Articles

In the Bush:

The Changing World of Work in Ontario's Pulpwood Logging Industry during the Twentieth Century

Cet article tente de replacer l'histoire de la culture matérielle de l'industrie forestière de l'Ontario dans son contexte géographique et social, par une étude des changements survenus dans le milieu de travail des employés au service des compagnies ontariennes de pâtes et papier, au cours du XXe siècle. Pendant tout le XXe siècle, des facteurs rattachés au milieu naturel n'ont cessé déposer des problèmes aux compagnies de pâtes et papier qui n'ont jamais pu exercer à l'extérieur un contrôle aussi serré du processus de production qu'à l'intérieur des usines mêmes. Néanmoins, les compagnies se sont continuellement efforcées de trouver des méthodes plus efficaces pour attirer les travailleurs dans des endroits éloignés, adapter les techniques d'exploitation à la forêt boréale et employer ces travailleurs et ces techniques de façon à accroître au maximum la productivité et à soutenir la concurrence sur le marché international. Les travailleurs de l'industrie forestière ont, en même temps, largement contribué à façonner l'histoire des méthodes de travail.

By examining the changing world of work for woods employees of Ontario's pulp and paper companies during the twentieth century, this paper attempts to place the history of the material culture of the Ontario logging industry in its geographical and social contexts. Throughout the twentieth century, factors related to the natural environment have provided a constant challenge to the pulp and paper corporations, which have never enjoyed as much control over the production process as has been possible in indoor mill conditions. Nevertheless, the companies have continually struggled to find more effective ways of attracting labour to remote worksites, adapting technologies to northern bush conditions, and deploying these workers and techniques in ways that maximize productivity and enable companies to compete in international paper markets. At the same time, woodsworkers have also played an important role in shaping the history of labour process transformations.

1 In the summer of 1980, the visitor to the museum of logging technology at Wakami Lake Provincial Park, deep in the remote logging district west of Chapleau, Ontario, could not help but be struck by a dramatic contrast. Standing like dinosaurs amid the silent forest, the museum's early twentieth-century logging artifacts vividly depicted the simple hand and horse techniques of a logging era as yet little touched by steam power or the internal combustion engine. The remote forest setting conveyed a sense of the isolation typical of most bush camps during the first half of the twentieth century. In order to reach the museum, however, the visitor had to drive many kilometres along a dirt road that passed by the modern bungalows of forest workers and their families and through some active logging operations where men operating chainsaws and enormous diesel-powered machines were rapidly turning spruce forests into a bleak, treeless wilderness. The visitor could only wonder how it had come about that bushworkers in the 1980s live in their own accessible bungalows rather than remote camps and work with powerful mechanical equipment rather than with horses and simple tools.

2 This paper seeks to answer that question by examining the changing world of work for woods employees of Ontario's pulp and paper corporations during the twentieth century. In doing so, it hopes to place the history of the material culture of pulpwood logging in its geographical and social contexts, and thereby help museologists who are seeking to bring to life the technological relics of an earlier period. Two major questions will be addressed. First, in what ways did the pulp and paper companies operating in Ontario organize woods work? Second, why did patterns of work change?

3 The history of the transformation of the labour processes of pulpwood logging in Ontario can be divided into three periods: the first quarter of the twentieth century when the new pulpwood logging industry borrowed the technology of the older lumber industry; the middle period, from 1925 to 1945, when woods departments of the pulp and paper industry began to innovate and pulpwood logging took on its own distinct features; and finally, the period since 1945, a period of dramatic technological breakthroughs. This paper argues that throughout the entire twentieth century, environmental factors — the uncontrollable weather, the changing seasons, the geography of the Canadian Shield, and the character of the boreal forest — have provided a constant challenge to pulp and paper company woods managers, who have never enjoyed the degree of control over the production process that has been possible in indoor factory or mill conditions. Nevertheless, the companies have continually struggled to find more effective ways of attracting labour to remote worksites, adapting technologies to northern bush conditions, and deploying them both so as to maximize productivity and profits and thus compete effectively in international paper markets. At the same time, woodsworkers have also played an important role in shaping the history of labour process transformations. The resulting pattern of development has been distinctive, differing considerably from the more familiar patterns in manufacturing, just as the way of life of the men who toiled in the dangerous and distant forests has also been distinctive.

The Early Years

4 During the first quarter of this century the pulp and paper industry of northern Ontario was a young, rapidly growing industry. Pulpwood logging on a significant scale began in northern Ontario at the turn of the century when the provincial government began granting timber rights on huge tracts of Crown land to a few pulp and paper corporations with the capital to construct mills close to the spruce forests, on rivers that provided log transportation, hydro-electric power to mills, and easy access via the Great Lakes to expanding newsprint markets to the south. Following the passage in 1900 of provincial regulations requiring the processing within Ontario of pulpwood cut on Crown land, and later American moves that reduced and then eliminated tariffs on newsprint, the industry expanded at a frantic pace, reaching a climax in the mid-twenties.1

5 These new science-based corporations of the pulp and paper industry poured enormous amounts of capital into scientific research and sophisticated technology for their mills, and yet in their woods operations they relied on the labour-intensive and remarkably static technological complex developed much earlier by the family firms of the province's lumber industry.2 Corporate executives of pulp and paper companies seemed fascinated by innovations that were continually expanding their control over production processes and costs within their mills. However, these men, with their modern engineering and financial training, appear to have been far less interested in what they regarded as the mundane matter of wood supply, where the tried methods of the lumber industry seemed more promising than costly experiments in a seemingly uncontrollable outdoor environment. It was far easier to hire woods management and production personnel whose knowledge of logging had been gained through practical experience with the lumber companies operating in the Ottawa Valley and the Georgian Bay and North Shore districts.

6 Certainly the pulp and paper companies found that the existing lumbering methods, which had crystallized into a system after long years of trial and error, were well suited to the geographical and climatic conditions of northern Ontario. Because the North's forest resources were spread over vast territories, far from concentrations of population, logging companies could not rely on an indigenous workforce nor on an existing network of roads. Instead, they depended on crude, temporary camps that housed fewer than 125 men within walking distance of their bush worksites. In the long tradition of the lumber business and the square timber trade, large companies were common, but large concentrations of labour were not. Big companies simply had numerous camps — perhaps as many as thirty — spread out across their limits. Altogether some 25,000 men worked in northern Ontario pulpwood camps during peak seasons.

7 The companies also adapted to the natural conditions by conducting most of their operations in wintertime when snow and frost conditions facilitated the transport of timber from the stump to the river, where the spring thaw would later provide the high water for river drives. Moreover, the thousands of seasonal workers the companies required were more readily available in wintertime when activities in agriculture, construction, and other industries were curtailed.

8 To recruit labour, the pulp and paper companies followed the example set by the lumber business: they sent out hiring agents, or contracted with private employment agencies in centres such as Ottawa, Pembroke, and Quebec City, where men seeking bush work congregated each fall. Such men included farmers, their sons, and their hired men, as well as construction workers. Desperate for winter work, the Ontario-born, Francophones from Quebec, and recent immigrants flocked to distant and hazardous logging jobs. Some endured the hard work and primitive conditions because it was possible to accumulate savings from wage work in isolated camps where board was provided and opportunities to spend money were few. Others preferred the camaraderie of camp life to the lonely bachelor's shack or the boredom of wintertime on the farm. In a devil-may-care manner, they spent their earnings in camp poker games or blew their stakes each spring on whiskey and women. Many lumberjacks liked the way of life — working outdoors, close to nature, living with other men far from the pressures of home life — and they were fiercely proud of their woods skills.

9 A woods department was fortunate if it could hire a good camp foreman with a loyal following of skilled lumberjacks who would stay the run and return year after year. Similarly, the pulp and paper companies sometimes sub-contracted logging operations to jobbers, many of whom brought relatives and neighbours with them to the camps.

10 In hard times, there was little difficulty in recruiting a stable and experienced labour force: bushworkers clung to their jobs. But during upturns in the business cycle, companies could only attract men and retain them in distant camps by raising monthly wage rates substantially and offering a greater variety of food, better accommodation, and a bonus for completing the run. Living conditions, nevertheless, improved only very slowly, remaining a far cry from those in the expensive model towns paper companies were beginning to construct in order to attract a stable, skilled labour force for their mills. Even in 1917, when labour was becoming scarce as a result of the Great War, the provincial sanitary inspector found that Abitibi Power and Paper Company camps near Iroquois Falls had unusable outhouses, all manner of garbage strewn on the river banks, filthy stables, a polluted water supply; camp buildings were "badly overcrowded," had "little or no ventilation," and used double-tiered, muzzle-loading bunks with hay for mattresses.3 It took time and the combined pressure of the community, government, and labour to improve conditions. Urban communities alarmed by the spread of diseases originating in logging camps, as well as the complaints of labour activists in the One Big Union, provided the impetus for closer Ontario government inspection and regulation of logging camps.4 More important, falling productivity, resulting from the refusal of workers to stay at jobs in bad camps when they believed conditions were better elsewhere, spurred the companies to make improvements.

11 The labour process in the logging camps of the early twentieth century was highly organized and routinized, although the tools used were simple. A favourite tale among lumberjacks concerned the city dude who was mystified by the methodical bustle of logging operations and the lumberjack's colourful language — words such as "buck beaver," "road-monkey," "swamping," and "crazy wheel." The organization of the work, nevertheless, was thoroughly understood by members of the camp crew, who learned through an informal apprenticeship system. Boys and young men, many of whom had already learned to use an axe and saw and handle a horse on their farms, would work as helpers for experienced men. Much in the manner of the artisan, skilled lumberjacks set their own pace, adapted to the capacities of men and horses, and suited to weather conditions. Although the camp foreman was usually even more physically imposing than the bullying foreman of the early twentieth-century factory, the role of the camp boss was not to drive the men, but to plan the network of logging roads and to maintain an overall discipline in the camp in order to cut down on wasted time resulting from disagreements and brawls.

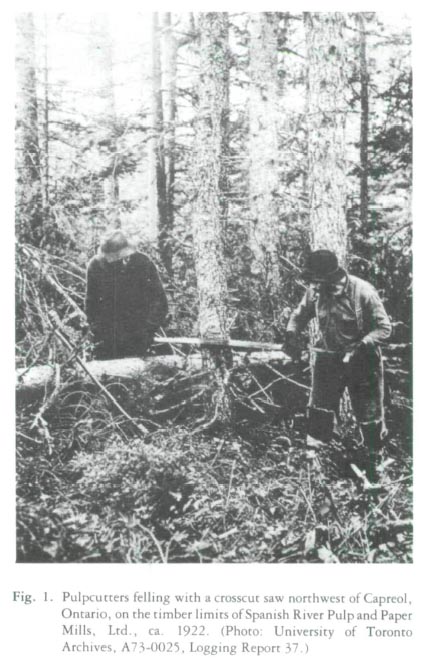

12 Logging operations consisted of four major stages: felling the trees and making logs; skidding them from the stump area to logging roads; hauling the logs in sleighs along these roads to a camp site and finally, in springtime, driving the logs down the rivers. In early twentieth-century pulpwood camps, felling gangs were composed of three men: a highly skilled chopper who sized up the direction in which the tree should fall and who used an axe to notch the tree; and two sawyers who then felled the trees by sawing about two feet off the ground with a long two-man crosscut saw and a great deal of muscle power. Once the tree had fallen, the chopper topped it, that is, he cut off the waste at the top of the tree, and he removed the branches. The sawyers then cut the tree into logs twelve or sixteen feet long.5

Display large image of Figure 1

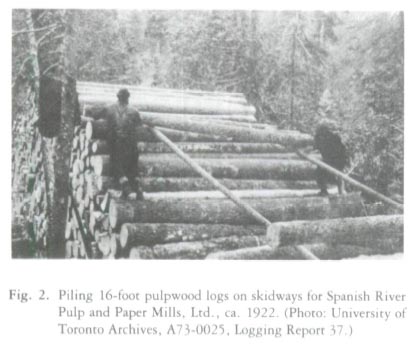

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 213 Next, a teamster, his helper, and a horse would skid the logs out of the cutting area. They simply wrapped chains around a few logs and then the horse dragged them along the snow-covered skidding trails which had been previously "swamped" or prepared by the buck beaver, a young, less experienced man, using a double-bitted axe and grub hoe. The skidding trails led to the logging roads beside which the logs were piled in skidways, either by men who had done the skidding or by pilers — strong men hired especially for this back-breaking task.

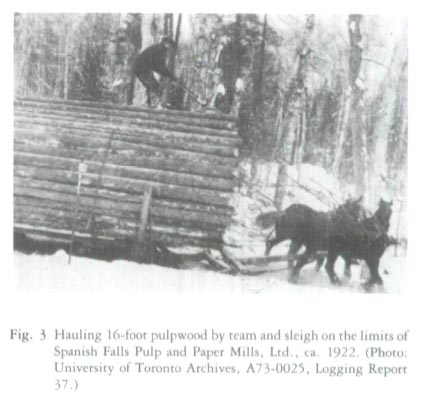

14 Later, during the period from mid-January to mid-March when snow and ice conditions were optimum, the haul took place.6 This was the critical stage of the logging year, for it was imperative that all wood cut that winter be removed from the bush before temperatures grew too warm to permit the rapid and smooth hauling of sleighs heavily laden with logs. To speed up the work, camp bosses encouraged lively competitions among hauling crews. Logs were rapidly loaded onto sleighs by means of a jammer, a tall, A-frame lifting device with a pulley and a cable drawn by a team of horses. A top loader, the boss of the loading crew, stood atop the sleigh to guide the logs aboard; meantime other men hooked on the cables and another drove the team of horses who provided the power. Sleighs were usually pulled by a team of horses along roads that had been carefully iced and rutted in order to minimize friction. Hauling could be very dangerous on a hill if the load proved too heavy for a team of horses to hold back, and so an American invention, the Barienger brake or "crazy wheel," was used to ease the load downhill. Since its operator could rarely see the sleigh as it descended the hill, he had to develop a keen sense of timing in order to know how much brake pressure to apply. Sleighs were unloaded by means of another jammer at the dump site on the river's edge or on a lake, in readiness for water transport after spring break-up.

15 Water transport of logs involved floating logs on lakes and wide rivers, and river driving, the practice of controlling the flow of spring run-off in rivers so as to force logs downstream past obstructions. Towing log booms across lakes in the backwoods had once required the work of countless oarsmen in pointers, and men or horses heaving at a capstan. But much of this "bull" labour was eliminated by the invention in Ontario during the early 1890s of the steam alligator, an amphibious vessel that could pull booms by means of a powerful steam-driven winch and even drag itself across portages.7 Once streams had been improved — dams and sluiceways constructed — the technology of the river drive was as simple as that of felling. River drivers using peavies and pike poles, little more than long sticks with metal ends, relied more on their own agility to survive the dangerous but thrilling adventure of the drive. Companies had no difficulty finding enough men for the drive, so popular was this work among "professional" lumberjacks who celebrated in songs and poetry their incredibly dangerous work. The ultimate objective of the year's work was the blockpile at the mill.

16 By the early twentieth century steam technology and mechanization had revolutionized production in many other industries as well as in some sectors of the North American logging industry. But steam power and mechanized methods had little impact on pulpwood logging in Ontario during its early phase due to the natural environment of the North. On the west coast, the mountainous terrain, the huge size of the timber, and its high value, made steam-powered skidding methods and logging railroads for hauling a paying proposition. Even in the Michigan lumbering districts neighbouring Ontario, logging railroads were numerous because of Michigan's dense stands of valuable white pine and the well-drained, flat forest floors. By contrast, throughout most of Ontario's boreal forest region, logging railroads and heavy steam log-haulers were too expensive because of the prevalence of steep slopes, muskeg, and rock, as well as the low density of timber stands. Labour-intensive methods were more cost effective.

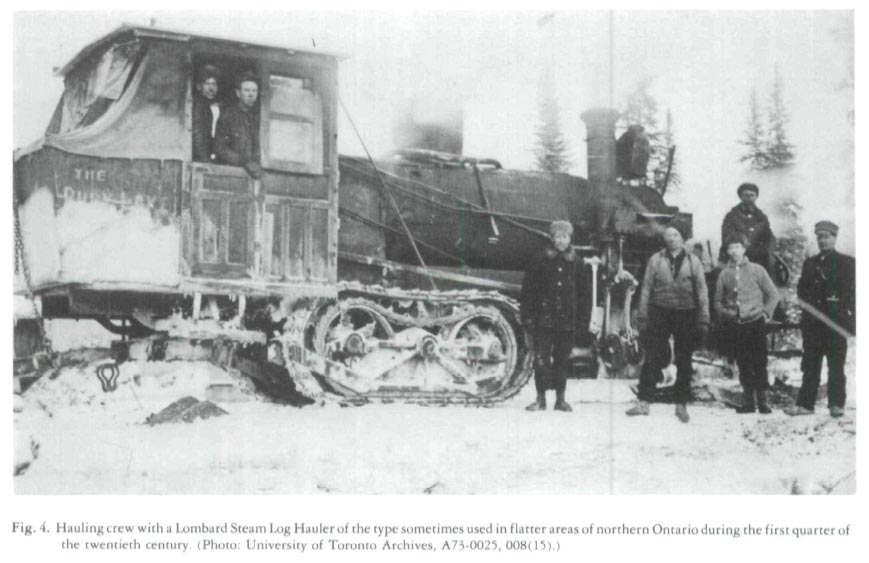

Display large image of Figure 3

Display large image of Figure 3 Display large image of Figure 4

Display large image of Figure 417 Even so, the industry's journal, Canada Lumberman, kept its readers informed about steam logging equipment, including the Maine-developed Lombard log hauler, a large steam engine mounted on crawler tracks and skis.8 Manufacturers of such equipment advertised in the journal and sent their sales representatives into northern Ontario. However, a market was found only in unusually flat regions such as the narrow band of pine forests along the north shoreline of Lake Huron and on the limits of the Abitibi Power and Paper Company near Iroquois Falls, where for decades hauling was facilitated by means of a permanent steam railroad. Overwhelmingly, however, the technology of pulpwood logging remained unmechanized.9

18 Similarly, the industry remained little touched by the ideas of scientific management which, in the early twentieth century, were beginning to gain currency in some other industries. Even the most "progressive" commentators expressed scepticism about the application of stopwatch techniques in the forest environment. Yale logging professor R.C. Bryant summed up the difficulties in an article entitled "Scientific Management in Lumbering," printed in the Canada Lumberman in 1912:

Nevertheless, Bryant did go on to suggest that the industry could greatly profit from innovations such as cost-accounting, profit-sharing for camp foreman and piecework. Indeed, there was a great deal of room for innovation.

The Middle Years

19 During the middle period of development, 1925-45, it was the pulp and paper sector of the logging industry that took the initiative and began to innovate by searching for new technologies and ways to deploy labour. As a result, the pulpwood logging labour process became different from that of the lumber industry. Yet the pace of mechanization remained slow, largely because of the relative cheapness of labour-intensive methods during the Great Depression.

20 Pulp and paper companies continued to borrow throughout the middle period, but they did so selectively and largely from industries other than lumbering. The woods managers' association (the Woodlands Section of the Canadian Pulp and Paper Association) became a significant force that informed members of technological and labour developments in various companies and regions and undertook research into new logging methods. The Woodlands Section, as well as being equipment salesmen, made certain that the woods managers were aware of the latest developments in the rapidly changing field of heavy-track vehicles and trucks. By reading the thousands of technical reports and conference papers published by the Woodlands Section, it is possible to study the process of technological diffusion as member companies learned about, and purchased, new equipment.11

21 In the late 1920s, gasoline-powered tractors became common sights in woods operations, where they were used to haul trains of sleighs on the main haul roads. In the early 1930s, the diesel-powered heavy-track vehicle was also used for this purpose as well as for the construction of logging roads and trails. Wheeled trucks also made their appearance; first to tote supplies, and later, after the introduction of powerful diesel trucks, as hauling vehicles.

22 As impressive as all this new equipment was, it affected the labour process very little. Essentially these vehicles replaced horses and equipment operators and drivers took over from the teamsters. The work was not fundamentally reorganized. Some new skills were required, though most of the younger teamsters were already familiar with driving automobiles and so there was little to learn. The mechanic, of course, became an essential figure alongside the traditional blacksmith. But the activities where most workers were employed — cutting, skidding, piling, and loading — were largely unaffected.

Display large image of Figure 5

Display large image of Figure 523 In the cutting and skidding phases of logging little technological change took place because existing machinery proved uncompetitive with labour-intensive methods in off-road forest conditions. Tractors were far less efficient than horses on the rock and muskeg of the Canadian Shield. During the 1930s the Woodlands Section reported on available power saws, but found that they were not yet portable enough for pulpwood loggers scrambling about in the northern bush. One executive's assessment of cutting machines in 1918 remained indicative of management's general approach for decades: "Give me two French Canadians in preference to any machine you can introduce."12

24 Nevertheless, despite the limited amount of technological change, the labour process in the cutting phase underwent a transformation that had profound consequences. The urge to cut production costs, not technological breakthroughs, was the major impetus for management's innovations. In the 1920s woods managers came to realize that the practice of using three-man cutting crews was wasteful of labour. In the old lumbering operations, the pines were so massive that two men were required to saw them, but the comparatively smaller pulpwood trees meant that only one man was necessary. More wood could be cut per day if the cutting crew was reduced from three men to one. At the same time, cost-conscious woods managers greatly expanded their use of piecework payment systems. Rather than being paid a monthly wage, cutters were paid according to the volume of wood or "cordage" they cut. Scalers measured each worker's piles of wood. In this reorganized cutting process, the strip boss assigned each worker his own strip of timber (about 66 feet by 660 feet), where he toiled throughout the day, rarely seeing another worker or even a foreman. According to discussions of woods managers, the piecework system provided an important incentive that increased worker productivity. Moreover, piecework minimized the need for close supervision, a costly and difficult proposition where the workforce was so scattered. The piece-rate system acted as an invisible foreman, pushing workers to higher levels of productivity.13 Logging had always fostered a significant amount of competition as crews vied to demonstrate their abilities. But with the introduction of piecework, competition was now at the level of the individual, who was eager to maximize his income and outdo his campmates.

25 As a result, pulp cutting took on a distinct image, attracting men who thrived on independent work and hungered for the relatively high piecework incomes. Competitive men with few skills demanded in well-paid urban jobs who were willing to tolerate tough work and the deprivations of remote, crude bush camps, found pulpwood camps appealing because they were one of the best places to make substantial savings. Many recent immigrants from northern Europe who had settled in northwestern Ontario were strongly attracted to the pulp camps of the North because they offered a means to fulfil their dreams of acquiring a farm either in Canada or back home. One such group was the Finns.

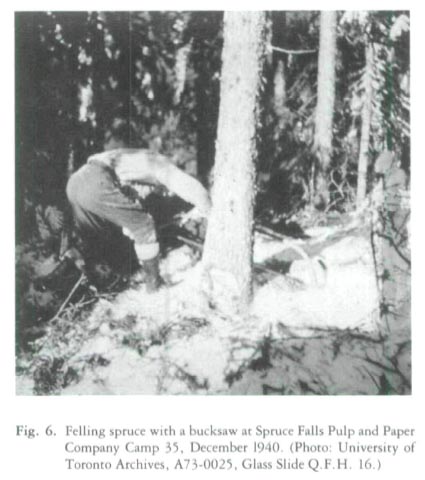

Display large image of Figure 6

Display large image of Figure 626 During the 1920s and 1930s, Finns played a vital role in the pulpwood logging industry.14 Many oldtimers recall that the Finns brought to the camps their fastidious habits, sauna baths, and female cooks and attractive young cookees, who added a new dimension to that overwhelmingly men's world. In addition, the Finns improved the technology of pulpwood cutting by popularizing the bucksaw or "Swede" saw. Because of its thin blade, the saw was efficient and easy to carry. Now the single feller bent double from the waist and felled the tree close to the ground. This reduced the amount of waste, an important consideration for the production conscious pieceworker. The bucksaw could also be used to cut the trees into logs of four or eight feet, lengths that could be handled more easily by the one-man crew, and driven down the rivers more easily, too.

27 Most important, the Finns were largely responsible for building the union movement among Ontario bush-workers. In the forefront of labour organizing activity throughout the late 1920s and the 1930s were the "red" Finns, many of them political exiles from their homeland. Through the strong networks of Finnish-Canadian cultural societies and sports clubs throughout northern Ontario, they were able to organize hundreds of the Finnish pulpcutters. Most of these immigrants were probably not very radical, but they were swayed by the radical leaders, who were backed by the considerable social influence of the halls and newspapers of the small, Finnish-immigrant community. Moreover, bushworkers of many nationalities who lived and worked together in camps followed the radical leadership. They struck frequently in order to combat primitive camp conditions, the favouritism of foremen, and to demand higher piece rates. It was in northwestern Ontario where most of the northern Europeans worked that this Finnish radical immigrant culture was crucial in overcoming the independence and competitiveness inherent in the work process. The common grievances and camaraderie of camp life helped organizers as well. Finally, in 1946 the militance resulted in the industry-wide recognition of the Lumber and Sawmill Workers Union.

28 The middle period of pulpwood logging had thus seen some technological innovation, and much more significantly, a reorganization of the labour process so that logging was characterized by competitive, highly independent workers who were also capable of uniting in militant struggles.

The Post-War Years

29 The end of World War II marked the beginning of a new period in the history of logging when numerous, dramatic technological changes transformed labour processes and, indeed, the whole way of life of the lumber-jack, who now had even taken on the new name "logger."15

30 Labour played a crucial role in forcing management to search for mechanized logging methods. In the post-war period, fewer workers seemed interested in taking seasonal jobs that required heavy outdoor winter work in remote locations. Rising incomes of agriculturalists, rural depopulation, expanding opportunities in the cities, and unemployment insurance eroded the seasonal labour supply on which woods departments had long relied. Woods employers found it increasingly difficult to attract and retain workers. Labour turnover rates were astonishingly high; the average length of stay in a bush camp during the late 1940s was less than forty-four days. Naturally, the corporations' problem in recruiting a stable labour force was an advantage for union leaders who were able to win substantial wage increases for their ever-growing membership and increase the union's strength and power.

31 In the early post-war period the acute labour shortage and rapidly rising labour costs seriously threatened the Ontario pulp and paper industry's ability to compete with southern United States paper in American markets. Ontario woods departments responded with two strategies. First, they sought to increase the labour supply. Executives pressured the Canadian government to direct "Displaced Persons" and other new immigrants to logging camps. Although waves of new immigrants — DPs, Hungarian refugees, and Portuguese — have taken up logging jobs in the post-war period, this was only a partial solution to the industry's dilemma. Some companies also tried to lure more workers to their camps and avoid costly wildcat strikes by providing more attractive living conditions — bunkhouses with two-man rooms, recreation facilities, and sports programmes.

32 Management's second and more promising strategy was to increase productivity by reorganizing the labour process, introducing new, mechanized methods, and stabilizing the labour force. Prohibitively costly labour-intensive methods were to be replaced by labour-saving machinery, thereby reducing wage costs and the number of employees who had to be fed and housed in the camps. In the early 1950s, the Woodlands Section began a concerted campaign to develop new mechanical logging methods designed for the Canadian Shield. Meantime, equipment manufacturers, finally convinced that the industry was willing to invest in mechanized equipment, also began to develop and market new machinery. The results of the companies' and manufacturers' activities have utterly transformed the atmosphere of bush operations. The shouts of men and the snorting of horses have been replaced by the roar of chainsaws and the steady din of heavy diesel equipment.

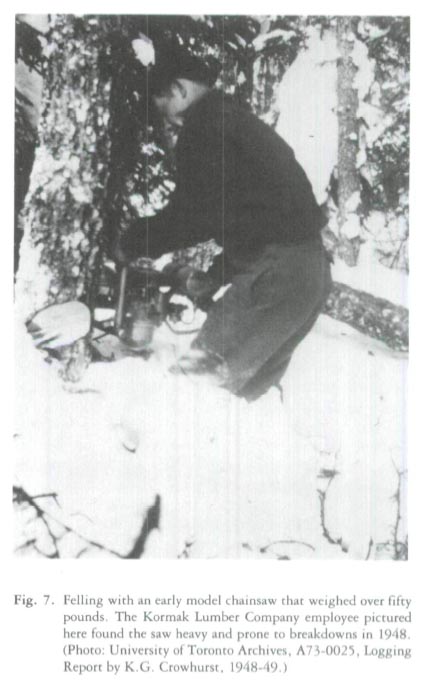

Display large image of Figure 7

Display large image of Figure 733 The first major innovation was the lightweight gasoline-powered chainsaw, developed by equipment manufacturers using the technologies of light metals and engines pioneered in World War II. Once the bugs had been eliminated, chainsaws were eagerly purchased in the early 1950s by piecework cutters because they could produce more wood in a day with less exhausting toil and earn higher incomes. Apart from the additional safety hazards, the chainsaw brought few changes to the labour process. Cutting remained a highly independent job paid by the piece, and one demanding judgement and skill.

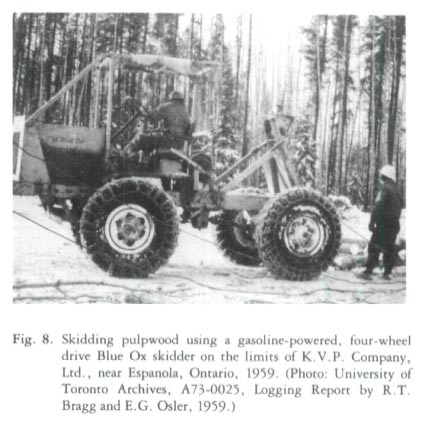

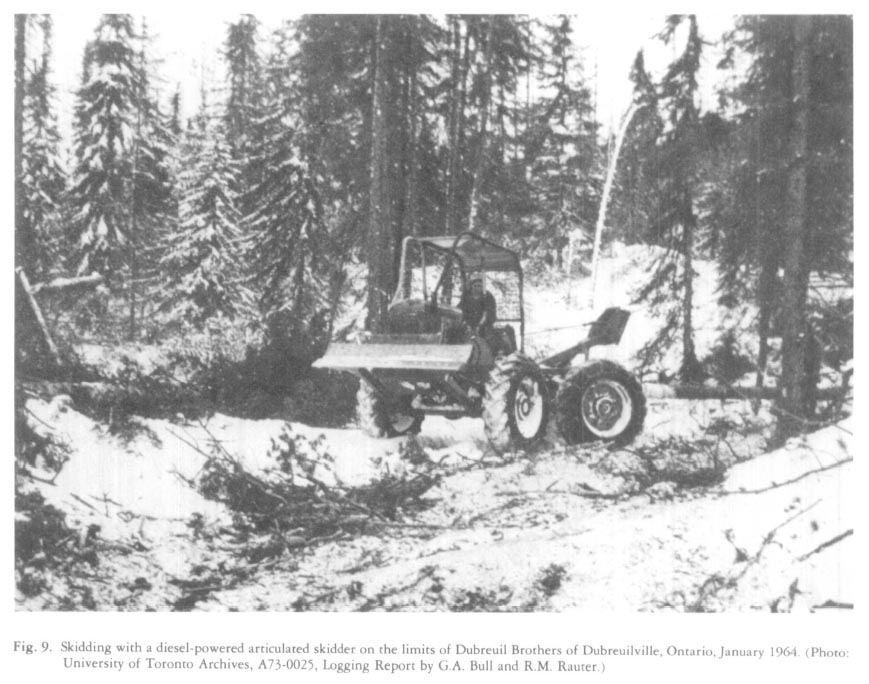

34 During the mid-1950s, equipment manufacturers introduced wheeled skidders as a substitute for the less powerful and disappearing work-horse. However, skid-ders like the Blue Ox, which was essentially a four-wheel drive truck with conventional steering, frequently broke down or became mired in muskeg. A few years later, the combined efforts of the Woodlands Section and manufacturers brought about the far more successful articulated wheeled skidder, a vehicle designed especially for northern conditions. Its articulated steering, where the frame is hinged in the middle, made it highly manoeuvrable, while its huge, low-pressure tires gave it the flotation and traction necessary for the terrain of the Canadian Shield. (Canadian factories have manufactured many thousands of these and sold them in numerous parts of the world.)

35 Because the skidder could travel faster and skid larger loads than the horse, the labour process was reorganized. Now a skidder operator usually worked in a team with one or more cutters who felled, limbed, and topped the trees. These tree-length logs were then skidded to a roadside landing where they were either loaded onto trucks and taken to a mill or cut into shorter lengths by means of a slasher, a kind of portable sawmill. Mechanical loading devices were also introduced in the 1950s. These new cut-and-skid methods, which were well suited to the geography of the north, resulted in a 45 per cent rise in productivity between 1955 and 1965.

36 Nevertheless, logging engineers, searching for logging systems that would save even more labour, developed the mechanical harvester, a revolutionary approach to logging. The widely used Koehring short-wood harvester, for instance, is a mechanical giant with seven-foot-high tires and a forty-foot hydraulic arm. The machine utterly dwarfs its single operator, who sits in a climate-regulated cab. By controlling numerous levers, gadgets, and joysticks, the operator guides his harvester through the forest, using the machine's huge hydraulic shears to fell the trees, which are then automatically processed into logs and stored at the rear of the vehicle. Although more closely supervised than the conventional cutter, the harvester operator works independently in his own patch of bush and is frequently paid an incentive bonus.

37 When operating efficiently, harvesters permit astonishing gains in productivity. However, harvesters have serious drawbacks. Because of their many integrated parts, they break down frequently, causing costly delays. Highly skilled mechanics and trained operators are hard to retain in remote camps. The men's continuing tendency to change jobs often, or to seek work requiring similar skills in other industries, adds greatly to operating costs. In addition, these heavy machines cause serious damage to the ecology of the forest by digging very deep ruts that upset natural drainage patterns. Engineers have not yet fully met the challenge of the forest environment.

38 The mechanization of the cutting and skidding phases of logging was accompanied by the mechanization of log transport from the bush to the mill. The widespread use of trucks and the construction of extensive networks of access roads during the 1950s and 1960s entirely eliminated the sleigh haul and the river drive. The competitive spirit of gangs of teamsters and river drivers gave way to the far less colourful but steadier work of driving trucks along the access roads.

Display large image of Figure 8

Display large image of Figure 8 Display large image of Figure 9

Display large image of Figure 939 These roads have had profound effects on the lives of loggers. Since bush camp workers can be bussed from camp to their worksites, pulp and paper companies can afford to build more permanent camps which have improved facilities and furnishings. Collective agreements now contain clauses concerning colour TVs, air conditioning, and humidifiers. On the other hand, in many operations, camps have been completely eliminated. Employees commute daily or weekly by bus or car from their homes to logging sites. For these bushworkers, life has been "normalized"; they can own houses, marry, and live with their families.

40 This trend has been encouraged by other factors as well. Mechanization has lightened the work, making it possible for far more men to continue logging until they reach retirement age. Mechanization has drastically reduced the seasonality of logging: most jobs are nearly year-round, which reduces turnover and permits steadier incomes. Now the industry employs many mechanics and heavy-equipment operators, men widely respected for their skills and in demand in other industries. The work more closely resembles routinized factory work in that foremen with stop-watches now goad machine operators, some of whom work on night shifts, felling and forwarding in the glare of powerful floodlights. However, men still enjoy a significant degree of freedom as they contend with mosquito-infested bogs as well as the bitter blasts of winter weather.

41 Generally speaking, the numerous changes brought about by the construction of access roads and by mechanization were heartily welcomed by workers and their union. The elimination of bull work, steadier, more secure jobs, and a closer integration with other types of work and with urban dwellers — these seemed obvious advantages of the new methods. Little de-skilling has taken place. Instead, loggers have learned new skills marketable outside the industry. At the same time, tough union bargaining during a period of growing woods labour scarcity ensured that some savings accruing to the corporations as a result of productivity increases were passed on to workers. High turnover rates have greatly softened the impact of job losses resulting from the introduction of labour-saving equipment; now there are fewer than 7,000 engaged in pulpwood logging in comparison with 25,000 seasonal workers a half-century ago. Since the early 1950s the Lumber and Sawmill Workers Union has declared its support for mechanization, although it has been vigilant in fighting management attempts to introduce practices harmful to workers. Recently, however, the proliferation of non-union "owner operators" — sub-contractors who own their own costly skidders and trucks — is posing a serious threat to the union.16 Meantime, the jobs of forest workers are being threatened by the downturn in the economy, the alarming lack of suitable trees to harvest, and the introduction of more and more labour-saving equipment.

42 In conclusion, the logging labour process has undergone many transformations during the twentieth century as companies have tried to meet changed circumstances. Workers, often unintentionally, have played a key role in shaping management's production strategies. The continuing tendency of woodsworkers to quit their jobs often, or to avoid jobs in remote camps, was partly responsible for forcing management to offer higher wages, introduce piecework, improve camps, and find labour-saving equipment. Labour's tendency to quit has also significantly decreased the efficiency of even the latest invention — the mechanical harvester. At the same time, organized labour has fought continuously and remarkably successfully for better camp conditions, higher wages, and fairer job practices.

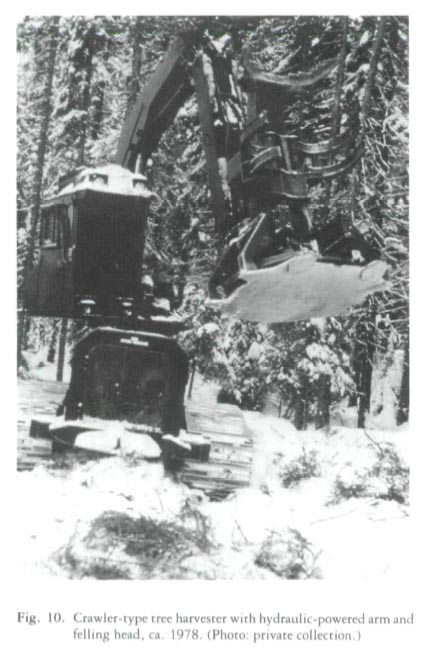

Display large image of Figure 10

Display large image of Figure 10 Display large image of Figure 11

Display large image of Figure 1143 Throughout the entire period, management has never been able to introduce factory conditions to the varied and variable forest environment. Although today's logging operations more closely resemble the factory than did woodswork seventy-five years ago, outdoor work in the modern pulp and paper company's woodlands offers a degree of freedom, as well as danger, not found in the company mill. Forest work, like the history of the changes in the logging labour process, is distinctive. Forest workers remain proud and independent.

This paper is an outgrowth of my York University Ph.D. dissertation-in-progress on the social history of the logging industry of northern Ontario, 1910-70, the research for which has been supported by doctoral fellowships from the Social Sciences and Humanities Research Council of Canada and a Labour Canada research grant.