Notes and Comments / Nouvelles brèves

Preliminary Investigations into Ocean Falls Pulp and Paper Plant, A Soon-to-be-abandoned Single-Resource Community

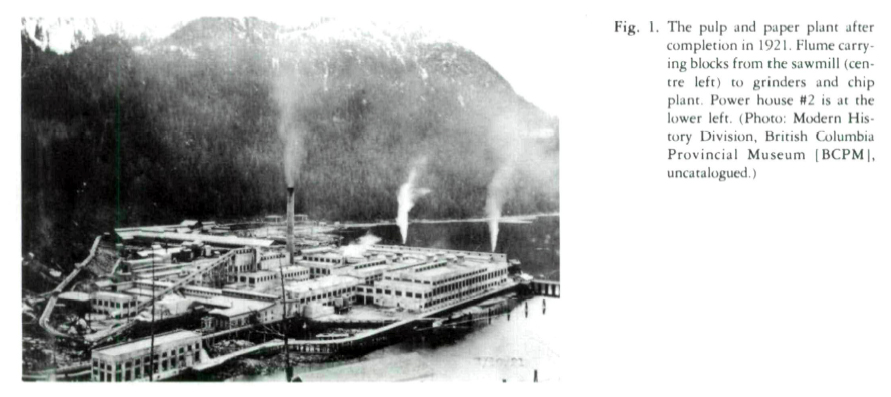

1 Ocean Falls, B.C., a small single-resource community, grew up around a pulp and paper plant in the first two decades of this century. Not only were vast supplies of timber available, but also, as the community's name suggests, a nearby waterfall could supply inexpensive hydro-electricity. These primary resources in such abundance allowed Ocean Falls, despite its distance from markets and its corporate reluctance to modernize extensively, to compete successfully in the pulp and paper industry from World War I until the 1960s. To cut costs, in 1967 Crown-Zellerbach closed the chemical portion of the pulp plant while rebuilding the mechanical or groundwood portion. This conversion was not sufficient to save the antiquated plant, and to prevent its closure the provincial government purchased it in 1973. The new company, Ocean Falls Corporation, subsidized the operation of the plant and the accompanying townsite until 1980 when the mill was closed permanently, or so it appears. During the period 1980-83, the plant and townsite were in limbo, and a community of 3500 had dwindled to under 70. Yet, much remains of the townsite and plant dating to pre-1920.

2 Although the isolation of the plant and community did not appear to have much effect on the plant's success through the first sixty-five years of its existence, that very isolation has ensured the survival of a relatively untouched company town and mill. The two authors visited the site for three days in August 1983, courtesy of the Friends of the Provincial Museum, a non-profit society which assists staff members in performing tasks which the regular budget cannot support.

3 The townsite, which began to be cleared in 1906, is an urban historian's delight. Although some buildings have been lost to decay and other natural disasters as well as controlled fire, the townsite remains remarkably true to its origin. On-site surveys can be done to great profit but further benefits are to be found in the Ocean Falls Corporation Archives where the original electrical, plumbing, housing, sewage, and road plans are located. We did not have the opportunity to assess fully the completeness of the collection of plans and drawings, but preliminary surveys indicate the townsite's physical or material history is fully documented. At the moment of writing, the authors are convinced those holdings will soon be placed in the Provincial Archives of British Columbia.

4 In that the townsite will likely be saved for another use, we concentrated our attention upon the technological processes within the pulp and paper plant. In this preliminary review we attempted to identify those processes that were introduced when the plant was constructed and those that were introduced in the succeeding sixty-five years. We began by examining the existing plant; more extensive study of artifactual and archival sources will disclose the numerous technological changes both borrowed from others in the international scene and those developed to deal with circumstances peculiar to the central coast of British Columbia.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 25 The Ocean Falls Pulp and Paper plant as seen today dates to 1917. Yet, the potential of the area had been recognized as early as 1902 when Robert Thompson of Tacoma, Washington organized the Bella Coola Pulp and Paper Company. Despite the favourable terms of the provincial government's 1901 pulpwood lease programme, Thompson had to find new backers who formed the Bella Coola Development Company in 1904. Following this 1904 reorganization, problems continued to plague the operation. The company was reorganized in 1908 with new backers as the Ocean Falls Company and again in 1914 when Crown Willamette acquired the firm and named it Pacific Mills Ltd. In 1956, it became an operating division of Crown-Zellerbach prior to its final sale to the province.

6 Our purpose at this time is not to provide a detailed record of technology at the Ocean Falls plant but to discuss highlights. We also will use this to illustrate our approach to industrial history, working from the general to the more detailed and from the present to the past. The first area examined will be the primary log breakdown, the sawmill, and from there we will proceed through power, pulp, and finally paper.

7 The first small sawmill was erected in 1907 or 1908 to produce material for initial townsite development, although it may also have supplied lumber for the construction of Prince Rupert. Construction of the pulp plant in 1911 necessitated the installation of a larger and better equipped sawmill which included a planing mill. It was sufficiently large and efficient that it was not replaced until 1952. The sawmill again underwent major renovation about 1967 in order to produce the proper size of block for the rebuilt mechanical pulp plant. Chips were no longer produced since the chemical plant was also shut at this time and the sawmill had ceased producing lumber.

Display large image of Figure 3

Display large image of Figure 38 The largest structure used for power production was the dam, which was first constructed in 1911. With the major rebuild of the pulp plant that occurred in 1917 this dam was considered inadequate and completely rebuilt; it was again expanded in 1923. It changed little in the succeeding sixty years and the original penstock engine was still in service when the plant closed in 1980.

9 Power was produced by two very different methods: hydroelectricity was produced by penstocks from the dam and power was produced by steam. The first hydroelectric plant was constructed in 1911 with the first pulp mill but was rebuilt as Power House No. 2 in 1917. The equipment consisted of four Pelton turbines directly connected to four General Electric generators. In addition, the pulpwood grinders were driven directly from Pelton turbines. This powerhouse continued to operate virtually unchanged in 1983. The steam plant, however, underwent a number of changes. Twenty-two boilers were in operation by 1928; when the plant closed in 1980 only three were in operation, all boilers having either been replaced or removed.

10 Ocean Falls was the most diversified pulp plant operating in British Columbia after 1917. Three processes were used to produce pulp: mechanical or groundwood pulp, sulphite pulp using an acid solution to dissolve the binding of wood chips, and the sulphate process using an alkaline solution. Mechanical pulp production had commenced in 1912 with hand-fed, three-pocket Jenkes grinders using sandstone grindstones, some of which remain on the site as landfill. These machines delivered 150 tons of pulp a day which was wet pressed and packaged for shipment. When new capital took over and extensive redevelopment took place in 1917 the number of Jenkes grinders was increased. There were no major modifications to the groundwood plant until a modernization in 1967 when the Jenkes grinders were replaced with seven two-pocket Koehring-Waterous Great Northern grinders.

11 Initially only the sulphite process was to be added in 1917, but it was decided this would be uneconomic and therefore the sulphate or kraft process was also installed. Three sulphite digesters were installed between 1918 and 1923 and operated until the chemical plant closed in 1967. The sulphate plant had four digesters, which were replaced in 1936 with larger units, and in 1946 one digester was again replaced, as were the other three in 1948. The numerous ancillary operations also underwent modifications but generally were not of major significance, with the exception of the introduction of zinc hydrosulphide bleaching for groundwood pulp. This process had been developed by I.H. Andrews at Powell River, B.C., during the early 1930s and worked particularly well on hemlock pulp, which if unbleached had a slightly reddish cast.

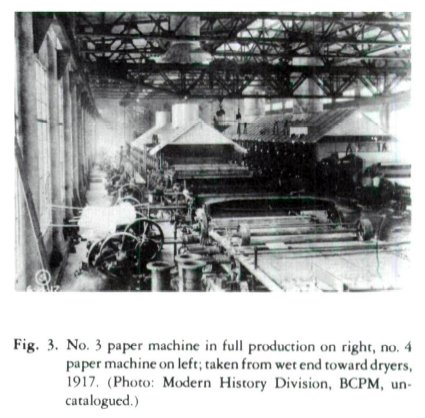

12 Four paper machines were installed in 1917. A fifth machine, a "Yankee" for specialty paper, was installed in 1926. These machines initially ran at 650 feet per minute, and most improvements to the machines have been the result of efforts to increase the speed, eventually to 1450 feet per minute. This was necessary since Ocean Falls was competing with modern plants with machines that operated at 3 500 feet. With the closure of the chemical plant in 1967 paper machines 3,4, and 5 were shut down while the "wet ends" of 1 and 2 were completely rebuilt. The dryer units, however, remained virtually unchanged from 1917 except for the improvements to increase speed. The finishing or packaging room was also automated about 1967. The majority of the buildings have remained unchanged from 1917 though the chemical plant is now in a serious state of disrepair.

13 This quick review reveals that although a number of modifications were made the plant in general remained significantly unchanged for a period of fifty years. The modificatons instituted were enough to permit the company to continue operating until the whole plant eventually reached a state of such obsolescence that it was no longer feasible to continue without a major capital investment. It is from this point that we expect we will be able to go back and trace some of the details of the plant. In the 1930s, for example, the Taylor syphon was developed at Ocean Falls to remove condensate from the paper machine dryer cylinders, and these syphons were still in use in 1980 when the plant closed. As yet we do not know the importance of such modifications to the plant, and there are probably many other seemingly minor innovations that may in total equal a significance beyond their individual worth. It is these changes we next hope to document.

James Wardrop