Articles

Characterization of Selected Nineteenth-Century Southern Ontario Domestic Earthenwares by Chemical Analysis

Abstract

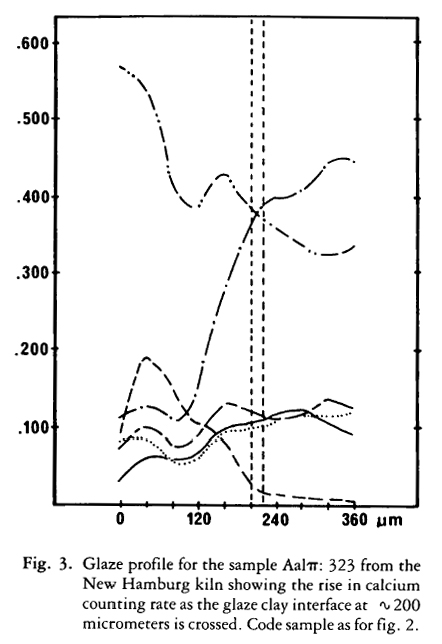

The elemental analysis of the glaze from domestic earthenwares at four kilns, including that of the David Burns Pottery, has been carried out in an attempt to establish an identification scheme for each pottery. No clear-cut identification for each of the four groups was found, although it seems possible to distinguish between glazed pottery from the David Burns and the Streetsville kilns and between pottery from the New Hamburg and the Egmondville kilns, on the basis of specific elemental concentrations.

Résumé

L'article présente les résultats d'une analyse des composants de la glaçure de faïences provenant de quatre fours différents, dont celui de la David Burns Pottery. Cette analyse avait pour but d'établir une méthode d'identification pour chaque sorte de poterie. Les auteurs rapportent que les résultats ne permettent pas de délimiter avec précision chacun des quatre groupes, même s'il semble possible défaire des distinctions entre la poterie à glaçure provenant des fours de David Burns et de Streetsville et entre la poterie des fours de New Hamburg et d'Egmondville d'après la concentration particulière des composants.

Introduction

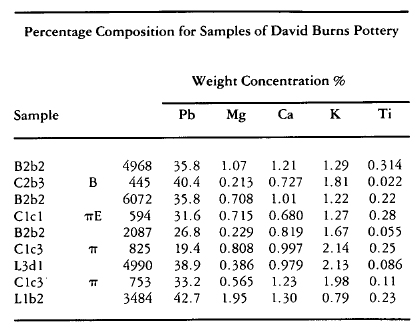

Display large image of Figure 1

Display large image of Figure 11 In an attempt to characterize the pottery from the David Burns kiln and three other kilns in southwestern Ontario, the glaze on domestic earthenwares from these sites has been examined for its elemental composition by atomic absorption spectroscopy (AAS) and by proton-induced X-ray emission (PIXE) spectroscopy produced with a proton microprobe. The locations of the sites from which the sherds were obtained are shown in figure 1. Although the history of pottery production at the kiln sites is well known, inscriptions or decorations which would link the potter to his wares were only occasionally found on the excavated sherds (Newlands 1979). Consequently this examination of the elemental concentrations was undertaken to establish a classification scheme with particular emphasis being placed on the material from the David Burns and the Egmondville potteries which are documented as representing the "English" and "German" traditions.

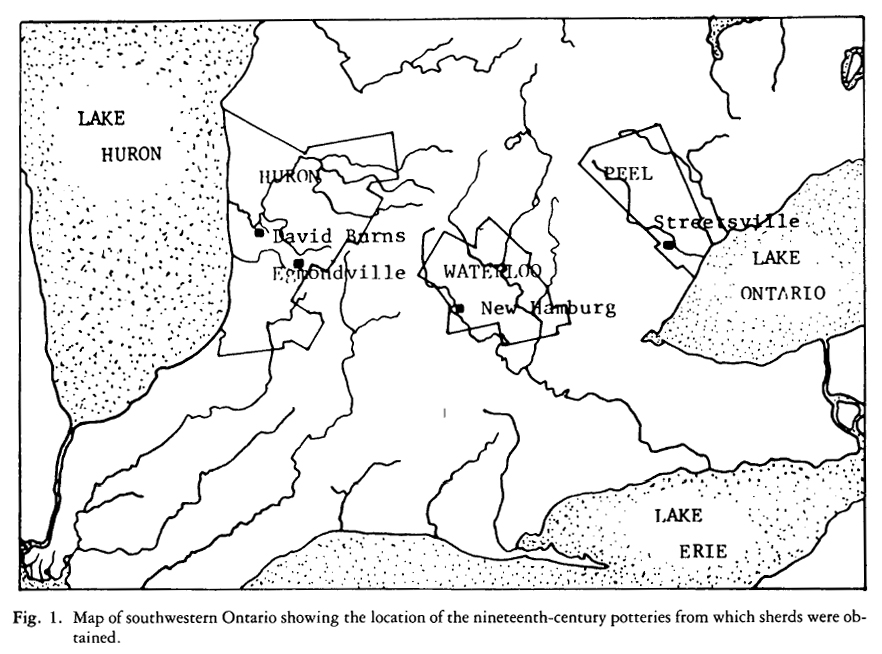

Display large image of Figure 2

Display large image of Figure 22 Several reasons can be advanced to suggest that elemental compositions would not be well defined for pottery from any one site. Among these would be the minor variation in concentrations of the raw material, the different mixtures of the raw material used to formulate the glaze, and the selection of the pottery shards, which came from a variety of sections and archaeological layers at any one site. The latter feature ensured that a good representation of the pottery throughout the kiln's operation was taken but may have prevented the classification of the pottery due to the different owners of any one kiln. With the exclusion of the David Burns Pottery, each had up to five owners who may or may not have been related to the founder of the business.

Method of Analysis

3 Quantitative analysis of glaze by the PIXE technique involved surface penetration with a proton microprobe operating in air (Green 1978). The proton-induced X-rays were detected with a lithium-drifted silicon counter from which the relative counting rates of any element higher in the periodic table than magnesium could be determined. To provide insights into glaze homogeneity and the nature of the glaze/clay interface, sherds were cross-sectioned, mounted in epoxy, and polished. These prepared samples were examined by the proton microprobe.

4 Samples collected for the flame-AAS determination were obtained by carefully grinding off the first 100 micrometers of the glaze (the average glaze thickness for any one group was 150 micrometers). Consequently this technique of glaze analysis is equivalent to averaging the results along a cross-section from the PIXE cross-sectional method.

Results

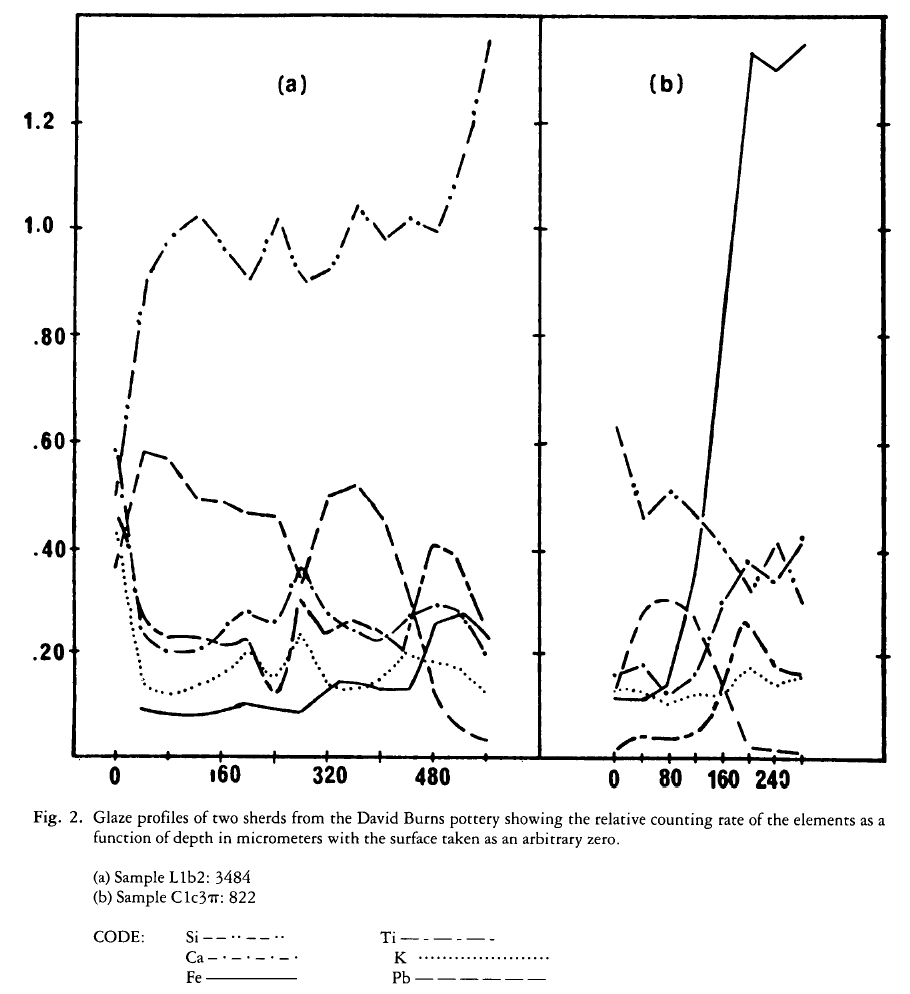

5 Examples of the profiles obtained with the microprobe are shown in figures 2 and 3 where the decrease in counts for lead is a clear indication to the edges of the glaze. Optical measurements always confirmed these measurements. From the many constructed profiles and the results from AAS, it was determined that the glaze of the sherds had been fluxed with lead and alkaline earth elements. Furthermore, the colouring agents, predominantly iron but occasionally also small amounts of copper, manganese, and chromium, were found throughout the glaze matrix not merely on the surface. These observations are similar to the conclusions reached by Webster (1971) in his analysis of the William Eby Pottery of Conestogo, Waterloo County.

6 Other features discernible in these profiles are the surface enhancement of calcium and potassium which occurred in one of the David Burns samples (fig. 2a), and the normal increase in calcium concentration at the glaze/clay interface (fig. 2b). Whether the latter feature of diffusion is due to the mode of glaze application, the nature of the clay substrate, or the length and temperature of the firing process is not clear.

Display large image of Figure 3

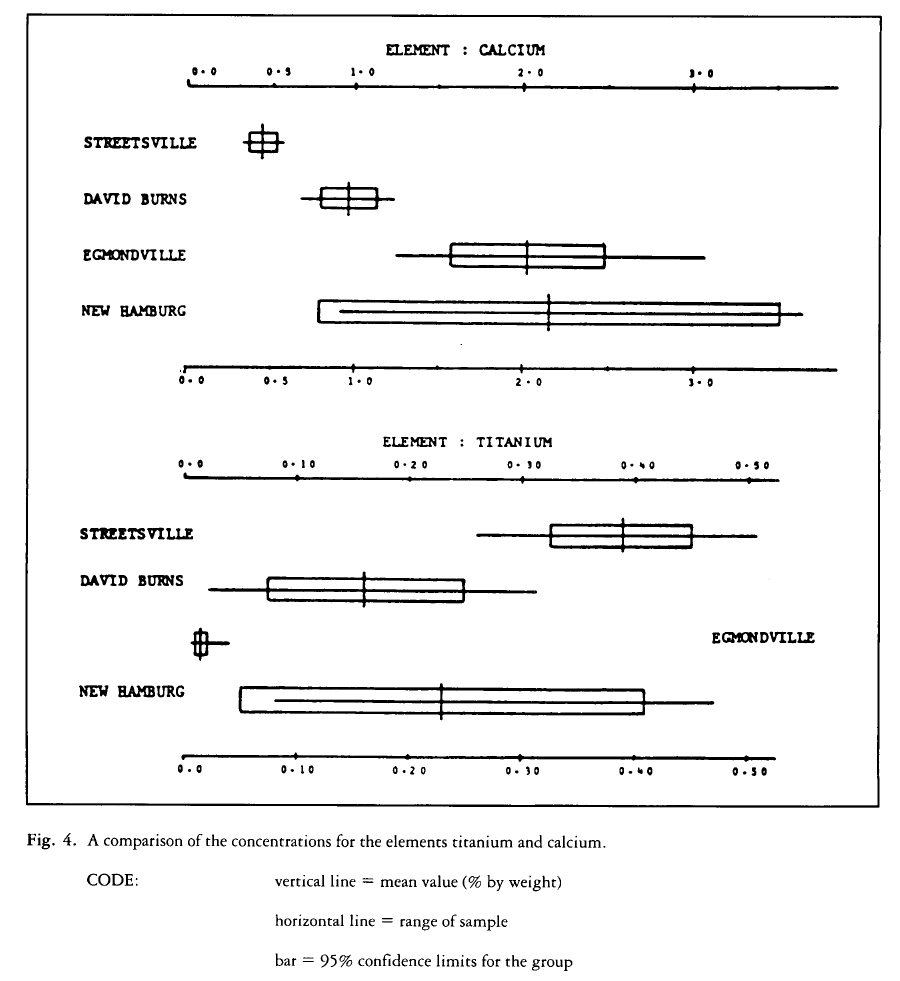

Display large image of Figure 37 Unfortunately not all four groups of sherds were analysed by the same technique. Therefore, although both methods were checked for accuracy against samples of known concentration with no significant discrepancies observed, comparison between all four groups of results illustrated in figure 4 must be treated carefully. This is particularly true since the numerical results presented for the PIXE analysis are not an overall average for the whole profile but only that of the surface which corresponds to a glaze depth in which there occurred minimal fluctuation in elemental concentration of any one sherd. Large variances in some elemental concentrations (especially for the New Hamburg Pottery) might be due to the selection of sherds from the kiln as indicated earlier.

Display large image of Figure 4

Display large image of Figure 48 On the basis of a statistical t-test the difference between the means of the calcium concentration in the David Burns and the Streetsville pottery is significant at the 95 pet cent confidence level. In a similar manner, PIXE analysis has established a significant difference between the titanium concentrations of the New Hamburg and the Egmondville pottery groups. It is tempting to go further and draw conclusions from the measurements among the four groups, for example, that the low titanium concentration in the Egmondville Pottery is a characteristic of this pottery and hence even of the Germanic school. Because we are not certain that the two analytical techniques sampled the same section of material, as was discussed earlier, we hesitate to draw this conclusion.

Conclusion

9 Although elemental fingerprints have not been found for the pottery from the four kilns examined, concentration differences have been observed in the glaze which seem to allow a partial classification. The external beam proton microprobe has proved to be a simple instrument to use and to give information about the elemental profiles of the thin glaze on the pottery.

* The glazed sherds from all four pottery sites were generously supplied by David L. Newlands of the University of Toronto. Without the many useful discussions with Professors J.A. Page and J.F. Hanlan this work would not have been completed.