Articles

From Workshop To Factory:

The Furnituremaker

Cet article examine la vie professionnelle des travailleurs du meuble en Ontario, au XIXe siècle. Il étudie d'abord le cas des premiers artisans qui devaient, pour vivre, exercer souvent divers métiers et qui fabriquaient, outre les meubles, un large éventail d'objets en bois. La formation et l'apprentissage se faisaient souvent de façon informelle. La concurrence était forte, surtout à partir des années 1830, époque à laquelle les produits américains arrivèrent sur le marché et que les fabricants canadiens purent commander aux usines américaines des pièces bon marché. L'ouverture des usines Jacques et Hay à Toronto et à New Lowell, dans les années 1850, marqua le début de la production industrielle à grande échelle en Ontario. Un autre changement eut lieu à la fin du siècle dernier avec la fusion de la plupart des grandes usines de meuble ontariennes en une seule société, la Canada Furniture Manufacturers Limited. Les techniques traditionnelles cédèrent le pas à la production en série et à la mécanisation. Toutefois, les changements se firent graduellement et on aurait tort d'idéaliser la vie des premiers artisans.

This paper examines the working life of Ontario's nineteenth-century furniture workers. It begins with a consideration of the early craftsman who often held a variety of jobs in order to survive economically and who produced a wide variety of wooden items in addition to furniture. Training and apprenticeship often were arranged informally. Competition was keen, particularly by the 1830s when strong competition was felt from the United States and when Canadian manufacturers could order inexpensive parts from American factories. In Ontario, large-scale factory production began with Jacques and Hay's factories in Toronto and New Lowell in the 1850s. Further changes came at the turn of the century with the amalgamation of most major furniture factories in Ontario under the banner of Canada Furniture Manufacturers Limited. Traditional skills declined in the face of mass production and mechanization. Changes came gradually, however, and it would be a mistake to romanticize the life and work of the early craftsman.

1 The working world of the nineteenth-century furnituremaker was complex and varied from the beginning. It is not enough to focus on the transformations which occurred through the interaction of new technology or mass production. Certainly these had profound effects; but from the earliest days of the nineteenth century, the furnituremaker faced challenges which we too often associate only with a later era. He faced periods of great economic uncertainty, changed jobs frequently, moved from place to place, worked in co-operation with others by making or finishing only one part of a piece of furniture, and engaged in strenuous competition with other makers or shops both inside and outside his community. Furnituremakers came from a wide variety of backgrounds, possessed widely varying degrees of skill, learned their work through apprenticeships both formal and informal, and developed numerous ingenious ways of selling their work and attracting customers. With increasing automation, unskilled labourers began to replace traditional craftsmen. Concentration of factory ownership and amalgamation by the turn of the century further impersonalized the work environment. Still, new materials such as rattan required much hand labour and old skills of woodworking and finishing continued to be necessary.

2 Much would be lost if we saw the work of the nineteenth-century furnituremaker only as a series of developments on the way to mass production. This paper attempts to provide a broad picture of the working life of a particular group. To do so, it draws on the experience of a wide variety of individuals, shops, and factories, and a wide variety of documentary sources.

3 Reference to Daniel Tiers of York, the first furnituremaker to advertise in an Upper Canadian newspaper, introduces us to the working world of many an early craftsman and entrepreneur. His advertisement in the Upper Canada Gazette for 23 January 1802, is couched in the polite, self-effacing language characteristic of its day. Tiers, a chairmaker, "returns his sincere thanks to his Friends and the Public for the great encouragement he has hitherto met with, and begs leave to inform them, that he now intends carrying on his business in all its branches without delay By his great attention to perform his promises, [he] hopes to merit protection and support."1 Despite his hopes, economic reality seems to have dictated that Tiers find employment other than chairmaking to supplement his income. He served as constable in the Town of York and was Keeper of the Court of Quarter Sessions and the Home District Court.2 In 1808, he seems to have given up chairmaking altogether and opened a "Beef Steak and Beer House" in York.3 In 1809, he rented space to Robert Palmer, who advertised "fashionable hair-dressing" for ladies and gentlemen.4 The following year, Tiers established the Red Lion Inn, on Yonge Street just above Bloor.5 By 1811, he extended his entrepreneurial activities to storekeeping, offering to buy produce from local farmers and evidently maintaining his ties with the courts by offering for sale "Blank Deeds, Bonds, Memorials, laws passed in the two last Sessions, &c."6 In 1812, Tiers made an arrangement with the editor of the York Gazette to handle produce sent in by subscribers in lieu of payment for their newspaper subscriptions.7

4 All this about Daniel Tiers suggests a pattern found often in Upper Canada and noted by historians elsewhere, that furnituremaking provided a precarious livelihood at best and that many early craftsmen had to supplement their income by other means. Some eventually gave up making furniture altogether, turning to innkeeping or opening a general store.

5 Another common pattern in the early nineteenth century saw the furniture craftsman turn his attention to other branches of woodworking. Some combined their cabinetmaking skills with those of carpenter, joiner, turner, carver, or cooper. The short-lived partnership of Ford and Carfrae advertised in 1821 as "house carpenters and cabinetmakers" on King Street in York, but also manufactured "Brewer's guile Tuns, Coolers, Stock-pieces, Water Cisterns, Common and Copper Chambered Pumps, do. do. Force Pumps, Patent Pumps to discharge double the quantity of water and so constructed as not to freeze, Hydraulic Engines for watering gardens, Distillers Steam Conductors, Rain Water Cisterns fitted up with or without Pumps." They also noted "Buildings contracted for, and the laying of under-ground Conduit water conveyances" and "Orders from any part of the Province, post-paid, will be punctually attended to."8

6 At Drummond Hill, near Niagara Falls, cabinetmaker Joseph Merriam advertised a wide variety of fashionable furniture along with "Ornamental Chimney Pieces" and agricultural machinery. An advertisement of 1824 reads: "J.M. can refer intended customers to furniture made at his Factory in gentlemen's houses in all parts of the District. Wire SCREENS and SIEVES, a variety of sizes, always for sale. Fanning Mills made on the most approved construction." Like many others, Merriam did at least part of his business on the barter system, advertising that "Country produce and Boards of every description will be received in payment."9 Garry Camp, also working in the Niagara area, operated a cabinet factory, but also advertised as a millwright (fig. 1).10

Display large image of Figure 1

Display large image of Figure 17 In the larger towns or longer settled areas of the colony, such as York, Niagara, and Kingston, furniture craftsmen of various sorts might try to specialize. As noted earlier, Daniel Tiers advertised as a chairmaker. Perhaps more successful was Chester Hatch, who advertised "chairs of all descriptions which will be warranted good" in the Kingston Gazette of 23 November 1816. By the summer of 1823, Hatch was successful enough to open a branch in York, which even then was surpassing Kingston as a centre of trade and commerce. In York, Hatch offered "FANCY, BAMBOO and WINDSOR CHAIRS" and settees "for Cash or Produce" and advertised "All Sorts of Sign and Fancy Painting done with Neatness and Dispatch."11 As late as 1857, he was listed in a Kingston directory as a chairmaker on Princess Street; although by 1865, possibly after his retirement, he was noted as the operator of a boarding house close to his old address.12

8 Other specialists included upholsterers, ornamental painters, carvers, turners, and marble cutters — specialists in the sense that they often carried out very specific and skilled tasks related to the making of furniture.

9 In 1825, W. Meckham advertised as an upholsterer in York and offered to pay cash for feathers and for horse and cattle hair. Meckham was still in business in 1834, referred to in a directory of that date as an "Upholsterer and Hair Manufacturer."13 As a "hair manufacturer" he was probably both cleaning hair for use in stuffing and weaving haircloth for upholstery. A large part of his business may have involved the making of mattresses.

10 Ornamental painting also was closely allied with furnituremaking, this at a time when most furniture of light-coloured common woods was painted, stencilled, or grained to imitate more expensive materials. Alexander Drummond offered in his shop at York "a large assortment of FANCY AND WINDSOR CHAIRS, warranted to be of the best quality, and finished in the latest New-York fashions." He also, however, specialized in "Heraldry, Historical and Masonic Painting; Views of Gentlemen's Country Seats, perspective Drafts of Machinery, Fancy Pieces on Silk and Velvet, Fancy Pieces on Glass, Christalizing and Tablet Painting, Transparent Window Curtains; Labelling and Enamelling on Show Cases and Apothecary's Bottles." He painted imitations of almost any exotic wood or stone, painted oil cloths and gilded, bronzed, and polished "Steam-Boat Cabins, Public Halls, Pulpits and Altars."14 His first appeal to the public is dated 26 August 1829; however, it is not known how long the enterprising, immodest Mr. Drummond stayed in business.

11 Carvers also were allied with the furniture trade, and the most skilful among them might offer their services to others less versed in the art. Often it is assumed that a piece of early nineteenth-century furniture is the product of one craftsman's hand. In fact, several may have been involved, particularly if elaborate carving, turning or inlay were involved. In an advertisement dated 1832 (fig. 2), Z.B. Porter of St. Catharines offered a wide variety of furniture for sale. But most interesting is the fact that he did carving to order, specifically "Sideboard and Bureau Columns and FEET, PILLARS and CLAWS for Tables; FIGURE-HEADS for Vessels, &c. &c."15 In 1832, St. Catharines was an up-and-coming place made prosperous by the building of the Welland Canal. Evidently a furniture craftsman with specialized skills could make a living there — although, again, it is not known how long Porter remained in business.

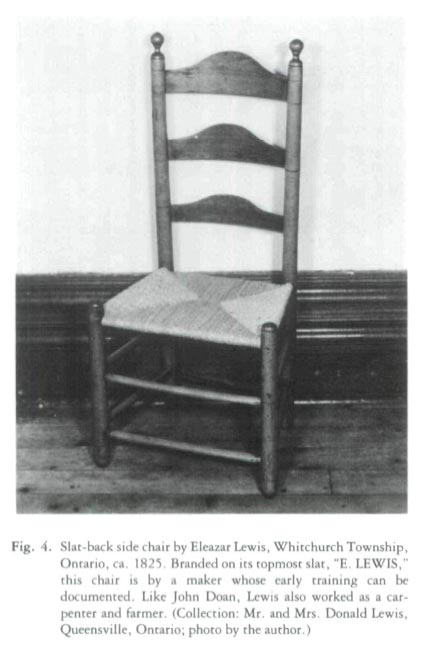

12 Turning, like carving, could be a specialized craft. In a Toronto directory from 1850, John and Joseph Parkes advertised turned bedposts, table legs, bureau and sofa feet, and drawer knobs. But they also made turned wooden screws, mallets, pail handles, bungs, hat pins, and bagatelle and billiard balls.16

13 By the 1850s, marble workers also came to be associated with the furniture trade. In 1856, D.C. and W. Yale of Toronto announced that they had extended their "Monumental Works" to include the manufacture of marble chimney pieces, centre tables, stand tops, and "Furniture Facings."17

14 In speaking of craftsmen who combined their furniture related skills with other trades or occupations, I have referred so far only to those who lived in towns and villages. Rural furniture craftsmen often combined their skills with those of carpentry or farming. Furniture-making might often be a wintertime occupation, secondary to the tasks of farming or building which would assume first importance with the spring thaw. It could easily be assumed that the furniture made by wintertime cabinetmakers or chairmakers would be poorly constructed or designed. Yet the surviving material evidence suggests that this was not always the case. Much crude, utilitarian furniture was made on the farms or in the house carpenter's shop; but the same could be said of more urban areas as well. The peculiar history of Upper Canada, which brought skilled craftsmen and skilled farmers alike to seek their fortune on the land, undermines the assumptions of a more settled society.

Display large image of Figure 2

Display large image of Figure 2 Display large image of Figure 3

Display large image of Figure 315 The work of John Doan (1768-1852) may be used to illustrate this point. His furniture is among the finest ever made in early Ontario; yet he earned most of his livelihood as a farmer in East Gwillimbury Township, York County. Like his brother, Ebenezer, he was a member of the Children of Peace and assisted in building the magnificent Sharon Temple. He was trained in Pennsylvania by his considerably older brother, Jonathan. Jonathan was a craftsman of some renown, having built the New Jersey State House of 1792 and Stanhope Hall at Princeton University. John Doan's work is probably best exemplified by a bird's-eye maple chest of drawers (fig. 3) and several desks which can be firmly attributed to him on the basis of signatures and descent through the Doan family. Obviously, he was a highly skilled furniture craftsman; yet the "official record," the directories, the census returns, and so on, list him only as a farmer or, occasionally, as a carpenter.18

16 Other parts of Ontario where furniture was made by skilled craftsmen in their "spare time" include the Niagara Peninsula and Waterloo County. There, some remarkably fine work was done by Pennsylvania German and German craftsmen of skill and ingenuity. Yet only rarely are their furniture making activities part of the written record.

17 Given the vagaries of their occupation and the frequent need to supplement their income by other means, how did Ontario's earliest furniture craftsmen learn their trade? Some received their training before coming to Upper Canada; Daniel Tiers19 and John Doan,20 for instance, in their native Pennsylvania; Joseph Merriam in Massachusetts;21 and Alexander Drummond in England.22 It is reasonable to assume that in Upper Canada, as elsewhere, many craftsmen learned their trade informally, from a father, uncle, or older brother. Or a formal indenture of apprenticeship could be undertaken. Eleazar Lewis, who made the chair shown in figure 4, was one craftsman whose early training can be documented by a formal agreement.23 Lewis, an orphan, was brought up by Joseph Collins, who consented to his apprenticeship to Reuben Burr, a "Joiner and House Carpenter" in Whit-church Township, York County. The indenture was signed on 15 June 1809, when Lewis would have been seventeen years old.24 It was to continue in effect until 1813, when he would turn twenty-one, the traditional age of majority. For his part of the bargain, the master, Reuben Burr, agreed to instruct his apprentice in "the art and mistery of Carpenter or Joiner Business" and provide him with room and board, clothing, washing, mending, and four months' schooling. (Lewis evidently could not write as he signed his indenture with a cross.) At the end of the apprenticeship, Burr was to outfit him with two suits of clothes, "one of them new." Lewis, in turn, agreed to serve his master, "his secrets keep," and "his lawful Commands obey." He put himself under his master's complete control, agreeing not to "Commit fornication" or to marry, not to play cards or dice, not to buy or sell, not to "absent himself day or night from his s[ai]d Masters service without leave," and not to "haunt Ale Houses Taverns or playhouses." Lewis gave up virtually all his personal rights and liberties in order to learn a trade.

18 Once an apprenticeship was served, a craftsman might open his own shop, if he had the necessary capital. Or he might work as a journeyman — that word coming from the French journée, meaning "daytime." In other words, he might seek employment by the day from a furnituremaker who had his own shop. Occasional calls for apprentices or journeymen cabinetmakers are to be found in Upper Canadian newspaper advertisements, although one is left with the impression that both were hard to find. Another alternative was a situation where a master craftsman might manage a business owned by an investor. This was the case, for example, in Niagara in 1834 when Rafaela Gabiott purchased a chair factory and paint shop and hired Joseph Poncett to superintend the business for her.25

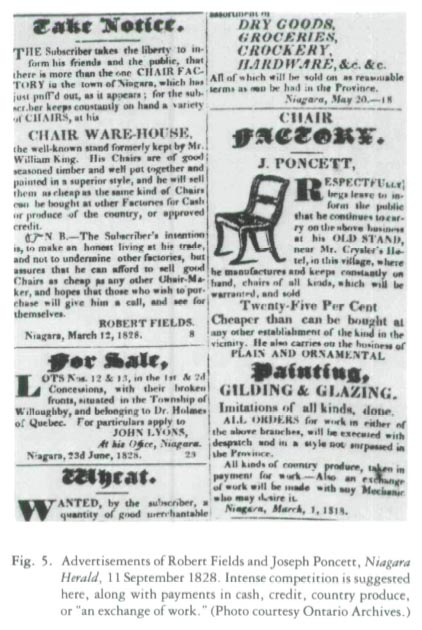

19 Poncett previously had his own business in Niagara. One of his advertisements from the Niagara Herald of 1828 (fig. 5) promises work "not surpassed in the Province," but at 25 per cent less than his competitors'. Typically, he offered to take country produce or "an exchange of work" in payment.26 On the same page of the Niagara Herald is another advertisement, this time by Robert Fields, suggesting intense competition. Mr. Fields, in a rather disdainful tone, noted that "there is more than one CHAIR FACTORY in the town of Niagara, which has just puffd out, as it appears." He offers to meet his competitors' prices and ends on a rather self-righteous note: "The Subscriber's intention is, to make an honest living at his trade, and not to undermine other factories, but assures that he can afford to sell good Chairs as cheap as any other Chair-Maker. " Evidence from the newspapers suggests that this sort of intense competition was often the rule, rather than the exception, in many upper Canadian communities. It was compounded by the arrival of increasingly large quantities of furniture and furniture parts from the United States.

Display large image of Figure 4

Display large image of Figure 420 Detailed customs records from the lake ports of Upper Canada are scarce, the official records often containing no more than the total value of imported goods. Even these may not present the entire picture. A report to the Legislative Assembly in 1835 stated: "It would be very difficult to ascertain the extent of trade of Upper Canada with the United States; the contraband commerce carried on in defiance of fiscal regulations imposed by the United Kingdom Parliament, and of the United States tariff laws, is very extensive—"27 The quantity of imports was large enough, however, that chairmaker Chester Hatch, with the support of 259 "mechanics of Kingston and the province generally," petitioned the Assembly "that means may be devised for stopping the great influx to this Province of manufactured articles from the United States, which so interferes with the industry of petitioners, as nearly to render abortive their utmost efforts to procure an honest livelihood."28 Ironically, even the ornate Speaker's chair in the legislative buildings themselves had been imported from the United States.29

Display large image of Figure 5

Display large image of Figure 521 Not only individual customers, but retailers and even furnituremakers themselves, imported furniture from the United States. Chairmakers were apt to order parts for assembly, as shown by entries in the York customs records such as that of 24 August 1821, where "500 chair bottoms" are noted.30 Major importers included P. and P.J. O'Neill, whose establishment on King Street East in the late 1830s and early 1840s was perhaps the largest in the city of Toronto. Toronto customs records of the time indicate that they imported veneer, lumber, varnish, clocks, piano wire, ivory, ebony, feathers, and finished pieces of furniture.31 In addition to being piano and cabinetmakers, they also were auctioneers and commission agents. They frequently sold new furniture at auction, presumably acting as agents for other cabinet-makers. This represents the beginning of a trend away from the older arrangement where a purchaser of furniture in Upper Canada would likely visit the cabinetmaker's shop itself. It must have seemed a profound change in the working life of any craftsman when the direct link between maker and buyer was broken. The process of change was accelerated by the advent of the "furniture wareroom," the forerunner of the furniture store of today, which came into being in many communities by the mid-nineteenth century. It coincides with the development of a new type of advertising, strident and demanding.

22 Along with the commission sale and the auction, a furniture lottery was another way to sell at this time. Occasional references appear in newspaper advertisements to the sale of tickets on an assortment of new furniture for the home. The St. Catharines cabinetmaker, Thomas M'Intyre (or McIntyre), held one such lottery, in March 1842. Two hundred tickets were offered for sale at $2 apiece on an assortment of new furniture valued at $400.32

23 Thomas M'Intyre is one of a very few Ontario furniture craftsmen whose working records survive. Craftsmen, like other nineteenth-century workers, left few written records behind. What they wrote — orders and accounts — had little value once the work was done or the bills paid. Like most of their contemporaries, many had little formal education and were not likely to be scribblers. A M'Intyre notebook, containing entries from 1842 to 1862, provides a rare glimpse at the working life of an Ontario furniture craftsman of the mid-nineteenth century. It is incomplete and must have been only one of many books kept around the shop or in the office, but contains some interesting information none the less. One undated entry from the late 1840s or early 1850s contains a rough sketch of the supporting base of an Empire-style centre table. This table was being custom-made for William Beatty. Despite the rise of the warerooms and the factories, this was still not an uncommon practice. The notes accompanying the sketch are simple and straightforward, yet probably enough to tell anyone used to making centre tables at this time what to do. They contain a reference to another piece probably being made in the shop at the same time: "William Beatty to have a walnut veneered Centre Table made bold and massy, medium size, pillar made same as side table pillar making for Ross — O.G. rim."33 Another simple sketch, with measurements added, accompanies a hurried notation: "Mr. Connoly to have a Scotch Bureau made of good solid walnut right off."

24 Along with orders for new furniture are references to alterations and repairs, an important part of any furniture craftsman's work, "putting New Arms on Chair" or "Putting Rockers on Arm Chair" are typical entries. As we might expect, other wooden articles are mentioned as well, as in "turning alley balls," "Turning Awl handles," "Taking down, altering & putting up 2 window cornices," "trimming pulpit & Desk," "a Hair work frame made of pine pretty well," or "walnut coffin Elizabeth Baker aged 21 years." Cabinetmakers had long been making coffins, yet coffinmaking and "undertaking" do not take a prominent place in Ontario cabinetmakers' advertisements until the 1840s. By the time of Confederation, many cabinetmakers in smaller communities earned a large part of their income through funeral services, often in conjunction with a retail furniture store. It was becoming more difficult to compete with large furniture factories and their customers' desire to choose from finished furniture in a showroom. Ultimately, many would stop making even their own coffins, but still would profit from embalming and from hiring out a hearse (fig. 6).

25 The M'Intyre shop, which eventually grew to be a small factory, was faster than many to take advantage of modern advances in furnituremaking technology. In 1834, the year of its founding, the shop offered sofas "spring-stuffed in the best manner." Spring upholstery had been patented in England only six years earlier.34 By 1843, M'Intyre was using a lathe propelled by water power. He also was using special equipment to produce "Lindley's Patent Bedsteads."35 Patent furniture was just beginning to come into vogue in the 1840s at a time when new technology and sheer gimmickry brought widespread attention to furniture that adjusted, opened, or moved in some novel way. Beds were particularly susceptible to the craze for "improvement." The first Canadian patent taken out on a piece of furniture was for the invention of "An Improvement on Patent Bedstead for the Sick and Wounded" by Joseph Watson of Oxford County on 31 January 1851.36

26 Patent furniture, water-powered lathes, and spring upholstery all suggest a working world very different from that of the early nineteenth century. Changes were coming to the shop of Thomas M'Intyre and to other shops across the province. Woodworking machinery, some of it developed first for use in sawmills, was gradually finding its way into the cabinetmaker's shop. Much of it came from the United States, but patent records indicate that Canadians were not slow to bring new ideas to woodworking. The earliest patent taken out by a Canadian cabinet-maker was that of Philip Schoolcraft of the Seigniory of St. Armand, District of Montreal, on 15 May 1830, for a "Machine for Cutting Timber into Sidings, Clapboards, Shingles, Laths."37 Five years later, Samuel and Lyman Judson of Leeds County, Upper Canada, patented "A machine for Planing, Jointing, Grooving, Tongueing, Bevelling, Rebating, Beading and Otherwise Preparing for Immediate Use Boards Plank, and Other Description of Timbers."38

Display large image of Figure 6

Display large image of Figure 627 The first to use the new machinery on a grand scale was the celebrated Toronto firm of Jacques and Hay. John Jacques and Robert Hay entered partnership in Toronto in 1835. By 1850, they employed more than 100 workmen. The English traveller, William Chambers, wrote of their factory that year:

This new machinery was run by steam power, and many a cabinetmaker's shop took on the eye-catching name of "steam cabinet manufactory" in the 1850s. In celebration of steam, an Ingersoll cabinetmaker, James McIntyre, wrote this poem, published originally in the 1880s.

It is prodigious power of steam;

And our little fast steam horse,

How he works with mighty force.

In his mouth chips and saw dust;

Which heats the blood in his veins,

Then how he saws and bores and planes.

But all the time he gaily trotts,

And every day he is full able

To make many a chair and table.

He feels so good he oft does snort,

As he trotts along his course,

Our little frolicksome steam horse.40

28 The transition to steam power from human power, animal power, or water power did not come suddenly or universally. Nor was the new machinery adopted in all shops at the same time. Many smaller shops probably never mechanized, but drew more and more of their income repairing or re-upholstering furniture, selling factory-made furniture in a showroom, or undertaking. Even as late as 1875, the Canadian Patent Office Record and Mechanics' Magazine carried an article on the work of the cabinetmaker and upholsterer and hardly mentioned steam power or the new machinery. Instead, traditional handwork was described, while an accompanying plate showed hand tools and the interior of a small shop.41

29 One major reason for the rise of furniture factories in late nineteenth-century Ontario was expansion of the lumber industry. Lumbering in the Ottawa Valley, Simcoe County, the Grand Valley, and the area around Georgian Bay in the 1850s and 1860s brought a seemingly limitless supply of raw materials and lured new capital into British North America.42 Railways linked the forests to growing towns and cities.

30 The firm of Jacques and Hay, the first to use the new machinery on a large scale, was quick to exploit the forest resources of Simcoe County which, in the 1850s, were linked with Toronto by the Ontario, Simcoe and Huron Railroad. By 1854, the firm had established a sawmill near Barrie and was anticipating the development of a community to be called New Lowell. The name recalls the model industrial city of Lowell, Massachusetts, and possibly even Robert Owen's New Lanark in Scotland. Robert Hay was a native of Scotland, while John Jacques received his training there. Of their personal life we know relatively little. In later years, Robert Hay was elected Conservative Member of Parliament for Toronto Centre and was known as a strong prohibitionist.43 Whether or not New Lowell was ever intended as a model community for Jacques and Hay employees is a matter for future research.

31 In addition to the sawmill, other buildings were erected where large quantities of parts were made for chairs and bedsteads. Correspondence between the Toronto and New Lowell operations suggests some of the difficulties of early factory production in Canada: orders frequently were confused, delays seemed inevitable, and reliable workmen were hard to find.

32 Despite the province's growing population, at times workmen had to be brought in from outside. A letter dated 26 September 185544 notes that "Mr. Blair promises to push the sawing, having got the promise of men from the States." During the American Civil War, some deserters, or "skedadlers," were hired, two being sent up to New Lowell with a note reading. "The Bearer of this Letter and his Friend are two 'Skedadlers' from the States; they are very destitute and are willing to do anything for very little money...." They were to be offered their board plus $4 a month.45 In 1869, a message stated, "I called at the Emigration office today about men and they are expecting a number in tomorrow and will endeavour to get some to go out."46 Most of the men who worked in and around New Lowell cutting trees, running the sawmill, making furniture or furniture parts, were not skilled craftsmen, and the best of them were hard to retain. One letter from the Toronto office reads,

There may have been little reason for skilled men to stay at New Lowell if even the watchman could be trained to work in the mill. Another letter which sheds light on hiring practices and working conditions of the time states, in 1857:

At first it would appear that the turner and his son have the upper hand in that they have come "to look at the place" and have come from the same area in England as one of the partners. But in the end, the deciding factor seems to be whether or not the old man will work cheaply enough.

33 The work done at New Lowell was probably dull and certainly repetitive. Parts required by the Toronto factory for assembling and refinishing were ordered by a number which probably signified shape, size, and material. An order for several thousand of just one number was not uncommon by the 1860s and 1870s. An order from 12 December 1872, called for 216,000 pieces to keep the Toronto factory busy for the next three months. One hundred and twenty thousand of this total — more than half— was for just two kinds of parts.49 Orders for parts often were confused. A frantic message on 23 September 1869, reads:

34 When orders were delayed, workers in the Toronto factory were left idle or sent home. This happened frequently and no doubt put great financial strain on workers and their families, who could ill afford to be without pay even for a few days. In 1873, it was anticipated that half the Toronto chairmakers would have to be sent home for a week because of delays in receiving parts and materials from New Lowell. It was feared that many would try to seek work elsewhere rather than come back once the layoff was over.51 Problems also arose over the poor quality of work which sometimes was sent to Toronto. Parts would be declared to be too rough, rhe wrong size, or incorrectly dried or bent.

35 Another aspect of work at New Lowell involved the cleaning and preparing of hair for stuffing and for weaving into haircloth. The extent of Jacques and Hay's hair business may be surmised by the size of one shipment alone: nearly 18,000 tails and manes, along with nearly 650 pounds of horse hair, 151 pounds of cattle hair, and over 83 pounds of hog hair were sent out from Toronto.52 The tails and manes would be prepared for weaving into haircloth, while the shorter hair would be thoroughly cleaned for stuffing.

Display large image of Figure 7

Display large image of Figure 736 One of the ever-present hazards in a woodworking factory was fire. Quantities of wood and sawdust, paint, and varnish were lethal when combined with an overheated engine, a faulty boiler, or a spark from a saw blade. A major fire struck the New Lowell operation at least once 53 and the Toronto factory of Jacques and Hay three times, in 1844, 1854, and 1856. In 1854, 200 workmen were thrown out of work. In 1856, an explosion occurred in a third-floor drying room. Fire spread quickly through the factory, resulting in the deaths of at least nine employees and the injury of others, many of them from attempting to escape by jumping trom upper floor windows. The houses of John Jacques, Robert Craig, the chief turner, and Charles Rogers, the chief carver, also were lost in the blaze. So important was Jacques and Hay's factory to the economic life of the city that large loans immediately were offered for its rebuilding. A public meeting held at St. Lawrence Hall discussed future plans and organized relief for the families of the dead and injured. Such support would have been essential at a time when wages for male employees of the firm averaged less than $30 per month, while those of women employees were half that. To stay above the poverty level, a furniture worker had to have steady employment. To compound the problem, many of Jacques and Hay's workers lost their tools in the fire.54 Each worker owned his own tool box and tools — a vestige of the days of small shops and independent craftsmen. Division of labour on a scale never seen before, repetition, and the hiring of unskilled workmen were changing the world of work for Ontario's furniture craftsmen. With those changes were the vagaries of layoffs, fires, and cycles of prosperity and depression.

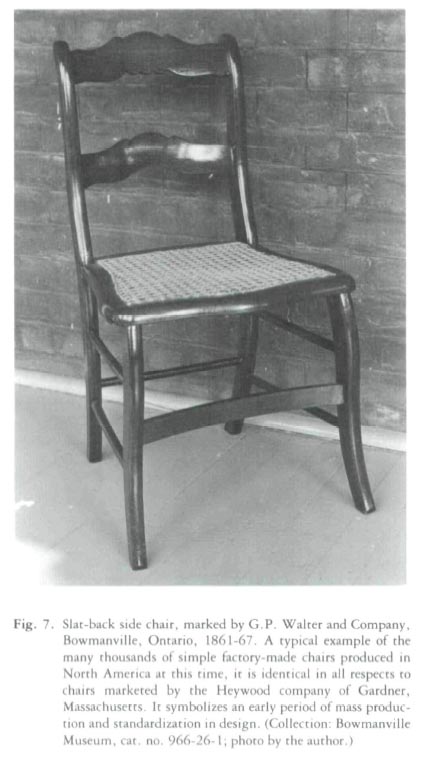

37 In 1872, after John Jacques' retirement, Robert Hay formed a partnership with Robert Craig and Charles Rogers. The new firm came to be known as Robert Hay and Company and lasted until 1885. Further reorganization led to the establishment of Charles Rogers and Sons Company, which lasted until 1922.55 So well known was the firm of Jacques and Hay that Ontario collectors, dealers, auctioneers, and sometimes even museums erroneously call anything from the late nineteenth century "Jacques and Hay." But unless it is labelled or documented in some other way, it should not be assumed that it was made by that large Toronto firm. Other factories, such as G.P. Walter and Company in Bowmanville and John Gibbard and Son in Napanee, were in business at the same time, producing furniture of similar quality and style (fig. 7).

Display large image of Figure 8

Display large image of Figure 838 By the last quarter of the century, the centre of furniture production in Ontario was shifting farther westward, closer to new supplies of wood and spurred on by the erection of higher tariff barriers through Sir John A. Macdonald's National Policy of 1878. Much of this expansion was led by craftsmen of German and English descent who, like John Jacques and Robert Hay a generation earlier, started as working cabinetmakers in a small shop and came to be entrepreneurs and factory owners. Among them were Thomas Bell, Daniel Knechtel, Henry Peppier, Andrew Malcolm, Hartmann Krug, and Simon Snyder. Throughout this period, new machinery and new processes came into use. Fully automated lathes replaced the work of the skilled turner, while pressed ornament replaced carving on many pieces of furniture.

39 New materials came into use as well, among the most popular being rattan. Rattan is a tropical plant which grows much like a wild grapevine, sometimes up to several hundred feet long. The strong, pliable inner core was known as "reed" and could be used to make household items ranging from intricately patterned backs for chairs to sides for baby carriages, using a hardwood or metal frame. The outer skin could be split into strands called "cane," commonly used for woven seats. Cane often was woven by women and children, sometimes working at home, until the invention of a loom for weaving cane web about 1870.56 Reed is believed to have first been used in Canada by James Hay and Company of Woodstock, Ontario, in the early 1880s (fig. 8). In 1895, the firm was taken over by O.G. Anderson but continued to make large quantities of reed goods.57 While mechanization was rapidly gaining ground in other branches of the furniture industry, reed furniture and other items required considerable hand labour, the more intricate designs often taking two days to complete.58 A new range of skills was needed, among them those of star-caner, reed worker, winder, singer, and finisher, as labelled Anderson chairs attest. Ironically, the introduction of this new material late in the nineteenth century brought a modest return to skilled handwork. This is one reason why rattan furniture often was priced higher than furniture of more conventional materials.

40 In 1901, the Anderson furniture factory was purchased by Canada Furniture Manufacturers Limited, an amalgamation of most major furniture factories then operating in Ontario. In a sense, this was the final step in a long process from independent shop to locally-owned factory to large conglomerate. As the process evolved, the working life of the furnituremaker changed from that of skilled craftsman to day labourer. The change was profound and, in the working life of an individual, probably far more disruptive than has been suggested here. Yet from the beginning the life of the craftsman could not have been an easy one.

41 In our own day, we have seen even greater changes. The factories of the turn of the century imitated handwork and often drew on many of the old skills in piecing furniture together, applying finishes, and adding the final touches to carved or turned ornament. Many of their products were well made and used fine woods. Quality may in fact have improved by the turn of the century; hand craftsman-ship in itself was never a guarantee of good design or good work. Today we are much farther away from the old traditions. Sheets of compressed sawdust and glue often are used in place of traditional materials, while vinyl facings imitate the grain of a hundred exotic and improbable woods. The frames of couches are held together with staples, while dovetails and mortice-and-tenon joints have all but disappeared in the commoner sorts of furniture. These signs of the times probably have meant as much to the working life of the furnituremaker as any of the changes described from the past.