Research Notes / Notes de recherche

Georgetown Mill, B.C.:

A Historical Salvage Project

Introduction

1 In 1978 a disastrous fire completely destroyed one of the oldest sawmills in British Columbia. The loss of machinery and buildings, some dating from 1875, is irreparable. The summer before the fire, the National Museum of Man, in collaboration with the British Columbia Provincial Museum and the Museum of Northern British Columbia in Prince Rupert, undertook to survey, photograph and study the production of the mill at Georgetown. With its history of minority employment, unique capitalization and management and its community organization, typical of small mill camp life style, the mill illustrates an important aspect of British Columbia's development. The tragedy of the fire points to the need to salvage remaining examples of the province's heritage.

2 The project was designed to determine changes in technology, economy and life styles through a study of logging and sawmilling at Georgetown. Fifteen researchers were divided into two document groups and a field group: the document teams were to research newspapers, corporate, provincial and labour archives, private collections, the Legislative Library and to interview people who had lived on the site; the field workers were to study the geography and technology of the mill, photographing, measuring and describing its parts. Another of the project's objectives was to draw up a list of artifacts to be collected.

Ⅰ. Training and Field Research

3 A two week training session was organized in Victoria where the staff participated in a series of lectures followed by discussions with members of the staffs of the British Columbia Provincial Museum and the Provincial Archives, the Provincial Archeologist, and a retired Provincial Chief Forester. The International Woodworkers of America sent a speaker on labour history. Films from the National Film Board and videotapes were screened. Each trainee gave an exposé of one aspect of sawmill technology. Field trips to sawmills and museums completed the programme. The field team, with gear for two months of work, set out from Victoria to Prince Rupert. Equipment, food and field-workers were transported to Georgetown on James Donaldson's tug, the "Two Rivers". Limited to half an hour at the Georgetown dock by the twenty foot tidal range, the team unloaded the cargo using a handpowered crane. The manager's abandoned and filthy cottage was swept out, plastic tacked on the windows, doors hung and stoves installed. Firewood and water were brought in, bread set to rise, and a quick photo survey made of the mill machinery to send to the Victoria team for their technology research. The "Two Rivers" left and the team settled in. The first five days were spent organizing the camp. The activities and achievements of the researchers are summarized below.

Display large image of Figure 1

Display large image of Figure 11. Georgetown Mills survey — Mark Marquette, Researcher

4 The terrain was surveyed with the plane table, alidade and metric tapes. The survey was refined to include the floor plans of mill buildings, mill outbuildings, the position of machinery, flumes and penstocks. The field notes were transferred to maps and shop plans drawn to scale. Finished drawings, listed as Drawings, were made later in Victoria.

2. Photographic survey — Eleanor Frisk, David Lawford, Researchers

5 The photographic survey was made with black and white fast film and diapositive fast film, using available light. The individual negatives were listed in a catalogue, showing the type of film, aspect, exposure, distance and exposure time, coupled with the subject reference. The survey included all aspects of the mill. Unfortunately, the poor quality of many photographs necessitated a second, smaller, survey in the summer of 1978, a few weeks before the destruction of the mill by fire.

3. Machinery drawing — Mike Perodeau, Researcher

6 Mike Perodeau, engineering student, spent several weeks analyzing, sketching, and measuring the 8 sawmill machines. The working sketches and measurements were transferred to preliminary schematic drawings, to scale. The engineering drawings, completed in Victoria, included a translucent overlay of the power train, showing the belt and sheave takeoffs from the main power shaft.

7 Jimmy Donaldson, who had managed the mill, and Jimmy Woodhouse, who had served as millwright, sawfiler and sawyer from 1920 through 1949, explained the flow of materials, power and organization in the mill, and the stationing of workmen at their machines.1 These informants were the major source of technical information.

Display large image of Figure 2

Display large image of Figure 24. Building survey — Marion Rose, Researcher

8 All the Georgetown dwellings and shop buildings were surveyed. Walls, door and window openings and chimneys were measured and floor plans drawn. The materials, mode of construction, and details were noted using an inventory sheet derived from the National Historic Sites building inventory.

5. Conclusion of research at Georgetown — Mary Shakespeare, co-leader

9 By mid-July, despite the poor weather, the team finished the tasks, checked measurements, sketches, photographs, and descriptions, packed the gear, and left Georgetown nearly as they found it.

10 The photographers and draughtsmen returned to Victoria in August to finish their work. Aural histories of millworkers and their families were taken by Mary Shakespeare and Marion Rose in Prince Rupert, Port Simpson, and Terrace. The United Church archives, the Prince Rupert Daily News and Evening Empire and the Land Registry Office records in Prince Rupert were searched for references to Geotgetown and the lumber industry.

Display large image of Figure 3

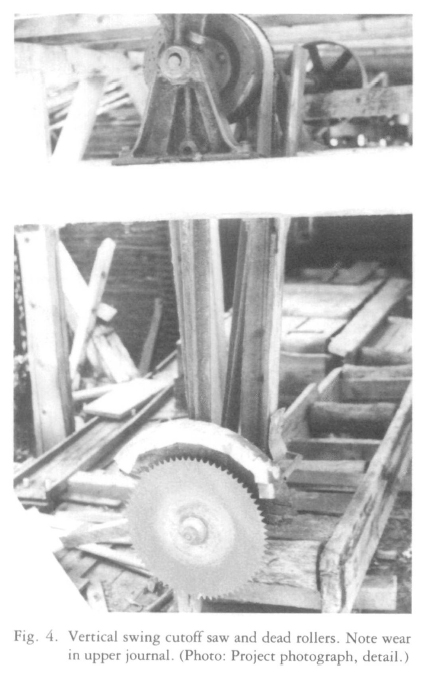

Display large image of Figure 3 Display large image of Figure 4

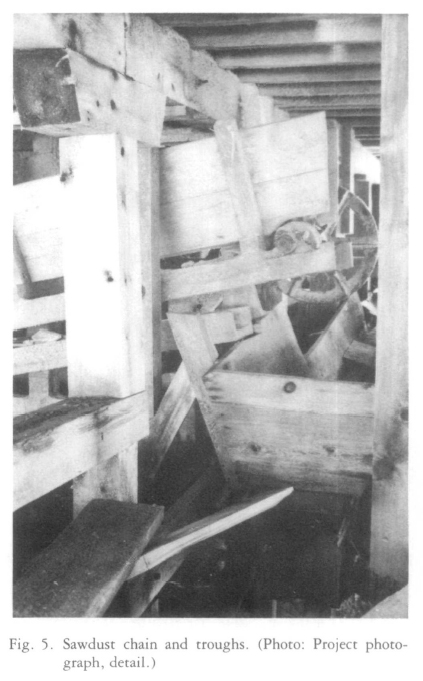

Display large image of Figure 4 Display large image of Figure 5

Display large image of Figure 5Ⅱ. Document Research

11 The major themes for the document research were historical background, changes in life style and technology, and the influence of markets on the lumber industry. The research subjects were to include general data on logging, sawmilling, transportation, forest product economy, labour and life styles in the Pacific northwest which would relate to the history of Georgetown Mill.

1. Early history preceding establishment of Georgetown — Karen Duffek, Mary Shakespeare, and Rodney Pain, Researchers

12 The Tsimshian Native People lived at the site later taken over by the people of Georgetown Mill. Captain James Cook,2 in 1778, and later Captain George Vancouver, who charted the Tsimshian peninsula,3 opened a century of rapid development and competition. The English opposed the Spanish, the Hudson's Bay Company contended with American and Russian traders. By 1875 the northern British Columbian coast was still largely empty of Canadian enterprises, but the religious community of Metlakatla, the Hudson's Bay Company town of Port Simpson, and the Inverness Cannery on the Skeena River, promised a small market for lumber.

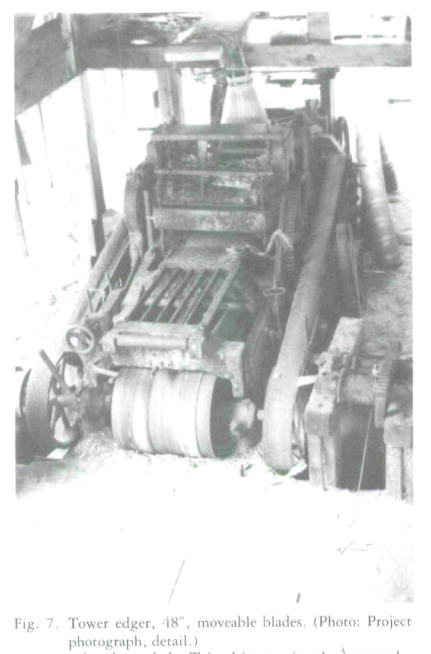

Display large image of Figure 7

Display large image of Figure 72. Corporate and biographical history — Ulla Hansen, Researcher

13 George Williscroft, Charles Morison, and Thomas Elwynn founded Georgetown Mill in 1875. Williscroft's father and Thomas Elwynn were Irish; Morison, English.4 Williscroft was from Bruce County, Ontario, where his family had contact with sawmilling. He came to Port Simpson, near Georgetown with Morison, who then left to help build the Cariboo Wagon Road.6 Williscroft ran a hotel for a while in the gold mining district or the Cariboo,7 and prospected for gold at Dease Lake and Fort Wrangell. Thomas Elwynn, Crimean War officer, mined at Williams Creek and worked for the Western Union Telegraph in the Skeena district, where he might have met Morison. First a gold Commissioner for the colonial government, then Deputy Provincial Secretary, Elwynn helped the sawmill from the government center in Victoria. Energetic, ambitious risk-takers, these three independent men joined to form one of the very few businesses on the coast. In 1875 they founded the mill at Big Bay, about eight kilometers from Port Simpson on the Nass River, thirty from Port Essington on the Skeena, and twelve from Metlakatla.

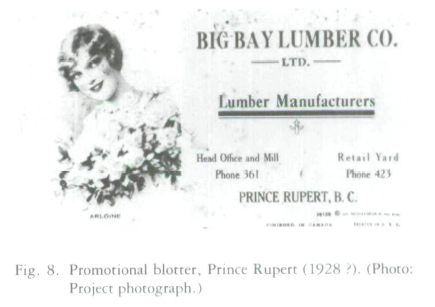

Display large image of Figure 8

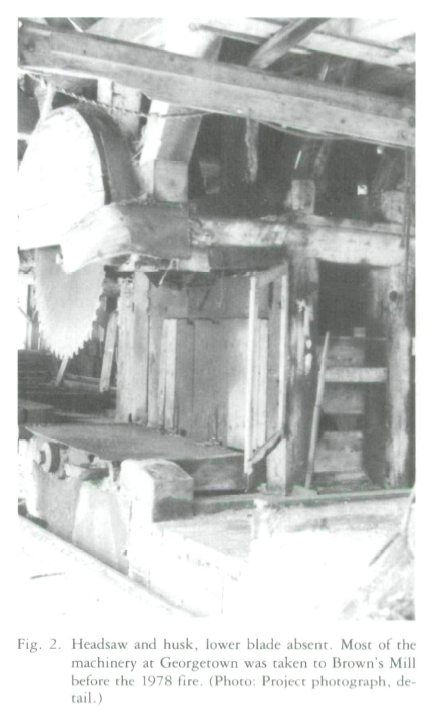

Display large image of Figure 814 Everything moved by boat, over sea and river. A market for lumber existed and within a year the waterpowered mill not only cut, but planed, lumber.9 The first salmon cannery in the Canadian northwest opened on the Skeena River in the same year as the sawmill. Canneries used lumber for boats, docks, floats, factory buildings, dwellings, and shipping cases. Cutting lumber meant getting timber to the mill. Elwynn, now Deputy Provincial Secretary, applied for a 2,000 acre logging site near Georgetown.10

15 Land costs were low for seven years. In 1882 Elwynn bought the 100 acres surrounding the mill for $5.00 and soon transferred it to Williscroft. No record of outside capitalization appears in the first years of corporate history. Oldtimers tell an unconfirmed tale of Williscroft's disappearances into the bush, emerging days later with gold dust to pay the millworkers wages.11

16 Williscroft bought out Morison in 1879. The mill continued to sell lumber locally and for export.12 In 1895 George Williscroft died, and his brother Walter ran the mill for three years. In 1897 the company reorganized, with local shareholders.13 Ownership of Georgetown shifted to William Kergin, Cyrus and Haliburton Peck, and then to Donald Moore, who with Cyrus Peck, owned Cassiar Cannery. Bad luck beset the business: fires ravaged the mill; the steamboat "Nell" burned, was refitted, and then sank.

17 World War One created a demand for airplane spruce which was found largely on the Queen Charlotte Islands, offshore from Georgetown. The British government appointed the Imperial Munitions Board to control the buying of spruce, with H.R. MacMillan and George McAfee on the Board.14 MacMillan, previously Chief Forester of British Columbia and later to become an international lumber baron, joined McAfee to lease and then buy the mill in 1919. The mill prospered with McAfee managing and MacMillan arranging exports. In 1927 the machinery was moved to equip a new steam mill at Seal Cove, Prince Rupert, where expansion and transportation could match the needs of the H.R. MacMillan Export Company. Reorganized as the Georgetown Spruce and Cedar Company, and then the Big Bay Lumber Company, the Prince Rupert mill made money until the Great Depression. Company records and interviews with survivors of the era imply deep discord in management. The mill was heavily mortgaged. McAfee and Sunbury bought out MacMillan.15

18 Under the new management of Selah Sunbury, the mill machinery was returned to a refurbished Georgetown Mill, and Big Bay once again had an industry and a community. Reorganized as the Georgetown Lumber and Box Company with Sunbury and Weldon R. McAfee in charge, after his father George died, the mill was sold in 1949 to James Donaldson.16

19 Cutting boxes for the halibut fishery of Prince Rupert, and alternating operations with the sister mill at Brown's Mill, on the Oxtail River, off the Skeena, the mill continued a reduced operation until 1969, when competition from cardboard containers made the mill uneconomical, and it closed.

3. Changes in life style (Sawmill community life, education, religion, labour organization, safety, clothing) — Penny Houlden, Brigid Weiler, Antoinette Donaldson, Theresa Low, Researchers

20 When Georgetown Mill was established in 1875, individuals from the gold rush were leaving the Cariboo, traders were established and religious missions were already operating among Native People. Steam and sailing vessels visited the area frequently.

21 The austere life style at the mill was typical for a western frontier settlement. The first weeks at Georgetown may be surmised from an account in the same year by Rev. Thomas Crosby at nearby Port Simpson: "...I had even to go to the woods to get out timber, not with oxen or horses, or even dogs. Our mode is to chop down the trees and haul the logs out of the woods by hand ....some so large, this was no light work."17

22 Metlakatla, with its reputation for hardworking, reliable Tsimshians, was about twelve kilometers by sea to the south. The Tsimshians of Metlakatla and Port Simpson had been exposed to a Victorian style of living, with European clothing, houses, trades, religions, services and foodstuffs. Although the number employed at Georgetown is not known, nor the proportions of Orientals and Caucasians, it is reasonable to assume that Indian families, single Orientals, and both single and married Caucasians made up the early work force. Their accommodations and life style would approximate those of the nearest settlements, with framed clapboard houses, stoves, European clothing, food, and religion. The Orientals would live in their own bachelor quarters.

23 In 1903, there were 1,800 whites, 240 Chinese, and 425 Japanese in the entire lumbering industry in British Columbia.18 A millwright made $17 a week; labourers, $6 to $12. Chinese were paid $6 a week; Japanese and Hindus, $6.60. A general shortage of workers gave Oriental immigrants opportunities to work in the woods.

24 Georgetown, in 1907, was big enough to have a store, church and school. The teacher earned $14 a week. In nearby Port Essington, oatmeal, beans and rice were 5 cents a pound; tea, 50 cents; and cheap coffee, 25 cents. The first school in Georgetown, in 1907, had ten boys and six girls. There were four trustees, all white, and all from mill management. The town was pretty, with shingled cedar houses and gardens, surrounded by the forest and flanked by Salmon Creek. The countryside gave trout, salmon, bottom fish, crab, clams, ducks, geese, deer, and an abundance of berries in season. Householders kept ducks, geese, chickens, goats, cows and dogs. The cows did not last however, since they did not do well on beach hay and sometimes even mired in the muskeg. Wolves and bears killed many dogs.

25 The disposition of the homes reflects the hierarchy of colour, wages and skills, which resulted in a tacit, but very real stratification within the community. The whites lived on the north bank of Salmon Creek and on the hill, while the Hindus, Chinese, Japanese and Native families lived on the south bank and on the shoreline. The whites taught school, managed the mill, ran the tugs, preached, gave first aid, and were the master craftsmen. Orientals and Natives were the labourers, "tail sawyers," at the discharge end of the big machines, working the booms and transfer dollies. Small exceptions to the stratification may have tempered minority antagonisms to the whites: a Japanese man was respected as an excellent blacksmith; a manager's house was built on the south, non-white, bank; some Chinese were housed on the hill near the manager's house; one manager was a half-breed. Many interviews of both men and women have, with one exception, elicited fond and slightly exaggerated memories of the mill. The last three successive mill managers were said to be mellow administrators who gave over seventy years of friendly leadership.

26 Managed from the outset by strong individualists, the mill set its own safety standards, which did not necessarily conform to those of the government. Trained first aid millhands or management, cared for the occasional amputated finger before shipping the victim, in the early days, to Port Simpson, and later to Prince Rupert. On one occasion, when a man was injured at full ebb tide with all the boats high and dry, the man had to wait until a boat could be floated to go to Prince Rupert. Although the man did very well despite the delay, the doctor protested to the Workmen's Compensation Board suggesting that at least one boat be anchored out in the stream, even at the lowest tides. Mill administrators were said to provide for the injured; when oiler Tatso was hurt on the log carriage and returned from hospital permanently incapacitated, he was pensioned and maintained in the camp.

27 The mystique of masculinity prevailed in the woods and in the mill, standing in the way of safety programmes. Safety clothing remained a matter of individual choice, with a workman buying his own caulked boots, gloves, or making a special safety apron from discarded wide belting. The caulked boots were probably the first safety articles in British Columbia and were initially caulked by the loggers themselves. The J. Leckie and Co. Ltd. which started making caulked boots in 1908, maintained that "a clumsy or illfitting boot may cause a man to miss his footing at a critical moment, and his life may pay the penalty."19 Following the Provincial Workmen's Compensation Acts in 1912, management and government gradually became more concerned with safety precautions and provided mandatory machinery guards and first aid specialists, as well as instruction about safe work habits. The mills were made safer. When exposed bevel gears on the live rolls at Georgetown took the fingers of a Native tail sawyer, the gears were boxed in.20 Safety and comfort were linked, and clothing was being manufactured for specialized occupational use by A.R. Clarke and Co., Toronto. They made a rigger's double palm leather glove, "[to] meet the growing need emanating from the premier industry ... It is an All Canadian and does all ... at the plant in Toronto."21

28 Religion, like safety, was an individual rather than an organized matter. Flanked by missions at Port Simpson and Metlakatla, Georgetown had its own religious figures, a church, and services which were held sporadically. There never was a resident minister, the Anglican and Methodist missionaries making occasional visits. The church building became a school, was then used as a storage for boat lumber, and was finally demolished and replaced by a home. The mission boats seemed to call more often for construction lumber than for religious services. Perhaps language was a problem for the missionary, who "spoke to the white people; the Japanese deckhand gathered his countrymen together in another place and spoke to them; the Chinese cook did the same for his friends; and Captain Oliver talked to the Indians in the Chinook jargon."22

29 The coal and hard rock miners in British Columbia had long been organized in unions when woods and mill-workers organized in 1912.23 Georgetown was not unionized until stevedores in Prince Rupert threatened to leave Georgetown scows loaded during World War II.24 "As soon as the organizer's boat got out of sight, the mill went back to work."

30 Isolation at Georgetown affected the ethnic groups in different ways. Single white men, living in the "Cook-house," and not well accepted by the permanent population, were often transient. Single Chinese men and white families stayed long on the payroll, as did single and married Japanese. Some Hindus were employed until elderly. Native Indians replaced the Japanese during the relocation of World War II.

31 Isolation gave Georgetown residents, self-styled "sawbusters," a special community experience. This experience was often expressed by comments such as, "the best years of my life," or "I wish I were there again." Shellfishing picnics, one-hoop basketball, cribbage, fishing, hunting, and visiting made happy memories. Trips to Port Simpson and Prince Rupert, after 1906, were free and frequent, depending on the weather, tide and schedule of scow trips. Jimmy Woodhouse would leave the mill on Friday evening and enjoy Prince Rupert until Monday morning. Single men drank and gambled, their liquor coming by mail, or "dropped off in a box by a fisherman."25 At other times Georgetown was a virtually dry camp.

32 Although other mills in the area had slumps, closures, wage disputes, or labour shortages, Georgetown seemed immune. The original Japanese families, presumably from Cassiar Cannery owned by Cyrus Peck, established a solid community and work force, not anxious to disturb the management. There is no record of the Chinese, Hindu and Tsimshian workers making labour trouble. Perhaps the security of a job, plus the isolation of the mill, inhibited labour unrest. Dissatisfaction may also have been hidden in the drinking and weekend binges. But, when questioned about labour dissatisfaction or unrest, former residents recall a remote, happy sawmill community. Individuals obviously forgot, or failed to mention, difficult times.

4. Machinery history of Georgetown Mill — Fraser Syme, Theresa Low, Researchers

33 A study of the first machinery at the Georgetown Mill provides information about the kind of technology available in 1875, the energy required to operate the machines, and the working conditions of the employees. The first machines in Georgetown were a headsaw, a log carriage, and a planer driven by a water wheel.26 The energy needed to run the water wheel was supplied by the 20-foot drop of Salmon Creek. Tidewater provided the sole access to sawlogs and the only way of shipping mill products. It was also the only way in and out of the mill for workers and their families. The mill could cut 5,000 feet of lumber a day.27 In 1880, the Victoria Daily Colonist wrote of Georgetown:

In 1879, a similar mill, at Chemainus, British Columbia, was ordered from Albion Iron Works in Victoria for $3,500.29

34 In 1875, Jeremiah Rogers, who logged the land where Vancouver stands, first used a steam tractor to move logs.30 The concentrated energy of steam was used to move more logs, quicker, to meet the growing demand for lumber. The harvesting of trees had to keep pace with demand, and in the 1870s, crosscut saws were introduced to speed up falling and bucking.31 The steam donkey replaced bull teams and the steam tractor. Logs were now yarded thousands of feet by cable from a stationary steam donkey.

35 Log and lumber transport at sea grew to meet the appetite for lumber. In 1874, the sidewheel steamer, "Beaver," was refitted as a towboat. Two years later, George Williscroft bought the schooner "Kate" to carry red and yellow cedar lumber to Victoria. Mill machinery, steam donkeys, tugs and locomotives increased in size and productivity.33

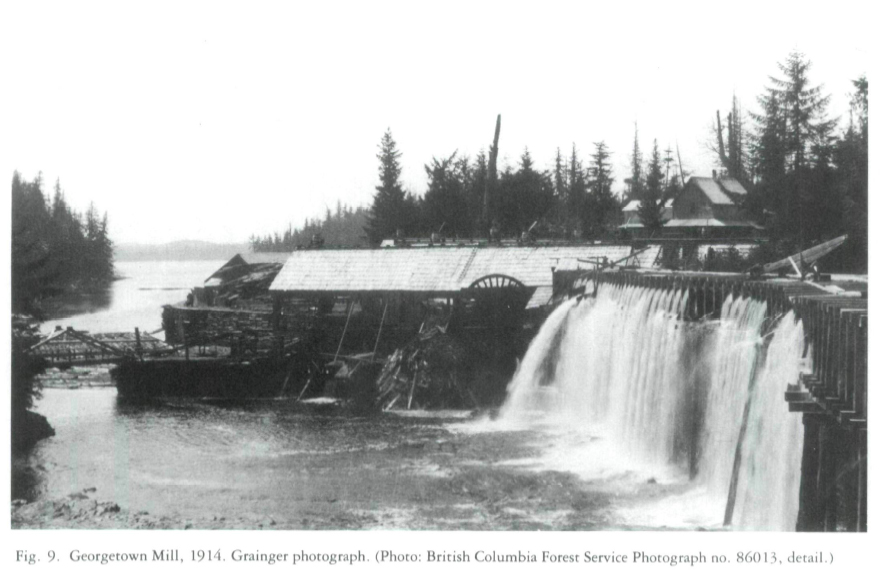

Display large image of Figure 9

Display large image of Figure 936 From 1880 to 1918, the impact of new machinery on Georgetown can be inferred from a record of increased productivity and demand. In 1886, there were six canneries on the Skeena; in 1896, nine.34 Port Simpson grew from a small Hudson's Bay Company post to a community of 800 Indians and 40 Caucasians. Georgetown Mill cut box shook and construction lumber for these markets. In 1906, Prince Rupert was created as the terminus for the Grand Trunk Pacific Railway. Georgetown Mill provided lumber for construction of the railway and town. The halibut fishery was greatly increased by the fast, refrigerated freighting to eastern markets, and halibut shipping boxes became an important Georgetown product for decades. In 1917, the mill, with 30 employees, produced 40,000 board feet a day of fir, and finished lumber and shook.35

37 In 1918, George McAfee doubled the capacity of Georgetown Mill by adding one relatively inexpensive machine, a water-powered electric generator. A second shift could then work by electric light.36

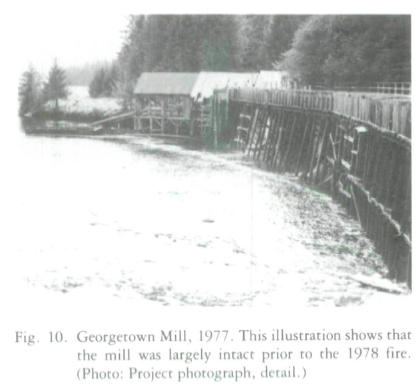

Display large image of Figure 10

Display large image of Figure 1038 Operating continuously through the early years of the depression, the mill prospered enough to allow installation of two new turbine water wheels and a new band resaw. These machines added 2,000,000 board feet to annual production.37 Machinery in the mill now included a headsaw and log carriage, cut-off and trim saws, edgers, a complete planing mill, a box factory, and the turbo-electric plant.38 Georgetown was remote from the railhead, and because of the limited amount of flat land, could not expand. In 1928, McAfee and MacMillan moved the machinery to Seal Cove, Prince Rupert, where dock and rail facilities were available, increased the capacity, and changed to steam power. Georgetown, on Big Bay, had been cutting 35,000 feet a day of aero spruce, box shook, and construction lumber.39 The new mill was rated to cut 50,000 to 60,000 feet a day. Within the year, a planing mill, moulder and edger, and new setworks were installed and McAfee contracted for six million board feet of logs to feed the machinery. They could now produce shiplap, smooth-four-sides dimensional lumber, dried spruce and cedar, ceiling and finish rustic, hemlock flooring, spruce-ceiling, boat cedar, and box shook for the salmon and halibut fisheries.40 Just as the mill achieved its greatest capacity, with its largest inventory of machinery and most powerful motors, the 1929 depression almost eliminated its markers. Four fires at Seal Cove and reduced sales brought a change in management. H.R. MacMillan was replaced by Sunbury. Most of the machinery was moved back to Big Bay and installed in the old mill to be used up to the time of closure in 1969.41 Georgetown would cut 20,000 feet a day and specialize in box shook.

39 The mill, with most of the machinery brought from Seal Cove, had a turbo-electric plant and a large double runner Samson turbine to run the mill, directly coupled to a 4½ or .115 m solid steel shaft, which powered the mill machinery. The main shaft was equipped with a wide pulley for each machine: the log winch, log turner, headsaw, carriage mechanism, live rolls, chipping hog, trim saws, edger, green chain, resaw, planer, and tumble saw. A pulley operated a reduction gear which powered a chain and cog gear to the machine and blacksmith shop at some distance from the mill houses. A separate penstock and turbine served the electric generator in a little house separate from the mill buildings.

40 Spare machines, saws, shafts, pulleys, gears, bearings, water wheel hubs, an old turbine, a moulding sticker, box printing machines, swaging and grinding parts and devices, a stock of flanges, couplings, nuts, bolts, and washers were stacked in the storage sheds, and in a midden, and in the edge of the woods. One huge planer sat in the weather on the loading dock. The machinery in the Georgetown Mill, identified more completely in photographs, drawings and descriptions, trade catalogues, and research cards can be studied as the mechanical culmination of a century of technology. It represents a century of alterations. Removed from engineering supplies and services, the men of the mill frequently had to improvise replacements. No automating devices were found. An archaic mill, kept in production by the box shook economy and saved from the scrap heap by its remoteness, Georgetown Mill never really entered the post World War Ⅱ era.

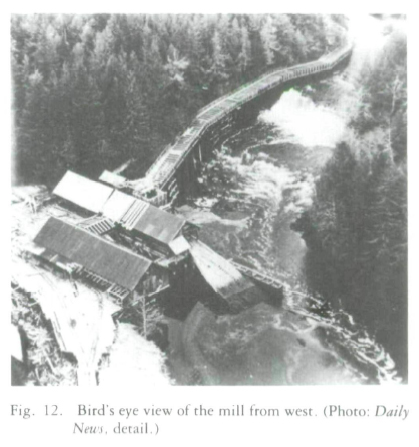

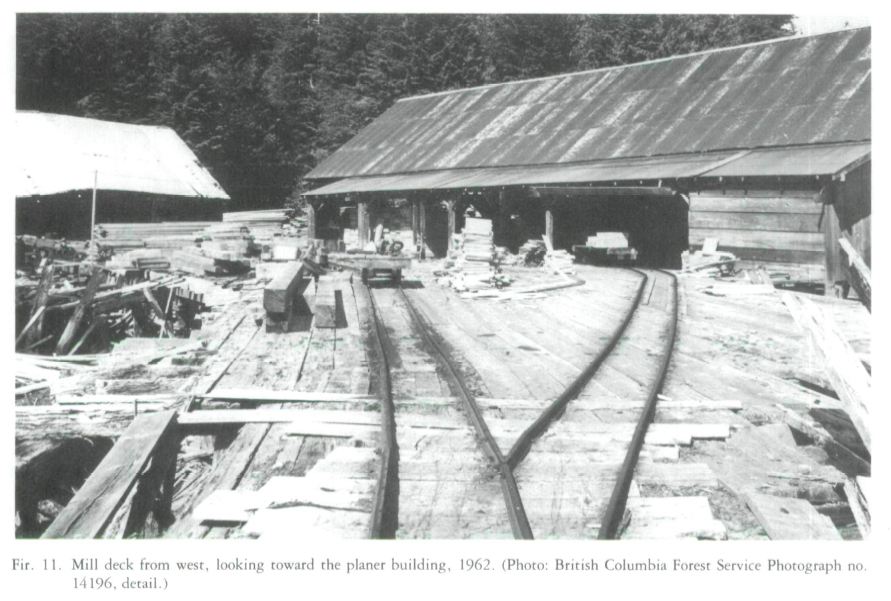

Display large image of Figure 11

Display large image of Figure 11 Display large image of Figure 12

Display large image of Figure 125. The economy and the mill: markets for box shook, dimensional lumber and logs — Grace Alexander, Researcher

41 Competitive for nearly a century Georgetown Mill declined because of changing technology and markets, and it died from lack of a market. Williscroft, Morison and Elwynn, the first entrepreneurs, travelled and worked throughout the Pacific northwest, from Victoria to Wrangell and from Port Simpson to Barkerville. Large distances, a small population, and isolated concentrations of activity were familiar themes to these men who brought technical skill, local knowledge, and a connection with the Victoria government, to their enterprise. They sought markets among the scattered settlements on an otherwise empty northern coast, serving the demands of trapping, fishing and canning, mining, storekeeping and religious missions.

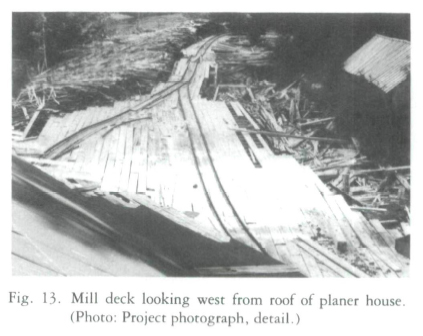

Display large image of Figure 13

Display large image of Figure 1342 Port Simpson and Metlakatla Mission built churches and houses to replace traditional native dwellings.42 Inverness Cannery opened at the mouth of the Skeena. The developing market for dimensional construction lumber and cannery box shook was partly served by ship from Puget Sound and Victoria, but there was enough demand left over for Georgetown Mill to come into being in 1875 and to survive the first decade.43

43 The salmon canning industry, starting in 1870 on the Sacramento River, California, with a demand for construction lumber and box shook, had moved up the coast from San Francisco to the Columbia River. From there it moved to the Fraser, and finally to the Nass and Skeena in 1875.

44 In 1896, the nine canneries on the Skeena used 100,140 shipping cases, a major market for Georgetown.44 The rise of the canneries resulted from a demand for cheap food protein in the expanding populations of western Europe, abundant salmon runs, effective canning technology, and efficient transportation to the markets.45

45 The trees of the Skeena country, cedar, spruce and hemlock, often close to the beachline and convenient for hand-loggers, met the needs of the trade. Cedar was used for dwellings, boats and industrial buildings; spruce and air dried hemlock for cannery cases. Technological advances (steam tugs, steam donkey engines, steam locomotives and effective turbines), contributed to the efficient production of planks.

46 After a prosperous decade (1936-1946), caused by World War II, the mill went slowly downhill. A change in halibut marketing eliminated wooden boxes. The fish were no longer shipped frozen in bulk boxes to the east. Packed in small, retail cardboard packages and done up in cardboard shipping boxes, halibut no longer needed the hemlock and spruce shipping cases. James Donaldson had bought the mill in 1949 to protect the markets for his Brown's Mill. He had a manager operate Georgetown, as his primary interest was in Brown's. Having recovered his investment in Georgetown, he yielded to the competition of the cardboard containers and closed the mill in 1969.

47 The economic history of Georgetown is a chronicle of personalities and markets. In the late nineteenth century, Williscroft saw a market for lumber and built the mill. Ninety-three years later, James Donaldson saw the failure of the fishbox market and closed it.46

48 The disastrous fire which destroyed Georgetown Mill indicates the necessity to act quickly to save existing mills. Because the owner of the mill, Jimmy Donaldson, had the foresight to transfer a lot of the machinery to his second mill, (Brown's Mill), the possibility of creating a historical museum still exists. If provincial and federal museums, in collaboration with local groups, could initiate work on such a museum in Prince Rupert or at Brown's Mill, it would create an added attraction for the 40,000 tourists who visit the area and provide residents with a source of knowledge and pride in their heritage.

* The authors wish to thank the following individuals for their help: Dan Gallacher and James Wardrop, History Division and John Kyte, Liaison Officer, of the British Columbia Provincial Museum; Bjorn Simonson, Provincial Archeologist; Lawrence Swannel, Provincial Chief Fotestet; Fran Gundry, Geoffrey Castle and Bonita Ilett, British Columbia Provincial Archives; Don Burchill, British Columbia Forest Products, Inc.; Ken McKuen, I. W. A.; Bob Griffin, Forest Museum, Duncan; and the Gardner brothers of the Saanich Historical Artifacts Society. In Vancouver, Bob Watt, Centennial Museum; Sue Baptie, City Archivist; and Jo Rowland, MacMillan Bloedel Company,. In Prince Rupert, M.J. Pattetson, former curatot of the Museum of Northern British Columbia and James Donaldson, mill owner. The latter's help and generosity were invaluable. Finally, at Ottawa, David Richeson and Thiery Ruddel of the National Museum of Man. Ruddel's help in all stages of this work, including the revision of two earlier drafts of this article, was a significant factor in the completion of the project.