Research Notes / Notes de recherche

Woodworking Patterns at the Sutherland Steam Mill, Nova Scotia Museum

Display large image of Figure 1

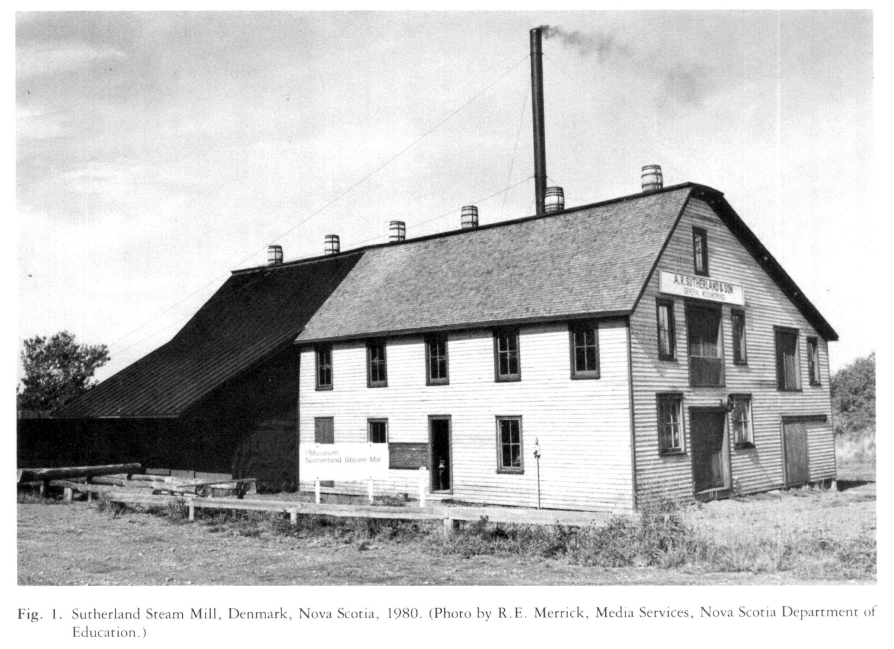

Display large image of Figure 11 In 1974 the province of Nova Scotia acquired a steam-powered sawmill and woodworking shop in Denmark, Colchester County. After a period of research, restoration, and stabilization, the mill was returned to operating condition and opened to the public in 1979 as a branch of the Nova Scotia Museum. The Sutherland Steam Mill is one of three wood product mills operated by the Nova Scotia Museum; the others are the stave and shingle mill at Ross Farm Museum, New Ross, and the McDonald Brothers' waterpowered sawmill reconstruction at Sherbrooke Village.1

2 The Sutherland Steam Mill was established about 1894 by Alexander Robert Sutherland (1866-1953), a carriage maker who operated a small carriage shop at West Branch, Pictou County, before moving to Denmark to set up the mill.2 By 1902 his brother, John Thomas Sutherland, a carpenter, had joined him in the business. Sutherland Brothers and Company is listed in McAlpine's Nova Scotia. Magdelene Islands & St. Pierre Directory ... 1902 as a sash and door factory. Thomas built several houses in the area using the products of the mill while Alexander specialized in carriage making and the operation of the mill and shop.

3 Alexander managed the business on his own from 1910 until 1930, when he was joined by his son Wilfred. During World War II the business responded to the great need for export lumber. By this time the demand for carriage making had all but disappeared. Wilfred continued to supply lumber, custom sawing, and custom mill work locally until he finally closed the mill in 1958 because of his health.

Display large image of Figure 2

Display large image of Figure 2 Display large image of Figure 3

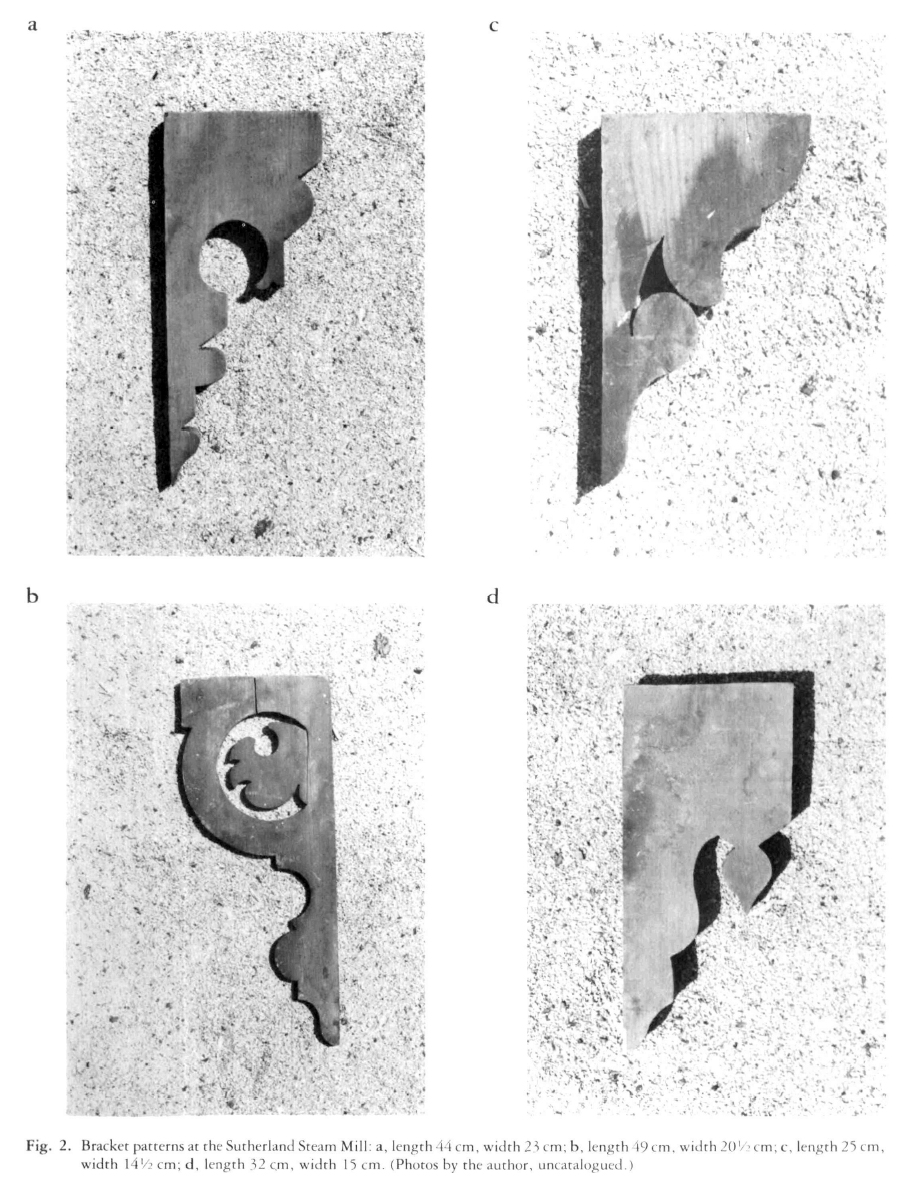

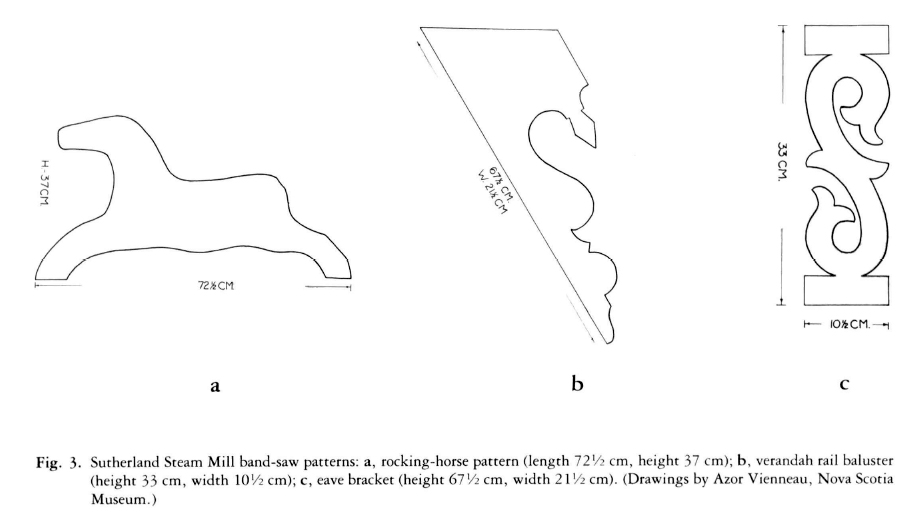

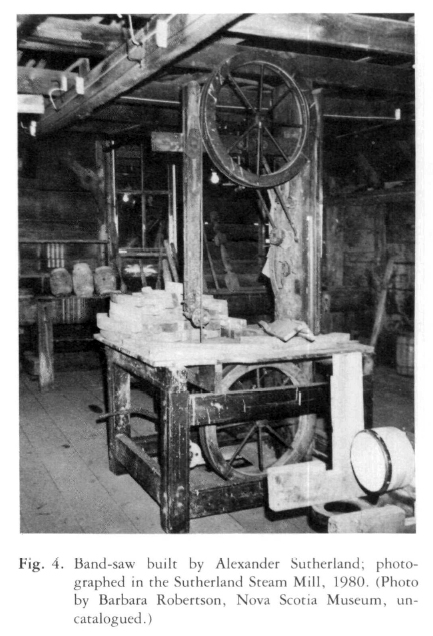

Display large image of Figure 34 A significant collection of patterns used in the production of specialty mill work in the woodworking shop have survived at the Sutherland Steam Mill. The patterns are softwood templates, ½ to 1 ½ inches thick, used to trace the outline of the intended product on dressed pine stock with a pencil or scribe before it was cut on either a band-saw or a reciprocating (jig) saw. Several of the woodworking machines in the mill were made by Alexander Sutherland. Included in the inventory of home-built machines are two band-saws and a jigsaw.

5 The majority of the patterns that remain in the woodworking shop are for various styles of exterior house trim commonly referred to as gingerbread. Other patterns include buggy-seat bases, wagon-jack parts, a rocking horse, and shelf brackets. To date approximately thirty patterns have been identified, measured, traced, and photographed. More remain to be discovered and identified amid the mass of mill ends, stock, and patterns in the shop.

6 The origin of the patterns is unknown but Wilfred Sutherland believes that they were copied or adapted from prevalent styles of the time. Much of the actual band-saw cutting was done by Alexander Sutherland or by apprentices under his supervision. Production of the decorative trim for houses continued into the 1930s when demand gradually tapered off.

Display large image of Figure 4

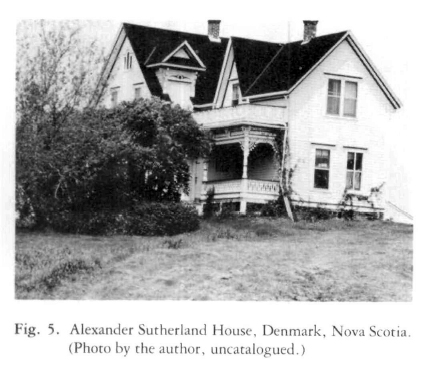

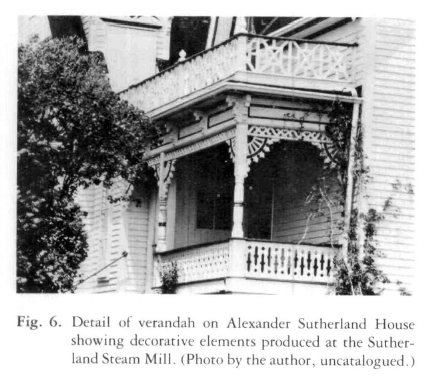

Display large image of Figure 47 Buildings in the area which exhibit decorative elements produced at the Sutherland Steam Mill include the Allister Hamilton house at Brule Point, the Denmark Community Hall, and the Alexander Sutherland and MacLeod houses in Denmark. Identification of all surviving buildings built by Thomas Sutherland in the region or built by others using decorative products from the mill has yet to be completed.

Display large image of Figure 5

Display large image of Figure 5 Display large image of Figure 6

Display large image of Figure 6*A report on work in progress on a collection of wooden patterns at the Sutherland Steam Mill. The author would appreciate hearing from anyone familiar with similar collections.