Articles

Carriage Making in St. John's, Newfoundland:

A Folkloristic Perspective on a Historical Industry

Abstract

This article examines the carriage-making industry of St. John's, Newfoundland. It seeks to explore, in a case study format, how small and isolated industries responded gradually to the realities of mass production in an era of industrial transition. In Atlantic Canada, both large carriage manufacturers and smaller craftshops existed; however, most prevalent were the small carriage factories which possessed some of the characteristics of rural craftshops. In considering the development and decline of the Newfoundland carriage-making industry, this paper provides a case study of one particular St. John's factory — Cornell's. Moreover, the limitations of the word craft are outlined and, in the context of carriage making in the Atlantic region, a broader definition of this term is offered.

Résumé

Cet article s'attache à l'industrie de la voiture à cheval à St. John's (Terre-Neuve). Adoptant la formule de l'étude de cas, il explore comment de petites fabriques isolées se sont progressivement adaptées aux exigences de la mutation industrielle et de la production en série. Dans les provinces de l'Atlantique, les grandes manufactures de voitures coexistaient avec les petits ateliers d'artisans, mais on y trouvait surtout de petites usines rappelant un peu les échoppes rurales. Tout en considérant l'évolution et le déclin de cette industrie à Terre-Neuve en général, l'article s'attarde au cas de l'usine Cornell's à St. John's. Il fait d'ailleurs ressortir les limites du mot anglais «craft» (artisanat) et propose au lecteur une définition plus large de ce terme dans le contexte de l'étude.

1 Large-scale progress in transportation technology in the twentieth century, particularly in the industrialized nations, has changed the material culture, daily activities and local economies of many communities. In Atlantic Canada, scholars have focused on the transition from a mercantile to an industrial society in an attempt to explain the rise and fall of large, primary-resource industries. While such works provide a greater understanding of how the region adapted to industrial capitalism, little is known about the material culture of these large enterprises. Even less is known about the so-called pre-industrial industries— the craftshops and local factories—which responded to the needs of a local population by providing various material objects ranging from barrels and furniture to coffins and horse-drawn vehicles.1

2 Carriage making, an integral nineteenth century industry in many rural and urban North American communities, had highly automated assembly-line operations in some areas of the eastern United States. Here vehicle factories could employ in excess of one hundred men by the 1820s, and the distribution of products to the United States, Europe and South America could yield a gross annual value of $100,000.2 In contrast, small family craftshops, which, according to Bridenbaugh, "belonged in the economic category known today as small business," were also very common.3 In Atlantic Canada, large carriage manufacturers and small craftshops existed; however, most prevalent were small carriage factories which possessed some of the characteristics of rural craftshops.4 St. John's, Newfoundland, and other Atlantic Canadian centres, such as Amherst, Truro, Westville, Sydney, Fredericton, Saint John, Montague and Charlottetown, had small carriage factories of this kind in the nineteenth and twentieth centuries.5

3 This article discusses the development and decline of the carriage-making industry in St. John's, Newfoundland, and focuses on one particular factory, Carnell's, to show that many of the characteristics often attributed to rural craftsmen were prevalent in these businesses. This study attempts to assess the limitations of the word craft, providing broader and more realistic definitions for this term, and to show how small and isolated industries responded gradually to the realities of mass production in an era of industrial transition.

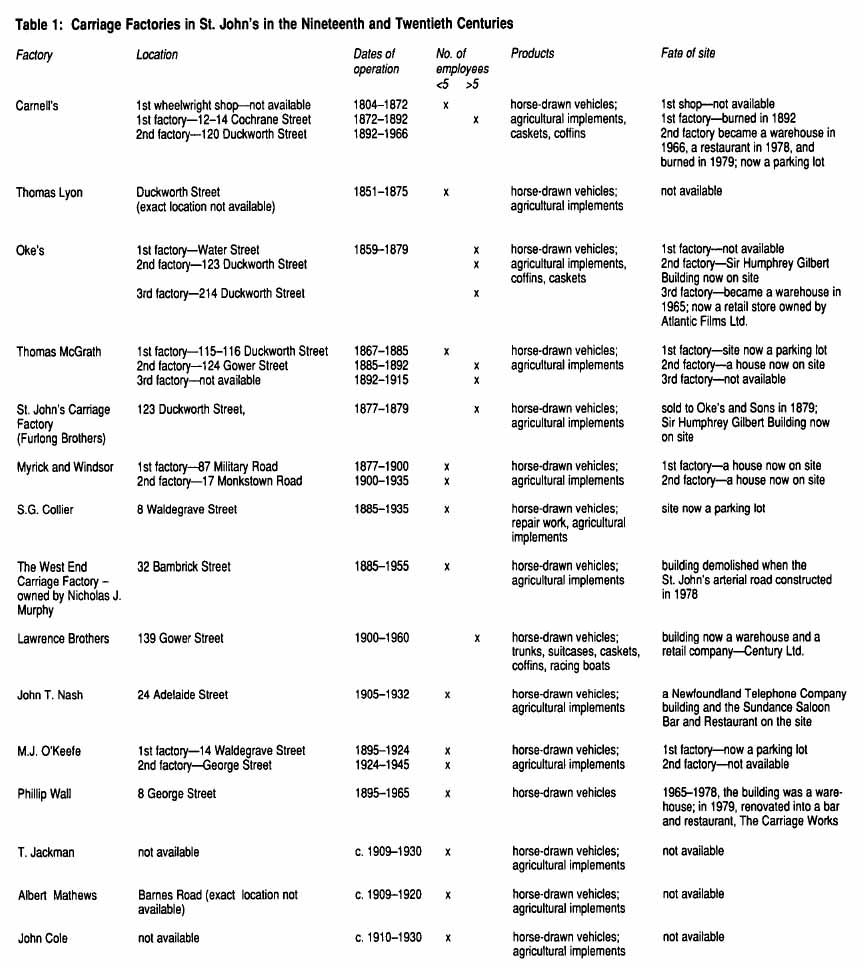

4 Carriage factories began to appear in St. John's by the mid-nineteenth century. Before this time local horse-drawn vehicles were either imported or constructed at local blacksmith and wheelwright shops. The carriage factories, which had developed by 1850, were small—only five out of the fifteen documented factories had more than five employees (table 1). Some consisted merely of one large room where all activities in the production process occurred, while others were three stories with separate rooms for the various manufacturing procedures. All used some form of machinery: lathes, handsaws, circular saws and planers were found in most factories. In the mid-nineteenth century, machines were powered by steam engines; in the early twentieth century, by gasoline engines; and, as the twentieth century progressed, by electricity. Each factory had only one power source attached to a network of belts connected to various machines. These factories were part of the machine age, which, according to Herbert Read, "by 1830 was fully and finally established" in Europe and North America.6

Display large image of Table 1

Display large image of Table 15 The St. John's carriage-making industry developed in three periods: early 1850s to late 1870s; 1880s; post-1892 fire to 1910. Between 1850 and 1879 five carriage factories began operating within the city. Carriage factories were opened by Thomas Lyon on Duckworth Street in 1851, William Oke on Water Street in 1859, Thomas McGrath on Duckworth Street in 1867, the Furlong Brothers on Duckworth Street in 1877 and Myrick and Windsor on Military Road in 1877 (table 1). Likewise, the Carnell family, which had operated a wheel-wright shop on Cochrane Street since the first decade of the nineteenth century, had transformed their establishment into a factory by 1872. All the carriage manufacturers were located in the east end of St. John's (fig. 1), where most of the city's residents lived. In addition to supplying the needs of urban residents, these businesses also provided agricultural implements and vehicles for the farmers who had established farms on the outskirts of St. John's.7

6 By the 1880s, two of the six early factories, Furlong Brothers and Thomas Lyon's, closed; however, two factories opened to replace them. One, owned by S.G. Collier, appeared at 8 Waldegrave Street, and another, owned by Nicholas J. Murphy, opened at 32 Bambrick Street. By this time, Oke's and McGrath's had relocated to larger premises; Oke's moved to the building formerly occupied by Furlong Brothers on Duckworth Street, and McGrath's to 124 Gower Street.

Display large image of Figure 1

Display large image of Figure 17 The third period of carriage factory construction began after a devastating fire in 1892.8 At least three of the factories destroyed in the fire, Carnell's, Oke's and McGrath's, were rebuilt at this time. In addition, the Lawrence Brothers opened a factory on Gower Street in 1892, M.J. O'Keefe at 14 Waldegrave Street and Phillip Wall at 8 George Street. In the first decade of the twentieth century John T. Nash opened a factory at 24 Adelaide Street and three other factories were established by Thomas Jackman, Albert Mathews and John Cole.

8 A pattern is evident in the development of carriage factories. In the first stage of development, factories were situated in the east end of the city (fig. 1). As the city expanded and commercial premises and family dwellings began spreading towards the west end, factories appeared there.

9 The increase in the number of carriage factories at the end of the nineteenth century reflects the increased prosperity of some areas of Newfoundland at this time. In 1894 a massive mining development occurred at Bell Island, about 19 km from St. John's. The Nova Scotia Steel and Coal Company, which had acquired property on the island, commenced open-pit mining and shipped their first cargo of iron ore a year later. In 1899, the Nova Scotia Steel and Coal Company constructed another tramway system and a second pier and sold their original transport system to the Dominion Iron and Steel Company. After 1898, the Reid Newfoundland Company was busy establishing a railroad, quarries, sawmills and flour mills.9

10 This increase in economic activity in and around St. John's resulted in a need for more horse-drawn vehicles. The year 1894 brought the start of a sharp decline in the number of men working in the traditional fishery.10 Much of this labour may have been absorbed by the Bell Island development and the small urban manufacturing industries such as carriage making.

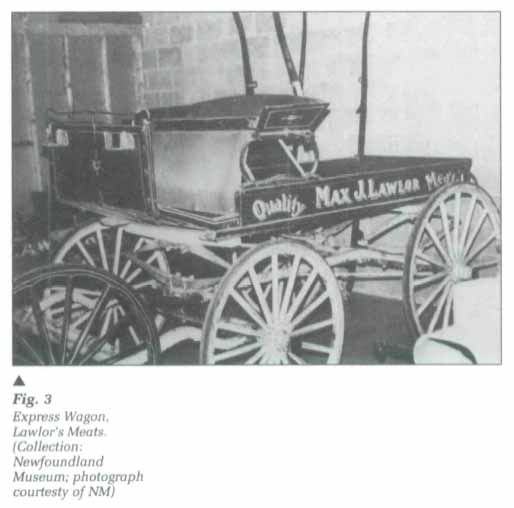

11 With an increase in the number of carriage factories and their products, fewer vehicles were imported from England and the United States. These factories produced not only catamarans, box carts, slides and long carts for the local fanners, but also slovens, express wagons and cabs for the St. John's industries. Ornate two- and four-wheeled vehicles were also produced for the growing merchant and professional classes of the town. In addition, agricultural implements such as hand plows, wheelbarrows and handles for tools were supplementary items of trade constructed in most factories. The larger companies, Carnell's and Oke's, became involved in the funeral business in the latter years of the nineteenth century. This included not only embalming and organizing wakes and funerals, but also making coffins and the vehicles used in funeral processions. One particular factory owned by the Lawrence Brothers specialized in making trunks, suitcases and racing boats for the annual St. John's Regatta. Another factory began building wooden tricycles, which could be marketed at a quarter of the cost of steel models.11

12 Such diverse products undoubtedly kept the factories open when vehicle orders were not plentiful. This ability to construct a variety of products is a characteristic often attributed to rural craftsmen. Like George Sturt's wheel-wright shop in Surrey, England, which built vehicles, plows, harrows and hames, the St. John's carriage factories supplied the sundry demands of local residents.12

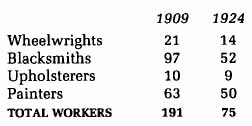

13 Accurate quantitative information about the workers in these factories is difficult to obtain. Those owned by Carnell, Oke, McGrath and Lawrence Brothers employed more than five men each, whereas some of the smaller factories only employed one wheelwright, one blacksmith and one painter. The largest factories also employed upholsterers. It appears that by 1924 the number of craftsmen in the St. John's carriage factories began to decline, as shown below:13

14 In some cases, St. John's directories list the carriage factories where particular craftsmen worked. These lists, however, are not entirely accurate (table 2). Some individuals who worked at factories could be listed as craftsmen, yet were not recorded as being affiliated with their particular place of work. For example, a newspaper account reveals that in September 1908 Carnell's Carriage Factory employed twenty workers, yet the directories indicate that Carnell's had only nine employees at this time (table 2).14

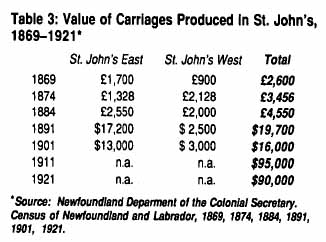

15 The Newfoundland census material, like the directories, is also inaccurate with respect to the carriage-making industry.15 Even though at least eleven carriage factories operated in 1921, the Newfoundland census accounts for only three.16 Despite possible inaccuracies, these statistics provide an indication of the scale of these factories. The capital invested in the physical plant and equipment of those recorded in 1921 amounted to $40,000. Employees numbered five "officers and clerks" earning in total $9,000, and thirty workers earning $44,800. According to the Newfoundland census returns between 1869 and 1921, production in the factories increased steadily throughout the late nineteenth century (table 3). The data indicate a slight decrease in productivity in 1901; however, it appears that it was not until 1921 that the number of carriages manufactured in St. John's declined substantially.

16 Meanwhile, automobiles began to replace horse-drawn vehicles. The first automobile to arrive in St. John's, according to local historians, was a Rolls Royce imported from London by Robert Reid, Jr., in 1903.17 Only wealthy merchants and professionals could afford these luxury items; it was not until after the Second World War that a great influx of automobiles occurred.

17 The carriage-making industry did not decline to negligible levels until the 1940s. The few factories still existing until the early sixties were the ones that had successfully made the transition from carriage making to coffins or box and trunk making. Carnell's and Oke's in their later years devoted most of their attention to the undertaking business; they possessed the tools, machinery and expertise for constructing coffins. As the twentieth century advanced, St. John's residents began holding wakes in funeral parlours rather than in their own homes. One craftsman describes the variety of work he performed in a carriage factory during this period:

In addition to being a trained wheelwright, this worker had to become familiar with the duties of an undertaker. This worker is still the manager of an undertaking business operated by the Carnell family.

Display large image of Table 4

Display large image of Table 418 While some former factory workers are still alive, the majority of buildings that housed carriage factories are not extant; the remaining structures are used for different purposes than were originally intended. When the industry died completely in the 1960s, some of the buildings were converted for use as warehouses. Carnell's, Oke's and Lawrence's, because of their size, were used for this purpose. Much of the machinery was sold, dismantled or destroyed at this time. Other factory sites were transformed into parking lots or residential housing. Following the trend to preserve and utilize historic buildings for commercial purposes, former carriage factories have been transformed into a variety of businesses. Carnell's Carriage Factory was converted into a restaurant and bar in 1978, but was completely burned in 1979. Phillip Wall's Carriage Factory on George Street was transformed into a bar and restaurant called The Carriage Works in 1979. Photographs of ornate carriages along with vehicle parts such as springs and axles now adorn the walls of this once productive factory, perpetuating a nostalgic view of the past.

19 The full acceptance of the automobile caused the eventual demise of the carriage-making industry. As automobiles produced in Central Canada and the United States reigned supreme, carriage factories, craftsmen and products became obsolete. The firms that successfully diversified into other businesses, such as undertaking or the fabrication of truck bodies, eventually closed their operations because of the difficulty in competing with outside enterprise.

20 While this historical survey illustrates the size, diversity and extent of the local carriage-making industry, it is only a glimpse at the way these factories operated. To fully understand the production context of carriage making, a close analysis of one factory is necessary. Carnell's Carriage Factory provides an under-Standing of the construction process and craftsmen's work within this industry.

21 Although the majority of craft studies stereotype craftsmen as rural, isolated country folk who construct "handmade" objects with few tools and without the use of machinery, the carriage business seems to be at variance with this definition.19 Characteristics of craftsmen include the passing down of craft techniques within one family for many generations; the learning of a craft through a formal apprenticeship system; close craftsman-client interaction; the craft transaction as a social event as well as a business matter; and use of a bartering system rather than cash payment.20 An examination of Carnell's Carriage Factory shows that some of the characteristics often attributed to rural craftsmen were prevalent. Industries such as carriage making have not been studied by craft scholars because of the limiting nature of the definition of craft. Before focusing on Carnell's Carriage Factory we must first examine the terms often used to define craft.

22 The terms handmade, tool and machine are used in most definitions of craft, yet are seldom clearly defined by scholars.21 Objects are sometimes said to be "handmade" even though the maker used a variety of tools and machinery in the construction process.22 If the strict, literal definition of handmade is used, few of our so-called "craft objects" could be included under the rubric of handmade. Most crafts involve the use of some form or machine in the process of constructing objects from natural materials.

23 Handmade is used frequently to refer to any kind of workmanship before the industrial revolution. People assume this transformation occurred in the nineteenth century and that before this period most objects were constructed without the use of machines. This assumption is inaccurate; it has been shown that various kinds of machines ranging from windmills to water-powered saws were common as early as the Middle Ages.23 The term handmade is too vague to be used as a major concept in the definition of craft; too many connotations are attached to this word.

24 Tools are usually viewed by craft scholars as simple hand-instruments manipulated by craftsmen. Sketches and photographs of the tools employed by craftsmen usually accompany a book or article on crafts. Furthermore, the term hand often precedes tool in most studies. Craftsmen are often stereotyped as isolated country folk who use only hand tools in the construction of their products.24 In contrast, scholars are unsure of how to categorize machinery in the definition of craft. For example, one scholar states:

This implies that machinery is a negative and regressive force. Others assume that machine-made products are totally distinct from and inferior to handmade crafts:

Others sidestep the issue by saying it is too difficult to delineate the traditional aspects of "professional crafts," like cabinet making, metal working and glass blowing, and that "more relevant to contemporary folklore studies are the continuing crafts of making toys and musical instruments."27 J. Geraint Jenkins acknowledges that machinery is essential for many crafts, yet he, too, is unsure of how to categorize machinery. One of the characteristics of craftmanship, according to Jenkins, is that "a true craftsman does not depend on complex machinery and equipment to complete his work."28 Unfortunately, he does not fully define "complex machinery" nor does he define the opposite—simple machinery.

25 In truth, many craftsmen, even those in rural, isolated settings, utilize machinery in the making of products. The chairmaker from Kentucky in Michael Owen Jones' The Hand-made Object and Its Maker used an electric drill press and a lathe for constructing his chairs.29 To argue that making objects is no longer "folk" if machines are involved is analogous, as Jones says, "to arguing that electrification and amplification destroy folksong and music."30 It is the conventional modes of expression, the way in which knowledge is transmitted and the traditional skills, not the machines or the hand tools, that create artifacts.

26 Even though machines were integral to the construction process at Carnell's Carriage Factory, many characteristics of factory workers similar to those possessed by so-called pre-industrial rural craftsmen existed in this setting.

Carnell's Carriage Factory: A Case Study

27 Carnell's Carriage Factory developed from one of St. John's earliest wheelwright shops. Gilbert Carnell, a millwright by trade, came to Newfoundland in 1804 to build waterwheels for water-powered mills. He saw a great demand for repairing and constructing vehicles and soon began operating a wheelwright's shop in the downtown of St. John's. Two of his sons became wheelwrights and worked in his shop. Gilbert died in 1841 leaving an estate worth £500, a substantial sum at this time.31

28 Samuel, Gilbert's oldest son, began operating the shop after Gilbert's death. By 1872 business had expanded to such a degree that the shop was referred to as Carnell's Carriage Factory. In this year, the factory was situated on Cochrane Street adjacent to the Carnell family residence. It is difficult to locate the first shop because of the great number of devastating fires occurring in St. John's throughout the first half of the nineteenth century. In 1880, Samuel retired from the business leaving the operation of the factory to his son, John T. Carnell.32 This building was burned in the fire of 1892 and a new factory was reconstructed at 120 Duckworth Street on the corner of Cochrane and Duckworth Streets (fig. 2). Although John oversaw the construction, he died before the building was completed, leaving the business to son, Andrew. In 1935 Geoffrey, Andrew's son, inherited the factory and managed it until 1966, when it closed down. The building became a warehouse in 1966, a restaurant in 1978 and burned to the ground in 1979.

Display large image of Figure 2

Display large image of Figure 229 Little information has been found concerning the first factory operated by Carnell's; however, the second factory is closely examined here. Built after the 1892 fire, this building was three stories high with a flat roof (fig. 2). An alcove on the east side of the facade led to the forge, situated in a small building behind the factory. One former worker provides an excellent verbal description of the interior of the factory:

30 The materials and products were lifted from level to level by a hand-operated elevator of about 3 m by 5.5 m. Along three walls were long work benches, approximately 4.5 m long and 1.2 m wide. A hatch in the floor to the half basement served as a chute where wood shavings were disposed. These shavings were used as fuel for the stove located in the centre of the room. This stove was a metal drum with the front cut out and a stovepipe going from the top through to the roof. Craftsmen's tools were stored on the walls facing the benches. The machinery in the room consisted of three planers, a band saw, a circular saw and a small lathe. All machinery was powered by a small gasoline engine connected to a web of belts running along the roof of the factory. This was an extremely dangerous system; many of the craftsmen working here received severe injuries to hands and fingers because of these moving belts.34

31 In the post-1892 Carnell's Carriage Factory, and most likely in the earlier factory, an apprenticeship system existed. Some of the individuals who began working for Carnell's at this period lived in the Carnell house, located near the factory on Cochrane Street for five years, and received room, board and a subsistence fee in return for their work. These apprentices were assigned to specific craftsmen—a wheelwright, blacksmith, painter or upholsterer—for a five-year training period. After this, the young apprentices moved out of the house and were officially designated members of their trade. The age of an apprentice ranged between 12 and 15 years.

32 The apprenticeship system was modified over time. By the 1940s, the length of study time required by craftsmen had decreased to a year. Robert Butt began working at Carnell's in 1942. He was assigned to "Uncle" Sam Harris, a wheelwright who had been with the firm since 1918. Mr. Butt describes how he obtained the position with Carnell's:

Mr. Butt obtained this job in a non-traditional manner, yet he learned the trade in a traditional way—by observation. The many nuances of the trade could only be learned by watching Sam Harris closely and attempting to follow the example set by the older craftsman. Mr. Butt says:

Questioning the craftsmen about how to perform certain tasks was not the sanctioned way of learning. Few words were used to describe the processes performed.

33 At Carnell's, some craftsmen-client interaction occurred. A buyer was able to discuss the kind of vehicle he wanted with the craftsmen within the factory. In some cases buyers were even allowed to enter the factory and oversee the construction process. One worker describes a particular case:

This craftsmen-client interaction enabled the workers to become familiar with the local needs and preferences of St. John's residents and to provide a quality product for the consumer (fig. 3).

Display large image of Figure 3

Display large image of Figure 334 In the early years of the nineteenth century, according to oral tradition, some business was conducted on a barter system.38 For example, if a grocer needed a wagon repaired or constructed, he could make an agreement with the owner of the factory to supply groceries for a certain length of time, rather than pay in cash. While Carnell's ledgers were not always detailed, they do provide excellent illustrations of the role the barter system played in the early nineteenth-century economy. The following is a good example of a record-keeping system that was still in place in the 1940s when a work-order arrangement was introduced:

35 Like boat building and other traditional crafts, patterns and molds were used within the factory. These were made of iron and wood and stored in the rafters on the first floor of Carnell's factory. Molds were available for every vehicle type and for the various wheel sizes. They did not, however, destroy the creative abilities of the craftsmen. If a mold was not available for a particular type of vehicle, the craftsmen were able to design what was needed. For example, Robert Butt describes how he designed a horse-drawn ambulance:

This passage shows craftsmen did have much control over the design process in the factory and that they could combine their creativity with the opportunities improved technology provided. Thus, this business was a craft.

36 Even though the factory was divided into various rooms, a great amount of interaction occurred during the construction process. The workers frequently talked with each other and discussed problems encountered while vehicles were being produced. The organization can best be described as a team. This interaction enabled each worker to become intimately familiar with the many work processes within the factory. For example, a wheelwright was familiar with a painter's or blacksmith's duties. While the wheelwright did not possess the level of skill of these other craftsmen, if necessary, he could still construct an entire vehicle himself.

37 This case study of Carnell's Carriage Factory shows that even though the factory was located in an urban setting and that machinery was extensively used, workers still possessed many characteristics often attributed to rural craftsmen: the factory itself was passed on in a patrilineal manner from father to son for generations; the factory workers had to go through a formal apprenticeship system; factory workers learned their respective trades in a traditional way—by observing more experienced workers; close craftsmen-client interaction occurred within this factory; some business was conducted on a barter system and only the most basic record-keeping procedures were common; the individual workers used templates and molds, yet were able to have some input into the design process; and although a certain amount of occupational specialization occurred in the factory, each worker was expected to know how to perform the tasks of the other workers.

38 Some of the major characteristics of Carnell's Carriage Factory are identical to many of those often attributed to so-called rural, handmade crafts. This shows the limitations of the term handmade in determining what is or is not a craft. A more insightful concept to use is the notion of workmanship put forth by the design historian David Pye. In The Nature and Art of Workmanship, Pye delineates two kinds of workmanship—workmanship of risk and workmanship of certainty.41 Workmanship of risk includes any kind of construction process where the quality of the work depends on the care, judgement and dexterity of the maker. In this kind of construction process, the product can be ruined at any time. In contrast, workmanship of certainty is any construction process where the quality of the work is completely predetermined.42 The more a construction process is similar to a fully automated, assembly-line factory, the less input the maker has into the objects being made. Carnell's Carriage Factory is an example of workmanship of risk. The hand tools, machines and patterns used by factory workers are shape-determining devices that predetermine, to a degree, what is being constructed in the factory. However, the many characteristics possessed by the factory workers and the way this business operated show that the workers made a great contribution to the final product. If crafts and industries are viewed in terms of workmanship rather than whether or not they are handmade, better understanding of people in relation to the objects they fashion will result.

39 The carriage-making industry is only one of many similar, small-scale businesses that prevailed in Atlantic Canada in the mid-nineteenth and mid-twentieth centuries. Cabinet making, furniture making, chair-making, coopering, blacksmithing and boot and shoe making are only a few of the occupations that may have been organized on the same pattern as the St. John's carriage-making industry. Only when scholars rethink the notions of "craft" and "factory" will serious attention be paid to these small but extremely important folk industries in many regions of Canada.

I would like to thank Gerald Pocius, Memorial University of Newfoundland, Terry MacLean, James St. Clair, and Norman MacDonald, University College of Cape Breton, for their helpful advice and suggestions.