Industrialization and Production / Industrialisation et production

From Craft to Industry:

Textile Production in the United States

Abstract

As one of the great forces behind the rapid social, economic and technological changes of the nineteenth century, the textile industry has held a significant and often-analyzed place in American history. Aware of the broad-based impact of the mechanization of textile production, local historians and entrepreneurs recorded technological and organizational developments of textile industries. In particular, cotton textile manufacturing received comprehensive study in the areas of business, labour and economic history. Despite the focus on textile production, the depths of historical enquiry into pre-industrial and industrial production has by no means been plumbed. This brief review summarizes some recent research in the areas of pre-industrial textile manufacture, outwork production and technological innovation, while suggesting issues of supplementary interest. The essay is not offered as exhaustive evaluation of past and present scholarship but rather as an opportunity to highlight questions which might broaden the scope of enquiry to include flax, wool, silk and synthetic manufacture and to encompass the mechanization of fibre preparing as well as fabric-producing trades. It might also encourage renewed interest in a field of enquiry that has received a great deal of attention over time.

Résumé

Parce qu'elle a été l'une des grandes forces derrière les changements sociaux, économiques et technologiques au XIXe siècle, l'industrie textile a occupé une grande place dans l'histoire des États-Unis, qui a souvent été analysée. Conscients des vastes répercussions de la mécanisation de la production des textiles, les historiens et entrepreneurs locaux ont noté les développements technologiques et organisationnels des industries textiles. L'industrie du coton, surtout, a fait l'objet d'études détaillées en histoire des entreprises, en histoire du travail et en économie. Malgré toute l'attention qui a été accordée à la pro-duction des textiles, on a à peine effleuré les possibilités d'étude de la production pré-industrielle et industrielle. Cette brève revue résume quelques recherches récentes dans les domaines de la fabrication pré-industrielle des textiles, de la production à l'extérieur des fabriques et de l'innovation technique, et propose d'autres avenues de recherche intéressantes. Cet exposé ne se veut pas une évaluation exhaustive des savantes recherches anciennes et actuelles, mais plutôt une occasion de faire valoir des questions qui pourraient élargir la portée de l'enquête afin d'inclure la fabrication du lin, de la laine, de la soie et des textiles synthétiques, et de rendre compte de la mécanisation de la préparation des fibres et de la production des tissus. Peut-être que cette revue aidera à raviver l'intérêt pour un domaine de recherche qui a reçu beaucoup d'attention au cours des ans.

1 Textile production and industrialization has held a significant and often-analyzed place in United States history for various reasons. The image of the colonial housewife hunched over a hand loom producing utilitarian fabrics for family use is a strong symbol of colonial self-sufficiency. Alexander Hamilton's Report of Manufactures promoted the industrialization of textile production as key to the United States' economic independence during the period of the Early Republic (1790-1840). Hamilton's suggestion, together with the importation of European textile technology and the need to re-shape the United States' foreign trade-dependent economy to one based on the export of domestic manufacturing resulted in cotton textile manufacture becoming one of the first mechanized industries in the United States. Cotton textile manufacture has received comprehensive study in the areas of business, labour and economic history.1 Despite attention focused on cotton textile manufacturing, the depths of historical enquiry into pre-industrial and industrial textile production in the United States has by no means been plumbed. In particular, flax, wool, silk and synthetic textile industries have received very little attention. Although the woolen industry has been studied by a few historians and economists, many of the issues studied for cotton manufacture have not been addressed.2

2 The following brief review summarizes some recent research in the areas of pre-industrial textile manufacture, outwork production and technological innovation while suggesting issues of supplementary interest. However, this essay is not offered as an exhaustive evaluation of past and present research but rather as an opportunity to highlight questions that might broaden the scope of enquiry to include flax, wool, silk and synthetic fabric manufacturing, the mechanization of fibre preparing and fabric finishing processes as well as fabric producing processes. Recognition of alternative themes might encourage renewed interest in a field of enquiry that has received a great deal of attention over time.

3 Pre-industrial or domestic textile manufacture during the colonial period of United States history is often rejected as a theme for study because of British injunctions against commercial fabric manufacture and the generally accepted concept of domestic self-sufficiency. An exceptional awareness of legal injunctions against commercial fabric manufacture in the colonies has contributed to the idea that commercial weavers did not practice their craft profitably prior to the United States' independence. Furthermore, the accepted view is that other than imported fabrics, the self-sufficient farmer and his family produced whatever goods were needed. The perpetuation of the image of the farm wife weaving cloth for domestic consumption arises from the lack of writing or research to document the business organizations and fabric manufacture of commercial hand loom weavers in colonial communities. Historical writers have generally accepted the idea of self-sufficiency from Alice Morse Earle's Homelife in Colonial Days to more recent publications such as Paul E. Rivard's The Home Manufacture of Cloth 1790-1840, Carl Bridenbaugh's The Colonial Craftsman and Julie A. Matthaei's An Economic History of Women in America: Women's Work, the Sexual Division of Labor and the Development of Capitalism. Recently, a few historians have eroded the notion of self-reliance by promoting the idea of co-operative networks. Although the interrelation of "good neighbour" networks responds to self-sufficiency and the rise of a market economy, it does not account for the quantities of textiles represented in the account books of commercial handweavers prior to mechanization or the absence of looms from a substantial percentage of domestic probate records. Numerous weavers' account books from the seventeenth and eighteenth centuries offer us the opportunity to question the concept of the textile self-sufficiency of colonial homelife. In particular, the survival of no fewer than eleven weaving account books for Essex County, Massachusetts, alone provides evidence to study how professional hand loom weavers responded to the local textile demands; what kinds of skills the tradesmen possessed; whether the masters of the craft trained subsequent craftsmen; what importance weaving income held in relation to the craftsmen's total yearly earnings; and a variety of other social, economic and technological questions.3

4 The survival of weaver's account books in manuscript collections provides us with a virtually untapped resource. Previous scholarship has analyzed the personal papers of single individuals rather than a population of weavers. A recent study of Pennsylvanian weavers by Adrienne Hood points the way towards achieving a better understanding of professional hand loom weaving prior to industrialization. Hood viewed fabric production as the by-product of agricultural pursuits such as the raising of sheep for meat or growing flax for seed exportation. The variety of records and accounts studied enabled Hood to make some valuable generalizations about the craft and craftsmen. In light of her work and the availability of research materials, the following paragraphs raise questions which might be answered by subsequent study.4

5 For instance, technological historians have noted that during the seventeenth and eighteenth centuries, as well as later, technologies crossed the Atlantic with emigrants to the New World or as a result of intercontinental communication. "Intercontinental communication" includes the well-documented trips of Francis Cabot Lowell, Zachariah Allen and other Americans who studied textile technology in England. Although transatlantic interaction facilitated technological diffusion, transported technologies often changed because of differing circumstances. For instance, plows and axes were redesigned to suit the needs of colonists in an untamed land. Wood, a precious resource in England, was abundant in the New World as were saw mills to process lumber. Colonists used wood unreservedly in architecture, machinery and for purposes unthought of where wood was scarce. The availability of vast tracts of land led to changes in land tenure and distribution systems from traditions established in England. With numerous examples of technological and cultural changes in transplantation, it would be incorrect to assume that the art of textile making would be unaltered by its transplantation to new surroundings.5

6 How might cloth production have been affected by new surroundings? What elements acted as a catalyst of change to fabric manufacture? The quality, staple and type of fibre available for manufacture may have contributed to changes in textile structure. The fibres used in New England may have differed in quality and staple from those exported to the colonies as fabrics from Britain. Commercial weaving in New England, for instance, relied on short staple wool sheared off local sheep raised primarily for meat or flax raised for seed exportation and hence harvested after the stalks were too mature for proper fibre production. In addition, farmers and their families could not have been masters of all trades. With numerous other vital responsibilities, we can not assume that equal time or expertise was expended in the completion of all tasks. In turn, the condition of warp and weft threads combined with the weaver's skill may have influenced the types and excellence of fabric woven from the materials. The weavers may have had to derive techniques or patterns to suit the specific characteristics of the fibres available to them.

7 In an effort to forge a place for themselves in local weaving, craftsmen may have developed unique patterns of cloths particularly suited to life in the colonies. The artisans may have cultivated a native colonial weaving tradition. Interaction between native American, British, Dutch, French and German weave practices may have resulted in as yet undocumented and unidentified modifications to weave patterns, cloth production and fibre processing. In The Comfortable Arts: Traditional Spinning and Weaving in Canada, Dorothy K. Burnham noted that Canadian textiles produced by transplanted European populations evidenced typically Canadian characteristics and techniques borrowed from other cultural sources. A study of looms, tools, fabrics and patterns used by the weaving profession in the American colonies might indicate adherence to, or divergence from, traditional craft practices.6

8 In addition to the possible changes in fabric patterns or techniques of textile production, the absence of a regulatory organization promoted changes in craft classification already in progress in Britain. The guild system was never re-established in the American colonies. The redefinition of craft was already in progress in England during the eighteenth century and accelerated in new surroundings. That is, the relationships among craft workers were not as sharp as those that had existed among artisans in England during the sixteenth and seventeenth centuries. During the initial emigration to the United States colonies in the seventeenth century, the labels "master," "journeyman," and "apprentice" had survived but their meanings had shifted in response both to the economic needs in the colonies and to the absence of guild oversight there.7

9 The definition and significance of the craft subclasses, master, journeyman, and apprentice, probably differed from colony to colony. In particular the works of David Montgomery, Philip Scranton and Cynthia Shelton suggest that craft regulation and distinctions were perpetuated by benevolent organizations and close-knit communities in the region of Philadelphia. The transference of craft from the Old World to the New and its impact on textile production is one field open for important additional research. Only by understanding changes to the craft prior to industrialization can we suggest the impact industrialization had on the craftsmen.8

10 As a consequence of the absence of guild oversight and the scarcity and expense of labour, weavers and people seeking the services of weavers experienced problems associated with improper training and scarcity of skilled finishing and spinning artisans. As a result, fabric quality and availability of domestic manufactures may have varied.9

11 Economic, social and technological changes that affected craftsmen and craft classification also initiated modifications to the industry as a whole. Mechanized textile manufacture during the late eighteenth and early nineteenth centuries delineated the refocusing of the United States' and particularly New England's economy from trade in foreign commodities toward manufacturing. This process induced changes in the lives and livelihoods of those who participated in the developing industry, those who resided near factories, and those who resisted change. Advancements in spinning, carding, roving and other fibre preparation processes led to the creation of positions for machine operators yet eliminated the market for outwork hand processing. The rise of new job descriptions and the elimination of work for crafts or trades displaced trained workers and provided opportunities for less skilled labour. But more specifically how did these developments affect traditionally-trained and formerly-regulated workers such as immigrant handweavers?

12 Both British and American labour historians have studied the process of adapting to mechanization and to the regularity and discipline of mill employment during the nineteenth century. Works published by Sidney Pollard and E.P. Thompson in the 1960s prompted complementary research into labour's response to factory work in the United States. Textile manufacturers had incorporated hand-operated machinery into workshops well before the end of the eighteenth century. The organization of spinning and weaving establishments in such places as Beverly and Worcester, Massachusetts, and in Hartford, Connecticut and Providence, Rhode Island, altered the workplace to a large extent during the Federal Period (1787-1801) and initiated changes in the regulation of time and labour.10

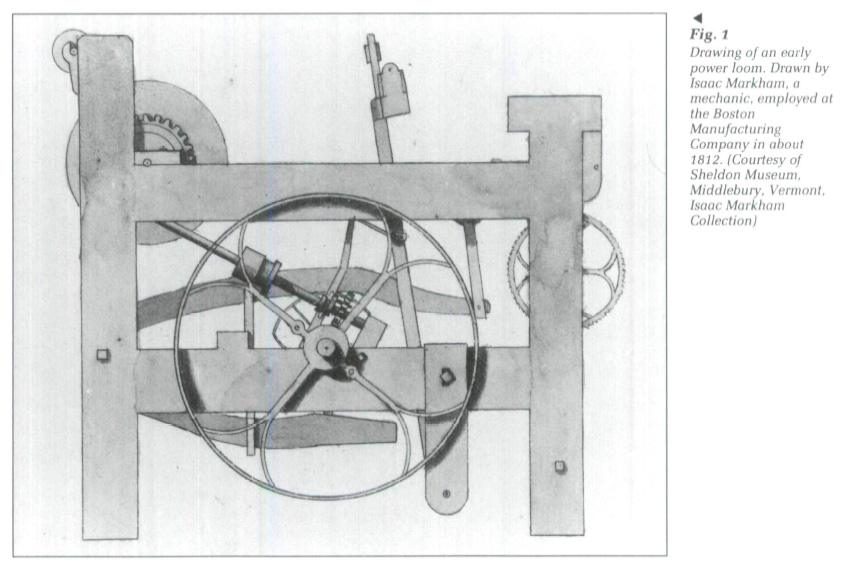

Display large image of Figure 1

Display large image of Figure 113 In an article published in Technology and Culture in 1988, this author describes the response of Rhode Island native and immigrant hand loom weavers to shifts in their work environment and routine.11 The study offers the view that the mechanization of spinning and the consequent rise of weaving workshops owned and managed by entrepreneurs rather than master craftsmen led to changes in associated handicrafts earlier than suggested by studies of nineteenth-century industrialization. Further, it indicates that trained full-time or commercial hand loom artisans responded to attempts to alter their craft classifications and their work habits by avoiding factory or merchant-owned weave shed employment, by shifting from job to job and by investing in independent competitive weaving workshops. More importantly, weavers formerly employed by entrepreneurs opened their own weave sheds, contracted to manufacture fabrics for the mills and wove cloth from machine-spun yarns for sale themselves. The occupational choices made by Providence, Rhode Island, weavers during the late-eighteenth century show that the weavers did not reject the product of machine manufacture, rather the oversight of entrepreneurs. Weavers opted to retain control over time, production and profits, but they willingly used the weft manufactured by hand-operated and later water-powered machinery.12

14 From about 1790 until about 1820, around five years after the development of a successful or marketable power loom, cotton mill-owners produced simple utilitarian fabrics either in mill-owned weave sheds, by contracting with commercial independent weavers, by using cloth agents or by putting out machine-spun warps to part-time handweavers. Between 1810 and 1821, outwork weaving became the predominant method of commercial handwoven fabric manufacture. Outwork networks grew during an era of technological and organizational experimentation in the textile industry. Technological change centred on reproducing British textile machinery and improving textile equipment already in use. Organizational innovation was concentrated on establishing efficient and productive work environments. Textile mill-owners drew on several systems used previously in other circumstances to produce fabric by hand prior to the development of a marketable power loom.

15 A growing body of literature on outwork and outworkers in New England from the late 1820s to the 1890s includes Thomas Dublin's study of palm leaf hat making, Gregory Noble's research on broom making and Mary Blewett's papers on shoemaking. Although none of these works focuses entirely on textile outwork, they analyze the significance of outwork to the life and livelihood of those who participated in the outwork system. These studies place outwork within the context of rural life and family economy during the last three-quarters of the nineteenth century. Textile manufacture was one of the first mechanized industries to incorporate outwork production into its manufacturing procedures. A study of early textile outwork would provide a missing link between outwork before and during industrialization. The era is significant in that it constituted a time of trial and adjustment for a type of labour that provided women, in particular, and young adults with a means of earning supplementary income within acceptable spheres.13

16 The popularity of putting-out and the demand for handweaving by textile mills during this era provided rural families with an important source of supplementary income for over thirty years. Although the putting-out system provided the textile industry with a plentiful and previously untapped labour force, outwork was a mixed blessing. Issuing warps to great numbers of local outworkers directly from the mill or factory store created problems that textile mill-owners found insurmountable.14

17 As early as 1812, mechanics and entrepreneurs in the cotton textile industry of the United States began to look toward mechanized weaving as a way to resolve some of their fabric production problems. The development of the power loom and improvements to it led to the ultimate dissolution of outwork weaving. First, the development of a variety of power loom mechanisms and the commercial success of a handful of them, led to the sharp curtailment of outwork. Some manufacturers limited their production to fabrics that could be produced by power looms to eliminate their need for outwork weavers entirely. As early as 1817, complex looms and improvements to power weaving mechanisms were incorporated into cotton textile mills further reducing the market for hand loom outworkers. The rise of multi-harness mechanisms, the drop box and stop actions all contributed to the shrinking of the market for handwoven fabrics. The innovations themselves contributed toward shaping the market for hand loom weaving.

18 By the mid-nineteenth century accounts of the birth of the cotton textile industry were authored by entrepreneurs. These histories consisted of insights into companies that were founded during the era and biographies of the men who made them. In addition, Nathan Appleton, one of the founders of the Boston Manufacturing Company in Waltham, Massachusetts, and the Rhode Island Society for the Encouragement of Domestic Industry examined technological developments as reminiscences of entrepreneurs and mechanics. These studies offered tales of "who did what first."15

19 In response to this view, historians have more recently taken a broader approach to the subject by examining how mechanization altered the work and work environment, modified business management and led to great changes in the society of the United States. Monographs by Thomas Dublin, Jonathan Prude, Philip Scranton and others have studied changes in work and society as a result of mechanization. However, with the exception of Anthony F.C. Wallace's Rockdale, the authors glossed over the specifics of technological inventions. David Jeremy's Transatlantic Industrial Revolution looks at how technological developments in British textile industry came to the United States and how improvements were shared with Britain. But Jeremy himself does not describe the mechanisms. In addition, the drop box, multi-harness power looms and stop actions are often highlighted as thresholds of change, yet we know very little about any of these technological developments.16

20 Nathan Appleton's Introduction of the Power Loom and the Origin of Lowell, Nourse's "Some Notes on the Development of the Power Loom in Worcester County," Gibb's The Saco-Lowell Shops, and the Transactions of the Rhode Island Society for the Encouragement of Domestic Industry, clarify some technological details of the development of cotton power looms. In addition, Isaac Markham's contemporary machine drawings of the Waltham loom provide us with a tantalizing view of the earliest marketable power loom and other textile mechanisms. Yet, there is no comprehensive study of early power looms or other significant technological developments in the textile industry. We know little about failed efforts and have a very unclear view of the technological successes.17

21 Some technological successes have received recognition. For instance, Nathan Appleton charged that "the success of the power loom in Waltham," in 1816 was "no longer a matter of speculation or opinion. It was a settled fact."18 Since Appleton had invested in the Boston Manufacturing Company in Waltham, his assessment of the situation in Waltham was accurate. With power loom technology generally available in 1820, why did only sixteen per cent of Rhode Island and Massachusetts cotton mills own power looms?19 As late as 1826, cotton textile turns in Pawtucket, Providence, Warwick, Central Falls, Smithfield and in almost every other Rhode Island city and town used hand methods of simple cotton cloth manufacture. Mill-owners continued to put-out warps over broad geographic areas encompassing cloth agents in Richmond, New Hampshire and Stonington, Connecticut.20 The great distances over which Rhode Island cotton textile manufacturers spread their warps suggest that between 1821 and 1829 the demand for hand loom weavers continued to exceed the local labour supply21

22 Several historians including Peter J. Coleman, Gary Kulik, and David J. Jeremy have noted the extensive outwork weaving networks maintained by Rhode Island textile entrepreneurs between 1821 and 1829.22 In each case the author viewed the retention of the putting-out system as anomalous and attempted to determine why outwork networks continued in light of available mechanical advancements. My paper on the subject advances the view that mill-owners relied on hand loom cloth manufacture because for a span of ten years economic and technological conditions made handweaving their only recourse. Rather than view Rhode Island's use of outwork from 1821 to 1829 as anomalous, it would be more appropriate to view the retention of the putting-out system as the most proper and profitable method of cloth production for the circumstances which existed in Rhode Island. By accepting the concept that there might be multiple appropriate and beneficial answers to any industrial, economic or technological problem, Rhode Island textile industry's use of outwork could be examined as one of several alternative solutions to problems faced by the textile industry from 1816 to 1830.

23 Despite the inordinate attention focused on the problem of Rhode Island outwork between 1821 and 1829, there are still some unanswered questions. How generalized was the outwork network in New England during the era? Is it an accident that the two existing cloth agent manuscripts list almost entirely the same Rhode Island firms? How might the information available to us in the accounts of cloth agents Silas Jillson and Russell Wheeler be evaluated in a broader context? How might the diffusion of power loom technology into cotton textile mills be compared to the introduction of mechanized weaving into woolen, linen or silk manufacturing?

24 As suggested earlier, industrialization and production requires additional study despite substantial scholarly interest in the United States' cotton textile industry. We have only begun to understand the basics of pre-industrial production, mechanization, societal changes and the impact of industrialization on labour. For instance, the history of technological developments suffers from a narrow focus. While spinning and weaving innovations have received some scrutiny, carding, slubbing, drawing, picking and the finishing processes are often disregarded. The inventors, inventions and the impact of the technological developments are documented in reminiscences and some personal papers as well as patent records after 1830. Improvements to seminal inventions, such as the drop box, multiple harnesses and automatic cutoff for the power loom are often mentioned in passing but not given the analysis warranted by the importance of the development.

25 More significantly, while we have begun to understand the basics of industrialized cotton textile production, few comparable studies are available for linen, woolen or silk manufacture. Much might be gained from comparative studies. Such concepts as technological diffusion, the impact of American culture on textile patterns, the effects of industrialization on labour and societal changes might benefit from comparative or monographic research. In addition, linen and woolen manufacture are described for the pre-industrial period, but, with a few exceptions, little research has been done on the industrialization of these industries in the United States. The study of cotton textile production is limited to the industrial period, but little heed is paid to the pre-industrial use of cotton particularly in regions where cotton was raised for exportation. Finally, despite the growing significance of synthetics such as nylon, dacron and polyester, few historians have ventured forth to this new frontier of textile production and the new generation of fabrics and machines developed because of new fibre characteristics.