Articles

The Mechanized Agricultural Frontier of the Canadian Plains

Le présent article poursuit trois objectifs: évaluer l'incidence des premières machines agricoles sur l'essor des Prairies du Canada, étudier l'évolution du tracteur de ferme et situer ces machines dans leur contexte socio-économique. Une étude des recensements et des chroniques de l'époque révèle que les premières machines agricoles ont eu une incidence phénoménale sur la vie dans l'Ouest, si bien que l'agriculture s'y est toujours pratiquée en fonction de l'équipement motorisé. La demande des fermiers de l'Ouest a donc donné lieu à une forte concurrence technologique entre les divers fabricants. On a établi l'évolution du tracteur de ferme à partir d'exemples tirés de la collection du Western Development Museum. D'autres sources ont aussi été consultées. Ces documents se sont avérés d'une grande valeur pour l'étude des premières machines agricoles. En tant qu'artefacts témoins d'une époque, les machines nous ont permis de mieux comprendre ce qu'était la vie dans l'Ouest canadien avant 1920.

1 The application of mechanically generated power to agriculture heralded a revolution in farming. As an agricultural frontier the Canadian plains were unique in that their development coincided with the widespread availability of engines. The Western Development Museum is fortunate in having in its collection many examples of these early engines. This collection provides an opportunity to study the early evolution of the farm tractor.1 By focusing upon this progression it is possible to examine the basic nature of plains agriculture. Furthermore, it is possible to investigate aspects of the social history of which the mechanical behemoths were a part.

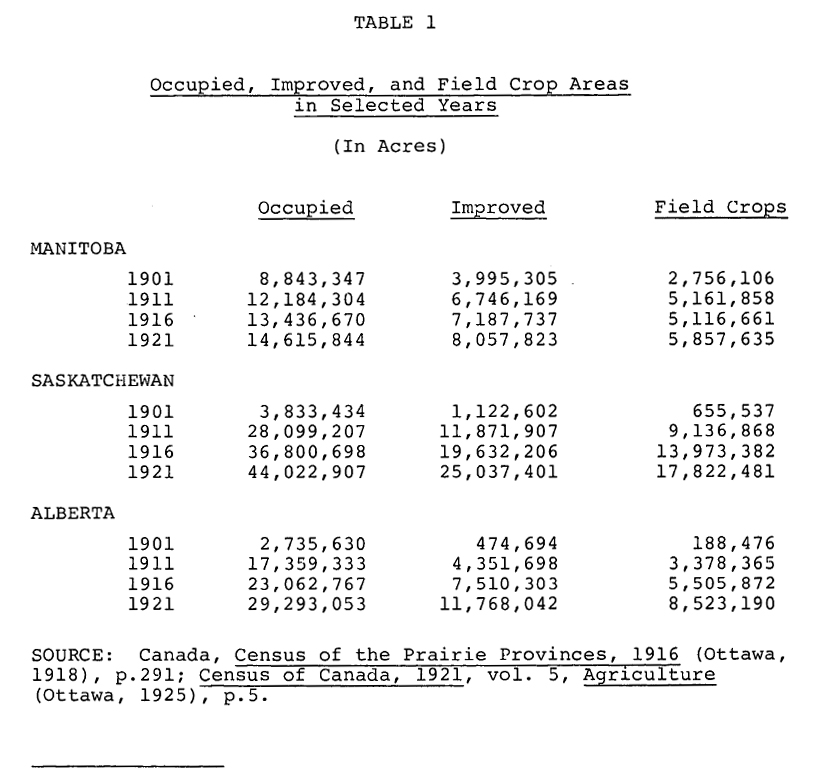

Display large image of Table 1

Display large image of Table 12 Plains agriculture grew phenomenally in the early decades of the twentieth century. Table 1 gives an indication of how great the gains were. The early engines played an important role in this growth. One qualified observer in 1909 estimated that over fifty percent of the breaking done in Alberta and Saskatchewan that year was done by steam traction engines.2

3 Preparing the land was only part of the job; the harvest was crucial and threshing was a major part of it. Engines provided the power that allowed Manitoba's spring wheat harvest almost to double between 1900 and 1920. At the same time that province's barley crop increased by over 380 percent and its oats crop by more than 270 percent. In Saskatchewan the increases were, if anything, even more spectacular. The spring wheat crop jumped from over 4,300,000 bushels in 1900 to almost 67 million bushels 10 years later for an increase of close to 1500 percent. By 1920 it had reached a figure just over 115 million bushels, an increase of close to 2600 percent since 1900. Alberta recorded similar large increases.3

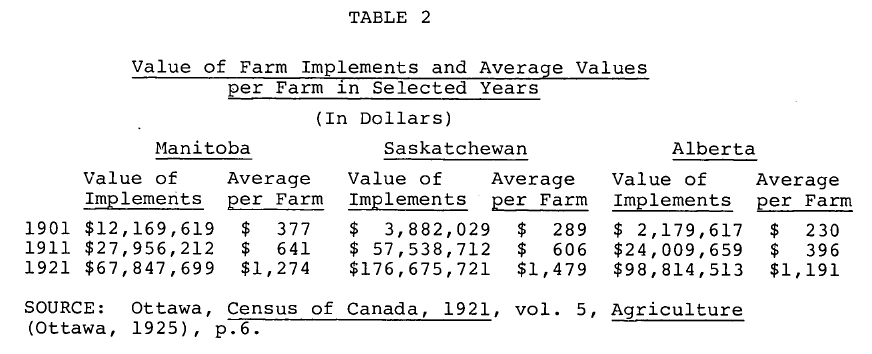

4 Akin to the great strides in production was the appetite of prairie farmers for power equipment. As the advantages became more apparent, farmers bought engines in steadily increasing quantities. One optimistic American manufacturer of threshing machinery declared in 1902 that United States factories would have to double and even treble their output to keep up with the growth of the Western Canadian market. Canadian import figures appear to bear him out. In 1907 Canada brought in 528 portable and steam traction engines for agricultural purposes. By 1911 these imports had jumped to 2,137 units, with a value in excess of 31 million dollars.4 Another indication of this trend was the large increase in the value of farm equipment on prairie farms as shown in table 2. Unfortunately these statistics do not itemize the various machines, but the trend is easily discernable.

Display large image of Table 2

Display large image of Table 25 This trend was apparent to contemporaries. In 1910 the Grain Growers' Guide noted that big steam engines were breaking sod in every prairie province:

The Guide went on to note that local dealers selling steam engines reported that business was growing faster than they could handle it. The manager of one firm claimed that he had done more business by the first of June 1910 than he had altogether in 1909.5

6 Other farmers wanted power- equipment because they had lost their crops or had had poor harvests because their grain went unthreshed before winter set in. Testifying before the Saskatchewan Farm Machinery Commission at Shaunavon in 1914, one farmer stated that because of a lack of machines in his neighbourhood his first good crop was not threshed and had stood out all winter. He did not need to elaborate to his farm audience on the consequences of this. At the Yorkton sitting of the inquiry a farmer testified that he was open to the arguments of company agents to purchase machinery because he could not get threshed when he wanted to.6

7 These statistics and comments illustrate a basic feature of Canadian plains agriculture. It was, virtually from its inception, oriented toward power equipment. Not that the horse was supplanted right away, but pioneer farmers saw what the engines could do and purchased accordingly. In fact their demand was so great that prior to the First World War the Canadian plains were considered to be the world's most important tractor market.7 The pioneer's successors continued the trend and today Western Canadian agriculture is one of the most mechanized industries in the country. This has had important social and economic effects ranging from the continuing battle with the cost/price squeeze to the increasing size of farms and the decline of the rural population. These issues have been prime ingredients in that volatile mixture known as prairie politics.8

Display large image of Figure 1

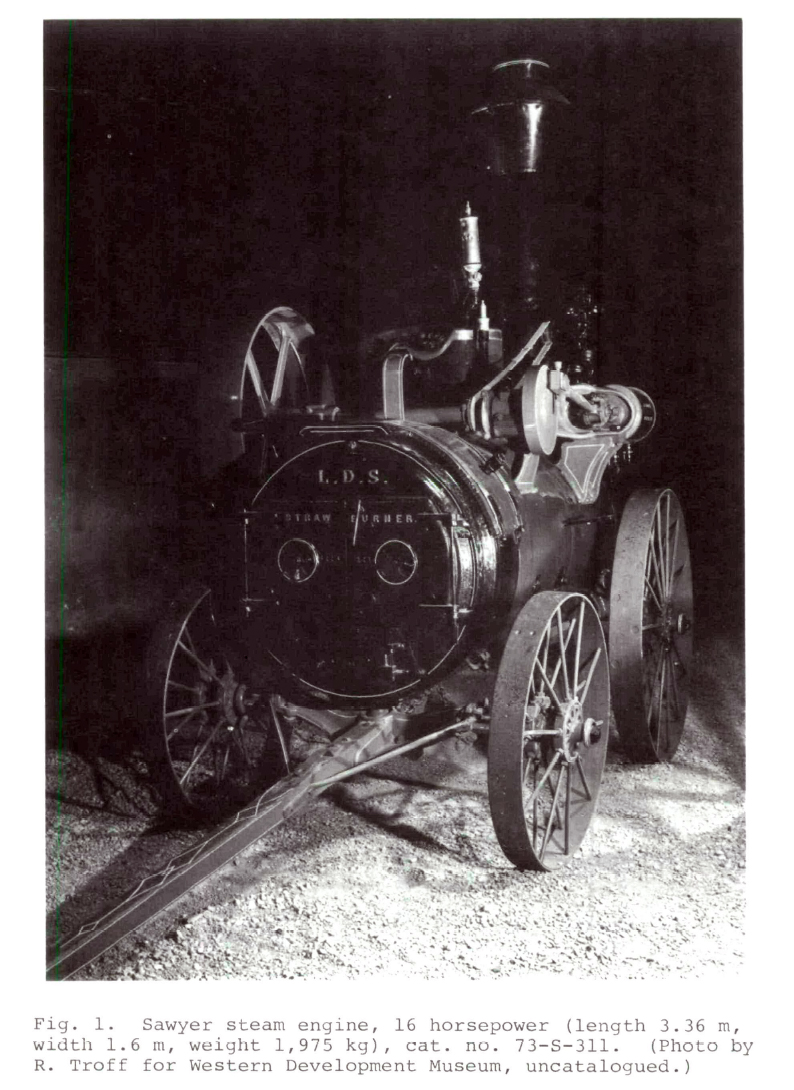

Display large image of Figure 18 It is necessary to stress that engines did not replace horses on prairie farms in this early period; in fact, horse teams were still a common sight on farms until after the Second World War. While engines were used extensively for plowing and threshing, horses were the source of power for virtually every other farm task.9 Still, farmers appear to have realized that tractors were the way of the future and there was a steady demand for engines, resulting in a variety of types being sold and in continuing technological development in the industry.

9 Focusing upon particular engines in the Western Development Museum collection makes it possible to trace briefly the evolution of the farm tractor. The starting point is steam engines which were moved by horses. These portables were used almost exclusively to drive threshing equipment. The sixteen horsepower Sawyer shown in figure 1 is a good example of this type of engine. This unit was used for threshing in the Sintaluta area of the then North West Territories until traded to J.M. Sanderson of Indian Head around 1895. Sanderson gave up a team of horses for this steamer and used it for threshing for six more years.10

10 The next step in the progression was the self-propelled steam traction engine. A popular variety on the Canadian plains was the Case 25-75 shown in figure 2. A unit similar to this one was purchased new from the J.I. Case Company representative in Regina in 1911 by the Norrich brothers of Strongfield, Saskatchewan. The brothers, who had come west from Grey County, Ontario, in 1905, had started farming with a pair of oxen. The Case engine must have made quite a difference since it broke an estimated 450 acres and threshed 100,000 bushels of wheat the first year that it was used.11

Display large image of Figure 2

Display large image of Figure 211 However, there were problems with steam power. In September 1908 the boiler of a threshing engine exploded on the farm of Alex Irwin of Opawaka, Manitoba. The explosion was terrific — both ends of the boiler were blown out and the flue sheets were torn apart. Several men were injured, the most serious being the fireman who was badly scalded and wounded after being blown 200 feet. Everyone else on the crew had some injury ranging from cuts and bruises to scalding. The men feeding the separator were hurled from their wagons. A year later another explosion killed a man near Deloraine, Manitoba, when the end of an engine's boiler blew out and sent the engine turning two or three somersaults into the separator.12

12 Fire was a great and costly danger in operating steam engines and appears to have been one of the major factors limiting their survival as effective farm equipment. As many as fourteen stacks of grain at a time were burned in accidents in which fire started from a spark from the engine. Sometimes the equipment itself was destroyed. Farmers were aware of these dangers and sought alternative sources of power. A farmer testified to the Saskatchewan Farm Machinery Commission in 1914 that he had purchased a gasoline engine because "... I thought I would not want steam, for fear it would set fire to the house or barn, and the wind might not be favourable, and therefore might set my buildings on fire as I wanted to blow straw into the barn. And I thought I wouldn't need the tank teams and fireman...." 13

13 Water was yet another problem facing the owners of steam engines. Since the engines needed large amounts for their boilers, they could operate efficiently only where water was plentiful. In October 1915 the Saskatchewan Department of Agriculture asked the Canadian Pacific Railway to haul water to Sceptre, Saskatchewan, because there was not enough for steam engines to operate there and a large amount of threshing remained to be done. The department also took account of the water problem in aiding the movement of threshing rigs, being careful to inquire whether steam or gas threshers were required. In October 1915 the department received two requests for help in locating threshers, both of which mentioned water supply problems and specifically asked for gasoline engines.14

14 The kind of water available was also a problem since the hard water found in many parts of Western Canada could scale boilers badly. Yet one thresherman testified to the Saskatchewan Farm Machinery Commission that scale could be prevented if the engineer attended to it and that scaling was a problem only if the engineer was too lazy to clean out his boiler.15

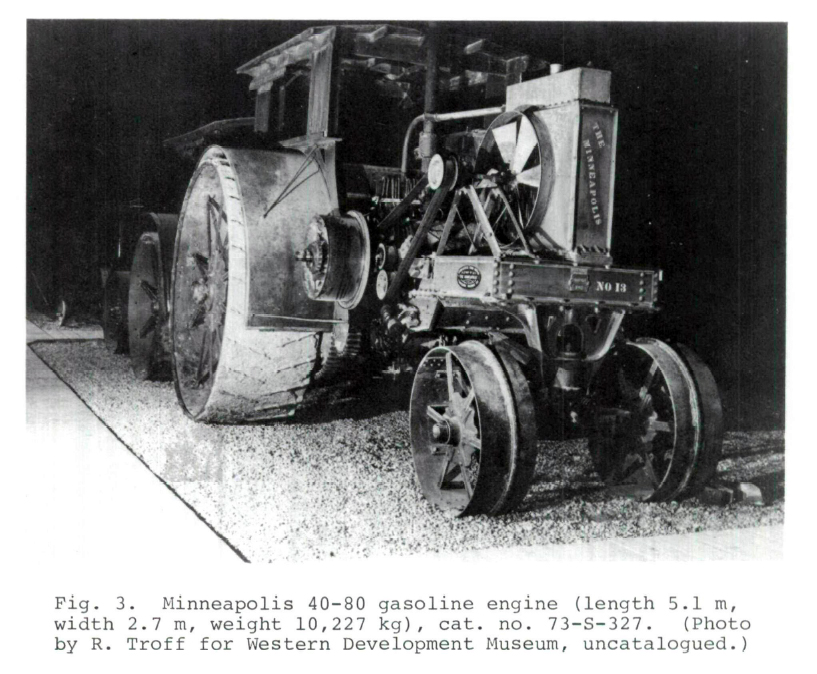

15 Steam engines continued to have a place in agriculture for some time. As late as 1920 there were fifteen American companies manufacturing steamers.16 As the problems faced by steam engine owners have shown, however, there were reasons for farmers to look to other forms of power equipment. Manufacturers were ready and willing to aid them and the appearance of the gasoline- (or more properly kerosene-) powered engine heralded another step in the evolution of the farm tractor. The Minneapolis 40-80 in figure 3, while of somewhat later manufacture, clearly shows that the gasoline units were first modelled after the steamers.17 This particular unit was used in the Aberdeen, Saskatchewan, district to thresh grain and to move large buildings.18

16 There was keen competition between the manufacturers of steam and gasoline engines. Advertisements fill the pages of such journals as the Grain Growers' Guide, extolling the merits of the various engines. Yet whether they preferred one type of engine or another, farmers faced similar problems. The cost of purchasing a complete threshing rig was often prohibitive for many small farmers and they relied upon neighbours or custom threshermen to get the crop into storage. A consequence of this situation was the movement of machines throughout the prairies. In Saskatchewan the Statistics Branch of the Department of Agriculture became a focal point for farmers and threshermen trying to contact each other. The branch also tried to aid the movement of threshing rigs on its own initiative. For example, in response to a thresherman in Rapid City, Manitoba, who had a rig available and wanted to continue threshing, the acting secretary of the department stated in part:

The reply also included the names of two contacts in Swift Current, Saskatchewan, though cautioned the thresherman about moving his rig so far.19

Display large image of Figure 3

Display large image of Figure 317 Shipping large pieces of machinery could be expensive, however. James Service of Pilot Butte, Saskatchewan, complained about the fee charged to ship his rig to Webb on the Canadian Pacific Railway. He contended that since he would be threshing along the company's main line, it would ultimately derive revenue from his work there. Whether through a realization of this fact, political pressure, or a combination of the two, both Canadian Pacific and Canadian Northern railways introduced special rates for threshers shipping their machines. Under the arrangement "...a machine which had paid full freight going is entitled on presentation of the Bill of Lading, to a free return to [the] original shipping point. The men of course will have to pay regular rates for their tickets."20

18 Relationships between farmers and threshermen were not always cordial. For example, in 1909 the Grain Growers' Guide informed its readers of an important decision recently handed down by the Alberta Attorney-General's Department. Under the Alberta Thresher's Lien Act it appeared that a thresherman could enter a farmer's premises and remove grain to pay for threshing if the account was still due. The department decided, however, that the thresherman would have to remove grain directly from the machine to benefit from the Act and that a farmer could forcibly defend his property if an attempt was made to remove his grain in any other manner. In another case a farmer sued a thresherman for $1,275 because his wheat had been burned in a fire caused by a spark from the thresherman's engine.21

19 Price was often an area of dispute between farmers and threshermen. In September 1910 the Grain Growers' Guide was informed that farmers in the Narrow Lake, Manitoba, area had agreed to bring in new threshermen when local threshers combined to demand higher rates. The editor of the Guide was not entirely sympathetic as he had once been a thresherman and knew something of the problems which they faced. His own experiences had included being charged three dollars for a load of water by a farmer to do the farmer's own job, being cursed for leaving weed seeds on the machines to fall off later, and being cursed if he swept them off instead.

The Saskatchewan Department of Agriculture also became involved in the question of threshing rates. In response to a farmer worried about the possibility of being charged exorbitant rates by threshermen in his area, an official of the department stated that while supply and demand would have to set the price, farmers should investigate the merits of smaller threshing outfits they could operate themselves. The department's concern was also reflected in its Annual Report of 1914 which contained a report on the work of small threshing machines in the province. This indicated that inexperience on the part of the farmer-operator and the slowness of the small outfits were drawbacks, but concluded that overall they seemed to be a decided success.23

20 Another way in which farmers overcame the price problem was to form "syndicates," groups which shared the costs of an outfit and had access to it when they needed it. While these groups are another example of the co-operative spirit which is so strong in rural areas, they are also interesting because they appear to have been vehicles for reaching across ethnic barriers and thus building local communities. The Ca-nor-e Syndicate Threshing Outfit of Kyle, Saskatchewan, for example, consisted of Eddie Ingvald, Elmer Pederson, Jimmy Wilson, Bill Gibson, and Bert Elderton, and drew its name from the nationalities of the owners: Ca-nadian, Nor-wegian, and E-nglish.24

21 Another method of financing a tractor or a complete threshing rig was through credit. Implement companies appear to have been anxious to extend credit -- too anxious according to some farmers who appeared before the Farm Machinery Commission.25 Virtually every sitting of the inquiry heard complaints that credit was too easily obtainable and thus many men were signing up for equipment they did not need or could not use. This complaint was usually accompanied by charges that interest rates were too high and that too much security was being demanded. Interest rates appear to have been from eight percent before to twelve percent after due. The major concern over security was that while horses and oxen were often taken as security, it was usually land which was demanded. A few examples will suffice. A farmer and his father had bought a steam engine and a separator from the J.I. Case Company but had trouble making their payments and had to sign over the son's farm as security. This man claimed that he was never notified that he was continuing to fall behind in his payments and that he did not know there was a problem until he discovered that the company had his land up for sale. He arranged for an extension and a loan but after eight years was still paying on the equipment. Another farmer was paying twelve percent interest on a Reeves steam plowing outfit. He had been given certain verbal assurances on its performance, but it did not satisfy him and he had yet to get satisfaction from the company. An American Abell "Cock-o-the-North" Engine purchased by another farmer was not delivered in time for harvesting with the result that he lost a lot of money and could not meet his payments. The company wanted a mortgage on his unproved homestead and forced him to sign one by holding him in a room and not letting him go until he did so.26

22 Credit was not the only problem for some farmers. Immigrants who knew little of their new country's ways or its language were targets for unscrupulous salesmen. A Mennonite farmer who did not speak English testified to the commission through an interpreter that he had been talked into buying a threshing rig, but when the machine did not work properly he lost money. A Galatian farmer, who neither read nor spoke English, told the commission that he had been approached by two salesmen to buy a Robert Bell engine. He was duped into signing a purchase order which was also a mortgage on one of his quarter sections. A Hungarian farmer stated that he had been made to buy an old engine and a separator when "under the influence." Immigrants were not the only targets though. A farmer who had purchased a new steamer and separator later found that the engine was an old one and had been patched up. The boiler would not hold water, the engine would not burn straw, only coal, and it never did "get up" proper power. One farmer was so bitter that he told the commissioners that "the Government should put a bounty on salesmen and let them [farmers] kill them when they come on the farm."27

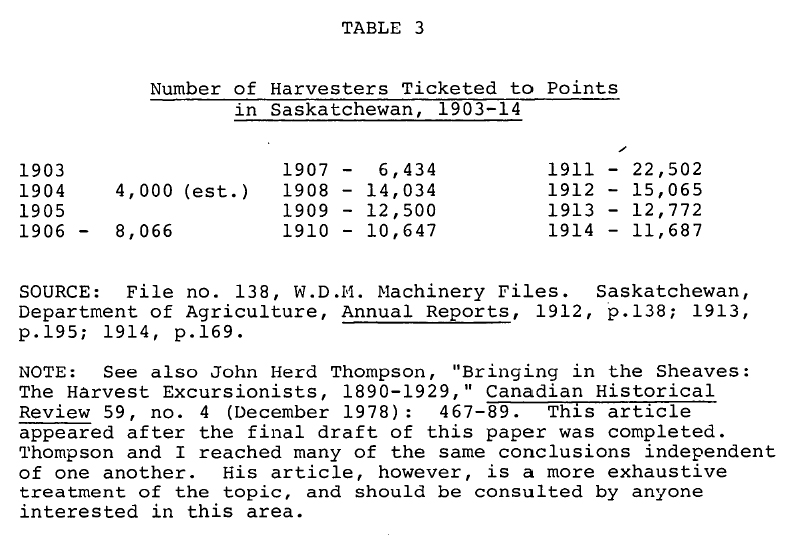

23 While the mechanically derived power of the early engines was a decided improvement over animal and even human muscle, there was still a labour problem, especially at harvest time. To take one example, a J.L. Case 32-110 horsepower engine now in the Western Development Museum was part of a rig which needed twenty-eight men to operate all of its equipment. While not all of the crews needed this many men, the problem is obvious. An understanding of the scope of the difficulty is possible when one examines the number of harvesters ticketed into Saskatchewan from 1903 until the First World War (table 3). Not all of these men worked on threshing rigs, but many did and even together with in-province labour supplies there were often not enough men. During the First World War when the shortage of manpower was particularly acute, there was a movement to organize "Patriotic Harvesting Clubs" which would organize businessmen, especially in the large eastern cities, to recruit men from their own friends and from their employees to volunteer to work a few weeks harvesting.28

Display large image of Table 3NOTE: See also John Herd Thompson, "Bringing in the Sheaves: The Harvest Excursionists, 1890-1929," Canadian Historical Review

59, no. 4 (December 1978): 467-89. This article appeared after the final draft of this paper was completed. Thompson and I

reached many of the same conclusions independent of one another. His article, however, is a more exhaustive treatment of the

topic, and should be consulted by anyone interested in this area.

Display large image of Table 3NOTE: See also John Herd Thompson, "Bringing in the Sheaves: The Harvest Excursionists, 1890-1929," Canadian Historical Review

59, no. 4 (December 1978): 467-89. This article appeared after the final draft of this paper was completed. Thompson and I

reached many of the same conclusions independent of one another. His article, however, is a more exhaustive treatment of the

topic, and should be consulted by anyone interested in this area.

24 Getting the harvesters to the West to help run the machines could be a problem in itself. In August 1908 the Manitoba Free Press carried a series of articles dealing with the "turbulence" experienced by trainloads of harvest workers from the East. One report noted the arrest of two men in Fort William. They had got drunk on the harvest train and when it stopped in Chalk River, Ontario, they had left it to loot a hotel searching for more liquor. Another item noted a five-day drinking spree on one train which kept non-participants awake. In addition, storekeepers in towns along the route locked their doors when the train appeared, forcing some to go without supplies. Others simply broke in and took what they wanted. Another train had been attacked between Fort William and Winnipeg by Italian railroad workers who were incensed at previous attacks by harvesters and took their revenge on this train. Revolvers and rifles were fired from the train in reply to stones being hurled through windows. One man was shot through the hand, while another had a grazed scalp. Another item noted that Winnipeg city police had to help the C.P.R.'s own police to quell a riot among harvest workers at the Winnipeg depot.29

25 Another aspect of the labour question were complaints about wage rates. In March 1920, for example, a farmer from Indian Head, Saskatchewan, complained to the Department of Agriculture about the high cost of farm labour and asked why Provincial Bureau of Labour agents seemed to be bent on putting men in the best-paying jobs rather than getting farmers good men at fair wages. In response the Commissioner of Labour outlined some of the problems his organization faced. Although wage rates were posted in the labour office at seventy-five dollars a month, a farmer would enter and loudly announce that he would pay eighty-five or ninety dollars a month. Labourers hired at seventy or eighty dollars per month were followed out of the labour office by farmers who added five dollars to the salary and thus hired them away from others. News of wage rates travelled fast and one consequence was that men demanded higher wages or left the farm.30

26 The men who worked with the early engines did not have an easy life. It was hard work and there was always the danger of accidents. The possibility of a boiler explosion with a steamer has already been noted and while these were somewhat exceptional other threshing and engine accidents were far too common. Farmers caught their clothing, arms, or legs in the moving parts or were pinned under their machines, suffering severe injuries. On 22 October 1909 Charles Gibson of Deloraine, Manitoba was seriously injured when he was caught in the drive belt and thrown against the belt tightener. He received a bruise and bad gashes on his head, broke his right arm in three places, and suffered two dislocations.31 The extraordinary weight of the old engines was a problem, causing them to break through culverts or bridges, sometimes trapping and injuring their crews. A threshing machine which broke through a culvert near Roseisle, Manitoba, pinned the engineer and fireman under the rear end. The men were rescued, but one had a broken arm and the other suffered two broken legs.32

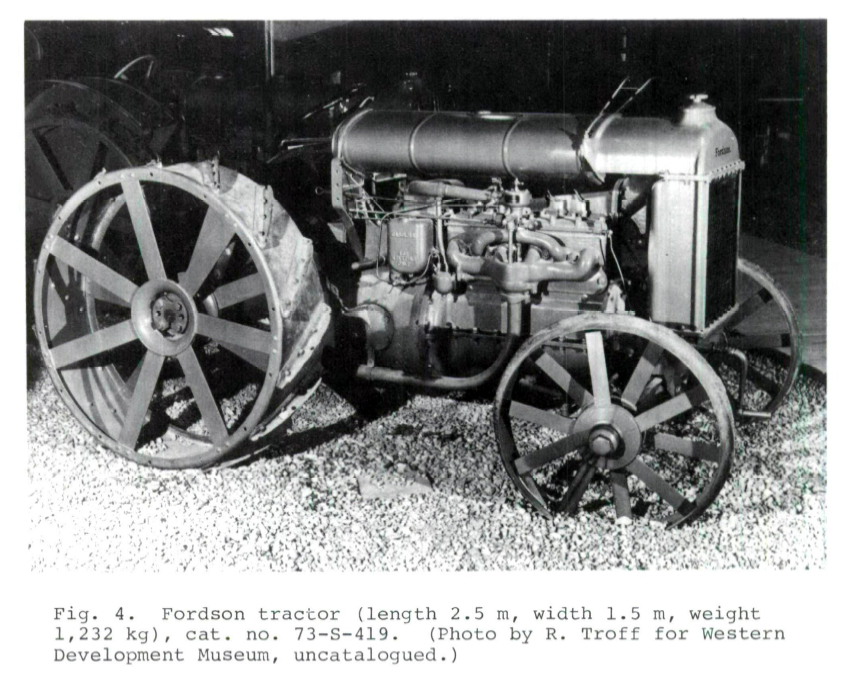

27 The use of gasoline engines was given a boost in the last year of the First World War when the Government of Canada and Henry Ford and Son of Dearborn, Michigan, combined to put over a thousand Fordson gasoline-powered units in Canada, the bulk of them on the Western plains. While other small tractors had preceded it, the Fordson is noteworthy for a number of reasons, though largely for the success it enjoyed. The Ford Company was already shipping five thousand of its units to Great Britain and the Canadian order appears to have developed from this. The federal government took part under its "Greater Productivity Campaign," while the company no doubt saw an opportunity both to contribute to the war effort and to establish future markets. That the latter was an important consideration is revealed in the fact that Ford made promotional films available to all Canadian provinces and attached the announcement of the Canadian government's purchase to monthly films circulated by Ford to theatres in Canada. The Fordsons themselves were good advertisements, especially with their $795 cash price tags and delivery at the nearest railway station. The Canadian government accepted delivery only of an initial one thousand, but was deluged with inquiries and did arrange for more.33

28 Designed by automobile men, the Fordson (fig. 4) was relatively small, but still powerful. It was a radical departure from the massive steamers and early gasoline engines and marked another step in the evolution of the farm tractor. C.A. Dunning, then Saskatchewan Provincial Treasurer and later Provincial Minister of Agriculture and Premier, was not far wrong when he told an interested farmer that "I feel certain that this tractor is destined to do in the farm tractor field what the Ford car did in the automobile field." 34 Ford, of course, had made the automobile available to nearly everyone, and the Fordson along with its imitators and successors made the tractor a fixture on every farm. Over the years tractors have grown in power and size until now, ironically, they rival the old steamers in size although their horsepower is far greater.

Display large image of Figure 4

Display large image of Figure 429 The impact of mechanically generated power on Western Canadian agriculture and society cannot be underestimated. Engines powered the plows which first broke much of the prairie sod and drove the separators which harvested the first crops. As the benefits to be gained became clearer, more farmers sought access to power equipment. There were problems though. Financing was always difficult, and getting enough men to run the early outfits was a problem. The big steamers were prone to starting fires, and both they and the early gasoline engines posed weight problems. The increasing demand for power and the problems the steamers posed were important reasons why gasoline engines challenged and finally overcame their old rivals. Yet they too were eventually replaced when more compact but still powerful engines appeared. Still, it was the early engines which were the first non-animal power sources in agriculture and as such they laid the foundation for our heavily mechanized farming industry. It was these machines which made the Canadian plains a mechanized agricultural frontier.35