Articles

Technical Advance and Stagnation:

The Case of Nail Production in Nineteenth-Century Montreal

Abstract

Nail production grew enormously in nineteenth-century Montreal. For most of the century it was the centre of the Canadian nail trade. There were radical changes in the types of nails produced, starting by handmade iron nails, progressing to machine-made cut nails, and finally to steel wire nails. While nails were made in small artisanal shops at the beginning of the century, by 1900 the majority were made in large, steam-powered rolling mill complexes. Important advances in secondary iron manu-facturing were made by these companies. The article also deals with the question of why some water-powered cut nail factories were able to persist in the face of larger, more advanced competitors and discusses Montreal's competitive position in nailmaking.

Résumé

Au XIXe siècle, la production de clous s'est développée de façon importante à Montréal. La ville a été pendant la plus grande partie du siècle le centre canadien du commerce des clous. Il y a eu des changements radicaux dans les différents types de clous produits, les clous fabriqués à la main faisant place peu à peu aux clous coupés à la machine et finalement aux clous d'acier tréfilé. Alors qu 'au début du XIXe siècle, les clous étaient fabriqués dans de petits ateliers artisanaux, en 1900, presque tous provenaient de grands laminoirs fonctionnant à la vapeur. Les sociétés productrices ont réalisé d'importants progrès dans l'industrie secondaire du fer. L'article explique en outre pourquoi certaines usines utilisant la force hydraulique pour couper les clous étaient capables de se maintenir face à des concurrents plus considérables et plus avancés techniquement, et examine la position concurrentielle de Montréal dans ce secteur manufacturier.

Introduction

1 The manufacture of nails, one of the most common of all metal artifacts, underwent enormous changes during the nineteenth century. During the early 1800s, machine-made cut nails challenged traditional, handmade wrought iron nails. Water, then steam power was used to increase nail production significantly. In the 1870s, a new nail production based on steel wire began to change the industry dramatically.

2 Montreal's industrial community, the centre of Canadian nail manufacture, benefitted from successive waves of new nailmaking technology. At any time, however, companies using old and new technologies operated in Montreal; large, well-capitalized rolling mill complexes co-existed with small, cut nail factories; and animal-, water- and steam-powered factories competed with each other. The cut nail itself changed remarkably little in the face of dramatic developments in business organization and technical practice. The experience of nail manufacture in Montreal reflects the inexorable pressure of technical progress, but it also illustrates the tenacious ability of older methods to persist in the face of what would appear to be overwhelming pressure to change.

Cut Nails

3 In a society based on wood — as North America was in the nineteenth century — nails were a vital commodity.1 Ever-increasing quantities were needed for the construction of houses, barns, industrial structures, ships, even railway bridges and passenger cars. In early days, nails were imported from Europe or were tediously cut from nail rod, then headed by local blacksmiths.

4 Montreal's first machine-made nails were produced by Joseph Bigelow (1767-1827), a blacksmith who arrived from the United States in the 1790s. He initially used a horse-powered machine to cut nails diagonally from a hoop of iron, later using machines that automatically cut and headed nails.2 Larger nails were cut from nail plate imported from Britain.

5 This was the beginning of an important Montreal industry. The city, at a major break in communication along the St Lawrence-Great Lakes waterway, was ideally located to both import manufactured goods from abroad and turn semi-finished materials into finished goods. Both these methods were used by Montreal wholesale hardware merchants, many of whom were Americans.3 In 1808, for example, Ezekiel Cutter arrived in Montreal from the U.S. to manufacture nails for George Piatt, an early hardware merchant. In the 1820s, Cutter and Thomas Whittemore were making nails and wool cards for Thomas Busby Wragg.4 Wragg was unusual in that he managed to remain independent of merchant control. Another nail manufacturer of the period, George Stacy, worked for Robert Unwin Harwood.5

6 A persistent problem facing nail manufacturers was the need for increasing amounts of power for their machines. One of the early stationary steam engines in Montreal was built by Bennet & Henderson for T. B. Wragg in 1831.6 This use of steampower was an exception, however: as late as 1839, T. D. Bigelow (d. 1863) was using horses to drive five nail machines.7 Most nailers were forced to seek water power sites around the Island of Montreal. Thomas Peck and T. D. Bigelow, for instance, made nails on the northern side of the island at Sault-au-Récollet, while John Mansfield Holland made them at the Lower Lachine Rapids on the south side.8

7 A byproduct of the reconstruction of the Lachine Canal across the Island of Montreal in the 1840s was the provision of water power for manufacturing purposes at three sites. Two of them, Canal Basin No. 2 and the Saint-Gabriel Locks, were actually within the limits of the City of Montreal. This was enough to attract nail manufacturers back to the city from the fringes of the island. In 1847, Thomas Peck (1808-1874) opened a nail mill on Canal Basin No. 2. When the basin extension was completed in 1851, lots were leased to Thomas Bigelow and to Mansfield Holland and his partner Patrick Dunn (b. 1820). Dunn and his brother Joseph (b. 1826) left for the Australian Gold Rush in 1853. On their return in 1855, they commenced making nails at Côte Saint-Paul — the third hydraulic site on the Lachine Canal — for the wholesale hardware firm of Frothingham & Workman.9 By 1856 there was a flourishing nail industry based on Lachine Canal water power. In all, there were 93 nail and six spike machines, plus three splitting machines at work. Two of the four factories produced 2000 tons of nails a year, plus spikes. The only non-water-powered nail factory was that of T. Wragg, which produced 900 tons a year.10 Another nailmaker to start on the canal was George Stacy who established himself at Saint-Gabriel in the late 1850s.

Rolling Mills

8 Necessity forced the nail industry to be innovative. Uncertainties in the supply and price of nail plate from Britain led to the construction of mills for rolling iron. The rolling mills converted scrap wrought iron into billets and then into nail plate, which could either be sold to other nailmakers or converted into nails by the rolling mills themselves. This was an important step in Canadian secondary iron production.

9 The first rolling mill in Canada was built by Mansfield Holland (1813-1884), a nailmaker from Maine who established himself in Montreal in 1829 and leased a lot on Canal Basin No. 2 in 1851. With the financial backing of Thomas F. Miller, a retired paper maker, Holland had an operating rolling mill by March 1859. Unfortunately, Miller did not find the enterprise profitable and forced Holland out of the partnership in 1860. Holland returned to cutting nails with his son at the Tate dry dock, just a few hundred feet away.11 Also probably in 1859, a second rolling mill was constructed at a cost of $30 000 by Thomas Peck, who had been making nails on the basin since 1847. An 1864 description says that a turbine wheel drove an immense 22-ton balance wheel that transmitted power to the rolling mill itself. Another turbine drove 38 nail machines while a third turbine drove two large spike machines.12

10 The two rolling mills used scrap wrought iron as raw material. When their combined appetites had eaten up all the scrap iron available in central Canada, mills were forced to erect special puddling furnaces that converted pig (cast) iron into wrought iron, which could then be rolled into nail plate. The two enterprises imported an average of 4000 tons (3628 tonnes) of nail plate a year up to 1859. In 1860 they produced 2000 tons (1814 tonnes) of nail plate from scrap iron, and by 1862 they produced 3000 tons (2721 tonnes) of nail plate from imported pig iron.13 When the tariff on wrought iron was removed in the 1860s, however, the rolling mills went back to imported wrought iron.14

Steam Power

11 After the ouster from his rolling mill, Mansfield Holland did not stay with simple nailcutting for long. In 1864 he was asked to build another rolling mill15 by the wholesale hardware firm of Morland, Watson & Co., which, like the older firm of Frothingham & Workman, had started to produce its own goods such as circular saws and axes. Holland's second rolling mill was built on the Lachine Canal, but since no water power was available, it employed steam power. Although stationary steam engines had existed in Montreal since 1811, their adoption for manufacturing purposes had been quite slow. The Morland Watson rolling mill was a large steam-powered manufacturing complex that also included an independently operated nail factory and lead works.16

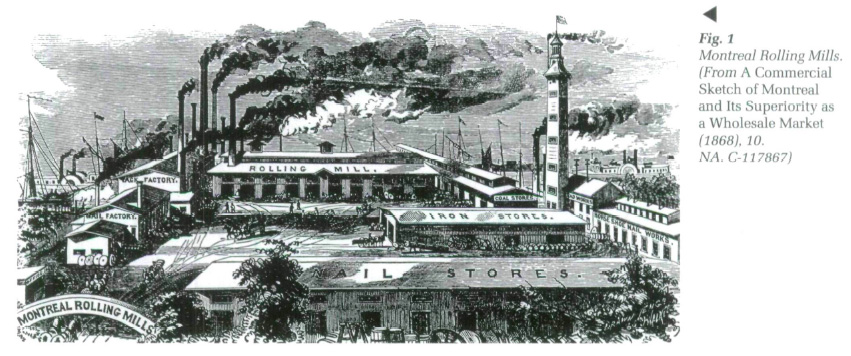

Display large image of Figure 1

Display large image of Figure 112 In 1868, a limited liability company, Montreal Rolling Mills Co., was formed to attract more capital, so as to gain control of the independent producers on their property and increase their output. Holland and the other independent producers were forced out. Montreal Rolling Mills attracted some of the most prominent businessmen in Montreal, including Andrew Allan, William Molson and Peter Redpath. Its $200 000 in capital was used to purchase the latest American labour-saving technology and the best brands of British iron in order to "bid defiance to all foreign competition." Montreal Rolling Mills had 100 nail machines plus 10 horseshoe nail machines in 1868: their combined output was 200 kegs of nails a day (Fig. I).17

13 Another rolling mill company also felt the attraction of steam power. Bigelow, Hersey & Co. had developed in 1868 as a partnership between Randolph Hersey (1829-1918), a nephew of Mansfield Holland and foreman of the Bigelow nail works, and John Pillow (1840-1902), a son-in-law to Theodore Bigelow (1832-1867). After Bigelow's death, Hersey and Pillow took over the Bigelow property and, later, the neighbouring Miller-Holland rolling mill. When fire partially destroyed the Pillow Hersey rolling mill on the Basin, they had an opportunity to change in order to meet the rolling mill's increasing power needs. By 1870 in the U.S., for example, 90 per cent of rolling mills used steam rather than water power, not surprising considering that the average power per waterwheel in American rolling mills was 67.37 horsepower while steam engines each delivered 101.07 horsepower in 1880. Hersey and Pillow decided to purchase 150 000 square feet (13 935 sq. metres) of land between the Basin and the Saint-Gabriel Locks along the Lachine Canal to build a steam-driven rolling mill. Nailmaking was moved to this site, leaving a nut-and-bolt works plus small hardware manufacturing at the Canal Basin.18

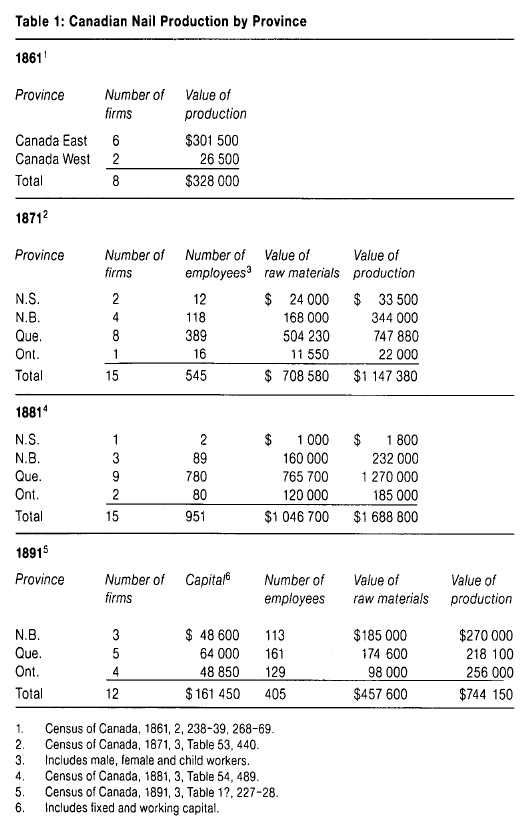

14 The advent of steam-powered rolling mills created a situation that lasted until the end of the century. At the upper end of the spectrum were two companies, Montreal Rolling Mills and Pillow, Hersey & Co. (which became the Pillow Hersey Manufacturing Co. in 1888),19 both large, steam-powered rolling mill complexes with extensive product lines including numerous types of cut nails, tacks, nails for horseshoes and hardware. They controlled a large portion of the market and, because of their large capital base, were able to ride out economic storms.

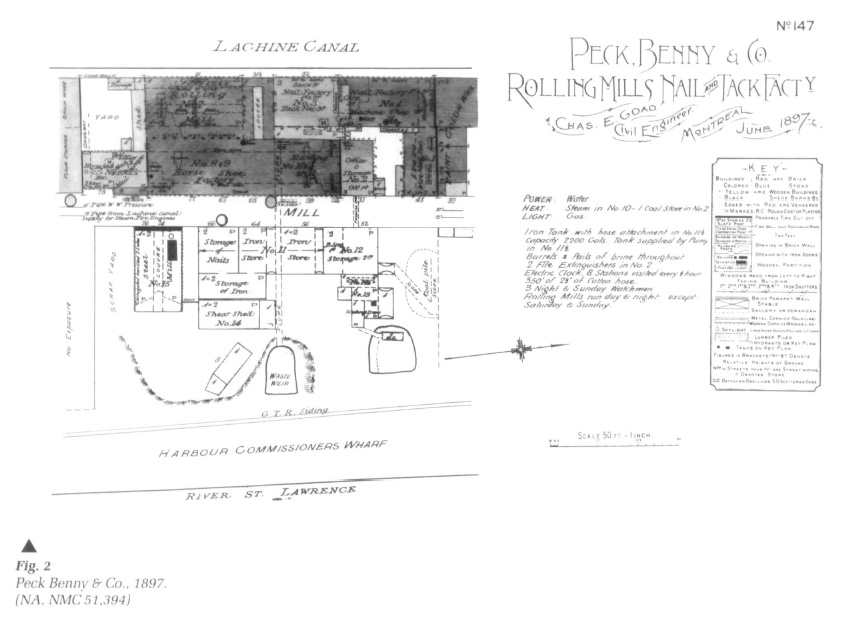

15 Alone in the middle was Thomas Peck & Co. (which became Peck Benny & Co. in 1870), which had a rolling mill but was water-powered. When a Royal Commission looked into the leasing of water power on the Lachine Canal in 1887, the company claimed to be the last water-powered rolling mill in North America (Fig. 2). Steam power could easily have been produced by putting boilers on top of their heating furnaces as Pillow Hersey had done,20 but the company only paid $1750 a year for water power. Converting to steam would have meant boilers, additional coal, engineers, firemen and annual repairs. It is possible that a steam-powered rolling mill was added when the company was restructured as the Peck Rolling Mills Ltd in 1903.21

16 At the bottom of the scale were the small, dependent nail producers. In 1871 they consisted of Patrick and Joseph Dunn at Côte Saint-Paul who produced nails for the hardware firm of Frothingham & Workman. At Saint-Gabriel, George Stacy Jr. produced for the firm of Mulholland & Baker. In addition to the rolling mills on the Canal Basin, there were two other small nail producers: Tate & Hodgson and Montreal Horse Nail Co.22 In almost all cases, a hardware firm either owned the nail factory directly or supplied the nail plate and took back nails, allowing only a set profit for the manufacturer. This was a putting-out system on an industrial scale in which nailmakers had little, if any, say in what happened. More serious still was the lack of capital with which to expand or upgrade production.

17 A number of factories such as these along the Lachine Canal did not participate in technological change, but preferred to continue to use their existing facilities to manufacture the same products. For a company with established costs, equipment and markets, there was little incentive to diversify or expand. The term "hydraulic conservatism" has been employed to describe the factories along the Lachine Canal that preferred the status quo to change.23

Wire Nails

18 The dominance of cut nails was threatened by a new nail technology based on steel wire which originated in Europe in the early nineteenth century. Because wire from a reel could easily be cut and then deformed to produce a nail, this posed a serious threat to cut nail companies with expensive rolling mills and cumbersome machines. The main manufacturing problem with wire nails lay with the supply of wire. In the United States, the first wire nails were produced in the 1850s, mainly for cigar boxes and other small chests where wood splintering was a problem.24

19 Wire nails began to displace cut ones only with difficulty, and wire nail production did not start to climb until the 1880s. Resistance to using wire nails was partially resolved by a series of scientific tests that demonstrated that their holding power was almost equal to that of cut nails. Their ease of manufacture, and consequent lower price, helped them supplant cut nails. In the United States, the production of cut nails fell from 8 million kegs in 1886, to 5.5 million kegs in 1890, to only 1.5 million kegs in 1900, while the production of wire nails increased from 0.5 million kegs in 1886, to 3 million four years later, to 7.25 million kegs in 1900. By 1913 wire nail production was at 13 million kegs a year while that of cut nails was less than one million.25 No Canadian nail production figures have yet been found.

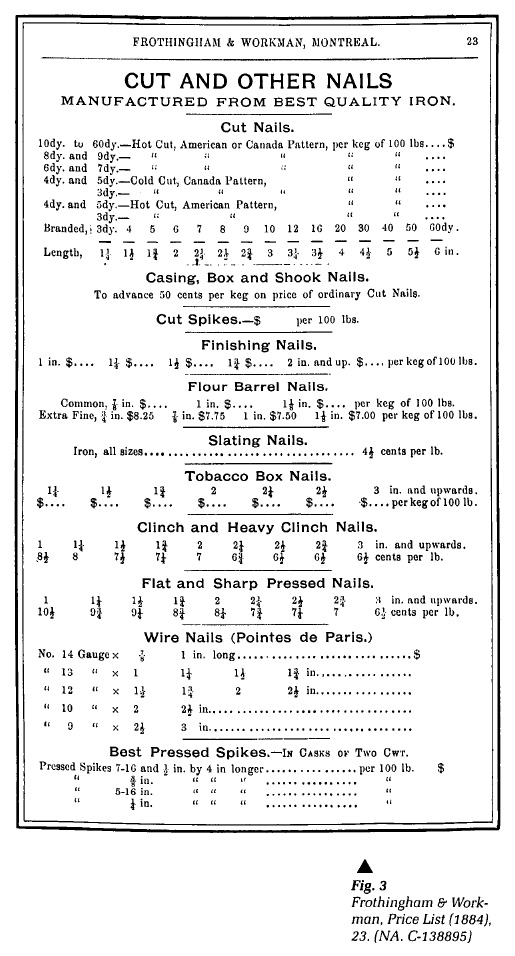

20 The introduction of wire nails is hard to date in the Canadian context. According to a notice in the Canadian Engineer of 1901, Pillow Hersey made their first wire nails in 1870, which makes them a very early manufacturer in North America and the first in Canada.26 Unfortunately, there is no other information available on this development. A Frothingham & Workman catalogue of 1884, which carried cut nails made at Côte Saint-Paul, mentions wire nails, calling them "Pointes de Paris" (Fig. 3). Montreal Rolling Mills installed wire nail equipment in the mid 1880s, and a mill was built in 1892 to provide wire for nails. Peck Rolling Mills was producing wire nails by 1905.27 The modern wire industry in Montreal started with the hardware wholesalers Cooper, Fairman & Co., who commenced manufacturing barb wire in 1878. By 1885 the company had become the Dominion Wire Manufacturing Co. Ltd with a large factory at Lachine, Quebec, producing many varieties of wire as well as wire nails, wood screws and other wire products.28

21 The companies that made the transition to wire nails are the same as those that adopted steam-powered rolling mills. These companies had large capital bases and integrated product lines that made the transition fairly easy. Peck Benny, a company with fewer financial resources, made the switch only later, while dependent cut nail producers never did.29 Because of their status, it is difficult to find information on these firms, but data gathered in 1882 by Robert C. Douglas for a study of water power generated along Canadian canals indicates that dependent nail factories contained over 100 nail machines and employed 180 people.30 The last comprehensive survey of these manufacturers comes from evidence presented to the Royal Commission on the leasing of water power on the Lachine Canal in 1886-1887. Joseph Dunn had a nail factory at Côte Saint-Paul and managed a shovel factory, both owned by the Frothingham Estate, which had title to all the land, the water power privilege, power transmission system, building and, in some cases, the machinery. Dunn paid $1000 a year for his factory while his brother Patrick, who had a much smaller shop making wire tracks, wire staples and, apparently, nail machinery, paid only $490 a year. The Frothingham Estate's primary interest was in receiving a four per cent return on its Côte Saint-Paul investment.31

22 At Saint-Gabriel Locks, George Stacy had an independent business that had been bankrupted by the failure of his major supplier/purchaser, Mulholland & Baker. When his business was picked up by another wholesale hardware firm, Crathern & Caverhill, Stacy paid $1700 a year for the land, waterpower and buildings, plus a portion of the taxes and insurance. His profit came from a percentage set by Crathern & Caverhill on nailcutting. Whereas Stacy had once had 54 nail machines, under the new arrangement he worked 35 machines with the help of 45 employees, producing between $100 000 and $125 000 worth of nails a year.32 The only nailmaker on the Canal Basin was W. M. Mooney & Co.'s Canada Horse Nail Co. It produced horse nails, a specialized form of cut nail for horse shoeing rather than construction. Mooney's shop was on the dry dock leased by G. H. and W. W. Tate; he paid $2000 a year for the use of a turbine, buildings and some machinery.33

23 According to Kilbourn, nailmaking went through a long period of declining profits in the later nineteenth century. From high profits in 1870, for example, Pillow Hersey's profits declined to 20 per cent later in the decade, and fell to 15 per cent in the 1880s. By the 1890s the company was showing small losses. The story was similar for Montreal Rolling Mills, which enjoyed high profits until the economic crisis of 1873. In spite of strong growth in sales between 1869 and 1893, profits remained stationary at about $46 000.34 This was partly due to the fall in the price of iron products, which saw a keg of nails decrease from $5.46 in 1872 to $1.08 in 1894.35

24 Interest in the development of cut nails remained strong even after the advent of wire ones. According to patent records, Montreal nailmakers were quite an innovative group: Mansfield Holland's spike machine of 1844; George Stacy's cut nail patents in 1853, two in 1871, and others in 1873 and 1879; Randolph Hersey in 1882,1886 and 1890. Other patents were taken out by Patrick Dunn in 1856, and by Ferrier, Mooney & Willis in 1870.36 Many of the later patents related to nail plate feeders for speeding up or automating nail production. The first Canadian patent for wire nails was not taken out until 1886. The number of patents for cut nails remained large until about 1898 when wire nail ones took over completely.37 Though nail patents do not prove technological advance by themselves, they do indicate a strong interest in technical development by Montreal nailmakers.

Competition From Outside

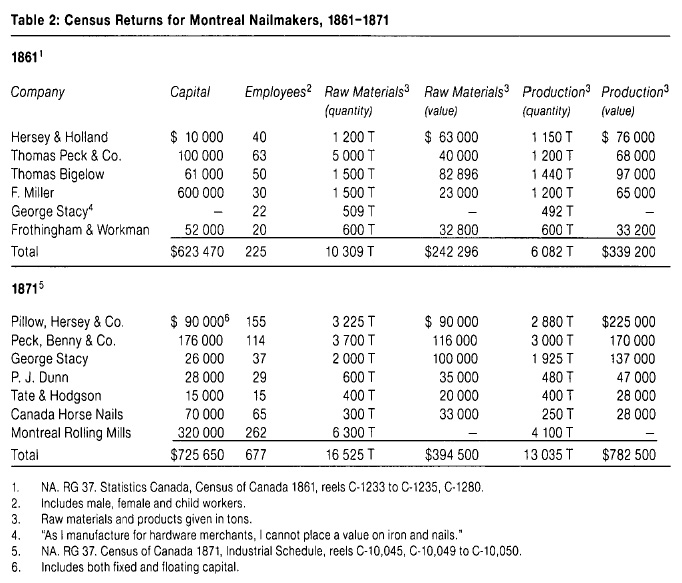

25 Montreal experienced competition in nailmaking from other Canadian cities. In 1871 their main rival was St. John, N.B., with some competition from Ontario; 20 years later New Brunswick and Ontario were both producing slightly more nails than Montreal, which accounted for most of Quebec's production (Table 1). The number of workers in Montreal nail factories fell from 780 in 1881 to 161 in 1891 and revenues fell from $1.27 million to a mere $218 000. Part of this decline can probably be attributed to a change in census classification from nailmaking to rolling mills (Table 2). The number of rolling mill employees in Montreal rose dramatically from 375 in 1881 to 1156 ten years later, while the value of the product more than tripled to $1.82 million.38 A very close relationship existed between rolling mills and nail manufacturing in Montreal that did not necessarily exist in other centres.

26 Competition from foreign nails was also a problem and made it necessary to introduce tariffs to protect Canadian manufacturers. As a result of the National Policy of 1879, the tariff on imported nails was set at 30 per cent.39 Even at this level, the tariff acted more as a protective wall than a stimulus to domestic production.40 No new nail factories appeared in Montreal, although the National Policy undoubtedly stimulated other industries which required nails. Ten years later, tariff protection was critical for the survival of the Canadian industry.

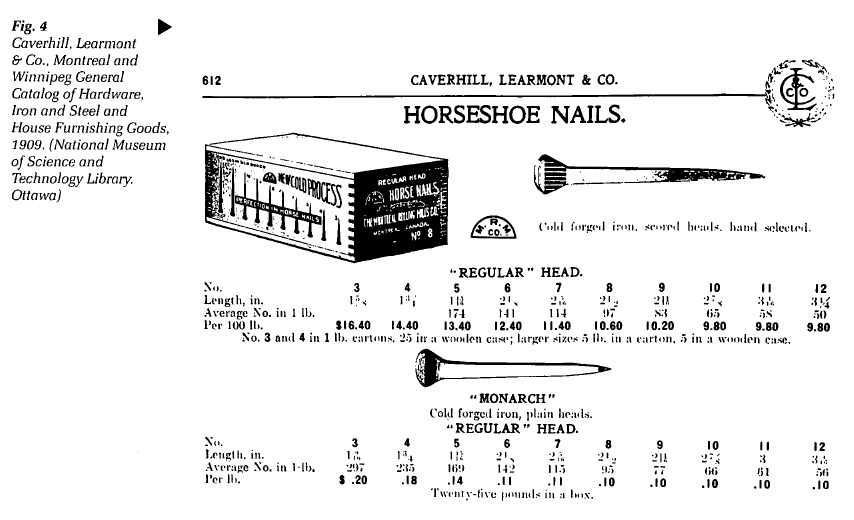

It is difficult to determine what eventually happened to Montreal's cut nail manufacturers. Although they continued operating much as before, these companies were into a slow decline by the end of the 1800s. Joseph Dunn remained manager of the Saint-Paul Works of the Frothingham Estate until age 82, in 1908, and his brother Patrick was a manufacturer until 1902. George Stacy's enterprise was listed in Montreal directories until 1892.42 The Canada Horse Nail Co. was controlled by W. M. Mooney & Co. until about 1892 when it was taken over by James Ferrier, son of the famous Montreal hardware merchant. In 1901, the company was incorporated with a capital of $100 000. John Torrance, of the well known shipping family, was president and William Smaill, an experienced employee in the hardware business, was secretary-treasurer. Their horseshoe nails had an excellent reputation and were known from coast to coast.43 It has not been possible to trace this company beyond 1908.

Display large image of Figure 4

Display large image of Figure 427 After the death of John Pillow in 1902, Randolph Hersey sold the Pillow Hersey Manufacturing Co. to its arch rival, the Montreal Rolling Mills for $500 000.44 Montreal Rolling Mills itself became part of the Steel Co. of Canada (Stelco) merger in 1910. A new company, Peck Rolling Mills Ltd, took over the assets of Peck Benny & Co. in 1903. Both Stelco and Peck Rolling Mills continued to produce cut and horse nails well into the twentieth century.45

Conclusion

28 The enormous growth in the production of nails in Montreal during the nineteenth century led to a number of important technical developments in manufacturing. One significant transition was from handmade nails to machine-made cut nails, and later to wire nails. These developments led to significant advances in secondary iron production such as rolling mills and puddling furnaces. Ever-growing power requirements forced producers from animal and natural water power to engineered water power on the Lachine Canal and, for the larger rolling mills, to steam power. The search for increasing amounts of power is an overlooked theme in nineteenth-century industrial development.

29 Technical changes in manufacturing were paralleled by changes in business organization. The first nailmakers were independent craftsmen, but by the 1820s some hardware importers were incorporating nailmaking into their organizations. The gradual shift from hardware importation to manufacturing was a noticeable trend in Montreal industrialization. The firms of Frothingham & Workman, Morland Watson & Co. and Crathern & Caverhill all played important roles in the development of Montreal's nail industry. In fact, Morland & Watson's rolling mill of 1864 became one of the major constituents of Stelco in 1910. A number of nailmakers managed to remain independent of merchant control. For example, Pillow Hersey & Co. and Peck Benny & Co. remained independent, although they themselves eventually became joint stock companies.

30 The differences in capital accumulation and technological requirements caused a dichotomy to develop in Montreal nailmaking. On the one hand there were large rolling mill corporations with extensive product lines that included nails. Of these, Montreal Rolling Mills was a deliberate outgrowth of Morland Watson & Co., while the Pillow Hersey Manufacturing Co. resulted from the slow accumulation of profits and facilities from Pillow Hersey & Co. On the other hand were companies controlled by hardware wholesalers such as the Dunn brothers, G. Stacy and, to a certain extent, the Canada Horse Nail Co. Between the two poles was Peck Benny & Co., which developed a rolling mill very early but did not convert to steam power until much later.

31 The question of why dependent nail producers did not switch to wire nails is difficult to answer without direct evidence. The major factor was certainly the ownership of the smaller nail factories by hardware wholesalers: as clients of these firms, manufacturers had little independence or capital. More serious still was the Frothingham Estate's reluctance to make additional investments in their Côte Saint-Paul property. Another factor was the link of the means of production - including the power source, machinery and workforce - to cut nail production. The age of the operators of these shops, such as the Dunns who were old men by the 1890s, probably also contributed by making them more resistant to change.

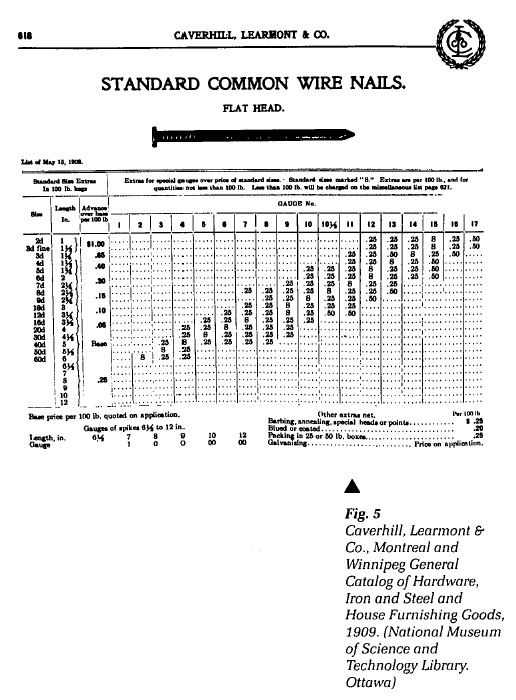

Display large image of Figure 5

Display large image of Figure 532 Montreal's nail industry is an example of the coexistence of parallel products and manufacturing systems. Cut nails did not die out completely with the advent of wire nails. The reputation of cut nails had developed over 75 years and had they become the standard in construction and engineering. These advantages were not easily overcome: some builders undoubtedly preferred cut nails, as the continuing demand for cut nails into the 1920s well demonstrates. However, large integrated rolling mills produced these rather than small specialized shops.

33 By the end of the nineteenth century, Montreal's share of Canadian nail production was declining. Other centres, especially those in southern Ontario, were seriously beginning to rival Montreal. This decline is probably part of the larger trend faced by Montreal merchants and manufacturers who imported British materials for redistribution or for use in manufacturing their own products. As American prices and transportation costs fell, Canadian cities closer to U.S. centres of production had greater cost advantages. Places such as Hamilton were therefore able to compete effectively with Montreal. Thus the locus of metal working in Canada began to shift to Ontario, as demonstrated in the formation of Stelco in 1910, headquartered in Hamilton.

34 Montreal's experience well demonstrates how certain products and techniques can persist in the face of more advanced methods. The nail industry in the city grew enormously during the nineteenth century. From small artisanal shops it grew to encompass large steam-driven rolling mill complexes, which became part of Canada's modern steel industry. At the same time, small nailmakers stayed with older products and manufacturing techniques that lasted into the twentieth century.