Articles

Ukrainian Peel Ovens in Western Canada

Peel ovens played an important role in the lifestyle of Ukrainians in western Canada for several decades. Traditional features, methods and techniques were transplanted from the old country and adapted to new conditions on the Prairies. By the 1960s, both indoor and outdoor versions of the Ukrainian pich, or peel oven, had largely fallen out of use. Recent, renewed interest in the pich continues to grow and innovative elements are introduced to take advantage of the availability of newer, non-traditional materials.

Résumé

Pendant plusieurs décennies, les fours à sole fixe avaient beaucoup d'importance dans la vie des Ukrainiens de l'ouest du Canada. Les caractéristiques, les méthodes et les techniques traditionnelles liées à ces fours ont été adaptées aux nouvelles conditions de vie dans les Prairies. Vers les années 1960, les modèles intérieurs et extérieurs du four ukrainien à sole fixe étaient plus ou moins chose du passé. Récemment, on remarque un intérêt renouvelé et grandissant pour ce genre de four, dont la construction fait appel à la disponibilité de matériaux nouveaux, non traditionnels, utilisés de façon créatrice.

1 When studying traditional Ukrainian folk architecture, domestic folk furnishings in the traditional Ukrainian home, daily life-style, folk ritual, or folk songs, it has always proven difficult to exclude any reference to the pich, or as it is more generally called, the peel oven. Thus in many ways, it can be looked upon as the "heart" of a home, providing a direct reflection of that home's inhabitants, their socio-economic status and cultural change. The peel oven was transported to the Canadian West with the Ukrainian immigrant and continued to play a role, however changing, in the lifestyle of Ukrainians in Canada well after they stopped being considered immigrants.

Development of the Pich in Ukraine

2 The origin of the peel oven has been attributed to the Romans.1 Of course, being developed by the Romans, its proliferation was guaranteed for a time until the Roman Empire finally dissolved. While varying in materials of construction and dimensions, it is still possible to recognize the common features of these early ovens:

In eastern Europe, some form of peel oven was in use in homes as early as the fourth or fifth century.3

3 Among the Ukrainians4 the predecessor to the peel oven within the home was an open fire. Food was prepared in vessels balanced on rocks heated by the fire. Thereafter, vessels were suspended above the fire. Up until this time, the fire pit was located on the ground. Smoke from the fire gathered along the ceiling of the room, eventually exiting through the open doorway (windows in these dwellings were fixed in the walls), which also allowed entry of the oxygen required for combustion. This had an obvious influence on the appearance of these living environs. A strong band of soot on the walls of the room identified the smoke zone that enveloped its upper, and not so upper, reaches when the fire was lit. Furnishings were sparse, and decoration in the room was virtually non-existent. Even furniture for sitting was specifically constructed low so that the inhabitants of the room would be as comfortable as possible.

4 Over time conditions improved. People added vent holes, either in the ceiling above the fire or in the adjacent wall high up near the ceiling, and raised the fire pit off the ground onto a clay platform built into the corner of the room most adjacent to the doorway. This meant that the door, still the only source of combustion air, would tend to be hinged on the side of the doorway closest to the fire. Cooking was done on the platform on or adjacent to the open fire. These changes improved living conditions in the dwelling by raising the smoke zone and accelerating the venting of smoke out of the room.

5 A short time after, a formalized oven cavity was created at the rear of the platform for baking or roasting, leaving the front free for a cook fire. With the specific exception of the Lemko sub-grouping, the mouths of these ovens faced the doorway. (Lemko ovens face into the room, away from the doorway.) It has been argued that locating the pich with its mouth facing the doorway in the corner immediately adjacent to the doorway was the most efficient location in the traditional style of Ukrainian home.5 Not only did the doorway provide combustion air to the oven, but this same draft drove the heated air from the pich farther into the room. This style of pich could be found well into the twentieth century in parts of Ukraine, especially among poorer households.

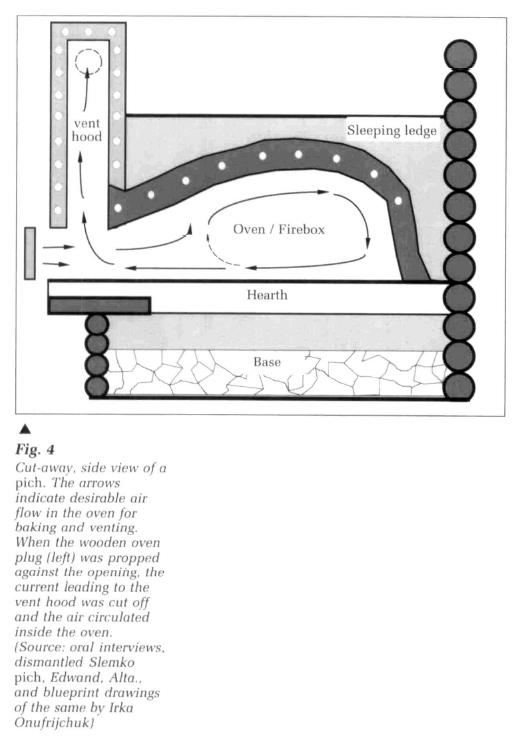

6 By the middle of the nineteenth century the pich had continued to evolve in conjunction with other improvements in the dwelling. By that time, the pich generally occupied about twenty-five per cent of the floor space in the single dwelling room of the home. A hood was constructed over the front ledge of the pich, over the mouth of the oven. Connected to the ceiling or wall vent, this hood trapped a majority of the smoke created by the cookfire or oven and directed it to the vent holes, which either expelled it directly into the attic area or into the adjacent ceilingless hallway. Although limited because of existing surtaxes and material costs, some houses even boasted masonry chimneys or woven wattle vents that eliminated smoke directly outside the home. A laying or sleeping ledge over the oven was also added in most cases, expanding the amount of useable space in the room.

7 Continued improvement of the pich throughout the nineteenth century reflected the general trends of improvement to yards and buildings in Ukraine. Even the cooking fire was being removed from its open location under the hood to an adjacent enclosed firebox called a shparhat, constructed of clay and covered with a cast-iron top.6 Consequently, the amount of intrusion of smoke into the living area became minimal by comparison with earlier eras. Lighting and hygiene were further improved once interior wall and ceiling surfaces and the pich were whitewashed. Decorative embellishments increased in the form of displayed textiles on walls and furniture and wall painting. Clay floors and plastered ceilings were covered in planking. Although not prevalent throughout, this was the ultimate version of home interior known to the average Ukrainian villager immigrating to Canada from the end of the nineteenth century onward.

Design

8 Many of the variants of the pich that developed among the western Ukrainians by the turn of the twentieth century were replicated on the Canadian Prairies. While differing in appearance, they also followed a rather uniform set of design principles. The most important of these principles concerned the size and shape of the baking/cooking cavity, which also served as the firebox.

9 The oven cavity was generally oval in shape with the opening, or cheliust, forming its narrowest point. Its size reflected the multipurpose nature of the oven. Extending upward from the mouth toward the back, the height of the pich cavity increased from about one foot (31 cm) at the cheliust to a maximum of about sixteen inches (41 cm). However, when speaking of peel ovens in general, a cavity as low as eight inches (20 cm) is seen as being ideal for baking because the oven is more sensitive and efficient. Ovens with cavity heights of eleven to thirteen inches (28 to 33 cm) are not uncommon and are recognized to be necessary for roasting and general food preparation, although their overall performance is not as fast or good.7 Larger cavities result in heat stratification, where each vertical heat zone has a different temperature and moisture condition. This also creates a tendency toward eddy currents in the convected heat inside the cavity, which may further promote non-uniform baking.8 Nonetheless, elements such as these could be taken into account, and ovens of much larger proportions are known to have existed.9 Thus, the larger cavities of the Ukrainian ovens, while not perfectly efficient, were well within the design principles associated with peel ovens. Furthermore they not only accommodated the general diet of the settlers,10 but their slightly larger cavities also allowed a person to crawl inside on his or her back to undertake any necessary repair of the inner surface.

10 The versatility of the pich design is also reflected in its main material of construction— clay. Whereas metal cookstoves and heaters were not unknown to the Ukrainian immigrants even before their arrival in Canada, it was difficult to find any single metal unit which could perform both functions efficiently. While still requiring more maintenance than the metal variety, the bodies of properly prepared clay stoves remained elastic even while subjected to wide ranges of temperature. Of course, even after the baking was done, the clay structure of the pich allowed it to function as a much more efficient heat sink than any manufactured heater or furnace. Although clay is only about twenty per cent as dense as cast iron or steel, it is capable of storing over eighty per cent more heat per pound (0.5 kg). Therefore, heat produced initially for food preparation could be retained well after the food was removed from the oven and released slowly to produce an even heat.11

11 To be able to achieve optimum conditions for preparing food and keeping maintenance of the unit to a minimum, the hearth and the walls surrounding the pich cavity were about four inches (10 cm) thick. To these were added other layers or accessories made of clay, often mixed with materials that differed from those used in the hearth and walls. While some of these additional layers contributed to the operation of the oven, others enhanced its performance. For example, the type and amount of material used under the hearth surface could determine the rate of heat transfer between the heating system of the oven and the food being prepared.12

12 The pich was designed for three forms of heat transfer: radiation, conduction and convection. In describing the function of peel ovens, the process of radiation is further separated into two categories: top heat and bottom heat.13 "Top heat" radiates or is forced downward from the top of the oven chamber onto the product being prepared, whereas "bottom heat" radiates upward to the bottom of the product. Although one might expect that equal proportions of bottom and top heat would be desirable for food to be heated with consistency, other factors come into play that call for differences in top and bottom heat. Products needing to be baked slowly, for example, require a maximum of top heat and a minimum of bottom heat radiation.14 Still, the efficiency of the radiation process not only varied with the temperature of the oven surfaces, but also with the temperature of the food which absorbed the heat from those surfaces.15 Even details such as shape and colour could affect the results.16

13 Conduction has been considered the most incidental of the heat-transfer processes because it is highly influenced by the conditions that were created for ideal radiant heat. Once these conditions, including hearth type, food container (in the case of the Ukrainians, mostly earthenware) and type of product are established, very few variables remain that could alter the existing processes of heat transfer. Therefore, conduction is a process that has been looked upon as little more than something that can be calculated or measured with a high degree of accuracy.17

14 Convection, being the least apparent, was probably the most underestimated and least conceivable process of heat transfer in the peel oven. Yet, in these direct-fired ovens, where the oven cavity alternately functions as the firebox and food-preparation chamber, convection is actually the principal mode of heat transfer. It involves the "transmission of heat from one point to another through the medium of a substance capable of free circulation,"18 and relies heavily on having the oven chamber built to a shape and size that are conducive to convective circulation. As mentioned previously, the pich chamber is oval in shape with a single opening or mouth whose height from the hearth is several inches (centimetres) lower than the highest point of the cavity. This uppermost zone (known in peel ovens as the dome or crown19) of the chamber, where steam accumulates as the food is prepared, is actually one of the most critical points of the oven. While baking bread in the peel oven, for example, "steam condenses on the cool surface of the dough and keeps it moist through the early stage of baking. This allows maximum expansion of the dough piece as a result of oven spring. The steam also facilitates starch gelatinization on the outside of the loaf. When the steam is discontinued and the baking completed in dry heat, the starch has a high glaze."20 Without the difference in height between the dome and the oven mouth, free or "passive" convection is impossible and the baking process is impeded.

15 In peel ovens like the pich, the media of heat transfer in the convection process are air and steam,21 and differences in air masses in the chamber cause steam-laden currents of air to circulate throughout the chamber. As the product absorbs heat from the oven walls and hearth and radiates it back into the cavity radiant heat transfer is perpetuated.22 The rather high chambers of the pich built by the early Ukrainian settlers in Canada actually hindered this reciprocating process, for they created an uneven distribution of steam-laden heat, affecting the quality of the food product.23 Thus, a pich could be doomed to failure in the earliest stages of its construction, for there were few ways of improving its performance if built without a dome of appropriate proportion to the rest of the oven cavity.

Materials and Construction

16 The style of pich first constructed by the Ukrainian settlers throughout western Canada at the turn of the twentieth century differed in no way from those in their villages of origin during the same period. Therefore, nothing has been found to suggest that the hoodless style of pich was ever utilized in Canada, although subsequent changes introduced in Ukraine to the hooded pich were also implemented on the Prairies.

17 The materials for the construction of these ovens—clay, willow saplings, straw and chaff, sand and wood for rails—were readily available in the areas settled by the Ukrainians.24 That, and the fact that construction of a pich required no cash investment, made the reintroduction of the pich to the life-style of the Ukrainians in rural Canada almost immediate.

18 The base of a pich was encased in a cribbing made of three- to six-inch (8- to 15-cm) wooden rails, notched and joined much in the same zrub manner as they were in the houses and outbuildings of the settlers. The cribbing was from one and a half to two feet (46 to 61 cm.) high, and its length and width were calculated to allow for as much as a six-inch (15-cm) ledge surrounding the exterior oven walls when finished. The space contained by the cribbing was at first filled with rocks and stones, mixed with the same type of yellow clay that was generally used in all building construction by the Ukrainian settlers. This mixture was regularly tamped down as it was added to the space, using a large, flat-ended club-like tamper. After several layers, the stones were replaced by sand. By the time that the clay, sand and stone mixture reached the top of the cribbing, it had been compacted to a concrete-like consistency. The last four inches (10 cm), in fact, were wet clay mixed with sand. Once dry, this layer formed the hearth of the pich.

19 Preparation of the base was followed by the construction of the oven walls. Several styles of construction are known to have been used traditionally.25 Probably the simplest involved the preparation of a form or plug made of such materials as earth, straw or wood, roughly shaped to the size of the proposed oven cavity. The clay mixture used for the walls of the oven was then simply patted over this form. As the clay dried, the plug was either pulled or burned out of the oven.26

20 Other techniques called for the preparation of a green willow sapling framework to support the clay walls of the oven as they dried. This style of construction can even be found in the "mud-and-cattied" chimneys of early America, whose builders also recognized the need for green saplings, "so they will shrink along with the clay as it and they dry and turn to char. The sticks act mainly as an internal scaffolding to hold the clay in place till it can dry and be baked to hardness by the heat of the fire."27 The saplings were about an inch (2 cm) in diameter. Looking somewhat like the inverted ribs of a ship's hull, they were pushed into the surface of the hearth along one of its sides at intervals of six to eight inches (15 to 20 cm). The ends of the saplings were bent over into bow shapes (kabluky) and inserted into the surface of the hearth again at the opposite side.28

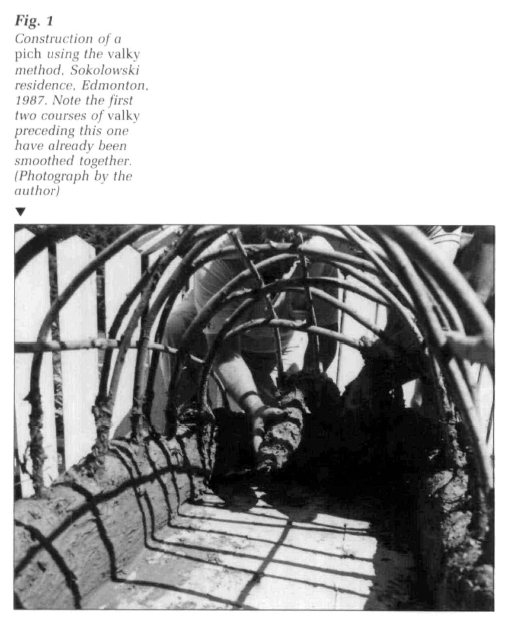

21 There were two methods used to cover the framework, involving two different ways of preparing the clay. One way was to create a mixture of clay, cut straw and chaff, and daub it on both sides of the saplings. This was done on the interior and exterior at the same time, starting at the base. Daubing was repeatedly built up on either side until it reached the top, thereby encasing the framework completely. Wet clay was then mixed with sand for the finishing layers, both inside and out. A second technique was similar to one used in constructing building walls in parts of Ukraine where logs were scarce. It involved the preparation of clay with uncut straw into long rolls. The rolls, called valky (sing, valka),29 were then interwoven with the willow framework, and the exterior and interior surfaces daubed with clay and cut straw or chaff to smooth them out. Whichever technique was used, it was difficult to discern the difference once the pich was completed. Also, although the first technique made the oven a more homogeneous mass, there is no indication that either technique affected the operation or maintenance of the pich.

22 The next step in the construction of the oven was to let it dry. Initially it was allowed to dry at room temperature. Then, a small fire was built inside the cavity to speed the process of curing, Of course, at this stage there was no mechanism to capture the smoke from the fire, and it functioned like the older forms of hoodless pich that had existed in Ukraine until the nineteenth century. The smoke that gathered along the ceiling eventually escaped through the vent hole (kahla) cut in the adjacent wall, just under the ceiling at a height taller that the doorway.

23 At this point in the construction individual or regional styles were incorporated, determining the overall appearance and function of each individual oven. For example, the shape and dimensions of the front hearth varied, while the materials used in their construction remained constant. They usually consisted of a large slab of wood about two inches (5 cm) thick or more, whose length extended along the whole front of the base. They were at least a foot (30 cm) wide, and usually even wider. They were supported along one side by the base of the pich and rested on two posts driven into the ground at either corner of the opposite side. This created a storage space for kindling or cooking pots under the ledge. The top surface of the ledge was coated with the same clay mixture that was used to finish the hearth on the inside of the oven and was the same level as the bottom of the cavity. This allowed the ashes from the oven to be scraped out onto the ledge with as little inconvenience as possible. Sometimes the ledge extended along the side of the pich as well to form a sealing ledge or work counter (depending on the height of the ledge). Although the traditional pich is described as having these ledges normally, almost none have been found in western Canada.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 224 The next portion of the pich to be constructed also reflected regional variation in style. The hor or horn was a canopy or hood that extended beyond the front of the oven, directly over the mouth. As the smoke produced during the firing of the oven cavity escaped from the oven, the hood trapped it and redirected it toward the kahla. This made the living area of the room a lot more comfortable, although not smoke-free. The hor was basically box-shaped, although some narrowed as they extended toward the ceiling. In many cases, it rested partly on the oven and partly on two posts, which in turn rested on the front ledge of the pich. In other cases, the front posts were eliminated, requiring the hood to rest primarily on the oven and be suspended in front from the ceiling. The method of framing and finishing the hor was identical to that used in the construction of the oven portion. It was found, however, that the willow framework of the hood was less likely to char and disappear completely since it was rarely exposed to direct flame, flu: exterior clay surfaces of the hor were often more aesthetically shaped, for the same reason.

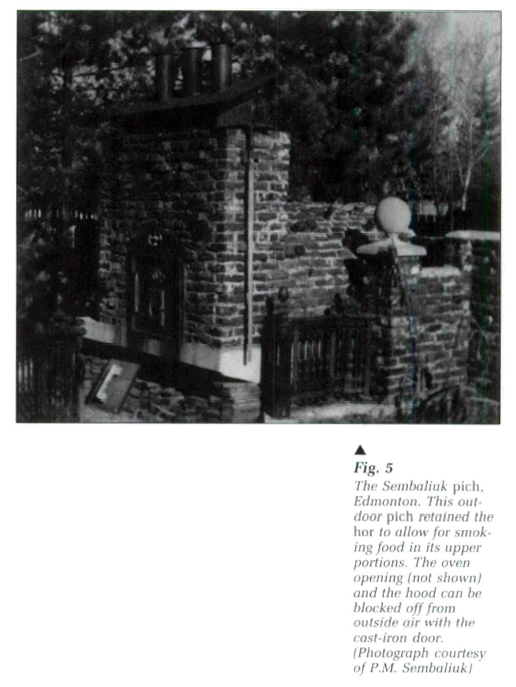

25 The hood (hor) was connected to the vent hole (kahla) by means of a clay and sapling tube or box called a tsivka. The hole inside the tsivka was not particularly large, sometimes being as small as six inches (15 cm) in diameter. A curious characteristic regarding the planning of these vent tubes was that they did not always encourage the escape of smoke from the hood in the manner of chimneys. In fact, some of these channels were almost horizontal in slope, allowing the smoke to overflow out of the vent hole into the adjacent room only after the hood had been completely filled with smoke. In these instances, it was not uncommon to see smoke billowing out from under the hood while the pich was being fired.

26 A final stage in the construction of the pich was actually quite optional and contributed very little to the its operation. Nonetheless, the ledge, which was built behind the hood over the iiven, is the component that often elicits the most nostalgic memory of the pich among those who grew up with them. Taking advantage of the heat that continued to radiate from the pich, the curved surfaces of the oven walls were supplemented with an additional stage of wet clay and sand to form a large flat ledge. The clay was kept in place with a form which was removed once the ledge had hardened. Out of view behind the hood, this space was used for the storage of large but regularly used household items such as the dough trough. It was also used to dry such things as vegetables and herbs, kindling, and wet clothing. However, it is usually fondly remembered as the cozy place where children or older folk had the occasion to sleep.

27 Compared with the main part of the pich, the firebox, or shparhat, had a rather short-lived existence among the early Ukrainian settlers. Many of them had already heard of the cast-iron cookstoves that were available in Canada before they emigrated from Ukraine, and it was not long before the shparhat was removed from the side of the oven and replaced with the metal cookstoves. Nonetheless, the shparhat was an integral part of the type of pich that was redeveloped in Canada, however briefly. Basically, it was constructed in a similar manner to the base of the pich. Following this, walls were built up around the perimeter of this mass of clay and straw, and this was covered by a metal plate top. A crude metal fire door, which also provided a draft to the firebox, was incorporated into the front of the stove. Smoke was vented out of the shparhat with stove pipe, or else a vent tube similar to the tsivka was prepared out of saplings and clay. Whichever was used, it was connected to the side wall of the hor directly opposite the kahla.

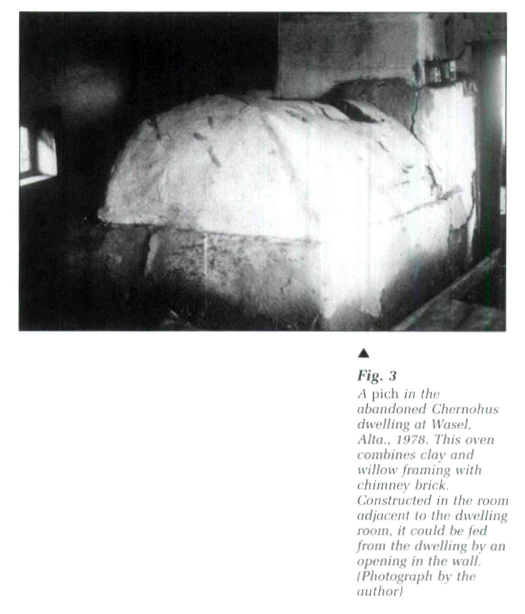

Display large image of Figure 3

Display large image of Figure 328 Thus, as with most of the rest of the material culture of western Canada's early Ukrainian settlers, the styles of pich that were constructed on the Prairies were replicas of those that the people had left behind in their native villages. It was only alter the immigrants had become more acclimatized to the components of the resident material culture in the West that they began to consider alternatives.

Adaptation and Change in Canada

29 As mentioned above, one of the earliest changes to occur in the style of pich constructed by the early Ukrainian settlers in western Canada was the replacement of the shparhat. Realizing some of the advantages of the cast-iron North American cookstoves over the shparhat, the settlers invariably removed it from their dwellings. The cookstoves literally took their place, occupying the same spot previously occupied by the shparhat, venting into the hor in relatively the same manner. The pich and its newly adapted North American accessory were not always linked in this way for long. The hor was often unable to clear the volume of smoke produced by the stoves at a last enough rate, and the smoke circulated into the fixing area unnecessarily. Soon, the Ukrainian tanners learned to vent the stoves separate of the pich, also choosing to incorporate masonry chimneys into the structure of their homes at this time.

30 A stage of adaptation that sometimes preceded the conversion to chimneys involved the creation of the slipyi komyn (literally "blind chimney"). A clay and sapling stub built in the attic onto a hole cut in the ceiling over the pich or stove, the slipyi komyn had a hole or holes in its side rather than in its top. This trapped and extinguished any sparks escaping from the stove or pich, leaving only the smoke to exit out the sides. The holes of the stub were often connected to stovepiping which passed through the roof of the home to the outside air. This series of adaptations greatly improved upon any previous attempts to eliminate smoke from the dwelling. Of course, the masonry chimney, when constructed correctly, perfected the process even more.

Display large image of Figure 4

Display large image of Figure 431 Brick, followed closely by mortar and concrete, were also adapted as construction materials for the pich. Sheet metal and metal wheel rims were also incorporated permanently into the form of the oven cavity. People believed these materials would reduce the amount and type of maintenance required. While this may have been true to some degree, the overall impact of these new materials on the operation of the pich was not significant. Each of the components was often only a normal or even sub-standard grade of construction material and not well suited to prolonged and regular exposure to high temperatures. On the other hand, these new materials did serve for as long as these ovens were a regular part of the settler's life-style.

32 An incidental adaptation affecting the operation of the pich was not concerned with its materials or construction. The earthenware the immigrants transported to Canada eventually cracked or broke, and because there were very few potters operating among them who could replace these traditional vessels, the settlers quickly converted to the metalware readily available in any general store. This necessitated changes in the way certain foods were prepared. Even the temperature to which the oven had to be heated required some attention.

33 The greatest impact on the role of the pich in the Ukrainian-Canadian life-style and its future after the first World War was created with the total relocation of this oven from the dwelling. In some cases, this was a gradual process. Some farmers constructed "summer houses" with a pich for summer use, when it would be uncomfortable to operate the one in the dwelling. Because these buildings did not replicate the traditional layouts or dimensions of dwellings, the placement of the pich in summer houses was somewhat haphazard. Although these ovens were usually built into a corner of the room, the mouth of the pich did not face any predictable direction.

34 During colder weather when the beat was welcome, people would use the pich in the house. However, increasingly it was felt that the North American cookstove could provide sufficient heat all year (after all, the Ukrainians usually chose homesteads where firewood was plentiful) and that the family could put the space occupied by the pich to better use.30 Therefore, the pich in the house was dismantled and a new one was built in the yard.

35 The style of the outdoor pich developed on the Prairies was a reversion to the type that had been built in homes in Ukraine a century before. Not having to be concerned with smoke in the outside air, the outdoor pich was built without a hor. Similarly, the sleeping ledge was without function outdoors and was not included.

36 It was soon rare to find any other food prepared in the outdoor ovens other than baked goods (mostly bread), although the height of the cavities of the ovens remained the same as when they were used to prepare a greater variety of food. A new feature, however, was added in an attempt to improve the baking efficiency of the outdoor pich. Some people put a hole at the rear of the cavity and some even added a length of stovepipe to the hole as a permanent fixture. It is possible that the hole was developed as a result of imperfect replication of the traditional model by the descendants of the original settlers, who often relied on mimicry in re-creating the material culture of their heritage. Many of the models examined in the field have cavities with minimal differences in height between the crown and the mouth. Since this would have interrupted the creation of passive convection inside the oven, the construction of a hole at the rear to be used at least when the pich was being fired would have created a tunnel of air which improved conditions of uneven heating in the oven. Subsequently, the common impression of generations of Ukrainian Canadians is that the outdoor pich with a hole and stovepipe at the rear is something that was brought over with their ancestors from the old country.31 (Actually, the relocation of the pich from the dwelling to outdoors in Ukraine was a much later process, occurring after the Second World War.32) Interestingly, those who are cognizant that the outdoor pich is nothing more than a redefinition of the indoor pich cannot explain why the indoor variety does not require a rear hole to function properly.

Display large image of Figure 5

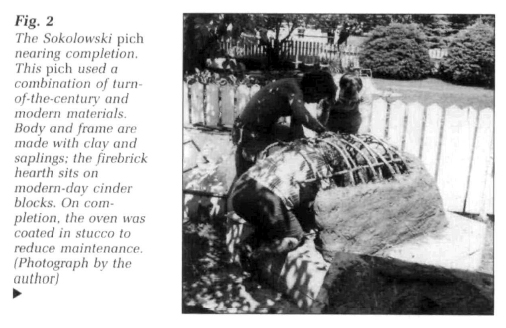

Display large image of Figure 537 By the 1960s, both the indoor and outdoor pich in western Canada had largely fallen out of use. They had become objects of curiosity, creating opportunities for reminiscences and nostalgia, to be fired up usually for community celebration of rituals or rites of passage. By and large, they were resurrected for these distinct occasions by those who could still make them work properly. In the late 1960s the pich was revived through festivals in the Ukrainian communities of western Canada, which offered demonstrations and competitions of bread-baking in specially constructed permanent ovens on the festival grounds. Interest continues to grow even today,33 and the number of privately owned ovens increases steadily in town and city alike. These are a new breed of pich, however, attempting to surpass the innovations of the past with even newer materials such as cast iron, firebrick, refractory cement, Stucco and cinder block.