Research Reports / Rapports de recherche

Settling in:

Tools and Farming Techniques of the Early Ukrainian Pioneers

1 The Ukrainian settlers who arrived in western Canada during the last decade of the nineteenth century and before the First World War came with specific objectives in mind: to acquire land—a homestead—and to engage in agriculture. They came prepared to meet the challenges facing them. Their most immediate tasks were to provide shelter for their family and, if they came early enough in the spring, to clear a patch of land for a garden, thus providing food for the family. The tools and utensils they brought helped them adjust to the pioneering condition and succeed in their efforts.

2 Dr. H.J. Hunter, erstwhile missionary physician of Teulon, Manitoba, writes:

3 True, such was the case with young married couples, or young couples who married after they came to Canada. Such was not the case, however, with the majority of experienced husbandmen who disposed of their properties in the Old Country. They knew the demands a new start in farming in the New World would place on them. They came prepared with the necessary tools and utensils, and their wives brought pouches of vegetable seeds and grain to plant. Some women even brought grates to be used over an open fire when cooking meals for the family. Packing cases held larger tools, such as the axe fitted with a helve, and a spade with handle attached, as well as the ever-useful hoe. Hand trunks contained smaller tools: chisels (mostly wood chisels), drills, handsaws, gimlets, gouging chisels, hand planes, a spirit level and a chalk line. They also brought hatchets (the carpenter's hatchet was called a barda) and broadaxes. One type of hatchet with a wood chisel cutting edge had an offset or curved handle to protect the carpenter from damaging his knuckles when chipping off rough spots in the log wall. Some broadaxes also had offset handles.

4 The axe and the saw were indispensable tools for building purposes and survival in the bush. The settlers brought several types of saws to be used in their carpentry and the cutting of wood. Light saws, with holders extending on each end of the blade for adjusting the angle of cutting (much like the ripsaw), were one of these types. The saw was made taut by twisting around the cord (linen cord was used in the Old Country) which pulled the side bars together to tighten the saw blade. When it was taut enough the winding stick was "sprung" around the cross bar. Most saws of this type were made in the same manner. For easier packing the saws were dismantled, and the blades rolled into a coil. The parts of the frame were packed separately. All that was necessary to ready the tool for use was to attach the blade at each end with a pin or nail and tighten the bar rope. For heavier work there was a crosscut saw with ends rounded to form a cylindrical tube into which were fitted detachable wooden handles. The crosscut saw was most handy in the cutting out of spaces in the log walls for windows and doors. (The log frame was built up ceiling high and "cut-ins" were made for these holes before the holes were cut out and frames inserted.) Some settlers also brought a saw like the Canadian bucksaw. The crosscut saw was used in felling trees and cutting them into logs of correct length; if a crosscut saw was not available the bucksaw was used. These saws could really be called European saws and were also widely used by settlers in eastern Canada.

5 The pod auger worked best for drilling holes in dry hardwood. Most houses in the Old Country were built of oak logs; sometimes these were spliced and holes had to be drilled for pegs. In eastern Canada, pod augers worked well for drilling holes in maple wood.

6 The hand trunk of some settlers (particularly the master builders) often included the smaller finishing tools: large and small wood chisels, a gouging chisel and a scraper for hollowing out wood for receptacles, gimlets, compasses, a marking gauge, a wooden square, a spirit level, a plumb line (pijon), a chalk line (shnur), a mitre box, a couple of planes and the ever-useful draw knife.

7 Some also brought cold chisels to make millstones for the quern. They brought the hammer called the molotok. (Claw hammers were not in use as most home furniture was assembled with pegs.) Some nails (like those for shoeing horses) began to come into use; in Canada, the settlers bought nails in stores before going out to the homestead. Four- and three-inch (10- and 8-cm) nails were most useful. With these, settlers could nail together rafters and crossbars for the thatch over the roof.

8 In Ukraine people were used to the metric system of measurement. The settler building a house, however, did not use the metric rule, but relied on the ancient cubit measure (the leekot, or distance from elbow to middle knuckle). Rough measurements were made by stepping off the length. Soon after their arrival, the men acquired the folding two-foot (61-cm) rule and abandoned the metric measure.

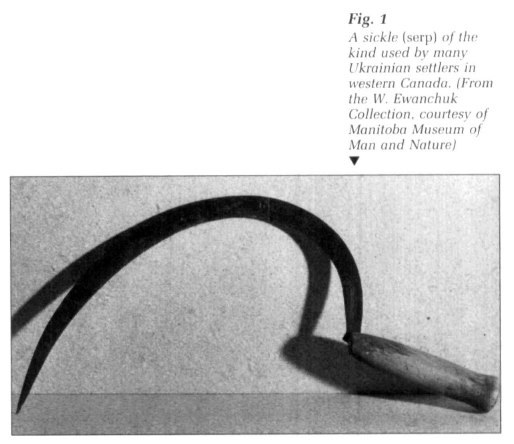

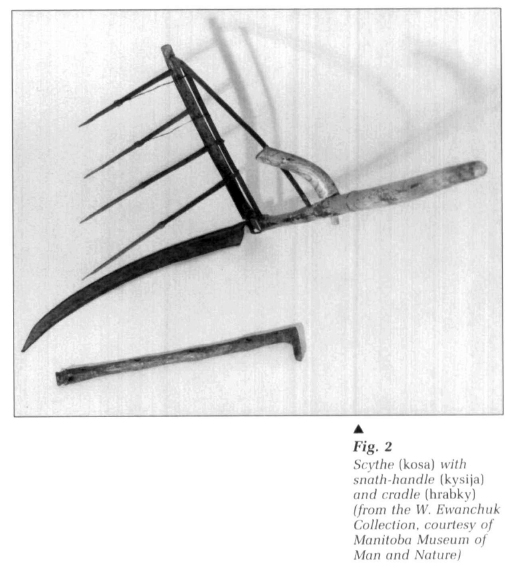

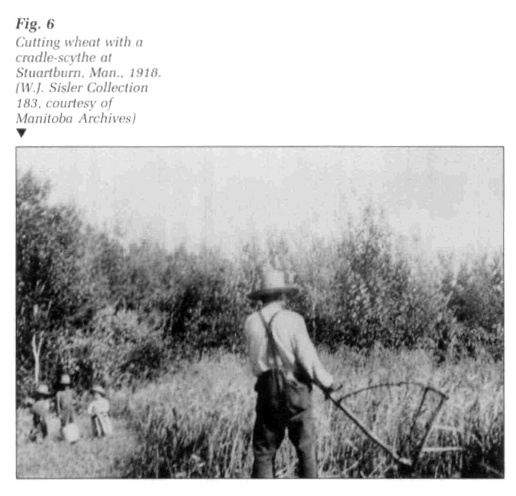

9 Packed among the clothing of Ukrainian pioneer settlers and carefully wrapped were two valuable implements: the sickle with a serrated cutting edge, and the scythe. The scythe was put into use almost immediately in cutting hay for the animals and for family mattresses; the sickle was used for cutting long slough grass and reeds for the thatch of the new home. A cradle assembly was attached to the snath for reaping grain when it ripened. The snath was Canadian-made of light wood, first of dry willow, then seasoned poplar and, later, well-seasoned ash. Straight two- to three-inch (5- to 8-cm) dry spruce saplings were also used for the snath.

10 The serrated sickle did not require sharpening and remained in good cutting condition for a century; a cradle, with good care, also lasted a hundred years.

11 To attach the scythe to the snath a special metal ring was brought from the Old Country. The scythe was then attached with two wooden gluts, one wedge-shaped. The cradle was attached to the snath by a wedge-like glut of the crossbar of the cradle. The crossbar was at right angles to the scythe and had four teeth running parallel to the scythe. The crossbar was secured to the snath with a bow-like attachment.

12 To keep the scythe in good cutting condition it was sharpened with a whetstone, usually carried in a wooden receptacle filled with water. When the cutting edge became dull through contact with stones, it had to be attenuated—pounded-out. For this purpose the settler brought a hammer and small anvil.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

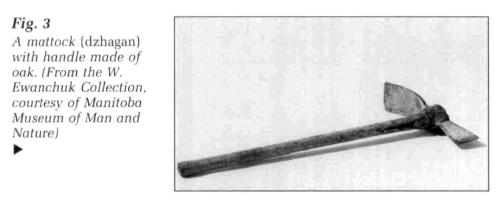

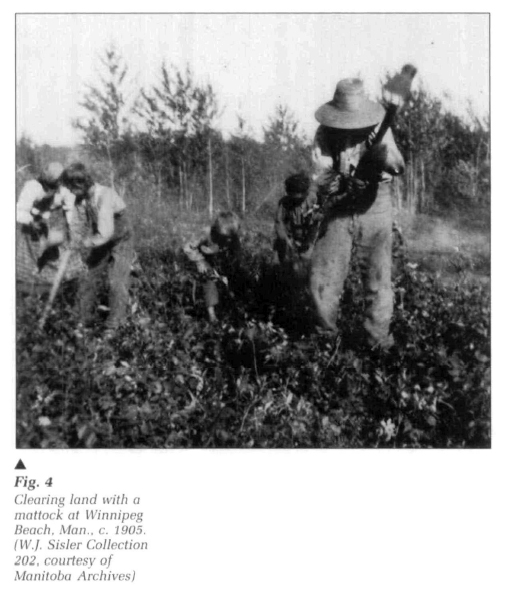

Display large image of Figure 213 The pioneer Ukrainians settling on hush farms applied their skills and folk tools and equipment to get started on the homestead. Once the building of their shelter was under way, the family cleared a patch of land for planting vegetables. And they had the requisite tools for doing that, too. With their axes they were able to cut down trees and brush; then they started to dig with their spades, chopping out roots with mattocks and sod with hoes. At this point a transition was made to the Canadian axe, which was better suited for clearing land; the Old Country axe was demoted to splitting firewood and cordwood. When the sod dried, it was chopped fine with the hoe, the roots were removed, and the plot was raked. The wooden rake had a willow crotch for a handle and a crossbar in which holes were drilled and four-inch (10-cm) pegs (the teeth) were fitted. Many settlers used the Canadian four-inch (10-cm) spike to fit the rake with teeth for rougher work. The light wooden rake with wooden peg teeth was later used for raking hay. The first forks were made of a willow crotch or dry ash. The pioneer farmers soon surveyed the woods on their farms, noting materials they could use for rake handles, forks, axe and hatchet helves, and poles for sleighs and wagons. Farmers cut dry oak or ash into small pieces to make pegs, gluts and wedges.

Display large image of Figure 3

Display large image of Figure 3 Display large image of Figure 4

Display large image of Figure 414 If pioneer farmers had oxen, the first type of equipment they acquired was the plough. These were single-furrow walking ploughs with a metal beam and steel ploughshares and cutters. Such a plough made a furrow of twelve or fourteen inches (31 or 36 cm) in width and was light enough for a yoke of oxen to pull. For breaking land that had many roots, a breaking plough was used. It needed two yokes of oxen unless the soil was light, sandy loam. When the furrows dried enough they were chopped up with spade, mattock and hoe, and then harrowed. The seed was sown by hand (broadcast), and the plot harrowed again.

Haying

15 The first animal the settlers acquired was a cow. It was, therefore, necessary to prepare an ample supply of fodder for winter feeding. Wild hay was plentiful around the sloughs and in the clearings and could be cut with scythe.

16 As the seasons changed, settlers faced new problems: they needed additional implements to do the work. To avoid spending too much money on implements, they made their own handles or helves for the metal parts they brought with them. They needed a bench or apparatus on which to fashion these parts. When boards and planks were difficult to get, farmers split logs and whittled them down to rough planks out of which they made a wooden vise (called the kobylnytsia, "shaving maid"). It was very much like the shaving horse used in shingle tapering in eastern Canada and operated in the same manner. Having this vise, farmers could use the draw knife to make other implements. As the haying season approached they needed not only rakes, but also forks, which they made on the vise out of sturdy willow or dry ash crotches.

17 If the settler had a growing child who could help with the haying, another straight snath was made; to it was attached the light Ukrainian scythe and the child started to train. Haying with this implement called for a rhythmic body movement to cut the green bay and form a windrow. On the other hand, the heavier and longer English scythe attached to the curved snath was operated in a chopping method, and was much harder on the user. Icelandic settlers also used the straight snath, but it had two handles and the end of the snath fitted under the left arm.

18 Once the hay was cut it was left in wind-rows to dry; then it was raked with the wooden rake and piled into haycocks with the wooden fork. Later it was hauled into the yard and stacked.

Harvesting and Threshing

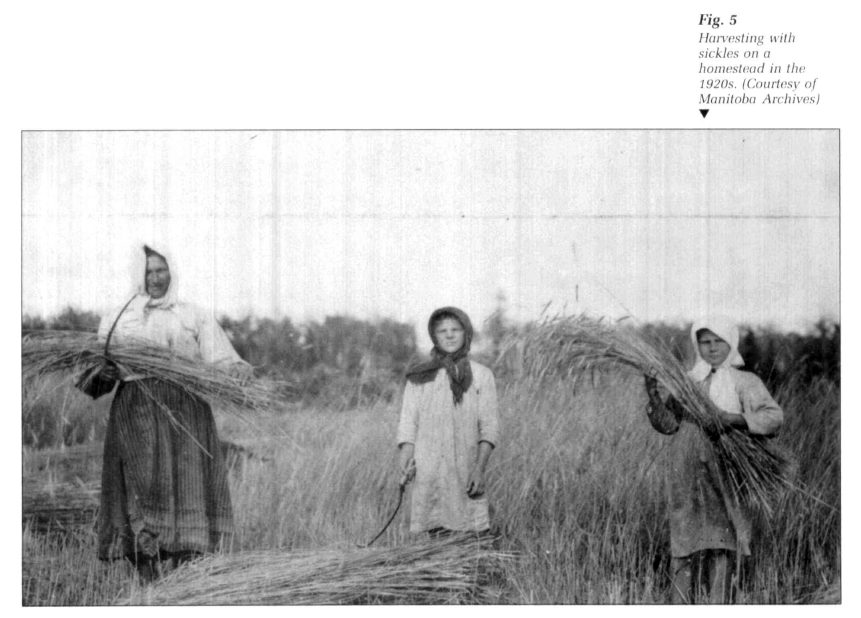

19 The harvest closely followed haying. The small patches of grain were reaped with the sickle or the cradle. The sickle was used to reap the fall rye and wheat, as these stems were long and difficult to cut with the cradle. Barley, oats and buckwheat were reaped with the cradle. I sing the cradle called for considerable skill, as the cut grain had to be laid in straight windrows with the beads falling close together on the far side. When the rye was reaped with the sickle, it was bound with bands of freshly cut grain. The large sheaves were placed into stooks and left to dry. The Ukrainian stook was called the polukipok and consisted of fifteen sheaves. It was built in the form of an X, with the heads upright, and covered by one sheaf. The fifteenth sheaf was placed on top to form a cap (a feminine appellation). This may have been because women did most of the reaping with the sickle in European countries ("alone she cuts and binds the grain"). Four stooks formed a unit of sixty sheaves, called the kopa. (During periods of serfdom peasants reaped grain for the lord of the manor and received the thirteenth sheaf or the thirteenth kopa for the labour done.)

20 Reaping buckwheat called for a special approach. It was reaped with the cradle, usually late in the evening or at night when the dew tell: the buckwheat whim damp tended to shed less. For the same reason, binding was also done at night. Since buckwheat stems are loo friable to make into bands, bands of rye or tall reeds were made earlier and kept damp in readiness.

21 After being hauled into the farmyard, the grain was threshed with the flail. Threshing was usually done when the cold weather set in. If the homesteader did not have a barn suitable for threshing, the ground was cleared of snow and a large patch of ice was made. The sheaves were then pitched close by the bands, cut and spread on the ice with the grain heads placed together; the spread grain was then flailed.

22 The flails the Ukrainian settlers brought from the Old Country or made in Canada were light and flexible. The beater (bijak) was usually made of ash or other harder wood so it would not split while beating the grain on the hard surface. The Ukrainian flail operated on the same principle as the Ontarian flail; however, where the English flail had the beater joined to the handle with metal ring, the Ukrainians joined theirs with soft rawhide. A leather cap was drawn over the head of the handle and the handle notched. At that point the leather thong was filled into the groove, retaining the strap in place. The handle, then, could rotate freely. The English flail rotated on a swivel.

23 Two people could flail the grain together after establishing a suitable rhythm. Young "flailers" got into difficulties at times: by breaking the rhythm they were hit over the head with the beater, and sometimes with the handle head. Getting hit with a Ukrainian flail head wasn't as bad as being struck with the handle head of the English flail, which had a metal ring.

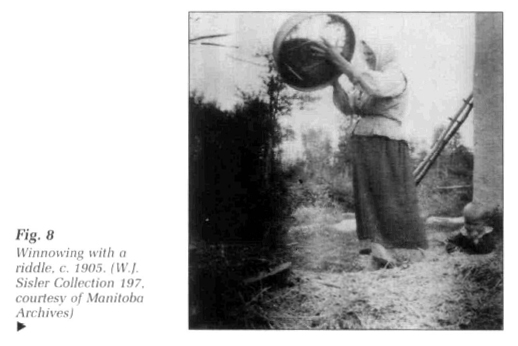

24 Alter a considerable number of sheaves were flailed, the straw was raked away and the grain and chaff shovelled into a pile or bagged ready for winnowing. Small amounts of grain could be winnowed in the wind, but larger amounts required a different approach. This other approach was only possible after the settlers had large barns without ceilings and open to the rafters. This type of barn (stodolo) made it possible to do the threshing and winnowing inside.

Display large image of Figure 5

Display large image of Figure 5 Display large image of Figure 6

Display large image of Figure 6 Display large image of Figure 7

Display large image of Figure 7 Display large image of Figure 8

Display large image of Figure 8Winnowing

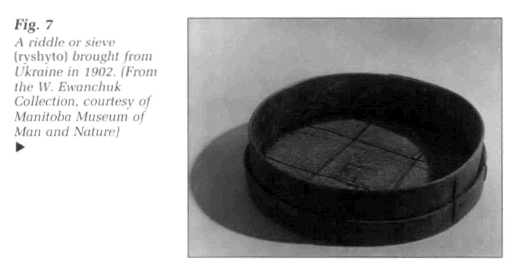

25 The pioneers brought to Canada two receptacles for cleaning grain: the riddle (a large sieve with a wider wire mesh) and a wooden trough (netsky). Both, in time of need, served a dual purpose: the riddle could cover a clucking hen to train it to remain in the nest and hatch the eggs. The wooden trough was used during the trip across the ocean to bathe a baby. Those with round bottoms could also serve as temporary cradles. Flat-bottom wooden troughs were used for kneading dough.

26 When cleaning a larger amount of grain in the barn, the farmer sat beside a pile and, with a wooden shovel akin to the dustpan, threw shovelfuls of grain and chaff in a broadcasting manner toward the far wall. The heavy grain travelled the farthest away, the chaff fell nearby and the lighter kernels and weed seeds fell in the middle. The good grain was swept together with a broom of burning bush stems and bagged ready for seeding in the spring or for being milled at the mill or on the quern. The other grain was collected for chicken feed and the chaff for feeding the hogs. In Canada, this was the Ukrainian way of separating the wheat from the chaff.

The Quern

27 The early Ukrainian pioneers often settled far from any flour mill; therefore, they had to depend on their knowledge and skills to process the harvests from their small fields and gardens. Many made querns of their own to grind their grain into coarse flour or meal. These querns were made of stone slabs found nearby.

28 The quern or hand mill was made of two rounded stone slabs on a wooden base. The upper stone (up to eighteen inches [46 cm] in diameter), encased in a loose frame, had a hole about three inches (8 cm) in diameter at the centre. Handfuls of grain were deposited in this hole while the upper stone was rotated by a short handle; the handle had a metal point inserted in a small hole in the stone. The lower stone was a little smaller in diameter and was tightly encased in a frame, permitting it to move up or down but not to rotate like the upper stone. In the centre of the flat wooden base was a hole, through which a spindle projected to adjust the pressure of the quern. The spindle was raised or lowered by a wedge to increase or decrease the space between the two stones. When the space was small, finer milling was produced; when the space was increased, the milling was coarse. Very large space was made for husking buckwheat and pearling barley. (Before these grains could be husked, they were dried in the outdoor oven, the pich.) As the upper stone rotated, the milling or the husked grain came out through a spout in the upper stone's frame. Flour or meal was then sifted. Husked grain was winnowed with a wooden trough. Winnowing was done by tossing the contents of the trough in a rotary motion: the lighter husks were thus tossed out and the kernels remained. In some cases, farmers cleaned the kernels further by using the riddle.

29 The quern is generally considered a primitive implement, but it served the settlers in this century well. It allowed them to utilize the fruits of their toil and provide a better diet for the pioneer family.

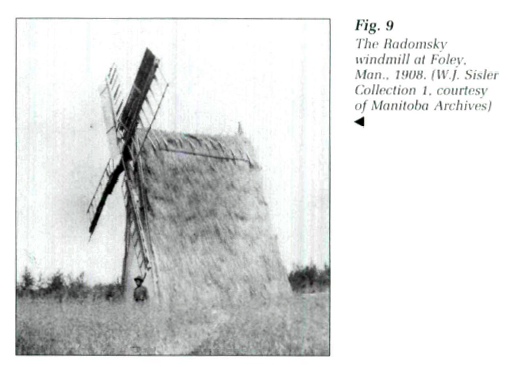

30 Not all settlers were able to make a quern; as the number of settlers increased, so did the demand for meal, which made a favoured nutritious bread, razoway khlib. To satisfy the demand for coarse rye flour, some Old Country millers built windmills replicating those of Ukraine. Two such windmills were in operation in the Manitoba Interlake region: one at Foley, northwest of Winnipeg Beach, and the other at Meleb, about twelve miles (19 km) northwest of Gimli.

31 The mill at Foley was built by Toma Radomsky. It had a roof of thatch. A pole was used to move the sails of the mill to face the wind. Since the whole structure had to be rotated on its base, a yoke of oxen did the work.

32 John Hykaway built the mill at Meleb. The millstones were chipped out of large stones found in his field. The gears were carved out of local spruce, and the sails were boards of local wood. The gears of this mill were not greased, and during operation the groan of the gears and the rumble of the millstone could he heard a mile away. Often the hopper was tilled in the evening, and the mill operated throughout the night. By morning the grain was ground. The mill remained on its original base and location until the 1970s, but the appearance of many good power mills in nearby villages had put it into disuse. A new owner sold the mill to a Ukrainian historical group at Winnipeg Beach. Unfortunately, it was "modernized" and made to look like a Dutch windmill.

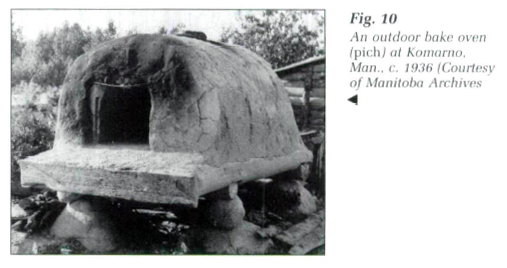

33 Bread was often baked in an outdoor oven (pich). In most cases the settler had the oven built even before finishing building the house. Some built indoor ovens. Two implements were used with the bake oven. One was the peel (lopata) for inserting the pans into the oven. The other was a type of rake for scraping ashes and coals out of the oven before the pans of bread could be placed in it to bake; it was called the kotsuba.

Display large image of Figure 9

Display large image of Figure 9 Display large image of Figure 10

Display large image of Figure 1034 The folk tools and utensils the Ukrainian settlers brought with them to Canada, and the knowledge of how to replicate some of the Old Country tools and equipment, were critical in the life of the early Ukrainian community. Without these, few of the settlers would have succeeded as farmers in the new Canadian environment.