Research Note

Mills, Factories and Craftshops of Ontario, 1870:

A Machine-Readable Source for Material Historians

1 Historians of material culture have a new machine-readable source — a data bank derived from manuscript schedules of industrial establishments recorded for the 1871 Census of Canada. During 1985-86, the first stage of a project to facilitate access to these data has been sheltered by the Department of Geography, University of Guelph. The work has been assisted by a grant from the Social Sciences and Humanities Research Council of Canada.

2 The manuscript schedules on industrial establishments, recently made available on microfilm as part of the whole 1871 manuscript census by the Public Archives, constitute a uniquely valuable source.1 Although similar details were collected in the censuses of 1881, 1891, 1901 and 1911, none of the manuscript schedules for those years have survived. While the 1861 census manuscripts have survived, their format is much more awkward to use, the industrial details being scattered through the household schedules.2 Moreover, the 1871 schedules contain a wealth of information which was not published at the time.

3 The 1871 census enumerators recorded the following details of activity in 1870 for each industrial enterprise that was included: name of proprietor(s); statement of type of establishment/nature of product; values of fixed and floating (working) capital; number of working months in the year; average numbers employed, distinguished into males and females over 16 years, boys and girls under 16 years; motive power other than manual (water, steam, horse) with the nominal force stated in units of horsepower; quantities and values of specified raw materials; quantities and values of manufactured products.

4 Only a very limited amount of this material was published in the official census volumes of the 1870s. The industrial statistics were organized primarily by various industrial types which were defined pragmatically rather than systematically. Summary data only were published for each of the 206 census districts (90 in Ontario); no industrial data at all were published for smaller area units. No details were made available for individual establishments, and the material collected on the use of inanimate power was not released in any form.

5 The summary industrial data published in the 1871 census volumes were used in important surveys of industrial activity in late nineteenth-century Canada by Chambers and Bertram3 and by Gilmour.4 But they had to make inferences based on totals for whole census districts (counties or portions of counties) and were limited by the definitions of industrial types employed by the 1871 census organizers. Our project now permits more finely tuned comparative analysis. We are also finding that our computer aggregations of the manuscript data are yielding totals significantly higher than those in the published volumes by as much as 15 per cent.

6 Since the 1871 manuscript schedules were first released in the early 1970s, several scholars have examined them to support studies of particular cities, districts or industrial types. Gregory Kealey, for example, used the Toronto data to provide a context for his study of industrial workers.5 The York Social History project, directed by Michael Katz, coded data for industrial establishments in Hamilton, as part of its analysis of industrial capitalism in that city.6 L.D. McCann has used the manuscript schedules for Halifax-Darmouth and for Pictou County, together with Dun credit ratings.7 Eve Martel reconstituted the general patterns of industry in Montréal,8 and Joanne Burgess, the organization of the shoe-making industry there.9 Paul Craven and Tom Traves have drawn on census manuscript data for evidence of industrial activity in railway workshops and yards;10 Jim Burant has featured the photographic studios of Saint John,11 and Ian McKay the confectionery and baking industry of Halifax.12

7 However, these uses of the 1870 manuscript data have been specific to each researcher's limited purpose. Different systems of classification have been used, so that comparisons with other places or industrial sectors or with later periods are almost impossible. Very few of these users have transformed the data into machine-readable form, and those who have done so have been unconcerned about making their records accessible to other researchers. Scholars interested only in one category or sector of industrial activity may be daunted by the time-consuming labour of searching through the microfilmed schedules for a handful of establishments, and could easily miss some that were slightly misplaced in storage or the microfilming process.

8 The project reported here makes the unpublished data for industrial establishments accessible, in systematic, standardized, and machine-readable format, to serve the research interests of economic, business, urban and social historians, historical geographers, industrial archaeologists, and historians of material culture and technology. By coding individual establishments within the framework of census districts, sub-districts, and enumerators' divisions, by classifying each according to the Standard Industrial Classification (SIC) and by using computer methods, we can achieve accuracy, consistency, comparability, retrievability, and aggregation.

9 In the first major phase of the work, the manuscript details for 6,821 industrial establishments in 146 urban or proto-urban centres have been made machine-readable. These establishments constitute 44 per cent of all reported for Ontario in 1871, but 61 per cent of Ontario's total industrial employment and 64 per cent of total provincial production. They also represent 20 per cent of all industrial establishments reported for the four Canadian provinces included in the 1871 census, but 28 per cent of total industrial employment and 33 per cent of total industrial production.

10 Details for all industrial establishments located within Ontario urban and proto-urban centres were read from the microfilmed manuscript schedules. All data, except for volumes of raw materials and/or products, were coded in preparation for data entry. It was decided to exclude volume data because of the extreme variety of materials and of units of measurement. A SIC code was added for each establishment, as well as location details of town name, census district name, and census enumerator's division. In the early stages of the project, details were coded for data entry by keypunch operators to the mainframe computer. Procedures were later adapted when an IBM-AT microcomputer was acquired for the project.

11 Intensive procedures were developed for verifying the basic data and for editing the data base so that it is suitable for statistical analysis, for indexing, search, and retrieval, for on-line transmission to or copying on diskette for other users, and for printing in hard copy. Particular attention was paid to the accuracy and consistency of the SIC designations and to the verification of the numeric data for capital, employment, wages, raw materials, and value of production. Proprietors' names and types of establishment/product were also checked against lists in the Dun reference books, directories and historical atlases. In cases where the census enumerator's spelling of the proprietor's name differed significantly from that in a contemporary printed source, while clearly referring to the same establishment, the record was "corrected" if this would result in a more plausible or conventional rendering of the name.

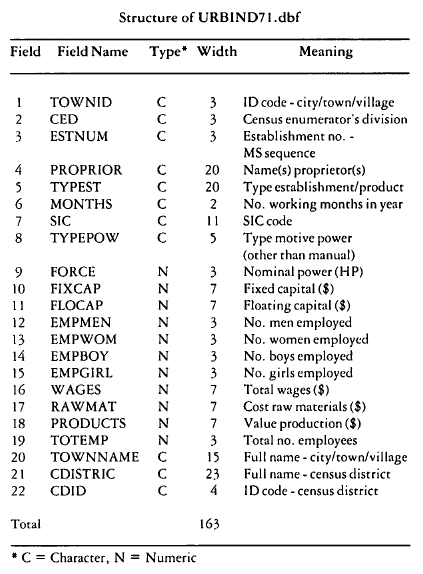

12 Every record now has the following fields in a dbase III file structure:

13 The project procedures now enable data for any establishment to be retrieved easily: details for groups of establishments may also be aggregated by geographical unit or industrial type. Both potentialities, which are likely to interest historians of material culture, are illustrated in the tables accompanying this note.

14 The 1871 manuscript data capture the industrial structure for one year at a time of transition from artisanal craftshops to factories. The aggregate patterns emerging from analysis of the data bank provide a comparative context for detailed study of specific enterprises or types of enterprises. The computer's sorting and indexing capabilities allow us to group enterprises in the same line of business, wherever they were located, and to rank them in order of any of their numeric variables, as we have done in tables 2 to 5. Historians of material culture working with archives or artifacts of a particular enterprise may know how that business compared with others in the same line in 1870. In cases where particular business records have not survived, the 1870 data may be used with other fragments of routinely generated material to piece together some account of the enterprise or type of industry.

15 Calculation of means and ratios is possible from the primary numeric data for individual establishments or for industrial or geographical aggregations, including the following: value added in manufacturing; number of employees per establishment; added value per employee; added value per unit of fixed capital; added value as per cent of total value of production; value of production per establishment; wage rates; extent of seasonal work; wages as per cent total value of production; fixed capital invested per establishment.

16 One type of data of possible interest to historians of material culture but which cannot be provided routinely by our data bank is that concerned with volumes of raw materials and finished products. The manuscript schedules did allow space for enumerators to complete details of the quantities as well as the dollar values of raw materials and of products. However, we decided not to code or enter these data for two reasons. The first was the extreme variety of materials and units of measurement — feet, bushels, yards, pounds weight, and so on — which in our judgement would have made the data bank too large and unwieldy. Secondly, we found that many enumerators did not complete the sections of the schedules relating to quantities and volumes. For example, the entry for R. Hay and Co., by far the largest cabinet-making and upholstery business in Ontario with production valued at $500,000 in 1870, specifies for materials only "140,000 ft lumber" and for products "cabinet ware of all kinds." Those wishing to trace details of quantities may use the precise locational references included for each establishment in our data bank (CDID, CED, and ESTNUM fields) to return to the original or microfilmed schedules (tables 4 and 5).

17 Some of the potential of the data bank may be illustrated by consideration of the use of inanimate energy in industrial establishments and of four different types of manufacturing business — flour mills, breweries, cabinet-makers and makers of agricultural implements. It would have been equally possible to consider sawmills, distilleries, tailors, and carriage-makers or any of about a hundred other industrial types. Each case is illustrated by output from the data bank and by discussion of particular businesses.

Display large image of Table 2

Display large image of Table 2Powered Establishments

18 To what extent was non-human energy — mainly water-and steam-, but also wind- and horse-power — used in nineteenth-century industry? This is an interesting question for historians of material culture, implying trends to mass production and standardization of manufactured articles as well as changes in the size and form of industrial buildings. Our project is revealing the 1870 evidence of non-manual energy in industry for the first time, none of the original data having been published.13

19 Less than a quarter (22.5 per cent) of Ontario's urban industrial establishments reported using water-, steam-, wind-, or horse-power in 1870. In rural Ontario, the proportion of powered establishments was nearly twice as high (44.2 per cent).14 Powered establishments were, of course, disproportionately significant in terms of investment and production, accounting for 72 per cent of the fixed capital investment and 64.5 per cent of the total value of industrial production in Ontario urban centres.

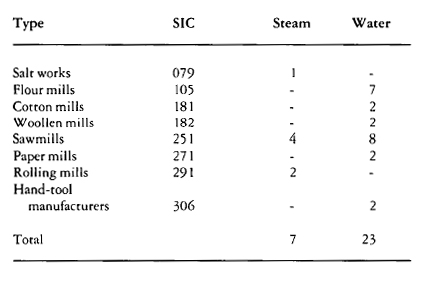

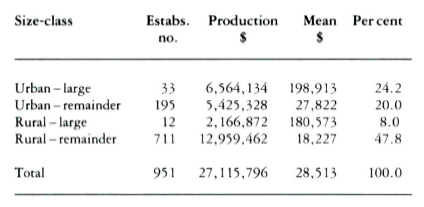

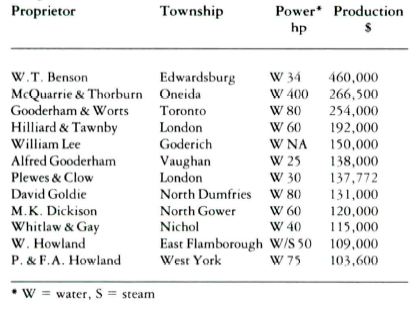

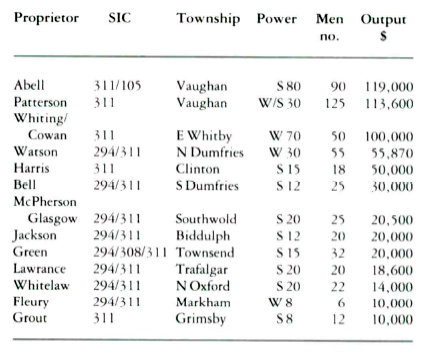

20 Establishments with the largest nominal power capacity were mainly water-powered and dominated by such traditional industrial types as flour mills and sawmills. Of the 30 enterprises with over 120 horsepower capacity in Ontario urban centres (table 1), only seven used steam-power, and the industrial types were:

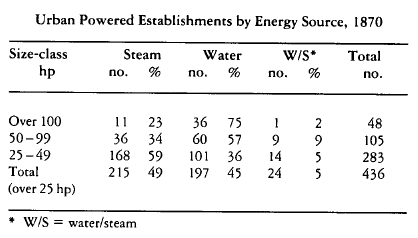

21 Steam-power was more common in urban centres than in rural areas. If we consider only establishments reporting 25 or more horsepower capacity, nearly half of those in Ontario used steam-power, compared with only 17 per cent of the rural establishments. Steam-power was also more likely to be used by establishments with smaller power capacity, as the following summary shows:

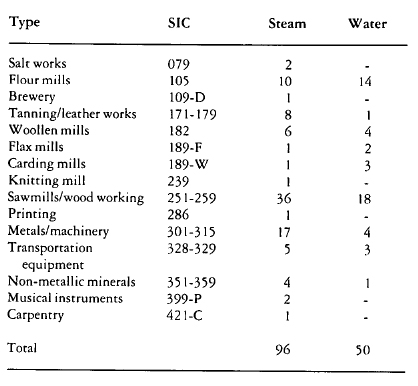

22 Steam-powered establishments were associated with a more diverse range of industrial types than those using waterpower. For example, an analysis of all urban industrial establishments reporting 20 horsepower capacity shows the following breakdown:

Flour Mills

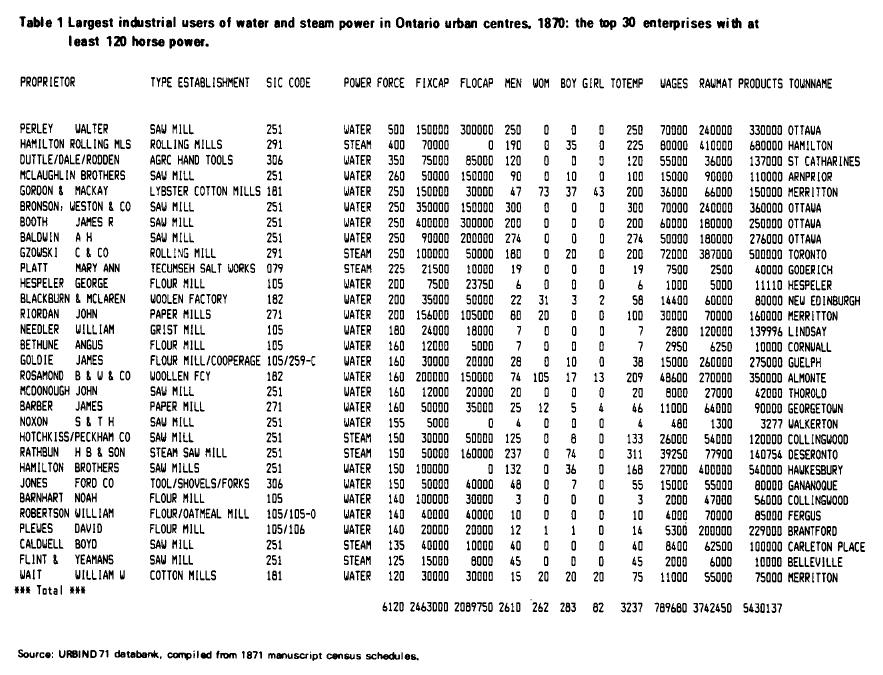

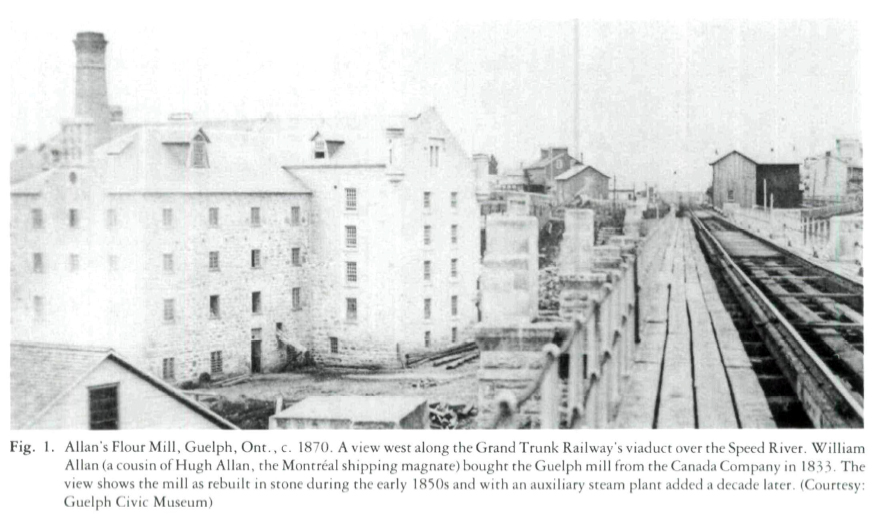

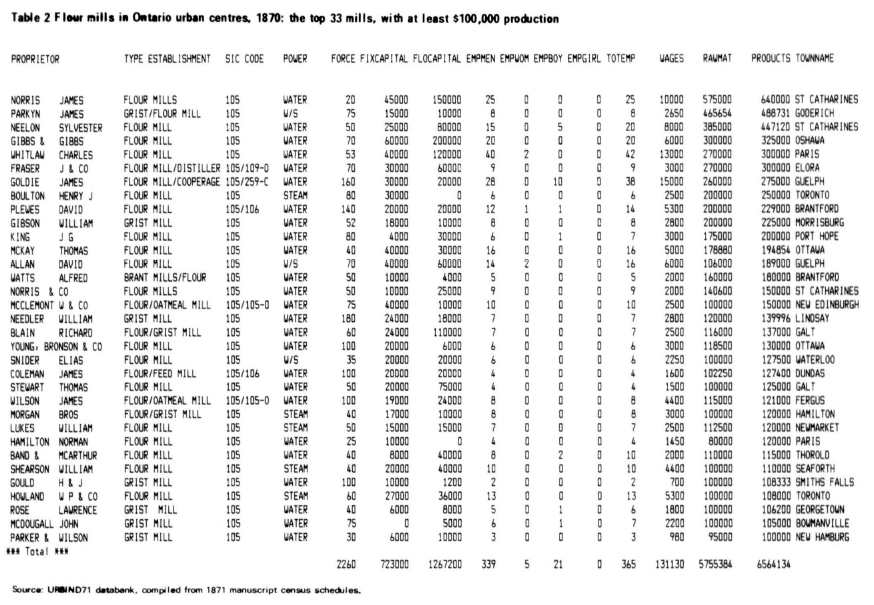

23 Flour and grist mills were always powered by inanimate energy, usually waterpower. They were the most substantial industrial enterprises in 1870, having been established in the early stages of settlement and community development in most districts. The 33 flour mills in table 2, grouped because they produced at least $100,000 worth of flour in 1870, constituted the largest single industrial type among the total number of 133 urban industrial establishments of that size in 1870. Proprietors of flour mills usually ranked among the elite in most communities, and the solid mill structures, usually of stone, were prominent landmarks.15 Flour mills were remarkable for their degree of mechanization and small labour force, a result of changes in technological processes which have been thoroughly reviewed by Felicity Leung.16

24 Although the largest numbers of flour mills were located in rural Ontario, the most productive mills were in the urban centres. The following summary table, in which "large" mills mean those with a production value of at least $100,000, illustrates this point:

25 To complement the details presented in table 2, the 12 "large" flour mills in rural districts are summarized below:

26 A map of the spatial distribution of the large flour mills in Ontario in 1870 shows that the majority — 24 urban and 10 rural of the total 45 — were concentrated in the zone between Goderich and London in the west and Toronto and St. Catharines in the east. Within that zone, 11 urban and 3 rural mills were located in the three counties of the Middle Grand Valley — Wellington, Waterloo and Brant.

Breweries

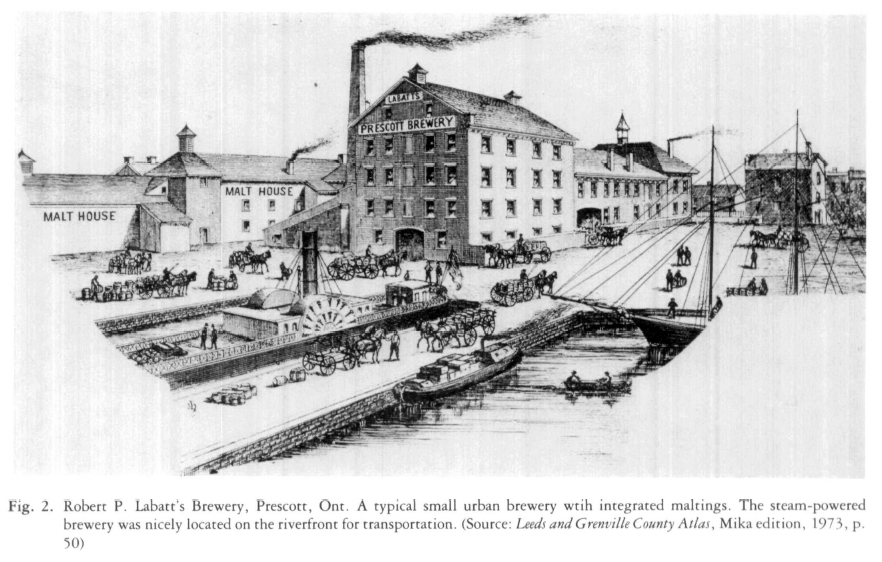

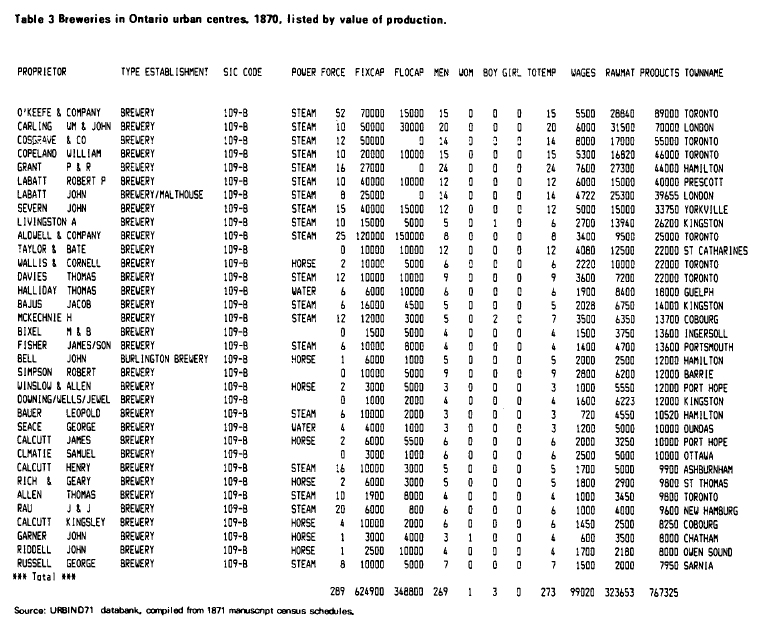

27 Breweries provide a contrast to flour mills in location and scale of operation. Because of the perishable and bulky nature of their product, these establishments were concentrated in urban centres, especially the large ones. Of Ontario's 105 breweries, 74 were in urban centres. The 34 breweries with a production of at least $7,500 are listed in table 3: Toronto had eight and Kingston and Hamilton four each, and London, Port Hope and Cobourg two each. An interesting detail was the distinctive family name of "Calcutt" for the proprietors of the breweries in Port Hope, Ashbumham (Peterborough), and Cobourg. None of the 1870 breweries was large, in relation to the enormous scale of distilleries, for example. Only three had a production value over $50,000; the urban breweries had a mean production value of $12,645, compared with the mean for rural breweries of only $8,489. Steam-power was characteristic of the somewhat larger establishments, while the smaller breweries used horsepower and sometimes only manual power.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Table 8

Display large image of Table 8 Display large image of Figure 2

Display large image of Figure 228 Though their product was ephemeral, breweries have interest for the material historian in several ways. The bottles in which beer (or other drinks, such as whisky, soft drinks and cordials) were transported and sold have fascinated the professional and amateur.17 Only two of the St. Thomas breweries considered in Herr's study appear in our data bank, that of Rich and Geary in table 3, and the smaller Reiser establishment, which produced $3,500 worth of beer in 1870. There was only one glass manufacturer operating in Ontario in 1870, H. Rutherford and Co. of Hamilton, which employed 83 workers and produced $85,000 worth of glass products.18 Glass bottles were at a premium and had to be constantly reused.

29 A significant number of the brewery businesses operating in Ontario in 1870 endured beyond the nineteenth century. Of the 34 "large" breweries listed in table 3, 11 survived until Ontario's declaration of prohibition in September 1916 under the same name. These were O'Keefe of Toronto, Carling of London, Cosgrave of Toronto, Copeland of Toronto, Grant of Hamilton, Labatt of London, Taylor and Bate of St. Catharines, Halliday of Guelph, Fisher of Portsmouth, Calcutt of Ashburnham, and Rau of New Hamburg. Seven of these 11 breweries reopened at the end of prohibition in 1927, five of them being acquired by Canadian Breweries in 1930-34. Only one of the breweries still operates, however — John Labatt of London.19

Cabinet and Furniture Makers

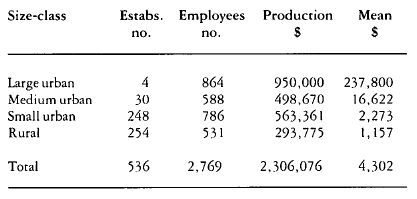

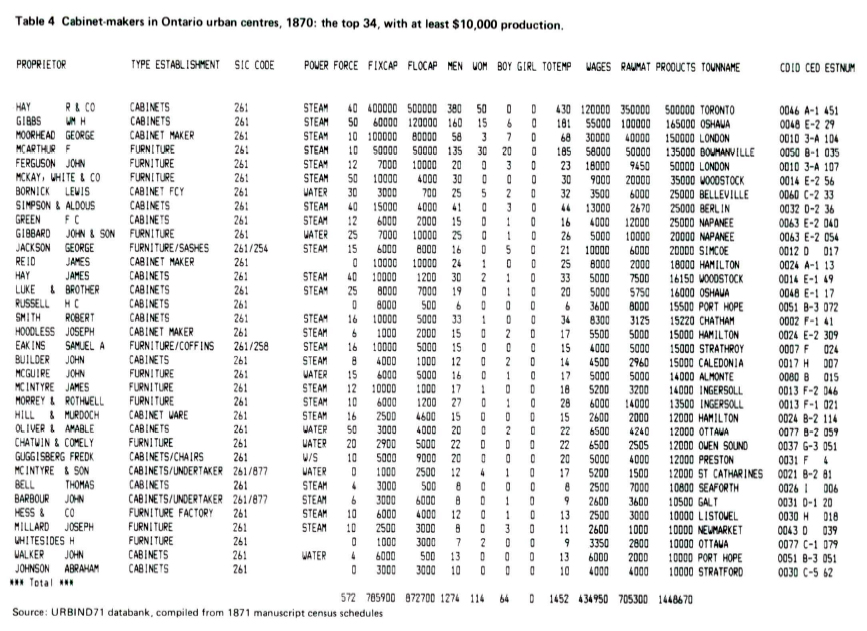

30 Cabinet-making establishments in 1870 ranged in size from the smallest one-man craftshops to a handful of the largest industrial enterprises of any type. Urban businesses were the largest and most productive, notably those with a production valued at over $10,000, which are listed in table 4, and especially the first four:

31 The four large urban enterprises, which form a class of their own, made over two-fifths of the total value of all Ontario furniture, and the medium-sized urban businesses contributed more than another one-fifth. The rural establishments, only three of which had a total output worth between $5,000 and $10,000, produced less than 13 per cent of the total Ontario value. The mean value of production per establishment (right-hand column) declined systematically through the four size-classes, as did the mean value of production per worker, from $1,099 in the four largest enterprises to only $553 in the small rural shops.

Display large image of Table 10

Display large image of Table 10 Display large image of Table 11

Display large image of Table 11 Display large image of Figure 3

Display large image of Figure 332 Virtually all the establishments producing over $10,000 used steam-power; for the small businesses with under $5,000 output, the proportion with non-manual energy declines to between one-quarter and one-third. Many cabinet-makers found it necessary to combine the making of wooden furniture with other activities, one of the most common being coffin-making and general undertaking services; another was the repair of furniture.

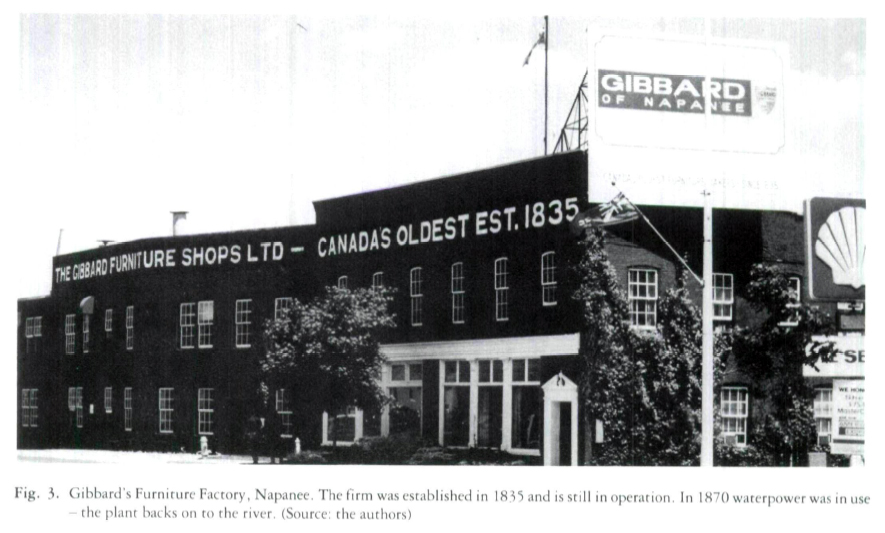

33 The cabinet-making and furniture industry has received a good deal of attention from historians of Canadian material culture; one factor in this interest is probably the collectable value of the artifacts. Only one of the several studies that have been traced has reported using the 1871 manuscript census data.20 Although Gibbard of Napanee may have been the only firm listed in table 4 to have lasted under the same name to the present, records for several other enterprises have survived, including those of Thomas McIntyre of St. Catharines21 and those of the leading furniture manufacturer, described below.

34 R. Hay and Company was nor only the largest furniture factory in Ontario, but also the third largest industrial employer, and ranked seventh among all establishments in value of production. Until 1870, this business had been Jacques and Hay (familiarly known as "Jakesenhay"); it had started in Toronto in 1835 and was the largest factory of any kind in that city by 1856.22 It continued to expand in the 1860s, practically doubling its value of fixed capital, number of male workers and value of production between the 1861 and 1871 censuses. Along with the other three large furniture factories, it was notable for the employment of women. In 1870, John Jacques retired, and Robert Hay took Charles Rogers (chief carver) and George Craig (head turner) into a partnership that lasted till 1885, when Hay himself retired. The business was then reorganized as Charles Rogers and Sons Co. which continued to operate until 1922.

Display large image of Figure 4

Display large image of Figure 435 Company records reveal the magnitude of orders, public and private, which were fulfilled by the company. In 1866, the Globe wrote:

The firm's records also document the subsidiary operations developed from 1854 at New Lowell, in Sunnidale Township, along the line of the Northern Railway near Barrie.24 Valuable hardwood forests there were transformed into parts for the Toronto factory, under the less-than-efficient management of Peter Paton, who was Hay's brother-in-law. According to the 1871 census, Hay and Paton's sawmill and furniture enterprise employed 32 men and used a 50-horsepower steam engine to perform the primary processes in furniture making.25 Chair backs, stretchers, top rails, legs, spindles, and bedposts were turned at New Lowell and shipped in huge quantities to Toronto, and animal hair was prepared for upholstery.

Manufacturers of Agricultural Implements

36 As Phillips has asserted, many of the establishments in this sector were "little more than blacksmith shops which supplied a variety of rudimentary implements for a local demand... the typical small Canadian manufacturer diversified his output."26 Consequently, there are greater difficulties of definition and categorization with this industrial type than with others. We have tried to identify all businesses in this sector from the lists of their manufactured products as well as from the stated type of establishment, using compound SIC designations when necessary. A large number of the smaller enterprises combined a foundry and machine shop with the making of agricultural implements, a practice well illustrated in the print of Robert Whitelaw's Oxford Foundry. Even the very largest manufacturers also diversified, producing a large variety of small tools and implements, perhaps in combination with boilers, steam engines and large mill machinery. The Joseph Hall Company, established in Oshawa in 1857 as a branch plant of the parent enterprise in Rochester, New York, was chiefly noted for steam engines and boilers but also produced mill machinery, printing presses, turbine waterwheels, and agricultural implements.27

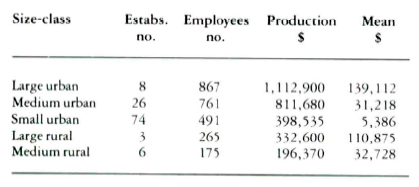

Display large image of Table 12

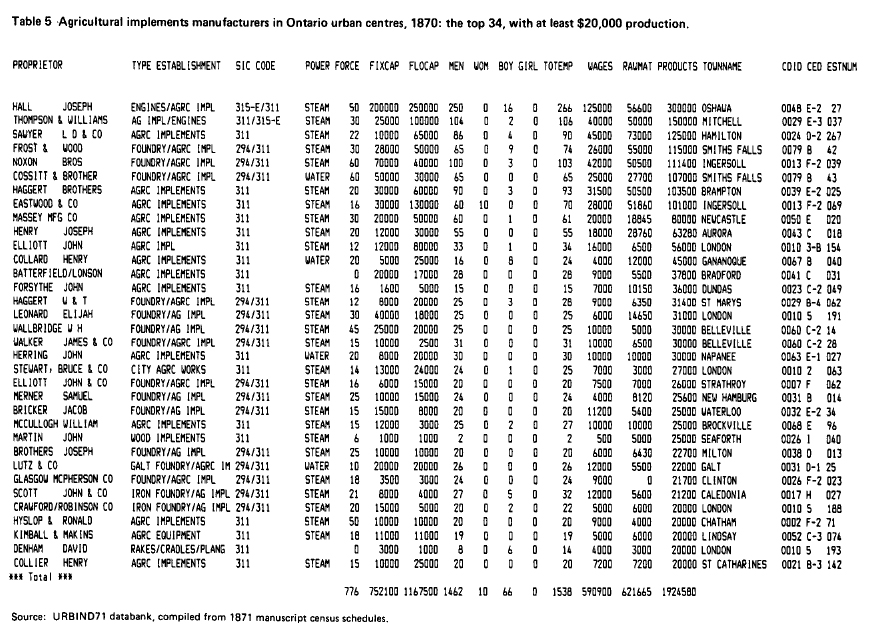

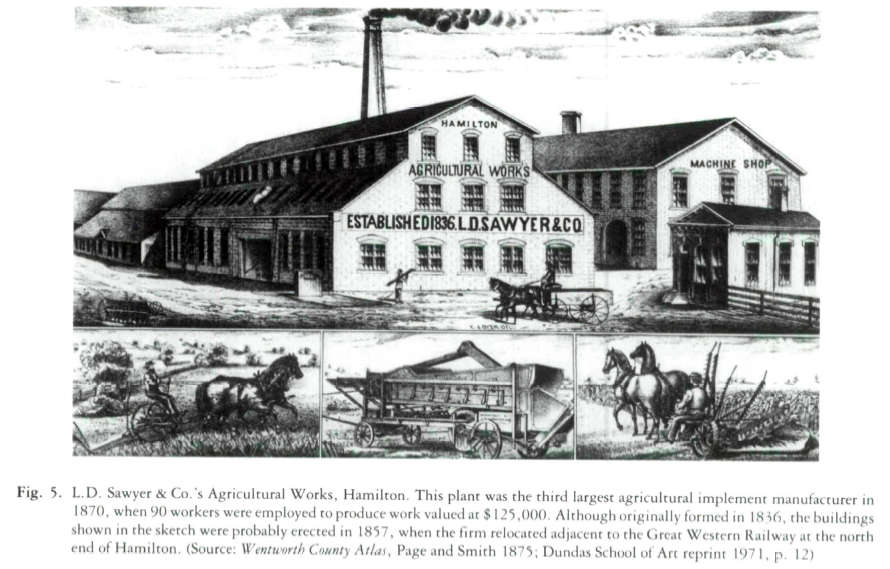

Display large image of Table 1237 Compared with the furniture industry, the making of agricultural implements was less concentrated in urban areas and characterized by more producers in the medium range, with output of between $25,000 and $100,000. While the most substantial producers of implements were located in urban centres in 1870, these tended to be smaller and middle-sized towns rather than the large cities (table 5). Based on our URBIND71 and RURIND71 data banks, we have summarized the general structure of the industry in the following table, in which "large" denotes establishments producing over $100,000 worth, and "medium" those producing between $20,000 and $100,000 worth: There were, in addition, some 56 rural establishments using non-manual power, but producing under $20,000 worth of implements in 1870.

38 A notable number of the larger and middle-range manufacturers were in rural areas, appropriately dose to their main markets. To complement the urban establishments in table 5, we present a list of the 13 rural businesses that had an output of more than $10,000 in 1870:

Display large image of Figure 5

Display large image of Figure 539 In 1870, the Ontario agricultural implements industry Future Directions reflected a period of prosperity in the 1850s and 1860s, when local entrepreneurs had adopted American inventions to supply local markets. Communities took pride in "agricultural works," many of which are illustrated in the county atlases of the 1870s. The 1871 manuscript census evidence also suggests the instability of businesses in this period. Massey and Harris, which would become the giants of the Canadian industry, were only middle sized in 1870. Their greatest growth would occur after they relocated, Harris from Beamsville to Brantford in 1872 and Massey from Newcastle to Toronto in 1880.

40 For historians of material culture, our URBIND71 and RURIND71 data bases constitute a valuable systematic, standardized resource, which can complement other sources to provide context for studies of particular enterprises, communities or industrial types.

Future Directions

41 The "1871 project" is now taking two directions. One is to explore the feasibility of extension to rural Ontario and to the other three provinces recorded in 1871: Quebec, New Brunswick and Nova Scotia. The other is to apply statistical analysis techniques to the records in the data bank, in order to explore various questions in the history of Canadian social and economic development.

42 A report is available describing the objectives and project procedures and outlining the research potential of URBIND71: Elizabeth Bloomfield, Gerald Bloomfield and Janine Grant, with Peter McCaskell, Industry in Ontario Urban Centres, 1870: Accessing the Manuscript Census (1986), 60 pp. It may be ordered from Publications, Department of Geography, University of Guelph, Guelph, Ontario, NIG 2W1, for $7.00 (cheque with order, please).