Articles

A Stitch in Time:

Sewing Machine Industry of Ontario, 1860-1897

L'objet de cet article est de retracer l'histoire et le développement de l'industrie de la machine à coudre en Ontario. Même si l'industrie de la machine a coudre aux Etats-Unis a fait 1 objet d'une certaine attention, au Canada, on a fait très peu de recherches en ce domaine. Entre 1860 et 1897, dans l'Ontario seulement, quatorze fabricants ont produit des machines à coudre pour l'usage domestique. Hamilton et Guelph étaient les centres de cette industrie, bien que de petites usines se soient installées à Belleville, Perth, St. Catharines et Toronto. Dans cet article, l'auteur fait la chronique des fabricants et des différentes machines qu'ils ont produites.

1 Today the early sewing machine is primarily remembered as a contrivance which relieved women of much of the fatigue and drudgery of hand sewing and helped provide them with time to pursue other interests. Yet, as the first domestic mechanical aid to be mass-produced, the sewing-machine's impact extended a great deal further. The machine not only revolutionized the home production of clothing and the ready-made garment industry, but was also largely responsible for the establishment of the first commercial pattern companies in the United States.1

2 The production or manufacture of the sewing machine itself was progressive for its time. By using precision manufacturing techniques based on the concept of interchangeable parts, sewing machine manufacturers were able to produce well-constructed, dependable, affordable machines. Although the concept of interchangeable parts was not new, its application for the mass production of the first consumer appliance was novel, and many innovative changes in nineteenth-century manufacturing and marketing were pioneered by the sewing machine industry. The availability of spare parts, convenient local machine servicing, instalment plan purchasing, and massive advertising campaigns were successful offshoots of the sewing machine industry that were later adapted to many other industries. The development of the sewing machine meant not only significant change in the lives of tailors, seamstresses, and homemakers, but also represented important new trends in manufacturing and marketing as well.

3 The invention of the sewing machine cannot be credited to any single person. Although the names of Howe and Singer have become synonomous with the sewing machine, there were literally hundreds of persons from many countries linked to its history. However, once Elias Howe patented the first completely successful sewing machine in the United States in 1846 the great boom was on. The success and popularity of the sewing machine promised opportunity and wealth for those engaged in its manufacture, and the third quarter of the nineteenth century witnessed the establishment of hundreds of factories throughout the United States, Canada, and the British Isles.

4 While the history and development of the sewing machine industry in the United States has received considerable attention, very little research has been conducted on the same industry in Canada. In fact, it is not commonly known that Canada even had such an industry. Despite the large number of American sewing machines sold here in the nineteenth century, however, a domestic industry did emerge which produced thousands of machines over a period of thirty years. The industry's development and decline can be measured from 1860 to 1897, a period when fourteen Ontario manufacturers, in business from as few as two to as many as thirty-four years, were producing family or domestic sewing machines.

5 These operations varied significantly in size and production output, the smallest employing 12 men and producing 2,500 machines per year and the largest employing 300-400 mechanics and producing approximately 1,500 machines per week. Since the primary materials required in the manufacture of sewing machines were coal, iron, and steel, factory locations were principally governed by transportation routes. As with most other industries, sewing machine factories tended to be situated either close to shipping centres along Lake Ontario or connected to the lake by the railroad. Ontario's sewing machine factories were scattered in a variety of locations, including Belleville, Perth, Toronto, St. Catharines, Hamilton, and Guelph, and although each of these towns or cities was capable of sustaining a certain portion of the industry, Hamilton and Guelph ultimately became the two major centres for sewing machine manufacturing.

6 Ontario-manufactured machines were based on exactly the same principles and elements as American machines. There was a trend among Canadian inventors to make additions or alterations to the basic principles; however, no significant new inventions in sewing machine technology were developed here. Stylistically Ontario machines were slightly behind their American competitors, but in quality and workmanship they were considered to be on a par.

7 Surprisingly, the sewing machine got off to a very poor start in Ontario. In the 1850s there was tremendous resistance to the "iron seamstress" from both tailors and housewives - ironically, the two groups who had the most to gain from using it. In the opinion of many tailors the sewing machine threatened to ruin their trade. Whereas it took an estimated sixteen hours and thirty-five minutes to sew a frock coat by hand, the same work could be done in two hours and thirty-eight minutes by machine.2 Therefore, the tailors reasoned, the sewing machine would put many of them out of business. In 1852 the introduction of a sewing machine in the Toronto tailoring establishment of Walker and Hutchison resulted in Toronto's first organized labour strike.3 A similar reaction occurred in Hamilton and for a time the sewing machine was set aside.

8 Many women were also skeptical of this newfangled device with its high price and complicated construction. They were reluctant to believe a machine could sew as well as they could. To prove that any woman could successfully operate a sewing machine, the manufacturers approached the problem in several ways. They hired female demonstrators to show off the versatility and ease of mechanical sewing. They provided free instruction to buyers in their own homes. And they even offered their machines at a reduced rate to wives of the clergy, hoping that these respected women might set an example others would follow.

9 During the 1860s the popularity of the sewing machine increased and several manufacturers built factories in Ontario. Due to favourable patent legislation, which encouraged manufacturers to pirate foreign technology, a variety of machines were produced. However, the still limited demand enabled only two of the companies to survive the decade.

10 Ontario sewing machine manufacturing entered its heyday during the early 1870s. Improved or refined technology resulted in well-constructed, durable machines that could be manufactured cheaply and sold at a price affordable by everyone. Favourable public reaction to this cheap, accessible, labour-saving device was reflected in the tremendous increase in demand during the 1870s. The manufacture of sewing machines clearly spelled opportunity and the decade witnessed the establishment of a wave of new companies and an enormous increase in registered Canadian sewing machine patents. It was also during the 1870s that the sewing machine became a leading Canadian export.

11 By the mid 1870s there were clearly too many Ontario sewing machine companies competing for the domestic market and a number of the smaller companies either folded or were absorbed by larger ones. The eventual decline of the industry occurred for a variety of reasons. Changes in Canadian patent requirements resulted in a proliferation of American branch plants on Canadian soil, a factor which seriously threatened Canadian dominance in the home market. Comparatively low tariffs on imports promoted the dumping of American sewing machines into the Canadian market at ruinous prices. In addition, overproduction and the depression of the late 1870s severely damaged the industry. The ultimate result was disaster for the once thriving sewing machine industry of Ontario and one by one the companies disappeared.

12 Although the factories and the inventors are long gone, a great many of the machines still survive and they tell a great deal about themselves if one takes the time to make a careful examination. Almost all are marked with a patent date, a manufacturer's initial or name, and the name of the model. Some even have the original instruction booklet tucked away neatly in a drawer.

13 Despite slight differences in appearance and construction, sewing machines from this period make either a chain-stitch or a lock-stitch. The chain-stitch is made by "passing the needle through the seam and bringing it back but leaving an open loop on the underside through which a second loop was thrust, this in turn secured by a third loop, and so on."4 The chain-stitch requires only one thread and the operation is simple and fast.

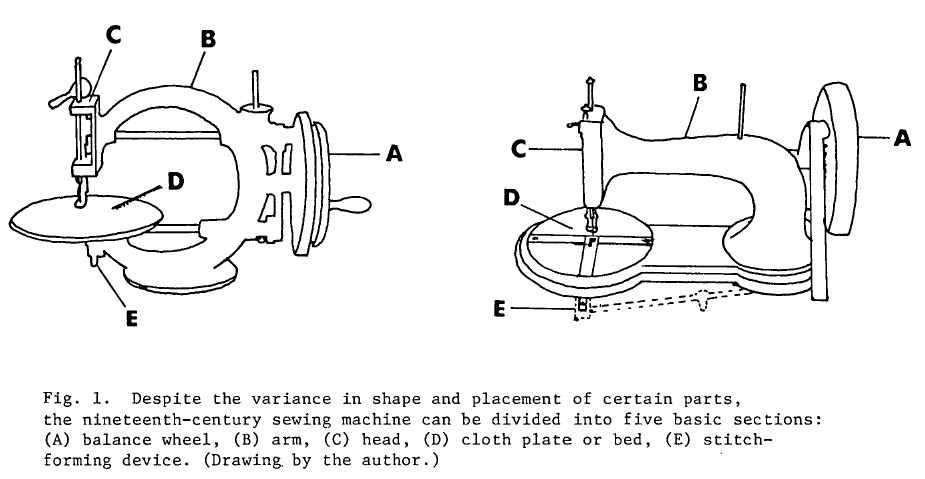

Display large image of Figure 1

Display large image of Figure 114 The more complicated but more commonly used stitch is the lock-stitch, a type of stitch peculiar to machine sewing. In this stitch "a loop of thread is pushed through the seam, as in the chain-stitch, but is secured by a second thread, which is thrust through the loop by means of a tiny shuttle before the loop is closed by retraction of the needle."5 The structure of this stitch is very simple and when, with proper tension, the threads inter-lock, the stitch shows the same on both sides and is very secure.6 Therefore, if the machine has a shuttle or a space for a shuttle directly below the needle, it is a lock-stitch machine. If there is no indication of this type of mechanism on the machine, it is probably a chain-stitch machine.

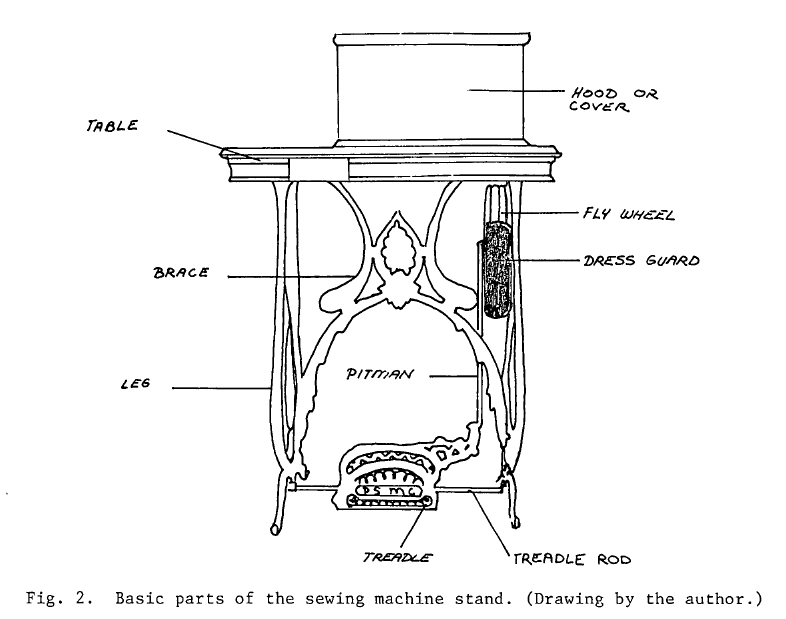

Display large image of Figure 2

Display large image of Figure 215 Ontario's sewing machine manufacturers provided something for everyone. In addition to the large variety of machines on the market, the buyer also had her choice of tables, castings, and decorations. Treadle machines came with plain stands, stands with moulding, stands with extensions, stands with extensions and/or drawers, and full cabinet cases as fine as any piece of parlour furniture. Sewing machines inlaid with ebony, mother-of-pearl, or other decorative embellishments were also available upon request.

16 Who were these manufacturers and what kinds of machines did they produce? The following section is a chronological sketch of the companies and machines which comprised Ontario's sewing machine industry from 1860 to 1897.*

R.M. Wanzer and Company

17 The first sewing machine factory in Canada was established at Hamilton in 1860-61 by Richard Mott Wanzer who, during the late 1850s, seems to have had a small sewing machine shop in Buffalo, New York, which manufactured Singer machines.7 For some unknown reason he left this business and shortly thereafter settled in Hamilton to begin anew. It took a week to turn out his first machine. During the next thirty years, however, R.M. Wanzer and Company grew to be the largest and most successful of all Ontario's sewing machine manufacturers.

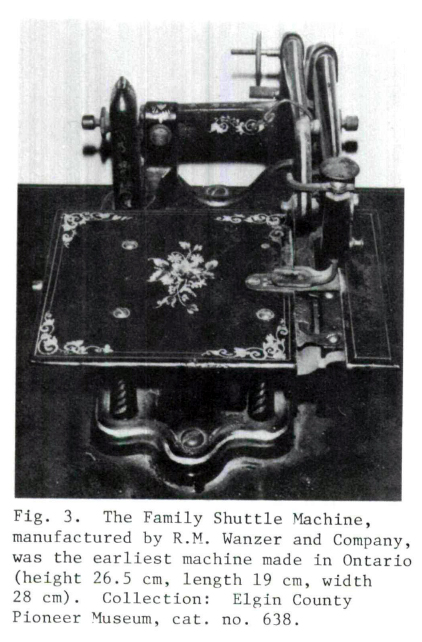

18 The earliest sewing machines manufactured by the Wanzer company were Singers (models number 1 and 2) and Wheeler and Wilsons8 and were proudly advertised as such. However, in 1862 Wanzer began to advertise a new home manufactured sewing machine that was patented in Canada. It was called the Family Shuttle Machine and actually combined the best qualities of both the Singer and the Wheeler and Wilson machines.9 The Family Shuttle Machine was delicately hand-painted with floral and scrolled designs in gold leaf, came with a stand made completely of iron - a rare feature - and sold for forty-five dollars. The markings on the front shuttle race slide read

Sewing Machine MFT'Y

Hamilton, C.W.

Patented Feby 19th, 1862

19 The second home manufactured sewing machine introduced by Wanzer was known as the Little Wanzer. Hailed as the "most Perfect of all Sewing Machines" the Little Wanzer's immediate popularity is evidenced by the claim that over 4,000 were sold in its first year of manufacture.10 By 1874 nearly 200,000 of these lock-stitch machines had been sold.11 The Little Wanzer's compact size, simplicity, and low price made it an instant favourite, and it became a leading export to such countries as England, France, Germany, Ireland, Austria, Sweden, Italy, South Africa, Turkey, Egypt, and Brazil.

20 The Little Wanzer, which came mounted on a marble slab, could either be set on a table and driven by hand or placed on an iron stand and driven by foot. In 1870 it sold for twenty-five dollars by itself or thirty dollars on a stand.12 All the cast parts of this machine were japanned and hand-decorated in gold leaf with flowers and vines. "Little Wanzer" was generally written on the centre of the arm and often an hourglass trademark with the works "Time Utilizer" appeared on the side.

Display large image of Figure 3

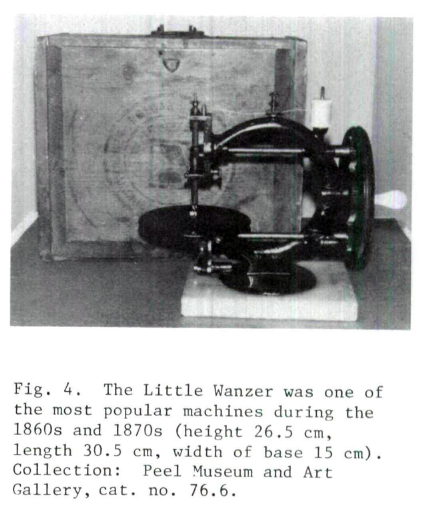

Display large image of Figure 3 Display large image of Figure 4

Display large image of Figure 421 In its general shape the Little Wanzer is similar to other American hand-operated sewing machines of the late 1850s and 1860s. It also incorporates a number of American features such as the vertical piston operating the needle, the manner of feeding the thread through the needle, the yielding pressure foot and the shuttle.13 Unlike most other contemporary machines, the shuttle moves in a vertical arc rather than on a horizontal race.

Display large image of Figure 5

Display large image of Figure 5 Display large image of Figure 6

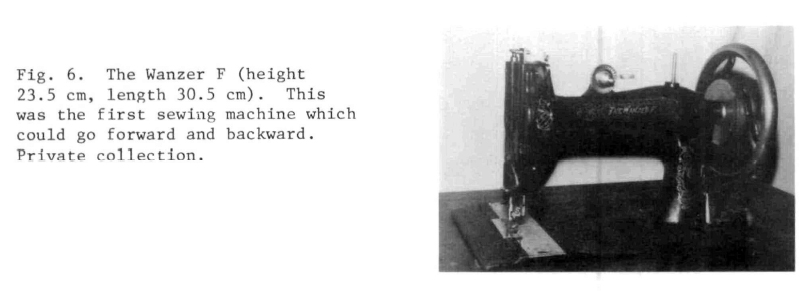

Display large image of Figure 622 By 1874 R.M. Wanzer and Company had expanded its line of sewing machines to include four additional models: Wanzer A, Wanzer D, Wanzer E, and Wanzer F. Both the D and E models were for tailors and manufacturers of heavy goods such as leather. The Wanzer A, for foot or hand operation, was quite similar in construction to the Little Wanzer, but did not seem to be quite as popular. Very few of these machines have survived.

23 The Wanzer F was one of Wanzer's most successful sewing machines of the 1870s. It was a foot-operated or treadle machine with heavy castings that completely encompassed the upper shafts, gears, and other working parts. Its most significant feature was the introduction of the reversible feed which enabled the operator to sew both forward and backward without stopping the machine. This development was a tremendous aid for it not only enabled the operator to fasten or secure the threads at the beginning and end of each seam, but also facilitated the strengthening of any part of a seam by double-stitching or back-stitching with a quick and easy motion.

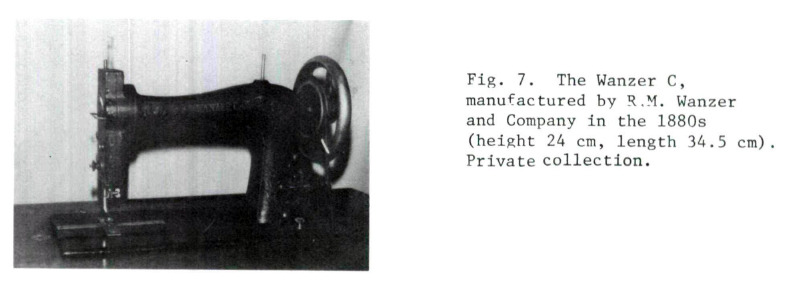

24 The last family sewing machine manufactured by the Wanzer Company was the Wanzer C, introduced sometime between 1877 and 1881. Although it was patterned after the Wanzer F, it was a deluxe model. The principal features of the Wanzer C were the large and roomy space under the arm, the adjustability of all its parts, a steel feed on both sides of the needle, a case-hardened triangular needle bar, a nickle-plated balance wheel, a self-threading shuttle, and an automatic bobbin winder.

Display large image of Figure 7

Display large image of Figure 725 Fortune seemed to smile on the Wanzer company during its long and productive history. Ingenuity and sharp business acumen rabidly carried Richard Wanzer to success. His sewing machines, which were exhibited in Canada and Europe, were awarded more prizes and diplomas than any other Canadian machines. The string of laurels attached to the Wanzer company was long and impressive, the most notable being the Iron Cross conferred upon the owner at the Vienna Exhibition of 1873 by the Emperor of Austria. Unfortunately, overproduction and a sharp drop in demand put a severe strain on the company in the 1880s and in 1890 the Wanzer sewing machine company, one of Canada's most important manufacturers for over a quarter of a century, passed out of existence.14

Charles Raymond

26 For over thirty years Charles Raymond of Guelph remained the principal rival of R.M. Wanzer and Company. Like Wanzer, Raymond was an American but one who had already established himself as a leader in the sewing machine industry. In 1858 he and William Nettleton were manufacturing a chain-stitch sewing machine in Brattleboro, Vermont, that had been invented by Raymond.15 In 1862 Raymond moved to Guelph, bringing with him fifteen men to form the nucleus of Guelph's first sewing machine establishment.16 By 1869 he owned one of Guelph's largest factories and employed forty people. An incredible rate of expansion is evident from the following description printed in the 1871-72 County of Wellington Directory:

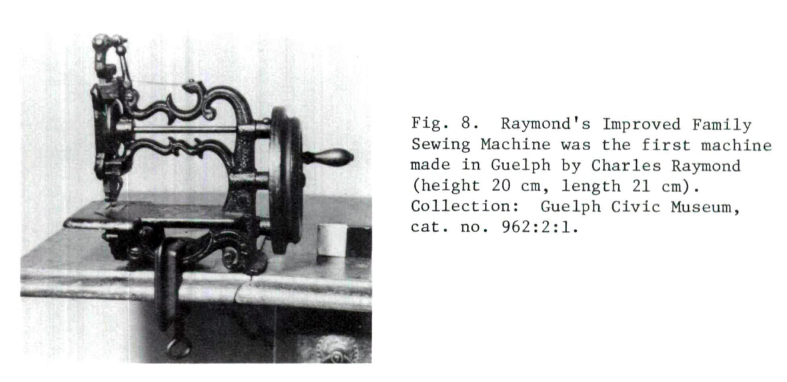

27 The earliest Raymond sewing machine manufactured in Canada was called Raymond's Family Sewing Machine or Improved Family Sewing Machine. It came in a little metal box and was a hand-operated, portable, chain-stitch machine which would be clamped to any type of table. It bears a patent date of 30 July 1861 on the throat plate and this refers to Raymond's last American patent for an improved sub-platform looper.18

Display large image of Figure 8

Display large image of Figure 828 This machine was manufactured with two objectives in mind. Most early sewing machines were combination machines (meaning they could sew on both coarse or fine material), but they generally required a skillful workman to put them in order for the weight of the material to be sewn. The aims of the Raymond machine were to be so simple that anyone could change it to accommodate almost any weight of fabric and "at the same time make it at so small a cost as to be within the means of everybody."19 This machine sold for twelve dollars and was probably the cheapest one on the market throughout the 1860s.

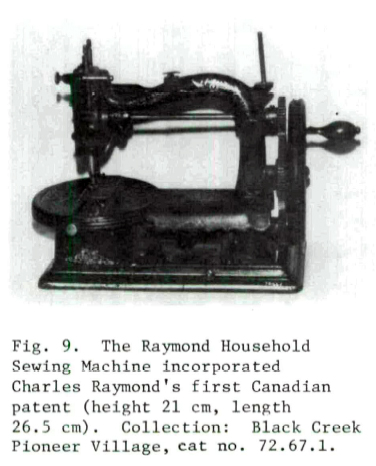

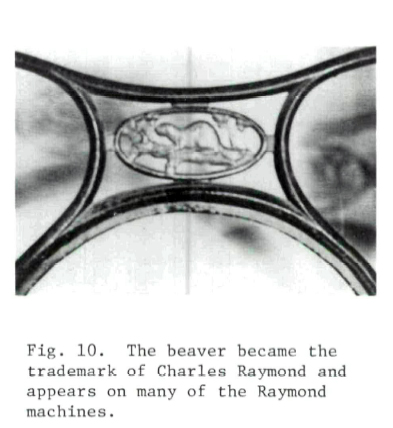

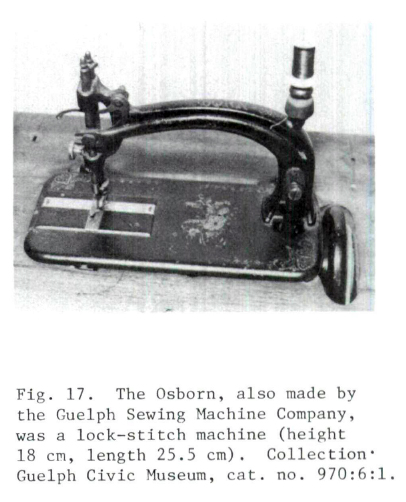

29 A single-thread machine has one major drawback. The chain-stitch is not always a sufficiently secure stitch for domestic sewing as it unravells easily and for this reason the lock-stitch machine is more desirable On 18 April 1872 Charles Raymond took out his first Canadian patent for "an improved sewing machine called the Raymond Household Sewing Machine."20 This is the earliest Raymond machine known to exhibit a beaver, which became the Raymond trademark.

Display large image of Figure 9

Display large image of Figure 9 Display large image of Figure 10

Display large image of Figure 10 Display large image of Figure 11

Display large image of Figure 11 Display large image of Figure 12

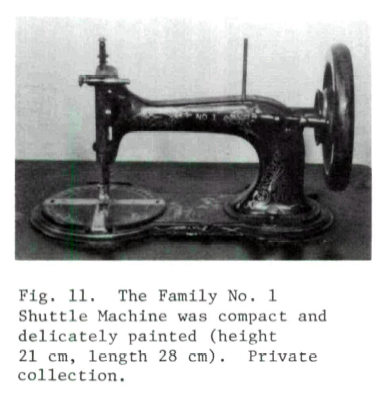

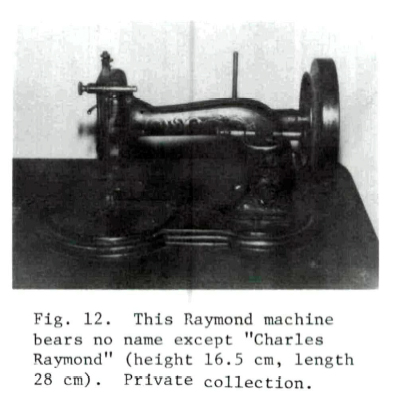

Display large image of Figure 1230 By 1871 Raymond's line of machines had grown to include a series of three more lock-stitch machines: the Family No. 1, No. 2, and No 3 Shuttle Machines. Both the No. 2 and No. 3 machines were adapted for heavy manufacturing. The No. 1 was a heavy machine bearing two patent dates (22 September 1879 and 7 May 1880) which refer primarily to improvements to the spooler spindle. Raymond manufactured another machine quite similar to the No. 1 except that it was considerably smaller. The only marking on this machine is the name "Chas. Raymond" stamped on both shuttle race slides. It is possible that this was an early edition of the No. 1 but more research would be necessary to prove it.

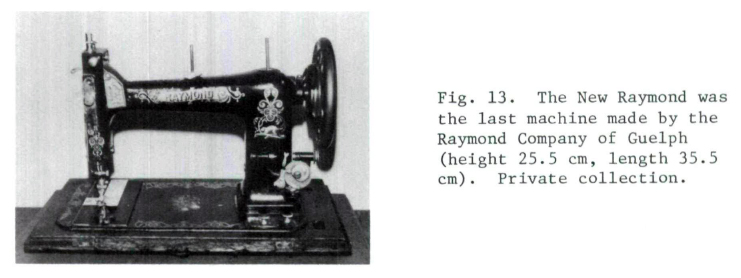

31 Like the Wanzer company, Raymond exported many machines to Europe. However, production was severely curtailed in the late 1870s and by the early 1890s competition from giant American sewing machine companies like Singer and White began to squeeze Raymond out of the market. In 1897 he finally sold his company to the White Sewing Machine Company of Cleveland, Ohio.21 Renamed the Raymond Manufacturing Company, this firm continued producing sewing machines until 1916. The New Raymond, based in part on Charles Raymond's patents of 1879 and 1880, was the last type of machine the company produced.

Display large image of Figure 13

Display large image of Figure 13Rogers Brothers

32 Frederick and Montague Rogers established their sewing machine manufactory in Hamilton in 1860 or 1861 and were probably Wanzer's first local competitors. Their machine was the first Canadian patent sewing machine to be offered for sale.22 Although patent specifications and ads exist which describe their machine, no actual examples have yet come to light

33 The Rogers's Patent Double Thread and Lock Stitch Family Sewing Machine was actually a double chain-stitch machine modelled after one patented by Grover and Baker of Boston.23 The basic model sold for thirty dollars; however, for those patrons who desired additional features such as silver plating, a glass pressure foot, a rosewood case, or a machine inlaid with mother-of-pearl, the price rose as high as ninety dollars.24 Ads for the Rogers machine appeared in Hamilton newspapers until 1863, at which time the company apparently went-out of business.

Charles Irwin and Company

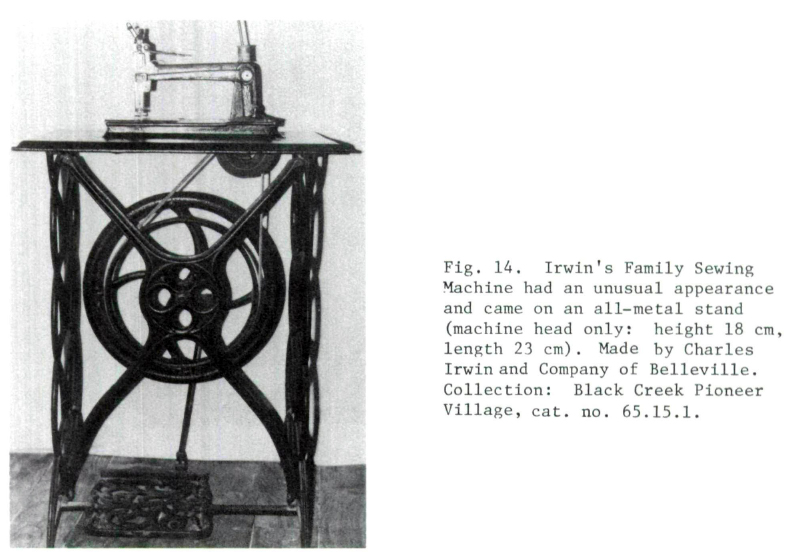

34 The Charles Irwin and Company sewing machine factory was established in Belleville ca. 1863 and is known to have manufactured one family sewing machine. This odd-looking machine formed a lock-stitch. Because of the placement of the balance wheel the Irwin family machine was only operable by treadle action. The position of the balance wheel also necessitated a centrally located fly wheel, rather than the usual side orientation. Like the early Wanzer machine, it was attached to an iron table. This machine was patented 12 August 1863 by George Henry Meakins of Belleville and was manufactured until about 1870, when the company disappeared from the records.

Display large image of Figure 14

Display large image of Figure 1435 The Irwin family sewing machine received a number of awards at Ontario Provincial Exhibitions, including First Prize in Kingston (1863), Extra and Only Prize in London (1865), and Extra Prize for the Best Family Sewing Machine in Toronto (1866), as well as a Diploma from the Paris (France) Exhibition of 1867.25 From the several prizes awarded and the favourable opinion expressed, the Irwin machine appears to have been one of the best and most advanced shuttle machines available in the first decade of the Canadian sewing machine industry.

G.W. Gates and Company

36 This firm, which began production in 1865, was the only sewing machine manufactory to be established in Toronto. The Gates company manufactured both chain-stitch and lock-stitch machines; unfortunately none of its machines has yet been found.

37 Records indicate that G.W., Gates and Company manufactured at least three kinds of sewing machines, including a chain-stitch model, a shuttle machine called the Queens Elliptic, and a third called the New Shuttle Sewing Machine. All three were available by 1868. Little is known about the chain-stitch machine except that it received prizes at the Provincial Exhibitions of 1866, 1868, 1869, and 1870. The Queens Elliptic was a hand-operated, lock-stitch machine which sold for fifteen dollars in 1868.26 The New Shuttle Sewing Machine was built for family sewing as well as light manufacturing and sold for twenty-five dollars.27

38 Although the Gates company was a fairly small one, its machines were apparently of good quality. In addition to being shown at Provincial Exhibitions in Ontario, at least one Gates machine was also displayed at the Paris Exhibition of 1867.28 By 1875, however the company was no longer in operation.

John W. Abbott and Company

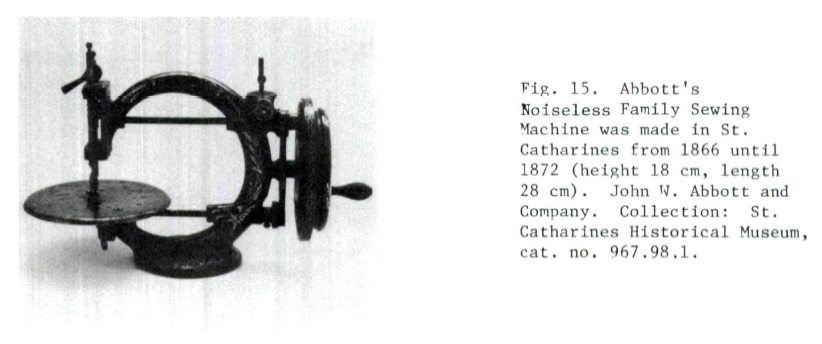

39 In 1865 or 1866 John W. Abbott established his small sewing machine firm in St. Catharines. By 1871 J.W. Abbott and Company employed 12 men and with the help of a three-horse-power steam engine was producing 2.500 machines a year.29 Although it was not a large company, it was considered to be an honest and industrious establishment and its sewing machines had a good reputation.

40 The Abbott Company manufactured a single-thread machine called Abbott's Noiseless Family Sewing Machine. This small machine was peculiar in that unlike most chain-stitch machines it could be worked either by hand or treadle.30 The Abbott was arranged for either light or heavy sewing and to prove its "combination" qualities it was put to the test at the 1867 Provincial Exhibition. The machine, which "walked through a piece of shingle and a fine piece of muslin, without change of needle,"31 was awarded a first class prize and diploma over such competitors as Howe, Singer, Wheeler and Wilson, and various other Canadian machines.

41 Although Abbott's machines were manufactured in St. Catharines, they were sold through two general agents in Toronto: G.W. Grout and Company (until 1868) and W.H. White and Company (1868-72).32 Acclaimed as the best family sewing machine, single- or double-thread, that could be purchased anywhere for the price, the Abbott sold in 1868 for fifteen dollars by itself or twenty-three dollars with a black walnut stand.33

Display large image of Figure 15

Display large image of Figure 1542 John W. Abbott died in 1872 and although his two sons were involved in the business, the company did not continue manufacturing after the death of its founder.

Guelph Sewing Machine Company

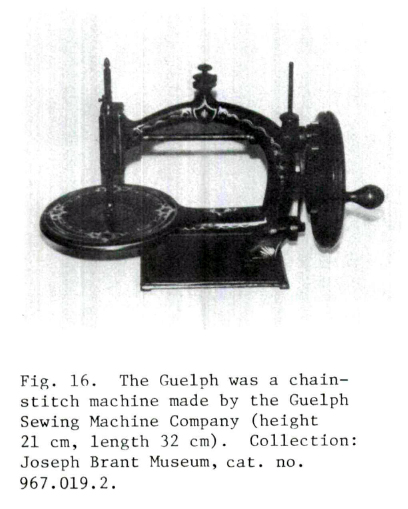

43 This second sewing machine factory to be established in Guelph began production in 1869. The company was also known as Keables, Osborn and Company and later as Wilkie and Osborn, after its proprietors. From the start it was a healthy and successful enterprise, probably the third or fourth largest sewing machine manufacturer in Ontario. In 1871 it was described in the Wellington County Directory as follows:

44 The Guelph Sewing Machine Company manufactured two types of machines, the Guelph and the Osborn. The Guelph was a chain-stitch machine which, like the Abbott, could be operated by hand or foot. It boasted two additional features which distinguished it from the leading competition - reversible motion and a patent elastic hook. In 1870 this machine sold for fifteen dollars and was advertised as the machine for the people - the poor as well as the rich.35 The Guelph was also one of the best constructed, most reliable machines on the market, taking top prizes in the single-thread category at the Provincial Exhibition annually from 1869 to 1872.

45 The Osborn, also introduced in 1869, was hailed as "the Great Desideratum in which all the essentials of a Perfect Machine are combined."36 The Osborn was a lock-stitch machine of high quality and workmanship, obtaining "from 1869 to 1873 the unparalleled number of Seventy-five First Prizes and Nine Second Prizes besides several diplomas and gold medals."37 The Osborn has a low, curved head with two overhanging arms, one which supports the pressure foot and positive take up and the other which moves the needle up and down. This was a fairly common style on American machines in the late 1860s and early 1870s. Identifying marks on the Osborn are to be found across the top of the arm and on the castings of the stand. At the centre of the brace or cross support are the letters GSMCo (Guelph Sewing Machine Company) and "Osborn" appears on the treadle. As with all sewing machines of the period, the Osborn was attractively decorated on the arm and bed with gold leaf.

46 While Charles Raymond branched out into exports, the Guelph Sewing Machine Company concentrated on the home market, proudly emphasizing the fact that its machines were based on Canadian innovation. All the patented principles of its machines were designed by John Osborn, one of the company's proprietors.

47 The Guelph Sewing Machine Company operated successfully throughout the 1870s but ran into difficulties in the early 1880s. In 1882 the company was sold to William Russell and renamed the Guelph Sewing Machine and Novelty Works. By 1884 the struggling company was producing only a limited amount of sewing machines as well as other iron objects and by 1887 it had closed down entirely.

Display large image of Figure 16

Display large image of Figure 16 Display large image of Figure 17

Display large image of Figure 17Canada Sewing Machine Company

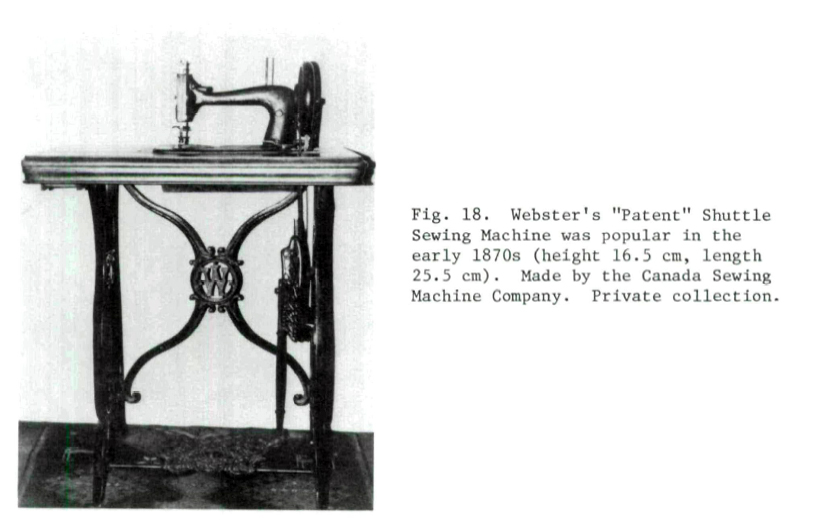

48 This company was started by two brothers, George and John F. Webster, and operated from 1872 to 1878 in Hamilton. At its peak it employed approximately seventy-five labourers.38 Only one type of sewing machine is known to have been manufactured by the Canada Sewing Machine Company and that was the Webster "Patent" Shuttle Sewing Machine. First exhibited in 1872 at the Provincial Exhibition in Hamilton, the primary distinction of this machine was that it was constructed without gears or cams.39 The throat plate bears the following markings:

Patent June 29, 1872

Manufactured by the Canada Sewing Machine Company

Hamilton, Canada

49 This patent (number 1531) was issued to the Websters for "Webster's Improved Sewing Machine" which featured the following innovations:

- a new and improved shuttle with fewer holes so the thread tension remains constant regardless how full the bobbin is;

- four-motion feed made with a much simpler mechanical device;

- face plate in two parts;

- stitch regulator at the base of the arm.

Display large image of Figure 18

Display large image of Figure 1850 Like most other sewing machine manufacturers, the Canada Sewing Machine Company displayed its wares at provincial and local fairs. At the Provincial Exhibition of 1873 ten different styles of the Webster machine were exhibited and to show off its capabilities a demonstrator stitched two thick pieces of sheet lead together for the audience.40 At the 1876 Exhibition the company held a draw - reportedly 1,142 women entered their names in the contest - and gave away a free Webster machine.41

51 The Canada Sewing Machine Company did rather well financially, considering it was one of six Hamilton companies producing family machines. In 1878 it was bought by R.M. Wanzer and Company which shortly thereafter discontinued the Webster machine and expanded its factory on the site of the former Canada Sewing Machine Company works.

Gardner Sewing Machine Company

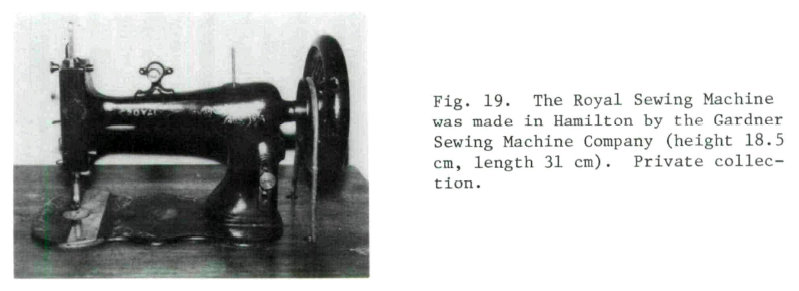

52 The Gardner Sewing Machine Company was established by F.A. Gardner and F.M. Willson in Hamilton in 1871. Although two types of shuttle machines are known to have been manufactured by the firm, only one model could be located for this study. The earliest machine produced was called Gardner's Improved Sewing Machine or simply the Gardner. This machine, patented 31 May 1870, claimed three distinctive features: a screw for tightening the needle bar, improvements to the shuttle, and a feeding apparatus regulated by a thumbscrew on the side of the arm.42

53 The second machine introduced was called the Royal Sewing Machine. The Royal did not claim any new inventions in the principle of the sewing machine but was rather an improved and updated version of the Gardner.43 In a circular to agents the improvements to the machine were described as follows:

54 Another distinctive feature is the spooler spindle which is attached to the table and runs off a separate belt from the fly-wheel. This is the only Ontario-made machine with this type of arrangement.

Display large image of Figure 19

Display large image of Figure 1955 A third, miniature model named the Governor-General was made especially for the Provincial Exhibition of 1872 as an added attraction to the regular display. It weighed a total of one and a half pounds (including the stand) and sewed as perfectly as any of Gardner's full-sized machines.

56 The Gardner Company, in operation during the peak years of Ontario sewing machine manufacturing, finally went out of business in 1886.

Wilson, Bowman and Company

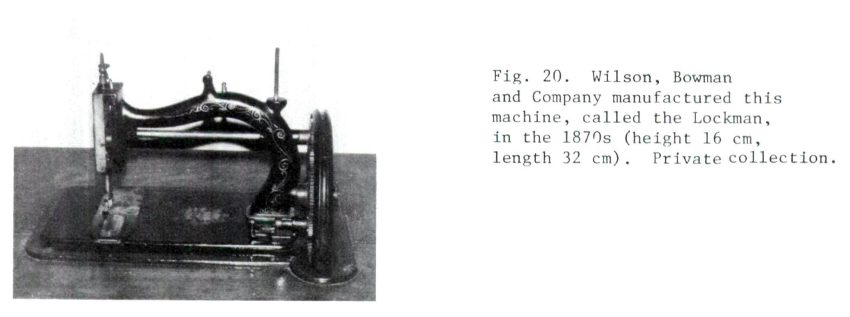

57 Another major sewing machine manufacturer established in Hamilton was Wilson, Bowman and Company. This firm was founded in 1868 or 1869 by three men - Andrew Wilson, a former bookkeeper for R.M. Wanzer, John Bowman, former agent for Wanzer, and Christopher Lockman, a machinist and inventor. Their combined talents created a prosperous and profitable operation which expanded to a second factory in Fergus in 1870.

58 Between 1869 and 1884 the firm changed partners and names several times. From 1869 to 1871 it was known as Wilson, Bowman and Company. In 1872, when John Bowman left to establish another company, the name was changed to Wilson, Lockman and Company. In 1878 the name was changed again to Wilson and Company. Finally, in 1883 the company was taken over by F.M. Willson (of the Gardner Sewing Machine Company) and became known as the Willson Sewing Machine Company.

Display large image of Figure 20

Display large image of Figure 2059 The Wilson company produced both manufacturing and family sewing machines. However, unlike most of the large manufacturers, the Wilson company did not make a series of family machines but stuck to one basic model, the Lockman Family Shuttle Machine. Very little is known about the development of the Lockman machine or the company. Andrew Wilson, who remained longest with the firm, took out two sewing machine patents in 1877 for various improvements. These patents were incorporated in an improved Lockman machine which was manufactured before the company went out of business in 1884.

Hespler Sewing Machine Company

60 Very little information has been uncovered on the Hespler company. In 1872 John Bowman (of Wilson, Bowman and Company) joined up with a Mr. Hespler to establish another sewing machine manufactory in Hamilton. As one source described it, Hespler "saw wealth in the manufacture of sewing machines and he hiked to Hamilton to start up a factory...He lowered his bank account by a few thousand dollars and then like a wise man dropped out of the game..."45 Although the exact date is not known, the company probably closed down before 1875.

Display large image of Figure 21

Display large image of Figure 2161 Although most references to Hespler machines mention heavy duty machines, it appears a small number of family sewing machines were also manufactured. The Hespler family sewing machine is unusually long and thin. Despite this unique feature it resembles the Lockman machine in two areas -the formation of the gears in the balance wheel and the peculiar throat plate section. The machine is highly decorated, both on its body and on the legs of the stand, and bears the following information:

Peters Patent

Hamilton, Ontario

62 "Peters Patent" refers to the two patents issued to Rudolph Peters of Hamilton in May 1871 and January 1872. His improvements to the thread take-up and stitch regulator were both incorporated in the Hespler machine.

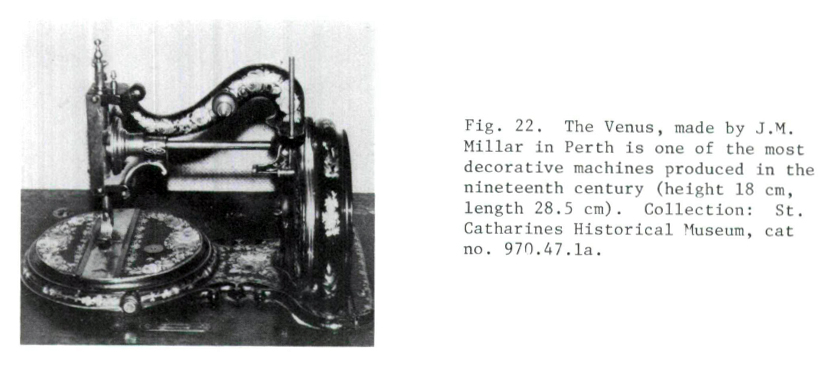

J.M. Miller and Company

63 The history of the J.M. Miller and Company, a small establishment located in Perth, is sketchy and virtually nothing is known about the manufactory except that it was in operation between 1872 and 1875. The company was also known as the Perth Sewing Machine Company and the Venus Sewing Machine Company.

Display large image of Figure 22

Display large image of Figure 2264 J.M. Miller and Company manufactured a lock-stitch machine called the Venus and it was certainly deserving of the name since the Venus was probably the most ornate and attractive sewing machine manufactured in Ontario. Every cast piece is not only delicately hand-painted with roses and leaves, but is decorative in shape as well. The Venus has a number of unusual features. Instead of a solid base or arm support on the right, there is a flat, shapely, cast section which hides the gears. The spooler spindle is situated high up on this "arm" and even it is shapely and ornate. The Venus also has a special thread guide which releases the thread when the needle goes down and holds the thread tight when the needle is raised. This feature replaces the more commonly used take-up lever.

Appleton Manufacturing Company

65 Although primarily noted for its knitting machines, the Appleton company of Hamilton also manufactured sewing machines between 1872 and 1874. The Appleton New Silent Sewing Machine was based on two patents issued in 1871 to C.J. Appleton. His improvements involved changes to the feed attachment and the shuttle motion of sewing machines.46 The machine featured a self-feed, which continually moved the work without guidance by the operator's hand, and a tensionless shuttle.47 At the Provincial Exhibition of 1872 the Appleton company displayed six of its machines, including one which was run by steam power.48 Although it attracted attention, there is no information on how well it sold.

66 Despite the Appleton Manufacturing Company's claims to the most scientifically constructed machine of the day,49 it was not the most popular and the company disappeared after 1874. No examples have been located.

Fergus Manufacturing Company

70 Research on the Fergus Manufacturing Company has raised more questions than it has answered. The only information on the company found to date indicates that it was listed in the Mercantile Agency Reference Books in 1875 and 1877 and was considered to be of moderate size.

71 The Fergus company produced a simple, sturdy machine called the Barclay which was quite likely designed, at least in part, by Robert Barclay, a watchmaker from Paris, Ontario. Barclay took out three Canadian sewing machine patents between 1866 and 1868 and a number of features on the Barclay machine can be identified in his patent specifications. Although the machine is quite ordinary in design and appearance, probably very few were manufactured Because of the poor condition of the particular model located for this study, much of the information is obscured and further research will be necessary to provide answers about the Barclay and its manufacturer.

Display large image of Figure 23

Display large image of Figure 2372 Ontario's sewing machine industry survived for little more than thirty-five years, but it had a significant influence on the social and economic development of the province. Not only did the industry provide jobs for skilled and unskilled labourers, but it also had a tremendous impact on women whose daily toil was markedly reduced by the efficiency and speed of mechanical sewing. The success of this domestic industry was equally important to Ontario from an economic standpoint, since it helped to keep money in Canada which otherwise might have gone to support manufacturers from the United States. Most of the machines produced in Ontario now stand idle and forgotten, yet they were some of the most treasured and over-worked appliances to be manufactured in nineteenth-century Canada.

* All photos are by the author.