Photo Essay / Essai photographique

Some North American Survivals

1 The survival of what remains of our engineering and industrial heritage has not been accidental. Continued use has generally been the reason for survival, though the historic importance of this heritage has occasionally played a part in preventing its destruction.

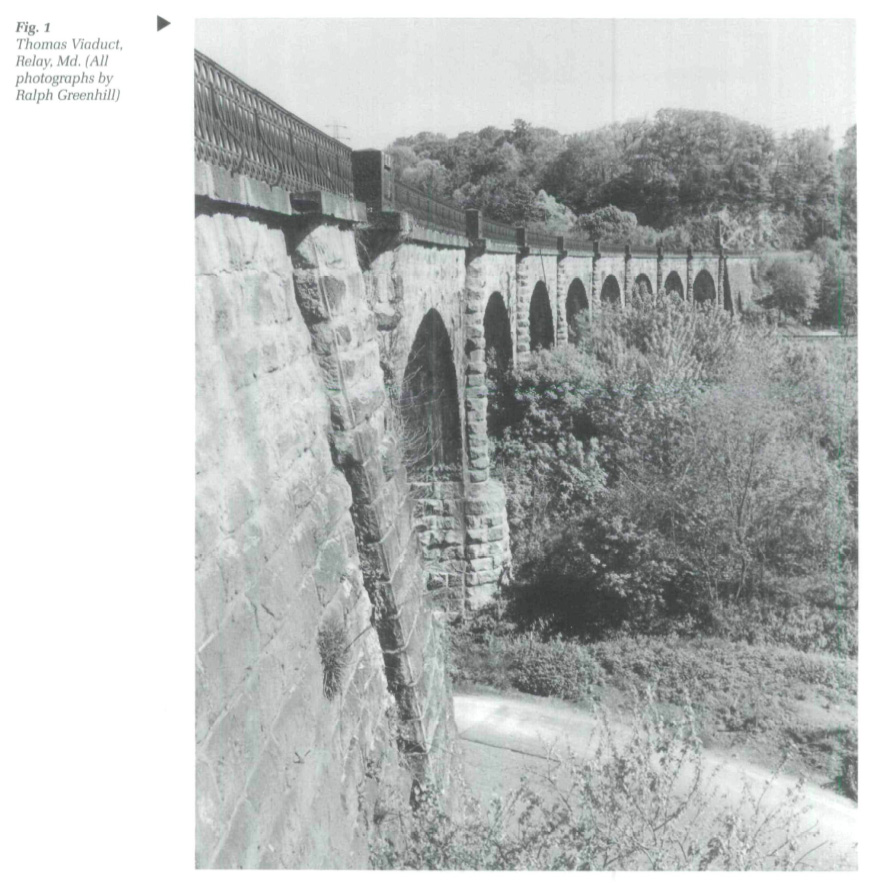

2 The Thomas Viaduct (Fig. 1) is an outstanding example of continued use. Built in the earliest years of the railroad in North America when the heaviest locomotive weighed no more than ten tons, Latrobe's superb granite arch bridge continues to carry the full weight of modern railroad traffic. The expense of such bridges made them unusual in North America until the later years of the nineteenth century. In the rebuilding of their trackage to permit faster and heavier traffic, the then affluent, usually eastern, railroads, revived the construction of stone arch bridges. The Pennsylvania Railroad built many, including the longest stone railway arch bridge in the world, the Rockville Bridge, completed in 1901 across the Susquehanna River above Harrisburg. Like the Thomas Viaduct, it continues to be very much in use today.

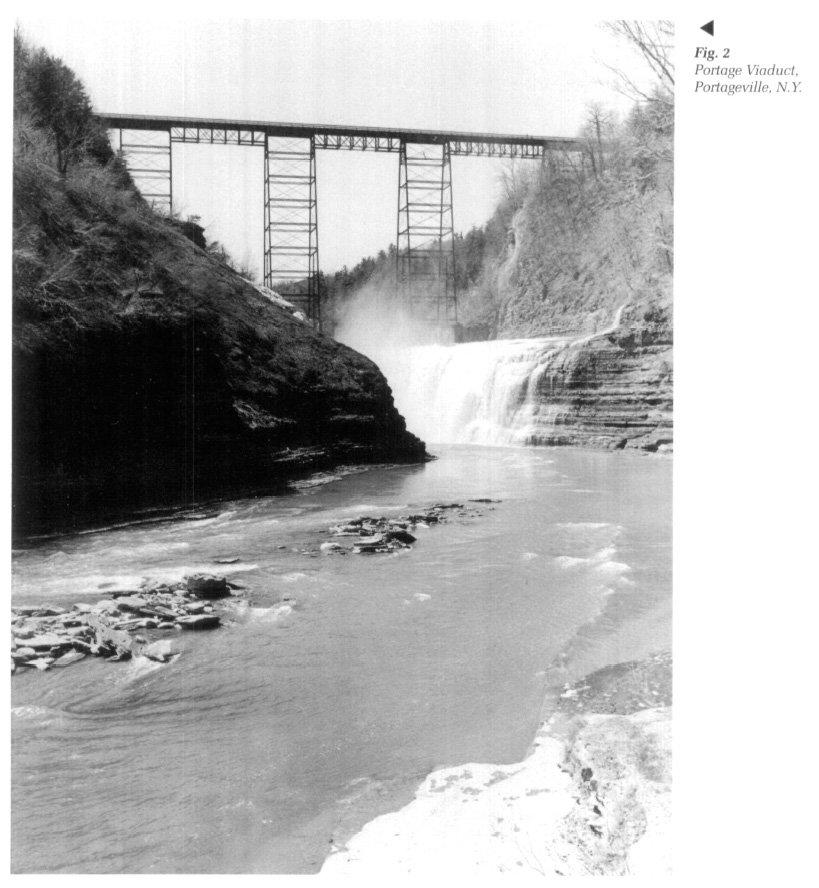

3 Because wood was both abundant and cheap, the majority of early railroad bridges in North America were timber structures. Iron truss bridges, which had the advantage of strength and durability as well as being free from the ever-present danger of fire from locomotive sparks, came into widespread use in the 1850s. With the steadily increasing weight of trains, most iron structures were replaced by steel around the turn of the century. The Portage Viaduct (Fig. 2) is not only a remarkable iron survival still in use, but also a fine example of the American railway viaduct in which two pairs of braced posts, or columns, take the place of a conventional masonry pier.

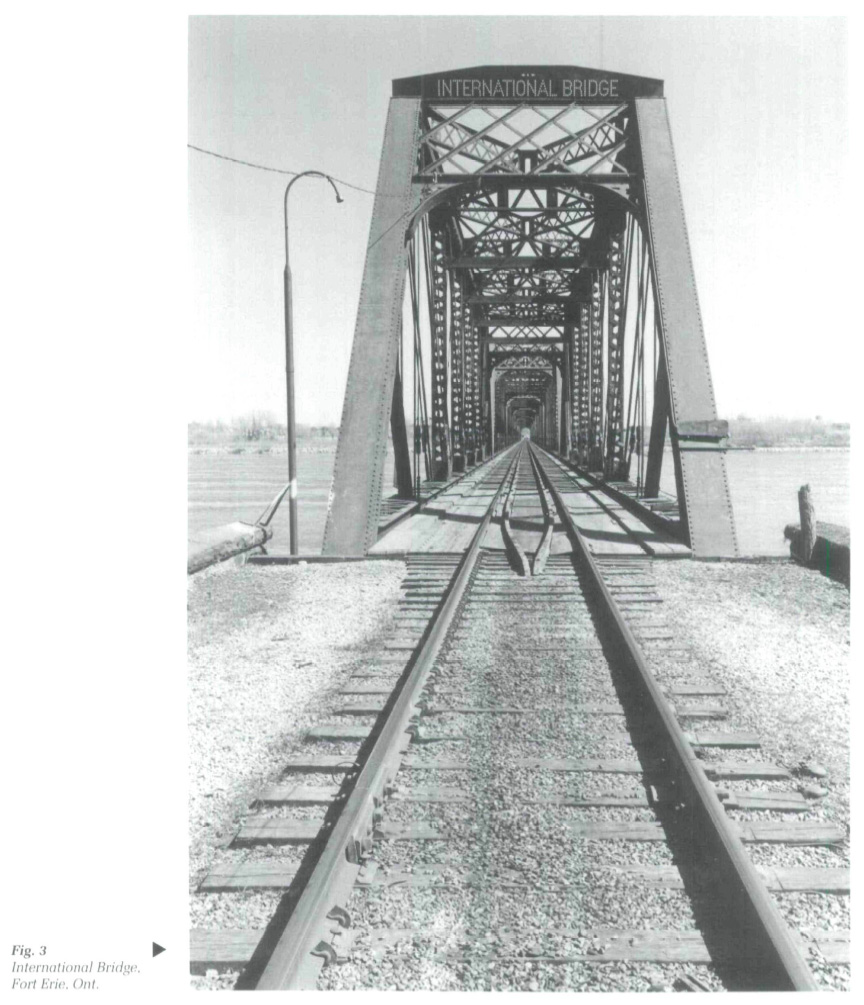

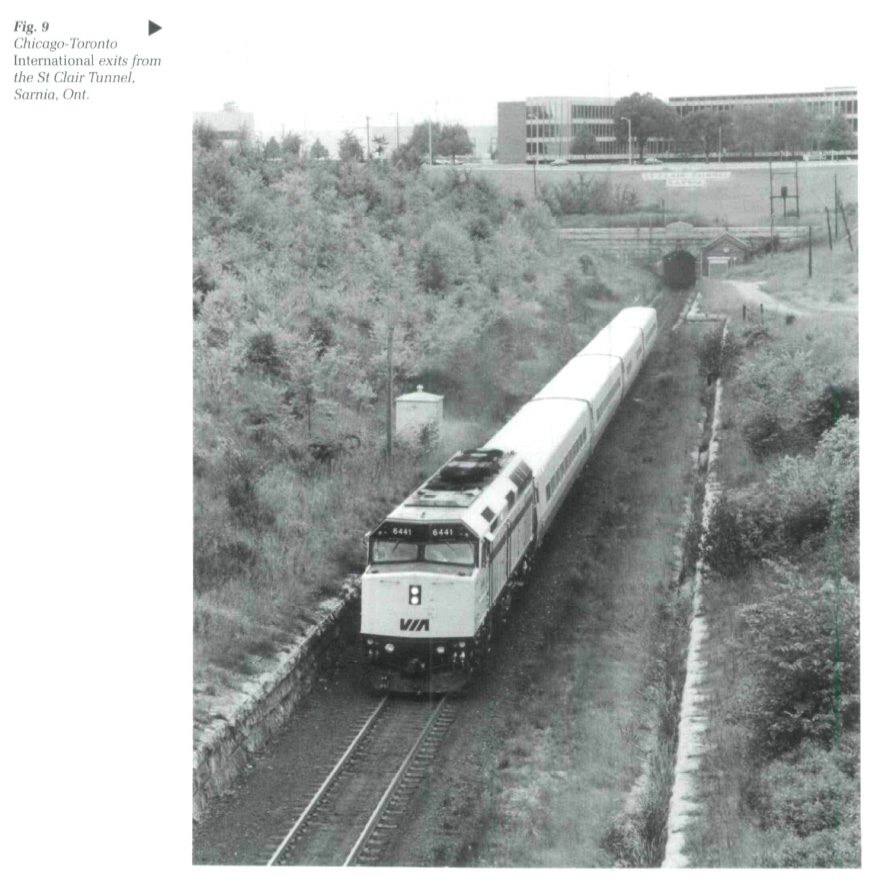

4 The steel through truss that replaced the original iron truss of the International Bridge (Fig. 3) in 1901 has enabled this bridge to continue to be an important link between Canadian and American railroads because the height of the truss provides ample clearance for modern double-stack container traffic. Unlike the International Bridge, the St Clair Tunnel (Fig. 9) does not have sufficient clearance for such traffic and modern oversize railroad cars such as multilevel auto carriers which have to be ferried across the St Clair River. With the emphasis today on cross-border instead of Canadian transcontinental traffic, surveying has already begun for the construction of a new tunnel, 25 metres north of the existing tunnel, capable of accommodating all modern freight traffic. When opened - possibly in the fall of 1994 -the new tunnel will make the ferry service redundant and will probably make the century-old tunnel similarly redundant.

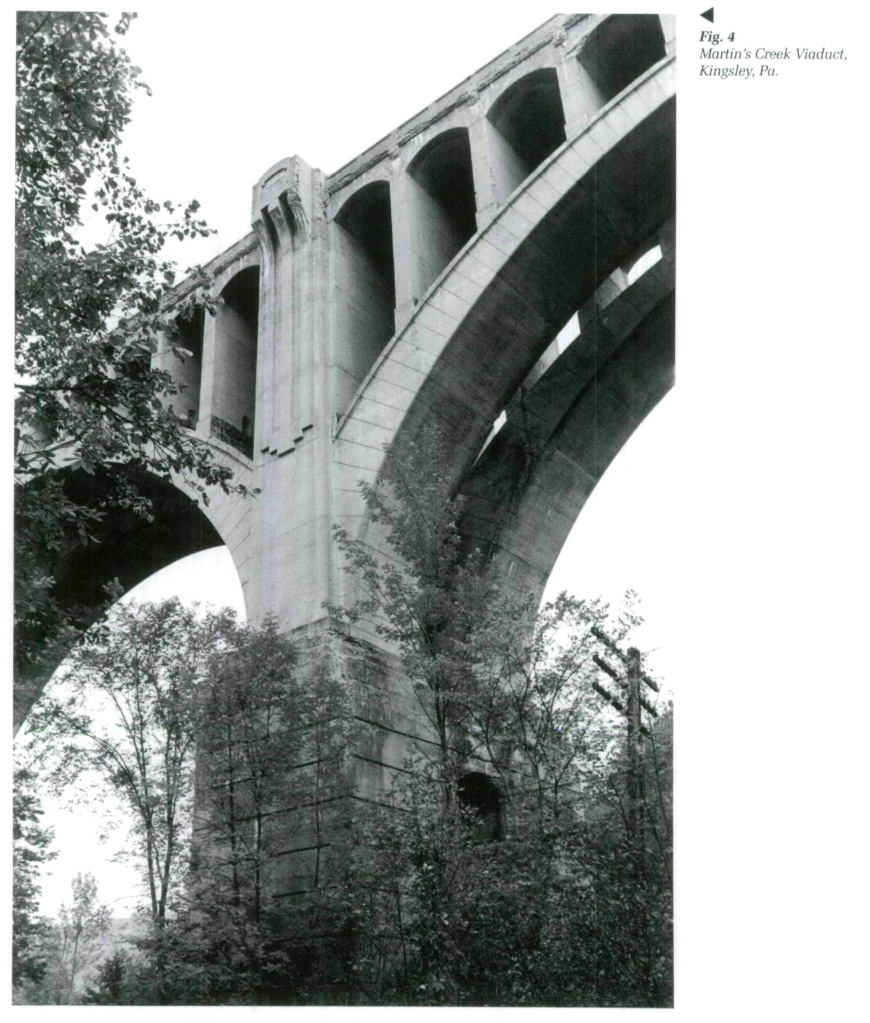

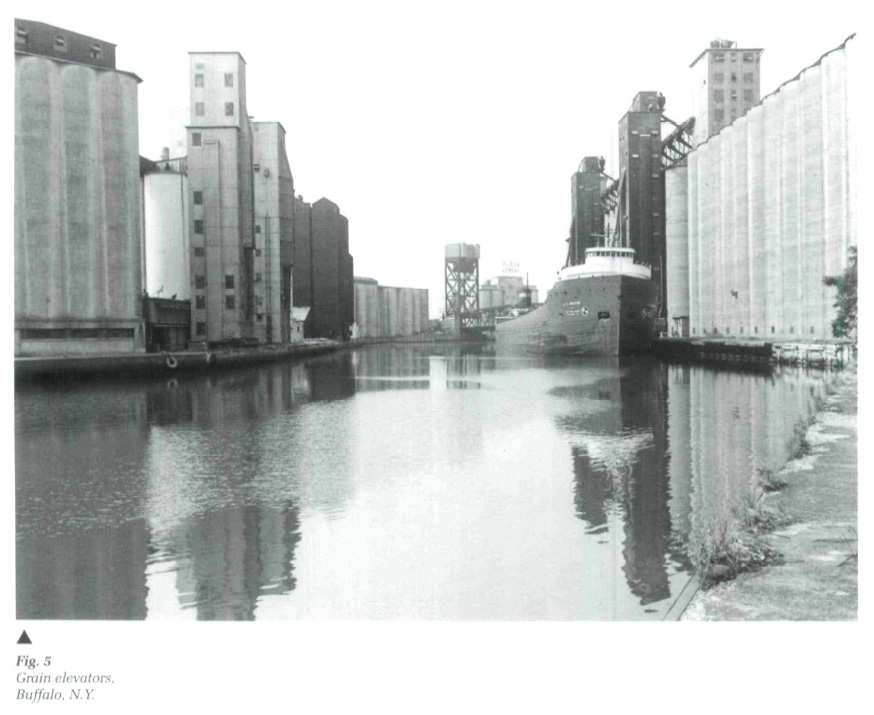

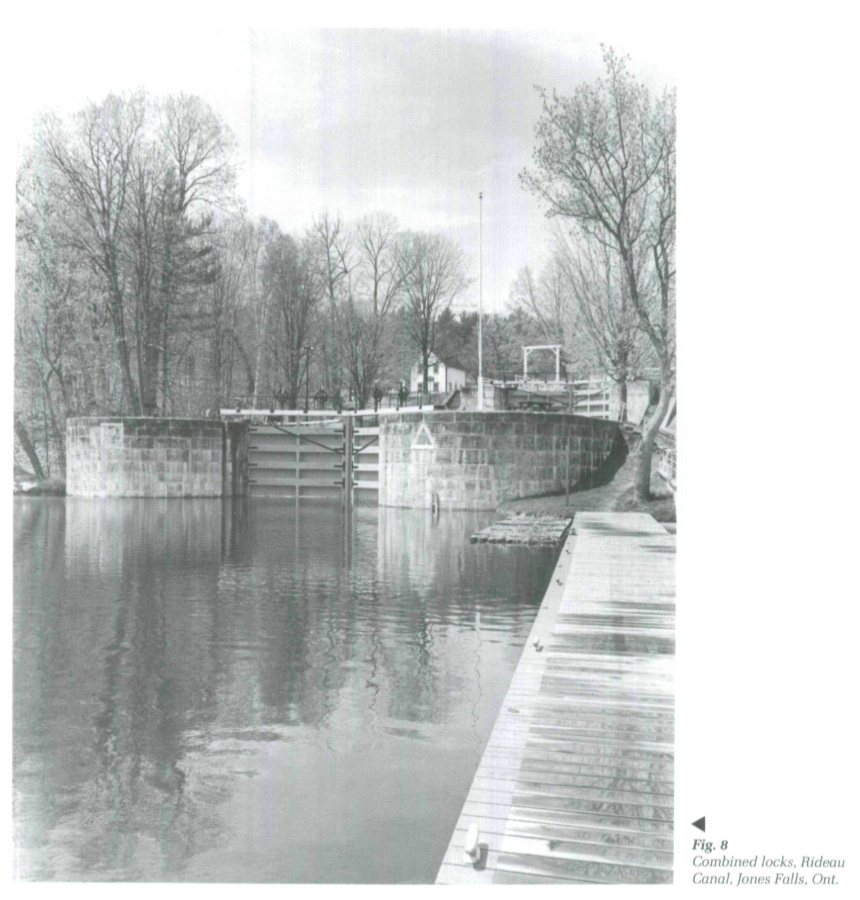

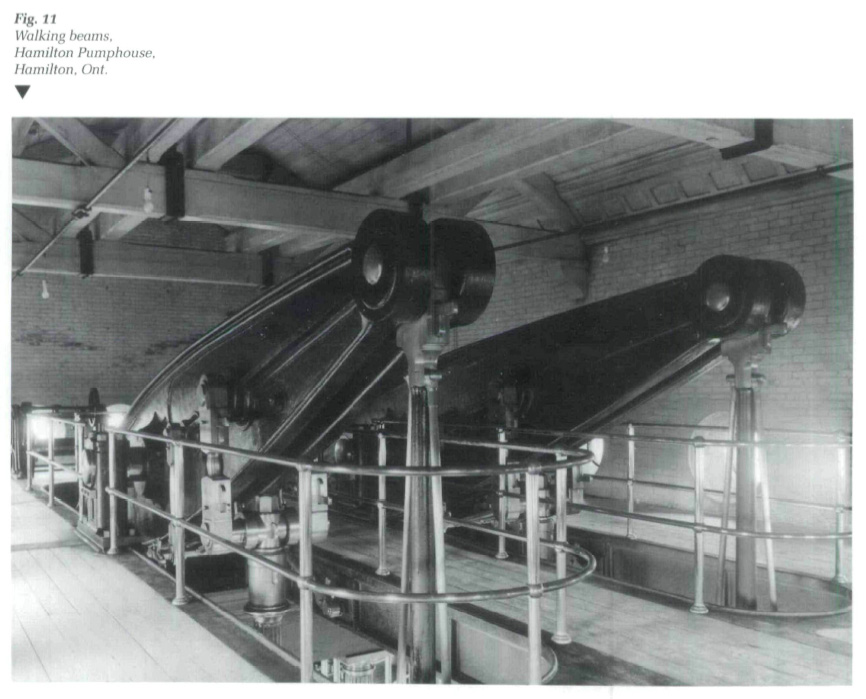

5 Plain mass and reinforced concrete became significant structural materials before 1900. The early years of the present century saw some spectacular uses of concrete. The Lackawanna Railroad's Tunkhannock Viaduct and its smaller Martin's Creek Viaduct (Fig. 4) are just two of a number of massive reinforced-concrete bridges built before 1920. One of the problems with such huge concrete structures is that they are enormously, if not prohibitively, costly and difficult to demolish when they have outlived their usefulness. While all of the Buffalo elevators illustrated in Fig. 5 are still in use — Buffalo is the largest flour-milling centre in North America — the colossal Concrete Central, farther upriver, has long stood unused and decaying in an all-but-inaccessible wasteland.

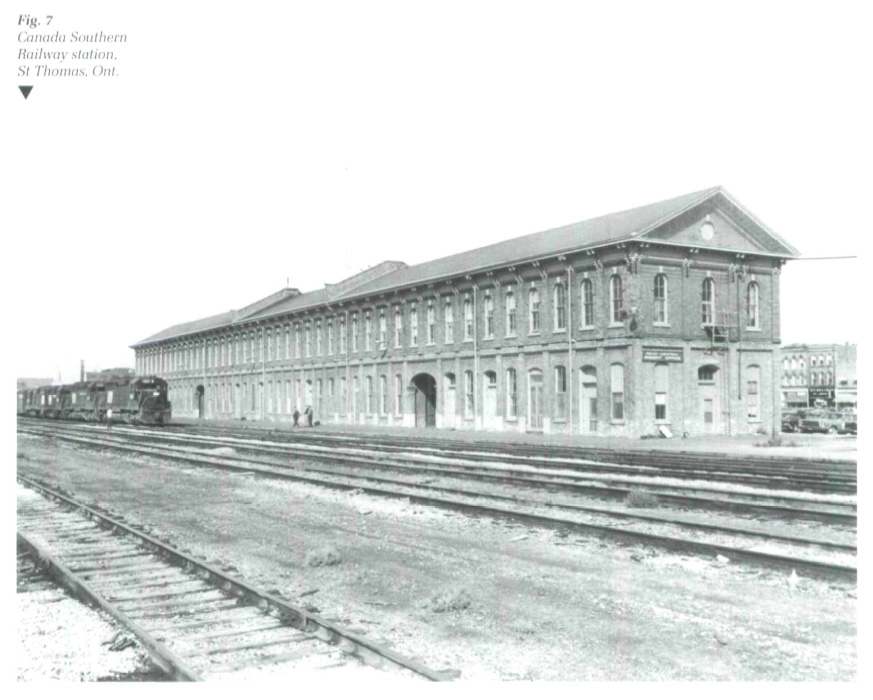

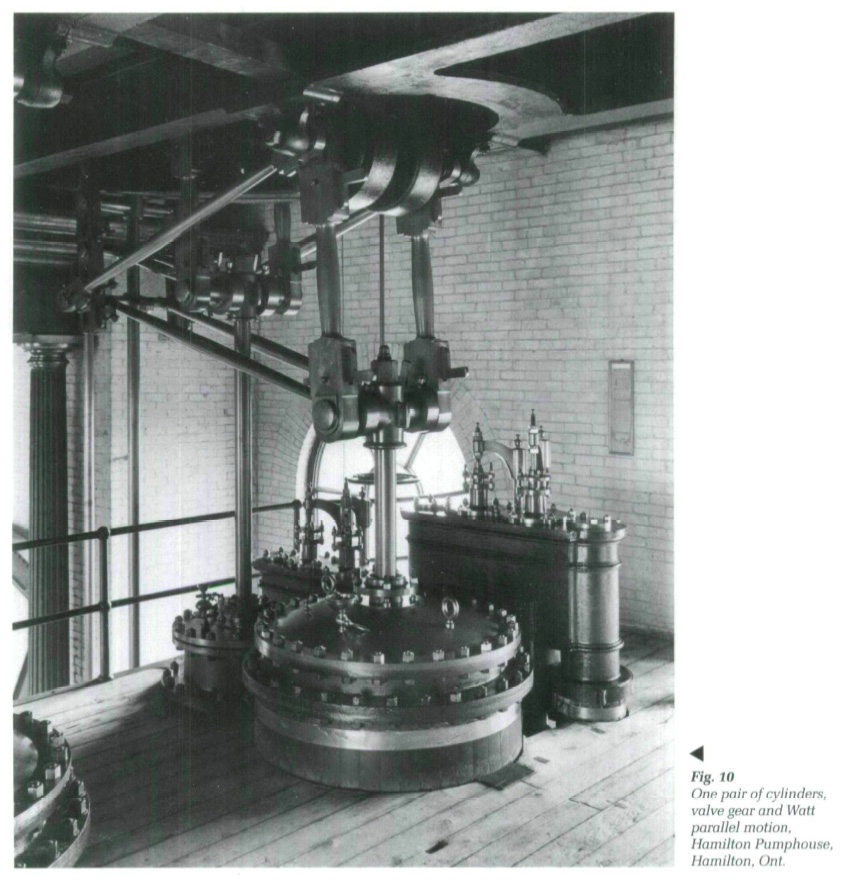

6 There were proposals to dismantle the Rideau Canal system in the 1930s, but these were dropped because of the valuable flood control provided by its dams and sluices. It was not until after Parks Canada had taken over responsibility for the waterway in 1972 that the policy was established to restore and preserve the historic nature of the canal with its hand-operated machinery and massive wooden lock gates (Fig. 8). The survival of the Hamilton Pumphouse is a different story. Long after the beam engines (Figs. 10 and 11) served any practical purpose, succeeding city engineers continued to maintain them as part of the city's heritage. When much of the earlier waterworks plants of the Hamilton Beach Pumping Station was dismantled and demolished after the complete electric station opened in 1954, the original pumphouse with its engines remained and was eventually opened to the public in 1983 as the Hamilton Museum of Steam and Technology.

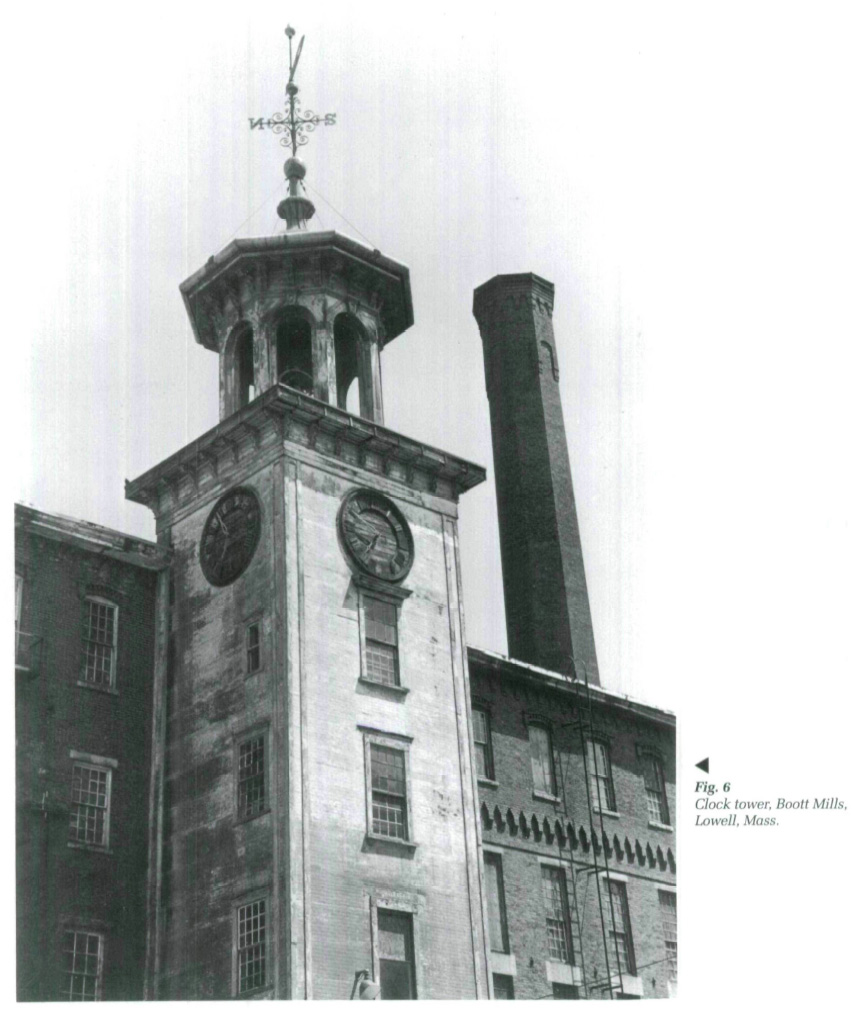

7 The future of the Hamilton Pumphouse has been secured, but that of Canada's "heritage" railway stations is less bright. The small stone station of 1858 at St Mary's, Ontario, is a National Historic Site, yet it stands abandoned, boarded up, fenced around, and deteriorating. It is only because of the present economic climate that some Canadian National Railways personnel still use the large St Thomas station (Fig. 7). The lower windows, except for the CSX Transportation crew room, are now boarded up. The interior is very dilapidated. The desire of CN to vacate die building and the prohibitive cost of any future restoration, make this station's eventual survival unlikely.

8 The Boott Mills complex (Fig. 6) was in an even more deplorable state when it was taken over by the U.S. National Park Service in 1978 as part of the Lowell National Historical Park — the first urban industrial national park. Consulting engineers had reported on the poor condition of the mills in the early 1900s, but little or nothing was done over the years to ameliorate working conditions or effectively restore deteriorating structures. The Park Service began restoration as part of a program to inject new life into the city, which then had one of the highest unemployment rates in the country. About three-quarters of the total complex has now been restored and is occupied by offices and high-tech corporations. The Massachusetts Mill nearby is being converted to residential condominiums.

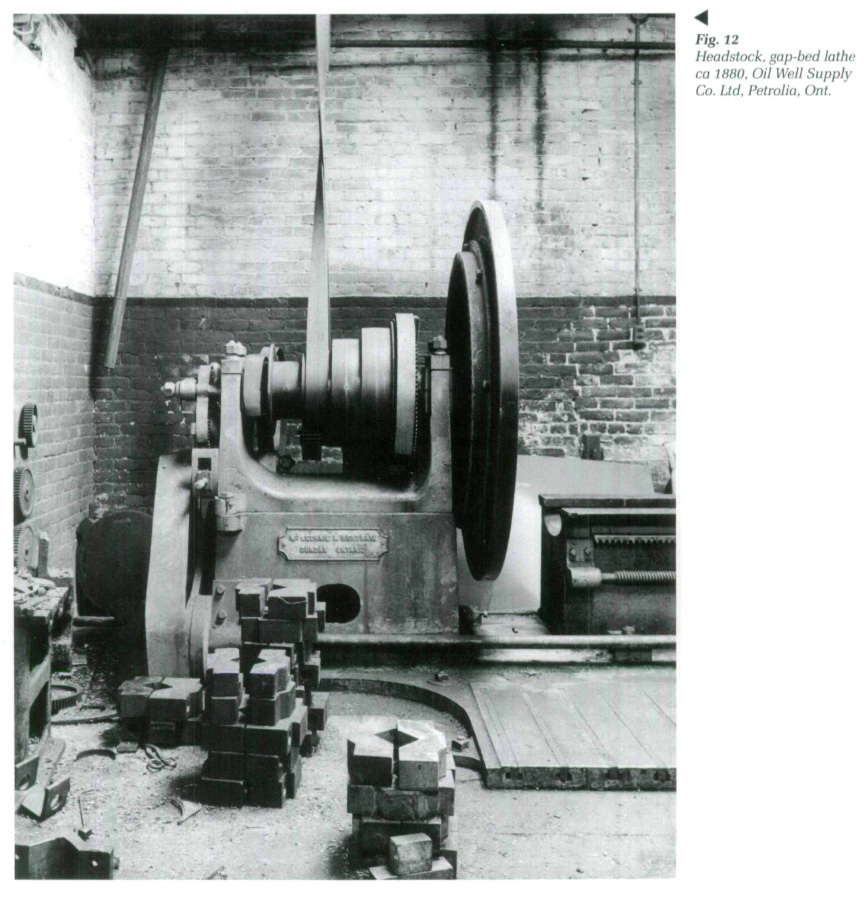

9 The preservation of our mechanical engineering heritage is very patchy. Old engines of every description have been salvaged by both private collectors and museums. But when the Oil Well Supply Company of Petrolia, Ontario, felt it had to replace its old belt-driven machinery a few years ago, the century-old gap-bed lathe by McKechnie & Bertram (Fig. 12) was scrapped. Machine tools, however historic and significant, do not evoke the nostalgia of old engines or the fascination of antique hand tools and so rarely survive.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 9

Display large image of Figure 9 Display large image of Figure 10

Display large image of Figure 10 Display large image of Figure 12

Display large image of Figure 12NOTES

Fig. 1 Thomas Viaduct, Relay, Md., 1981. The Thomas Viaduct, named after Philip Thomas, first president of the Baltimore & Ohio Railroad, was designed and constructed by Benjamin H. Latrobe II when he was principal assistant to the railroad's chief engineer, Jonathan Knight. Completed in 1835, the Thomas Viaduct was the first multispan masonry railroad bridge in America. With an overall length of 612 feet (187 metres), its eight arches span the Patapsco River and its narrow valley approximately 18 metres below, on a curve which required differences in span and pier width between opposite sides of the bridge. The Thomas Viaduct has continued to carry double-track mainline traffic between Baltimore and Washington to the present day.

Fig. 2 Portage Viaduct, Portageville, N.Y., 1982. The iron Pratt-truss Portage Viaduct built in 1875 is one of the very few iron railroad bridges not replaced or entirely rebuilt. It was designed by George S. Morison to replace the Erie's immense timber viaduct (1852) which had been destroyed by fire. The bridge has ten spans of 50 feet (15 metres), two of 100 feet (30 metres), and one of 118 feet (36 metres), and carries the railroad more than 61 metres above the Genesee River where it enters a spectacular 19 kilometres-long gorge. The bridge was designed, fabricated and erected with astonishing speed; the timber structure was destroyed by fire on May 6, and its iron replacement officially tested on July 31. In spite of some reconstruction in 1903 and again in 1943—44, its appearance remains essentially unaltered.

Fig. 3 International Bridge, Fort Erie, Ont., 1987. The Grand Trunk Railway's International Bridge, opened in 1873, was the first bridge to span the Niagara River above the Falls. The chief engineer was E. P. Hannaford, the railway's chief engineer. The strong current and depth of the river made it impossible to construct cofferdams within which to build the bridge piers. These were founded on caissons built ashore and floated into position with great difficulty. The single-track bridge took nearly four years to build. It consisted of a main bridge from the Canadian shore to Squaw Island of seven fixed spans varying in length from 193.5 to 248 feet (59 to 76 metres) and a draw span of 362 feet (110 metres), as well as a smaller bridge across the Erie Canal at Black Rock with a fixed span of 219 feet (67 metres) and a draw span of 218 feet (66 metres). In 1901 the iron truss superstructure was replaced by steel. A double-track swing span, known as the Harbor Drawbridge, was constructed in 1910-11 to replace the smaller bridge across the canal.

Fig. 4 Martin's Creek Viaduct, Kingsley, Pa., 1981. In 1912, work began on a major relocation of the Delaware, Lackawanna & Western Railroad between Scranton, Pa., and Binghamton, N.Y. This entailed the construction of two massive reinforced-concrete bridges designed by the railroad's bridge engineer, A. Burton Cohen. The larger of the two bridges is the huge Tunkhannock Viaduct, still the largest concrete bridge in North America. Less well known is the smaller Martin's Creek Viaduct with a span of 1600 feet (488 metres). The whole project, including the two viaducts, was completed in late 1915. The line today forms part of the Delaware & Hudson's main line between Scranton and Binghamton.

Fig. 5 Grain elevators, Buffalo, N.Y., 1982. It was in Buffalo that Joseph Dart constructed the first practicable grain storage elevator in 1842. Dart himself acknowledged that he used Oliver Evans' plans for handling grain mechanically in developing his steam-powered elevator with its marine leg to lift grain from the hold of a ship. The concrete elevator, however, originated in Minneapolis. The light-coloured bin to the left of the photograph is part of one of the earliest concrete elevators in Buffalo - the American (now Peavey) Elevator built in 1907. On the right, the J. L. Mauthe of the Interlake Shipping Co. is being unloaded by the moveable marine towers of the Standard Elevator, built in 1928 and extended in 1942. This scene on the Buffalo River represents the largest concentration of concrete elevators in the world.

Fig. 6 Clock tower, Boott Mills, Lowell, Mass., 1982. The Boott Cotton Mills form the most intact surviving nineteenth-century mill complex in Lowell. They were named after Kirk Boott, the first agent of the Merrimack Manufacturing Company which established and controlled the development of Lowell, beginning in 1822. All of the original six Boott mills, built between 1835 and 1843, survive, although substantially altered. More buildings were added to the complex in later years, and the clock tower, now restored, probably dates from the 1870s. After World War II the New England textile industry began moving to the South. Production at the Boott Mills finally ceased in 1975. Today, the mills are part of the Lowell National Historical Park.

Fig. 7 Canada Southern Railway station, St Thomas, Ont., 1971. When the St Thomas station opened in 1873 as both passenger station and headquarters of the Canada Southern Railway (CSR), a local paper boasted that it surpassed "anything of the kind owned by any one Railroad Company in the broad Dominion." Although the building, 354 feet long and 36 feet wide (108 metres long and 11 metres wide), has lost its eight chimneys and encircling veranda, it is still impressive as it stands largely empty, facing mainly disused tracks. With an almost straight and level track between the Detroit River and Niagara frontiers, the railway was built as a bridge road for traffic between Chicago and New York, and was under American management from the time of its first survey in 1870. Eventually part of the Michigan Central and later the New York Central, the CSR was jointly purchased from Conrail in 1985 by Canadian National and Canadian Pacific.

Fig. 8 Combined locks, Rideau Canal, Jones Falls, Ont., 1980. The Rideau Canal, built between 1826 and 1832, is the only early nineteenth-century North American canal that has most of its original structures intact. Connecting the Ottawa River with Kingston on Lake Ontario, the canal is actually a canalized waterway with only about 29 of its total 198 kilometres artificially constructed. A stone arch dam was built at Jones Falls, 62 feet (19 metres) high and 350 feet (107 metres) along its crest. Three combined locks carry the canal to a natural basin, and a single lick raises the canal again to the level of water backed up by the dam. Today, the works remain virtually as constructed, except for three large wood-stave penstocks installed to supply water to a small generating station at the foot of the gorge below the dam.

Fig. 9 Chicago-Toronto International exits from the St Clair Tunnel, Sarnia, Ont., 1991. By the 1880s, the Grand Trunk's ferry service across the St Clair River between Point Edward, north of Sarnia, and Port Huron, Mich., was becoming a serious bottleneck in its major trunk line for traffic from Chicago to the Atlantic seaboard. The railway decided to explore the practicability of a tunnel under the river; Joseph Hobson was appointed chief engineer. After discouraging test borings, the failure of an exploratory drift and a first attempt to drive a full-size tunnel, work on the tunnel was resumed in January 1889 by the railway itself. Hobson designed the tunneling shield that was used, together with compressed air, in the difficult soft-ground conditions under the river. Opened for traffic on September 19,1891, the St Clair Tunnel was not only the first in which both shield and pneumatic systems were used on a large scale, but also the first major sub-aqueous tunnel in America.

Fig. 10 One pair of cylinders, valve gear & Watt parallel motion, Hamilton Pumphouse, Hamilton, Ont, 1977.

Fig. 11 Walking beams, Hamilton Pumphouse, Hamilton, Ont., 1977. The steam engines at the Hamilton Pumphouse represent the most advanced form of the beam pumping engine which had originated with Newcomen's early eighteenth-century "atmospheric" engine. The only other surviving installation of beam engines in North America, the pumping plant of the Chesapeake & Delaware Canal at Chesapeake City, Md., provides an interesting contrast to the pumphouse at Hamilton. The single-cylinder engines of the canal powerhouse employ a pair of slide bars to guide the piston rod, with the cross heads connected by two links to the walking beam, whereas the compound engines at Hamilton are fitted with the "parallel motion" devised by James Watt to guide the piston rod in a straight line. Built by John Gartshore of Dundas, the first engine was started in October 1859 and the second engine the following month. The pump-house, now a museum, formed part of the waterworks designed by Thomas Coltrin Keefer.

Fig. 12 Headstock, gap-bed lathe ca 1880, Oil Well Supply Co. Ltd, Petrolia, Ont., 1979. McKechnie & Bertram, the manufacturers of this large lathe, established their partnership known as the Canada Tool Works in Dundas, Ont., in 1863. Both men had earlier been shopmates at John Gartshore's Dundas Foundry. Three of John Bertram's sons were apprenticed at their father's works, and after Robert McKechnie retired in 1886, the firm became known as John Bertram & Sons. It developed into one of Canada's major engineering firms. The Oil Well Supply Company dates back to the discovery of the Petrolia oil field in the 1860s. As Canadian drillers moved to newly opening oil fields in Eastern Europe and elsewhere in the 1870s and 1880s, the company became an exporter of drilling rigs and tools. It is still in business in its original location.