Articles

Shanty Life in the Kawarthas, 1850-1855

The papers of the Mossom Boyd Company, deposited in the Public Archives of Canada, enable the researcher to investigate the intricacies of manufacture and trade in the square timber and sawlog economies throughout the second half of the nineteenth century. The wide assortment of material available in this collection also gives some indication of the lifestyle and working conditions of those employed in these economies. For these men, working for a newly established business isolated in the backwoods of the Kawartha Lakes area, life in the 1850s was extremely hard. Primitive living quarters, insufficient diet, hard physical work, constant dangers, and poor pay were the mainstay of their existence. While the vast majority of lumbermen employed by Mossom Boyd seemed to accept their lot, as the labour market probably gave them no alternative, a few indicated their resentment through absenteeism, drink, and simply leaving their employment.

Les documents de la Mossom Boyd Company, conservés aux Archives publiques du Canada, permettent au chercheur d'étudier le domaine complexe de l'industrie et du commerce du bois équarri et du bois de sciage au cours de la seconde moitié du XIXe siècle. La grande diversité de données de la collection laisse aussi entrevoir le mode de vie et les conditions de travail dans ce secteur de l'économie. Pour les employés d'une jeune entreprise au fond des bois de la région des lacs Kawartha, la vie pendant les années 1850 était extrêmement difficile. Des baraquements rudimentaires, une alimentation inadéquate, un dur labeur, la présence constante du danger et un maigre salaire composaient leur lot. Même si la plupart des forestiers à l'emploi de Mossom Boyd semblaient s'accommoder de la situation, sans doute parce que l'état du marché du travail ne leur laissait pas le choix, quelques-uns manifestaient leur mécontentement en s'absentant du travail ou en buvant, ou abandonnaient tout simplement leur poste.

Introduction

1 By the mid-nineteenth century the square timber trade was of prime importance to the economic development of Upper Canada. Although the Ottawa River Valley was by far the single most important source of square timber other areas, further to the west, were also becoming involved in the trade. In one of the areas, the Kawartha Lakes, the papers of the Mossom Boyd Company enable the researcher to not only examine the intricacies of the trade itself but also indicate the lifestyle and working conditions of the men who lived and worked in the woods. While the papers do not answer all the questions one might have about life in the woods they do allow a fairly accurate description to be presented and some conclusions to be reached.

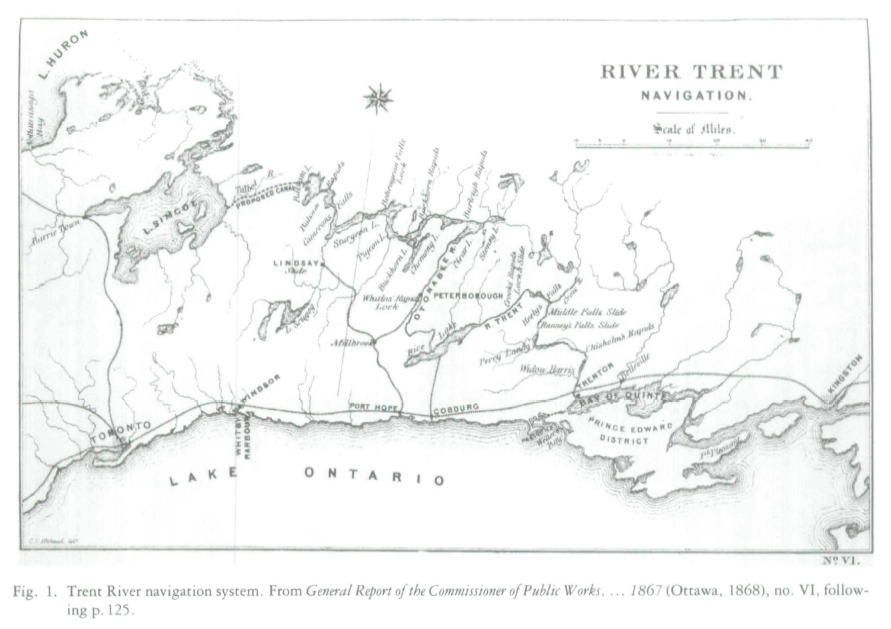

2 In the first half of the nineteenth century lumbering activities throughout the Trent River-Kawartha Lakes region were limited. In the lower regions of the Trent, square timber was stripped from Seymour Township in the 1820s and 1830s, but the inadequacy of the Trent River for transportation and the natural advantages of the lower Ottawa River in its proximity to the Quebec market mitigated against extensive exploitation of the area for square timber.1 Throughout the Trent River and the Kawartha Lakes there were a number of small sawmills supplying sawn lumber for the local settlers, but the business was limited, again by the geography and settlement of the region.

3 During the early 1840s there were a number of significant developments that considerably increased the viability of the square timber trade in the Kawartha Lakes area. The first was the completion in 1844-45 of the dams and slides on the Trent and Otonabee Rivers which allowed the safe passage of timber to Lake Ontario. At the same time the forest cover along the lower Ottawa River had been exploited and the new areas further up the river now made the Trent River area competitive in terms of cost. Thus by 1845 over 50 outfits of various sizes were involved in exploiting the forest resources of the Trent-Otonabee area, sending down river 143 cribs of hardwood timber, posts, staves, or sawn lumber, 2,508 cribs of other lumber or sawlogs, 54 masts, and 43 pieces of other timber.2 By 1848 Thomas Keefer reported that the timber along the Trent River was about exhausted and that future supplies would come from the Otonabee area.3

4 In the same year Mossom Boyd first entered the square timber trade, cutting trees in the vicinity of Sturgeon and Pigeon Lakes. Boyd had emigrated to Upper Canada in 1834, one of the "gentlemen farmers" who moved into the Kawartha Lakes region hoping to become part of a new landed aristocracy in the British colony. By 1838 Boyd had found that farming gave little return and had settled in Bobcaygeon where he assisted Thomas Need in the running of his small sawmill. In 1844, on Need's return to England, Boyd took over management of the sawmill and in 1847 took possession by a mortgage from Need. In the next 8 years Boyd not only moved into the square timber trade with Great Britain but also expanded his sawmill and began exporting considerable quantities of sawn lumber to the New York market. By 1858 he reported his business to be in a "very flourishing state" with 2,576 pieces of white pine, 43 pieces of elm, and 153 white pine masts for the Quebec market and £13,000 worth of sawn lumber for Troy, Albany, and New York on which he hoped to make a "handsome profit."4 During these first ten years of his operations the papers left by Mossom Boyd are sporadic and incomplete, but when added to other printed and documentary sources they do enable us to survey the living and working conditions of a number of men employed by a young and relatively inexperienced business competing in a large staple trade with many others.

Display large image of Figure 1

Display large image of Figure 15 Throughout the nineteenth century the process of lumbering was inextricably tied to the seasonal weather patterns. In late summer and early fall the first men were sent into the woods to locate and build a shanty and storehouse. As the fall progressed supplies were taken into the woods. When the shanty was ready and the ground was frozen hard, the axemen were sent in to cut and square the timbers and chop the sawlogs. After Christmas, when the snow was deep and the temperature at its lowest, the teamsters moved in to skid the timber and sawlogs from the woods to the rivers and the streams, where they were left for the spring thaw. For the men involved, life in the bush was hard. Living conditions in the shanties were primitive and working conditions included long hours and strenuous and dangerous physical work with little rewards even in the way of pay at the end of the season. In the crowded British North American labour market, however, there were few, if any, alternatives and only during the periodic and regional labour shortages did the nun have any bargaining ability.

Shanty Life

6 Once the lumberman determined the area he wished to cut and controlled access to this area by purchase of land, purchase of timber rights, or obtaining a licence, he was free to start the year's work. For the small outfit, perhaps a father and his sons or a few hired hands, or even the small time lumberman, little in the way of capital was needed during the early years. If the lumber was cut on Crown land without licence, or on private land in trespass, all that was necessary was a winter's supply of salt pork and flour, the staple diet of the subsistence settler, some axes, and horses or oxen. For the larger business enterprise capital was needed to pay advances on the licence, to purchase supplies, and to pay the fares of the men going to the camp if hired from Quebec or outside.

Display large image of Figure 2

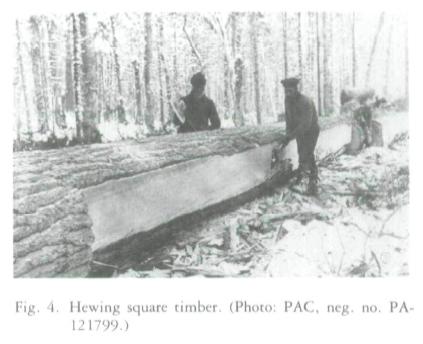

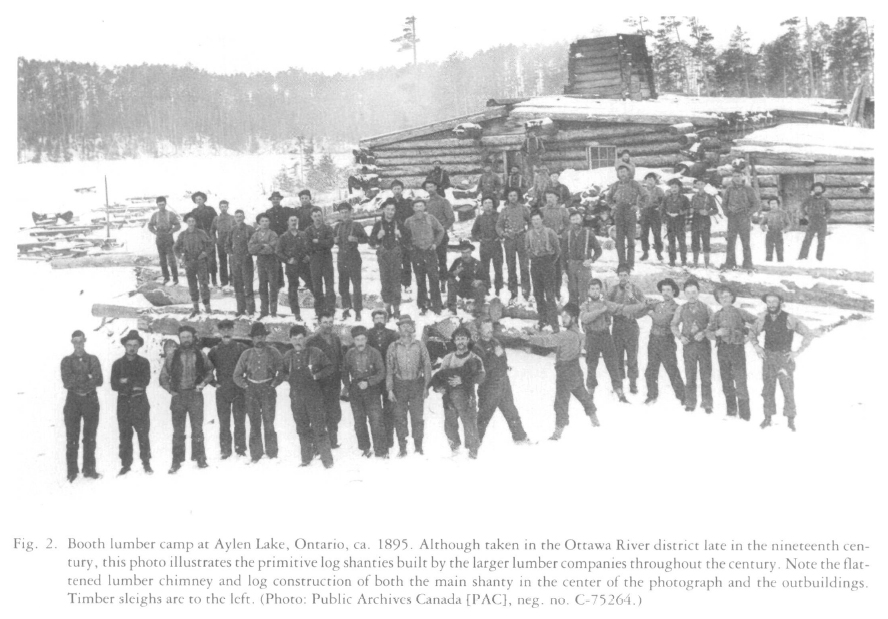

Display large image of Figure 27 The first task, whether a small outfit or a well-established company, was to prepare winter living quarters. The shanty, or hut, was usually placed on a stream at the centre of the area to be cut in the ensuing period. This guaranteed a supply of water and the most efficient travelling from the shanty to the actual work place. Once the appropriate site was chosen, the building was constructed of notched logs laid tier on tier to a suitable height with a roof of shingles covered with hemlock or spruce boughs for insulation beneath the snow. A large hole was left in the centre of the roof for the smoke to exit, as the fire was placed in the centre of the shanty. Other similar buildings were constructed for draft animals.5 Inside the building "hay, straw or fir branches are spread across the whole length of the habitation, on which they all lie down together at night to sleep with their feet next to the fire."6 Once the buildings were finished work was started on clearing roads which were used for bringing in supplies and, later, moving the timber and sawlogs out to the streams.

8 In November when the ground was hard and there was often some snow, the actual felling of the trees could begin. By this time the supplies would be sent to the camp along with the majority of the men if it was more than a family affair. In the Kawartha Lakes area it seems that there was a considerable mixture of men employed in the woods. Mossom Boyd hired local men and French-Canadian lumbermen for his shanties. He used his buyer in Quebec to hire the French-Canadians who were given advances for their transportation to Bobcaygeon in order to begin work. Although records of the various companies and individuals working in the woods at this time are at best uneven, it seems that Boyd's practice of hiring both local and outsiders for his camps was common.7

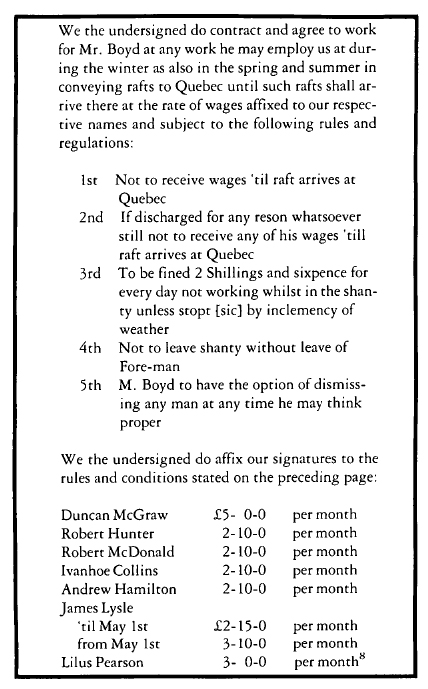

9 When hired, a contract was signed between the lumberman and those who were to work for him. The following contract from the Boyd papers gives a good idea of the typical contract as well as the conditions of employment and pay in 1850.

10 Prominent in the contract is the fact that the obligations rested with the employees while all the legal rights remained with Boyd, the employer. Thus the employee had no right to the product of his labour until the end of the season, other than that given in terms of board and lodging. More importantly, every day not worked could result in a fine equal to 12.5 per cent or ⅛ of his monthly wage, if his wages were £2.10.0. A few days lost for any number of reasons from sickness to drunkenness would very quickly deplete a lumberworker's yearly income. In addition, there was no way for the worker to bring legitimate grievances to the employer. This left quitting as the only way for the worker to react to anything he found unfavourable, and his ability to do even this final act was circumscribed by his inability to collect his wages.

11 The men brought all their own articles of clothes with them or, once in the camp, bought from their employer. All items bought, including tea, tobacco, boots, knives, and combs, were charged to each employee's account and deducted from his monthly wage. The prices for these goods varied depending upon the time of the year bought. Generally all goods became more expensive in the late winter and early spring before new supplies for the year arrived. The purchase of a typical shantyman can be seen in the case of Robert McDonald, who worked for Mossom Boyd in 1851.

½ lb. tobacco 0-0-7½

½ lb. tobacco 0-0-9

Feb. 3

1 pr. shoes packs (moccasins) 0-3-9

1 pr. mitts 0-1-6

13

1 pipe 0-0-½

16

1/2 lb. tobacco 0-0-9

26

1/2 lb. tobacco 0-0-9

1 pipe 0-0-½

Mar. 7

1 pr. boots 1-0-0 y9

12 Other goods such as soap, tea, medicine, doctors' bills, sugar, and trousers, were all charged to the men's accounts. For some of these goods there was a mark-up. In 1851 Boyd was paying R. Nicholls of Peterborough 1s.6d. per pound for tobacco and selling it at the same price to Robert McDonald (see above).10 Others, however, were being charged ls.9d. per pound, a mark-up of nearly 17 per cent. Other accounts suggest that a mark-up, if applied, was done in a rather haphazard manner. In 1851 Boyd was paying from 2s.2½d. to 3s.4d. per pound for tea while charging his men the same. There also seemed to be no mark-up on mitts, drawers or socks sold to the men.11 Thus, although probably expensive due to the distance goods were being transported and certainly expensive in terms of a monthly wage of £2.10.0, there was no huge mark-up as reputedly existed in other lumber camps.

13 Wages for the shantymen fluctuated with the general supply of labour and the particular conditions of the timber economy. Thus, while Boyd was paying £5.0.0 ($20.00) per month for his foremen and £2.10.0 ($10.00) for his other shantymen in 1850, the improved lumber market in 1851 meant that considerably higher wages had to be paid. In September of 1851, David Burnet, Boyd's Quebec agent, informed him that the foremen he hoped to hire demanded $30.00 and that broad axe men "expected" from $20.00 to $24.00 per month and "good hewers" $12.00 per month.12 The wage differentials noticeable here also underline the value of the more skilled shanty-men and their ability to demand considerably higher wages. Whatever the wages it is clear, however, that little was left for all except the most parsimonious shantymen at the end of the season as the cost of goods bought in the shanties as well as the cost of transportation to the shanty and home again if from Quebec would considerably deplete the season's income. Of those hired in 1850-51 by Mossom Boyd, the following accounts give some indication of cash at the end of the work season.

at £3-0-0 = £ 8-5-0

account against him £ 9-9-8½

at $18.00 = £10-4-0

account against him £ 2-1-3

£ 8-2-9

tea 1 ¼ £ 11-4

paid £ 7-3-5

at £3-0-0 = £ 7- 2- 0

account against him £ 4-15- 1½

paid £ 2- 6-11½

at £1-15-0 = £ 5- 9- 8

account against him £ 4-16- 8

paid £ -13

at £2-10-0 = £11- 6- 8

account against him £ 8-19- 5½

paid £ 2- 7- 2½13

14 As well as goods bought by the shantyman there were other actions or events that resulted in loss of pay. As the contract stated, days not worked resulted in fines. This seems to have primarily resulted from drunkenness, for which men were fined 15s. or $4.00.[The differences in the exchange rate between British and Canadian currencies are found in the original sources.] Time lost due to sickness or injury also resulted in loss of pay. Boyd's account books show that in 1851 Andrew Hamilton "got burnt" on February 4 and "lost 4 days." An unidentified shanty time book shows that in 1855-56 it was normal to have at least one man in a shanty of 20 to 30 men sick for a few days in any given one-week period.14

15 Given the low wages and the multitude of deductions it is not surprising that few shantymen had much to show for their labours at the end of the season. Only the most frugal could take home much money at all, and the cases such as Silas Pearson, who owed money to Boyd after working all winter, must have been far too common. Due to the lack of details in the account books and lack of knowledge of the individuals involved, it is difficult to know whether the money was expended on "luxury" items or the necessities required for working in the woods. It was common for men to have money forwarded to their wives and families or, if they lived in the vicinity, to take small cash advances home when they visited. In the account books this would be noted as "cash advances" only and so there is no way of knowing what the money was used for.

16 Living conditions in the small shanties of the Kawartha Lakes area were primitive, bur not strikingly different from those which faced many of the poorer immigrant settlers. Samuel Strickland reported that the shanties themselves were "large, warm, and comfortable. Standing-bed berths are constructed on the two sides and one end of the building, similar to those on board ship: the door is at the unoccupied end."15 Equipment and furniture in the shanty were minimal and give further evidence of the rudimentary conditions. In October 1851 Mossom Boyd had the following "furniture" delivered to James Lambert at the shanty: tour bake kettles, one soup pot, one tin kettle, two pails, five tin plates, three big dishes, one knife, seven spoons, one shard, sixteen pairs of blankets. Additional spoons, blankets, knives, and bake kettles were delivered later, presumably as more men arrived at the shanty.16 Other than blankets the only amenities provided were for the cookery, a very important aspect of shanty life.

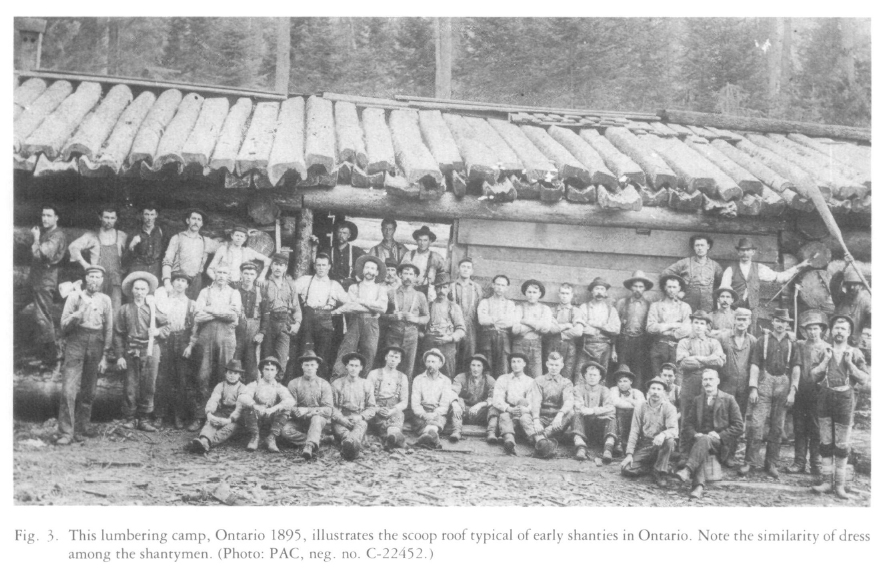

Display large image of Figure 3

Display large image of Figure 317 For the most part the diet of the early shanty worker in the Kawarthas was, in variety and nutrition, probably as limited as it could be. The Boyd Company order books show that pork, flour, and potatoes were the major and almost only food items sent to the shanties in the 1850s. It had been reported that peas were also a staple of local lumbermen from as early as the 1830s and it seems likely that this item was also supplied to Boyd's shantymen.17 In addition the diet would have been supplemented by fresh meat or fish provided by the men and any other local purchases that they could make as individuals at their own cost. The only exception to this was tea which, while supplied by Boyd, was charged to each individual's account.

18 The meals were probably similar to those prepared in the early shanties or the Ottawa Valley: a concoction of salt pork, potatoes, and pork grease thickened with flour or bread, potatoes, and pork. This was cooked in a pot over the open fire while the bread was baked in the kettles which were sealed and buried in the hot coals.18 While the calorific content of this diet may have been adequate, there was limited nutritional value in it even with the addition of "tea, sugar, onions or other luxuries" provided at the shantyman's expense.19 It was, however, a similar diet to that of many lower-class Upper Canadian settlers, although by the late 1840s and early 1850s men in the Ottawa Valley camps received fish, beef, biscuits, rice, barley, and peas in addition to the staples offered by Mossom Boyd to his men.20

19 The shantyman's dress seems to have been similar throughout the province and consisted of "Canadian grey cloth trousers, a flannel shirt, or coarse Guernsey frock, and a blouse made of fustian, or a blanket coat fastened round the waist with a red or tri-coloured sash." Basically this was a warm, heavy wearing, coarse costume, tied with the coloured sash which was French-Canadian in origin but apparently common throughout the lumbering shanties. For footwear many French-Canadians wore moccasins or "shoe-packs" or the cowhide boots which were more common among the other lumbermen.21 In 1849-50 Boyd's account with a bootmaker included the cost of repairs for men's boots at 3s.6d., boots at £1.0.0, and "Cobourg" boots at 12s.6d.22 In comparison to his wages, clothes were an expensive item for the shantyman if bought in the bush. Mitts sold for 5s. and socks for ls.6d. in 1851, and in 1855 "Janzy" shirts were 6s.3d. each, shoes 10s., and hats 3s.6d.23 Regardless of the exact wages these items were costly necessities for the shanty-man, once again reducing his seasonal income.

20 In summary the actual living conditions in the shanty were poor. The building itself was adequate, but primitive. Only the minimum of amenities were provided. The diet was extremely limited and that supplied by Boyd probably required extra personal expenses if a reasonable standard of health was to be maintained. Extras and "luxury" items could be purchased by the shantyman but were expensive. This rather grim picture was not improved by the actual working conditions and wages of the shantyman.

Workers and Work in the Woods

21 In the woods the shantyman could look to long days of very physical work at low wages. Work was dangerous with injury and sickness being relatively common among the men. The danger and excitement of the work gave some respite as did the odd bout with alcohol. This, however, was an expensive diversion for the shantyman, resulting in fines as well as loss of pay. While the labour market for lumbermen was already an international one, the poor wages and conditions show that rather than there being competition for labour, in most years there was an excess in supply.

22 The shantyman's work week was from Monday through Saturday with Sunday off. The hours of work were governed primarily by the hours of daylight. The shanty-man's day began before dawn when he was wakened by the cook, given breakfast, and then sent on his way to the woods where the cutting was to take place. Here the pine was selected for its size and quality and the demands for the British market: "straight, free of rot, disease and well squared."24 Although the Select Committee on the Lumber Trade reported in 1849 that "little or no skill was required in its manufacture," inexperienced shantymen usually made a substandard product.25 This latter point is substantiated by Mossom Boyd in 1851 when he was anxious to hire a foreman "who knows elm." He went on to request two or three good hewers and good liners "used to elm" to "make a beginning."26

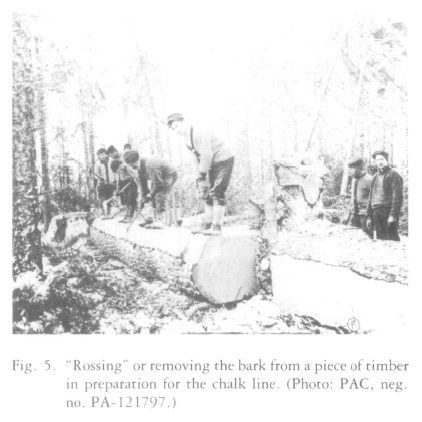

Display large image of Figure 5

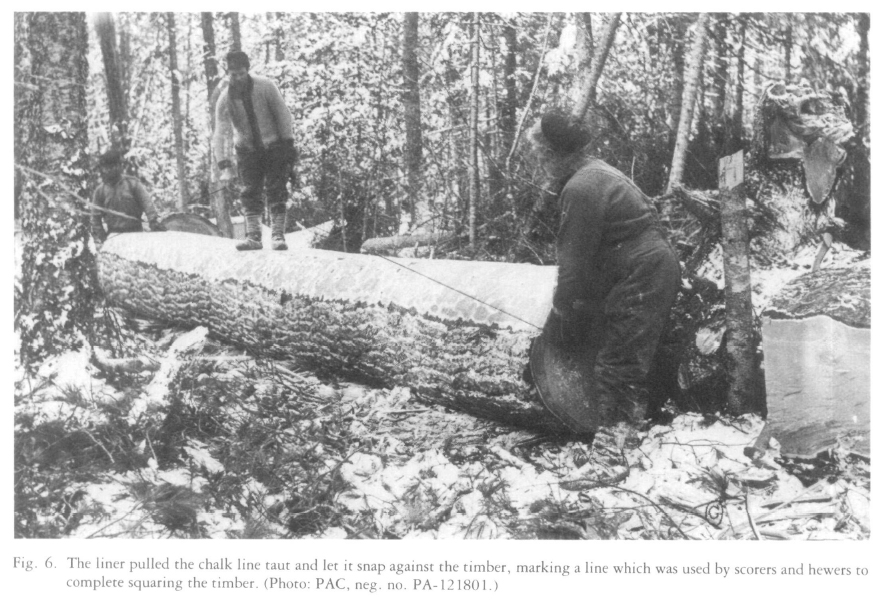

Display large image of Figure 5 Display large image of Figure 6

Display large image of Figure 623 In the woods the largest and best trees were chosen for masts and spars, then those that could make a twelve-inch square at the small end were selected and cut down. The process of cutting and squaring timbers in the Kawartha Lakes has been described by Samuel Strickland, from whom the following description is taken. The shantymen were divided into gangs according to their individual skills. One gang cut the trees, letting them fall on a bed of smaller trees, thereby keeping the timber tree from freezing to the ground, ensuring that the axes would not hit stones or dirt, and facilitating the loading process. Once the tree was felled a liner "rossed" (removed the bark a few inches wide along the length of the trunk so that a chalk line could be seen) and lined the tree. The tree was cut to a length determined by the liner, the butt end was squared, and a mortice hole was left at both ends so that withes could be passed through when rafting. The tree was then ready for the

24 The process for making masts was somewhat different. The bedding was carefully prepared for these tall trees "eighty, ninety, and even one hundred feet being not at all uncommon," as irregularities in the ground "might cause the top to break off too low down, and thus spoil a valuable stick of timber." Once safely on the ground the bark and knots were removed from the trunk. The butt end was then morticed in order to allow a chain to be passed through for drawing the mast to the river.28

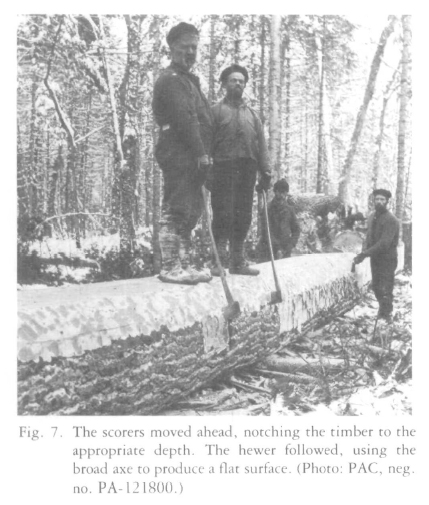

Display large image of Figure 7

Display large image of Figure 725 Sawlog cutting was a relatively simple matter at this time. Sawlog gangs consisted of choppers only, with one man the master chopper. Once the tree was down it was cut into 13.5-inch or 16.5-inch lengths. In central Ontario each tree produced about 5 logs and 75 logs per day was a good output.29

26 All the supplies and equipment necessary for work in the woods were obtained and delivered to the shanty by the owner. In the 1850s this included axes, augers, chains, S-hooks, rings, splice links, clevis, chalk lines, chalk, rope, and crotch chains.30 Axes, the main tool in the bush, were supplied without handles by the manufacturer, each user being left to provide his own handle in the shape he was most comfortable with.31 In cutting down the trees the narrow poll axes were used. When felling a tree the axemen had to be careful in order to avoid serious injury or death. The direction of the wind, the natural lean of the tree, "bounce-back" of a tailing tree, and flailing limbs or widow-makers were all part of the hazards that brought danger to an inexperienced or careless shantyman.32 The men hewing and squaring the trees used broad axes which were flat on one side, had a cutting edge 10 to 12 inches wide, and weighed about twelve pounds.33

27 The average gang of men, according to A. R. M. Lower, could cut 6 timbers, or about 400 cubic feet per day.34 Thomas Wilson, the overseer of the Trent works, estimated in 1844 that the average gang of five men made 2,000 feet per week, a slightly smaller amount than Lower's figure, but still within the approximate range.35 In a 26-day month, therefore, each gang would make approximately 10,000 feet pet month.

28 Once the timber was squared, the logs cut, the masts shaped, and the spars finished, the company's mark was placed on the piece and it was ready to move out of the bush and to the river. Sometimes this included two separate operations, from the bush to the roadway, called "skidding," and then by teams to the river. Timber and particularly spars and masts could also be taken directly to the stream.

29 Preparations for skidding were made in the fall when the main roads or skidways were cleared to the stream. As much as possible the roads were made either level or on a downgrade in order that the timbers could be hauled more easily. The closer the timbers were to the stream the better as it meant easier and therefore cheaper transportation. The maximum distance for hauling timbers was about four miles as the costs of moving timbers farther than this became prohibitive in terms of the profits to be made.

30 Both horses and oxen were used for skidding. Oxen tended to predominate in the earlier period and they had a number of advantages. They could live on coarser foods, withstand harsher conditions, use cheaper equipment, and pull more than horses. The horse was more easily managed and worked at a faster rate. To some extent the use of horses and oxen may have depended as much on what was available, particularly with the small outfits that depended on local farmers to supply the teams. In the early period of settlement farmers were more likely to have oxen than horses because, in addition to the above reasons, they were considerably cheaper to buy and keep.

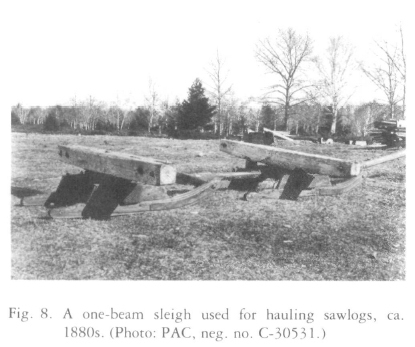

31 Skidding might be done as soon as the timbers were squared; more often it could be done later, usually after Christmas when there was plenty of snow on the ground to make it easier to haul. Mossom Boyd, at least in the early years, did not start skidding or teaming until after Christmas.36 For skidding the timber was attached by rope or chain to a "go-devil," a crotch of a hardwood tree. One end of the tree rested on the go-devil which the horse pulled, effectively dragging the timber to the roadway or river. Also used was a "bobsleigh made with a 'heavy traverse bunk of hardwood fixed to support the great weight it had to sustain' and six-inch runners reinforced with steel."37 Sawlogs were first hauled to the road and piled in rollways. For transportation from the roadway to the river timbers and logs could be piled on sleighs and either hauled to the dumps at the edge of the water or actually placed on the ice.38

Display large image of Figure 8

Display large image of Figure 832 As with other work in the woods, the process of moving the timber and logs to the rivers and streams held its own dangers and excitement. This was particularly so when hauling masts. Because of their size and weight masts were usually cut close to the river. A road was then prepared which avoided hills as much as possible and was approximately twenty feet wide.39 Hills were not only difficult to pull a mast up but more importantly there was always the danger of losing control on the downhill side. Once the road was completed the mast was loaded on a bobsleigh and drawn by "twelve to sixteen span of horses or oxen." The most difficult part was to start the mast moving, an operation which required simultaneous effort by all the teams.40 In one of the few extant descriptions of this operation Robert Harrison conveys the excitement, danger, and work involved in hauling a mast 120 feet long to the Trent River just below Hastings. Because the snow was melting and the roadway becoming soft, little time remained before the way would be impassable. At the top of the hill a last rest was taken and then

33 As the season progressed cutting was gradually reduced and men were transferred to assist the teamsters haul the timbers, masts, and spars to the river in readiness for the spring thaws. Men who were considered superfluous to the operations were let go and gradually the numbers in the camp diminished to the point where only those hired for the drive and rafting to Quebec remained.

34 Throughout the winter life and work in the forests of the Kawartha Lakes was hard, dangerous, and not particularly rewarding for most of the shantymen. In addition to this there is some evidence that sickness of one sort or another was a problem in the shanties. Although comments on employees are remarkable only by their absence in this period, a few Boyd Company shanty time books for 1855-56 give some indication of this problem. It was not unusual for at least one day per week to be lost to sickness in the shanties due to problems such as "ague," tooth-aches", or "swelled leg." In one shanty in the year 1854-55, sickness was particularly prevelant with anywhere from three to nine men out of sixteen to nineteen in the shanty off work for at least one day each. In the week of 26 March 1855 20.5 of a possible 120 man-days were lost due to sickness of an unnoted nature. At the time the records indicate that Boyd was hiring primarily French-Canadians, but there is no evidence to suggest that the problem of sickness was peculiar to French-Canadian shantymen.42

35 These same shanty time books also give some indication that the poor living conditions, dangerous work, and low wages were not accepted without reaction by at least some of the shantymen. Lack of employment and expensive land may have forced them into a transient, womanless, homeless way of life, but there were ways of showing an individual's frustration of dissatisfaction with this existence.43 This reaction was individualist and showed up in the amount of absence from work, leaving the shanty, and drunkenness that took place. While reasons for being absent were usually not given, the number of men recorded as absent on a Monday indicates that taking a day off without pay as well as the possibility of being fined was one way of showing discontent. Certainly the costs to the individual would be high, but the effect on shanty efficiency would also have been noticed. There is, of course, the possibility that there were legitimate reasons for being absent, but the fact that these were French-Canadian workers makes it likely that the absences were to get away from the shanty rather than to visit family, for example.44 For various reasons the number in the shanties was constantly changing, but the loss of manpower was of serious consequence as it was more difficult in the middle of winter to obtain men for the bush due to the isolation of the camps. Probably more directly related to poor work and living conditions was drunkenness. This clearly was expensive for the employee as it resulted in fines of 15s or $4.00, lost days in wages, and the expense of obtaining the liquor in the first place. While one drunken spree may have broken the monotony of camp life, the situation in one of Boyd's shanties in 1855-56 indicates that something more was involved. Throughout January and the first week in February 1856 two or three men lost at least one day each due to drunkenness. At least one of the men, G. Beavert, was involved in three of these incidents.45 These occasions would cause considerable disruption in the organization of work and within the isolated social environment of the shanties, thus having a real effect on productivity for the owner.

36 In further support of this contention it is clear that in the Kawarthas the shantymen did not have the reputation for being antisocial that was prevalent in other sectors of the country., Samuel Strickland remarked that "I must do them justice to say, that large numbers of them have been lumbering close around me for the last four or five years I have received nothing but civility at their hands nor has a single application for a summons, or warrant, against them been made to me in my magisterial capacity". John Langton viewed the shantymen as "rascals," but certainly did not go on to denounce their moral or social habits.46 In sum, it must be accepted that absenteeism and drunkenness were at least partially a reaction to the work and life the shantymen were forced to endure in order to maintain a minimum standard of existence in an overcrowded labour market.

Conclusion

37 Life in the shanties was, in all aspects, hard and relatively primitive. The employer, in this case Mossom Boyd, could take advantage of the labour market in the 1850s in order to cut his costs. While the initial rates of pay were high in terms of later years, this was more than balanced by the minimal diet and lack of amenities. This would also help explain Boyd's business success in the early years. When hiring men in the labour market of Quebec Boyd would have to pay the going rates. However, once the men were in the shanties, out of touch with others and already owing for their passage to the Kawartha area, he could cut his costs in the area of food and housing. For the individuals involved, the shantymen, this would mean a reduced capacity to endure the hard physical labour required and also a greater susceptibility to sickness. This could be particularly evident among French-Canadians who were used to a better diet than the English farmer-settlers.47 Although there is no record of collective action by shantymen to change their living and working conditions, the various attempts to relieve the monotony of camp life through drinking and absenteeism, while extremely expensive to the shantyman, can be considered as individual attempts to resist the enforcement of these conditions. This type of resistance was, however, in a clear minority, and one can only conclude that the oversupply in the labour market resulted in a generally docile work force, a situation of considerable assistance to the growth of a new industry in the backwoods area of the Kawartha Lakes.