer-barrel staves were equally thick, but the barrels were smaller because they were cycled as rapidly as every month and were frequently handled. Among historical cooperage, most large barrels containing 200 to 500 litres have staves of 1.0 to 1.5 cm thickness, suggesting that their contents did not have the same viscosity or trade value as today's spirits or wine; in other words, they were "dry tight." The high standard of liquid tightness implied in the "wet tight" cooperage descriptions of Kilby, Taransaud and Diderot is not representative of the majority of historical barrels.

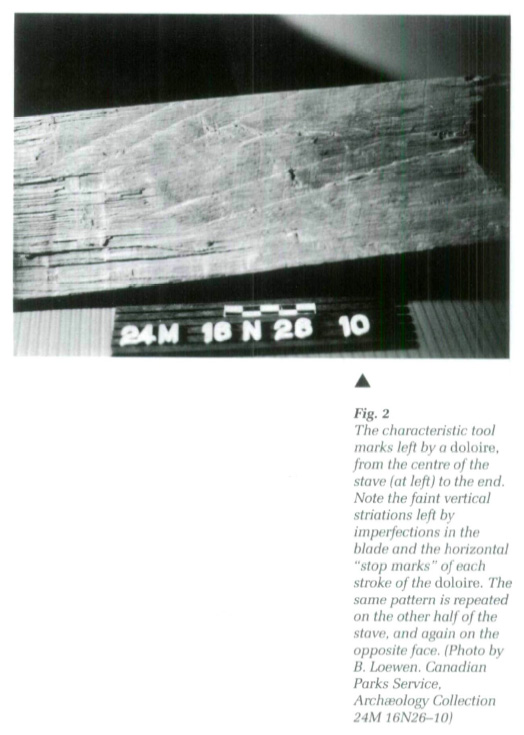

19 The greater the cambre of the staves, the greater the barrel's tension and the tighter it can be, but a barrel with a large cambre, or "pitch," is also more difficult to make or reassemble. Here again, most historical cooperage falls short of the standards described in the literature on cooperage of the last hundred years. It is rare to find a circumference more than 15 per cent greater at the bilge (middle) than at the ends of an archaeological specimen; the collection of some 70 oaken barrels conserved from the Red Bay site clusters around 7 to 10 per cent. More than any other indicator, the degree of liquid tightness found in the vast majority of archaeological cooperage deviates from the literature that is commonly used to support a cooperage study. It appears that the branch of cooperage to survive into the twentieth century, the small specialization for wine, spirits and beer known as "liquid tight" and which is described at length in contemporary literature, is not representative of most historical cooperage which falls into a huge category more consonant with what is called "dry tight" cooperage by Kilby.

20 Another analytic variable related to a barrel's contents is its use-cycle, which is also related to the human history of a given trade. Was the barrel used once, to be broken up after it was emptied? Did the owner of the contents retain ownership of the barrel once the contents were sold? Were the contents inspected while still in the barrel by a buyer or port customs agent? Was the barrel "shaken" or dismantled for return shipment? Was it ever repaired? Did the barrel hold another container for the shipment of valuable commodities? Answers to those kinds of questions can be found in archaeological barrels by studying the reassembly marks, inspection holes, and the marks of the cooper, shipper or owner - or the lack thereof. Such evidence can, in turn, be related to documentary evidence of the packing and shipping technologies of a given trade. It is rare to match shippers' marks with marks known from documents; of the 56 marks recorded in the Red Bay cooperage, for example, none matched the 16 marks known from the archives of Bordeaux during the same time. While our existing data is generally insufficient for direct comparison between marks from artifacts and documents, it is possible to begin understanding the type of mark observed. The sixteenth-century marks are often composite, containing recurring symbols and letters, as well as some evidence of enumeration. They were used as shippers' marks for the Terranova and Flanders trades for a variety of goods, and the marks of Biscay and Bordeaux are comparable in style even in the latter half of the sixteenth century, a century after the Bretons displaced the Basques as shippers of Aquitaine wine.24

21 Evidence relating to the use-history of a barrel appears to indicate changes over time in the history of cooperage, changes which reflect gross trends known from literary and documentary sources. Roman cooperage artifacts do not contain inspection or sampling holes, suggesting one of two scenarios. Either the contents were decanted before sale by the producers of the contents - as described by Strabo - or the barrels were used solely for transport by the end-user of the contents, for example, by the Roman army. Saxon-era cooperage finds from the London Docklands project do not contain sampling holes, raising questions about the nature of early medieval trade.25 Early modem barrels from Europe, on the other hand, have numerous inspection or sampling holes and have evidence of frequent reassembly and repairs. These holes indicate that the barrels were reused by the producers of the contents, and that conventions of inspection before the opening of the barrels were in place. Colonial American barrels were inspected for the standard of the barrel and its contents, leaving material evidence such as the marks of various inspectors, coopers and the producers of the contents.26 These marks are evidence of an export trade in which barrels were sold with their contents - a profligate use of barrels which in America certainly played a role in the failure of coopers to develop the solidarity and status associated with coopers' guilds in Europe,27and an example of how die use-history of a barrel is related to the division of labour in the cooperage where it was produced.

The Division of Cooperage Labour

22 We have looked at cooperage in the context of the trades which furnished the materials for the staves and the hoops of a barrel, and of the trade which contributed its contents. The last variable in historical cooperage to be discussed here is the division of labour in the workplaces where the barrel was made and used. Historical cooperage also included repairs, disassembly and reassembly, filling and inspecting. Very little is known about the organization of cooperage labour before the later middle ages when guilds dominated the trade. The guilds declined in importance during the modern period, particularly as long-distance trade in staple commodities mushroomed and cooperage was practiced in a wide variety of conditions. The nineteenth century witnessed a general mechanization of cooperage production, premonitions of which can be found in artifacts dating from the advent of mill-powered sash saws. Today, it is possible to observe barrels being made in highly mechanized factories employing more than a hundred people,28 or in nearly unmechanized workshops owned and operated by up to five family members.29The end result may be a standard wine barrel, but the process of making it can be dramatically different.

23 Differences in cooperage technology are often evident in artifacts, especially in the tool marks. Ethnographic field enquiries in contemporary cooperages show that, irrespective of the size of the operation, certain characteristic marks are used by coopers to communicate with each other or to remind themselves where they were in the preparation of a batch of barrels. Such marks for communication, or "cognitive marks," occur particularly in the preparation and installation of heading and in the fitting of hoops. Some occur identically in archaeological objects from Roman times to the modern period, and they can betray the division of labour in the cooperage.

24 More easily studied than "cognitive marks" are the traces of tools used to shape and finish the components of a barrel. The most important marks are related to the shaping of the staves and "chimes" or ends of staves, the fabrication of the heads and hoops, and the assembly and subsequent maintenance of a barrel. These marks also provide evidence of historical diversity and change in the division of cooperage labour.

25 For example, Kilby describes a method of shaping the faces of staves using a drawn knife, a tool which is not found in archaeological cooperage.30 Prevalent instead are the traces of a tool called a doloire, or cooper's axe.31 Here again is evidence that the cooperage technology which survived into the twentieth century, and is described in contemporary literature, is not representative of the bulk of historical cooperage. The traces of the doloire - and its attendant trade of the doleur which, in some places, developed its own guilds32 -are also the earliest to be replaced by the marks of machines, primarily sash saws, as early as the 1740s.33 One is led to ask whether the development of a separate trade and guild for the repetitive work of shaping the faces of raw staves was but a preparatory step in the mechanization of this work. The doleur's guilds had disappeared by the eighteenth century, and by the nineteenth, the doloire had become a collector's item.34Nineteenth- and early twentieth-century cooperage manuals contain descriptions of numerous machines for shaping staves, preparing chimes, and serrying staves by mechanical windlasses into the form of a barrel.35 These machines -and the tool marks they left on archaeological barrels36 - performed the same tasks once done by hand, but gradually simplified and regularized over time as cooperage labour became increasingly subdivided. In a cooperage of more than 100 employees in Charente-Maritime, only three are capable of the traditional work of hand cooperage and their work consists of repairs and maintenance.37 "Coopers" capable of hand cooperage at large bodegas in the wine-producing region of La Rioja are today occupied in repair and maintenance, and it is reasonable to interpret tool marks found on eighteenth-century naval cooperage as representing a comparably subdivided, if less mechanized, coopering trade.

Display large image of Figure 2

Display large image of Figure 226 Inventories of cooperage tools38 are often surprisingly limited in their variety and number when compared to the lists of tools found in Kilby, Taransaud and Salaman39 and to museum collections.40 In fact, the inventories correspond closely to the types and numbers of tools found in cooperages today.41 Again this may be seen as evidence that individual cooperages were limited in the range of products they made, concentrating on a specific range of products for dominant regional trades, and employing a rather "laconic" technology.

27 Documentary sources, from late medieval evidence of the entrenchment of guilds to the mechanization of cooperage in the nineteenth century, describe a wide variety of cooperage labour conditions. Virginia tobacco hogsheads were prepared by plantation slaves;42 Biscayan whale oil barricas were prepared by coopers who doubled as ships' officers and, on occasion, had apprentices.43 Only in the very early history of Boston do coopers' guilds figure in colonial American history,44 while in London, the coopers' guild continued into the twentieth century.45 The image of a lone rural cooper making the rounds like a tinker46 contrasts with the coopers' streets which existed in most ports from the middle ages on,47 and with entire towns like Saint-Macayre on the Gironde that were devoted to cooperage.48 No doubt, the division of cooperage labour from region to region, and from trade to trade, shows great diversity and change in the course of its long history.

Conclusion

28 This paper arose from an invitation to report on cooperage from the point of view of "continuity of technology." The greatest interest in such an approach lies in the contrast between the continuity of cooperage as a form of container, and the great diversity and change in the technology which produced these containers. The focus has been on the early modern period, to the neglect of classical and medieval cooper-age on one hand and mechanized cooperage on the other. It appears that the choice of materials represents complex considerations, and that the technology of working these materials into a barrel varied greatly, but was in accordance with the economies that used the container. Extending the study of cooperage into the life cycle of a barrel can provide additional evidence, which in turn can provide points of reference between documentary and artifactual evidence. The approach of seeing cooper-age as evidence of staple trades, wood technology and commerce brings it out of the realm of a "static" and traditional craft, and into the domain of the historian interested in causality, change and diversity.

Thanks to Nancy Anderson, Marc-André Bernier, Gérard Gusset and Olive Jones for reading a draft of this paper and for freely offering their critique.