Articles

Early B.C. Sawmill Machinery:

1869

1 The discovery of an inventory taken in 1869 of machinery at the Hastings Sawmill, Burrard Inlet, in the colony of British Columbia, is a valuable find in terms of the technological history of the forest industry. It also provides an opportunity to comment on this find in relation to current research in the field and the availability of artifacts of the kind listed.

2 The inventory was located as a result of research undertaken in the development of a new local history gallery at the Centennial Museum in Vancouver. The gallery deals with the period 1865-1890. During that period the first European settlement occurred on the site of what is now Vancouver, built around the establishment of a large export sawmill constructed during 1865-1867 on the south shore of Burrard Inlet by the British Columbia and Vancouver Island Spar Lumber and Sawmill Company an English firm. In 1869 the mill was sold to a San Francisco company and a year later the name was changed to the Hastings Mill.1 Although the broad outlines of the mill's early history were fairly easy to find problem of what machinery was used, its origin, the floor plan of the operation and other associated gestions proved to be a very different matter.

3 It was, of course, necessary to try and find answers to these questions in order to decide on what the relevant portion of the gallery would contain, to select proper artifacts and to provide the correct associated text.

4 It quickly became apparent that the few historians who had examined the early B.C. forest industry had paid very little attention to the tools and machinery used.2 This neglect is not quite so glaring in works dealing with the industry in other parts of North America, but it is generally noticeable. The obvious answer, that technology is only one part of the story, is of limited comfort to the museum historian or curator trying to put together a gallery.

5 It was my good fortune to contact, in the early stage of the research, Gerald Wellburn, founder of the British Columbia Forest Museum at Duncan, B.C., who owned a mill on Vancouver Island for many years and has a great interest in the history of lumbering in the province. Mr. Wellburn loaned to me a number of documents which he had rescued forty years ago when the offices of an early Victoria law firm, Drake and Jackson,3 were being closed and the records dispersed. Among the papers he saved was an indenture, dated 31 May 1869, covering the sale, by mortgage, of the B.C. and V.I.S.L.S. Company mill to a partnership composed of a London businessman, George Campbell, and a San Franciscan, Edward Davis Heatley, trading out of San Francisco under the name Dickson DeWolf and Company.4

6 Part of the process of sale involves an inventory of all the mill machinery which together with "...the Mill Engine House, Steam Engine Horses and oxen now in or about the premises and land of the said company at Burrard's Inlet..." are to be signed over to Dickson DeWolf through their local agent. The inventory, which appears below, was taken 18 May 1869, presumably on site, and witnessed by Charles Leggatt who was a solicitor with Drake, Jackson and Aikman of Bastion Street, Victoria. It is also endorsed by J.C. Nicholson, attorney for the B.C. & V.I.S.L.S. Company.5 As far as our research and planning for the gallery was concerned, this inventory was only the beginning, although it was an excellent find. To my knowledge no earlier or as complete a listing for a B.C. mill of the size has been located. The interpretation of the inventory began with attempts to discover who had made the machinery and what it looked like. It is known that Captain Edward Stamp, the builder of the mill, had the equipment shipped out from Glasgow in 1876 on the barque Kent, although installation was not completed until 1867 since several key parts were missing from the first shipment.6

Machinery now Working

1 21 inch cylinder 36 inch stroke HP engine

1 9 inch cylinder 21 inch stroke HP engine

1 10 inch cylinder 18 inch stroke HP engine

1 Log hauling Machine & chain

1 Double Circular Saw with all appurtenances [sic] (carriage 80 feet long)

1 Edger Circular Saw with all appurtenance table 60 feet long

2 Butting Saws

2 T & G Plaining [sic] (Wordsworths old patent)

1 Pair 48-inch French Bur Stones with plant for Grain crushing

1 Iron Lathe

1 Vertical Drilling Machine

1 2nd Edger Saw & Table

1 Set of 2 Boilers for ditto

1 Surface & Edging Planing Machine

1 Surface Saw Table (incomplete)

1 Woodbury patent planing machine

4 Circular Saws

May 18th 1869

Witness

Chas Jas Legatt

Victoria, V.I.

J.C. Nicholson

Attorney for the British

Columbia & Vancouver Island

Spar Lumber & Saw Mill

Company Limited

on behalf of the Company

7 An initial enquiry to the Science Reference Library in London, England, was referred to the Timber Research and Development Association at High Wycombe in Buckinghamshire. Through them I was put in touch with the two companies whom they believed, on the basis of the information I had given them, could have been the manufacturers of the machinery, Thomas White and Sons in Paisley, Scotland, and Thomas Robinson and Sons, Rochdale, Lancashire.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 2 Display large image of Figure 3

Display large image of Figure 38 Thomas White was considered because that firm was the lineal descendant of John McDowell and Sons of Johnstone near Paisley, a wood-working machinery manufacturing concern, founded about 1825.7

9 The directors of these two firms proved extremely helpful and forwarded, along with background information, copies of early catalogues showing machines of the type they felt were those described on the inventory. The question of which of the two firms was the supplier is still not entirely clear, in part because neither firm produced all of the machinery listed in the inventory. In addition, the staff at the Robson works felt that if all the machinery were shipped from Glasgow, then shipment from Rochdale in Lancashire to Glasgow would have been a tough job, especially since the through railway line to Glasgow was not completed until the 1870's. It would have been much more sensible to ship out of Liverpool.8 It must also be admitted that there is no way of being sure of how much machinery listed came out on the Kent and how much, if any was purchased elsewhere, perhaps in San Francisco, and added to the basic stock between 1867 and 1869. Nor is it possible to state what sort of modifications to the British machinery might have been made in order to cope with the huge fir and cedar logs that were cut from the virgin forest in the lands around the mill.

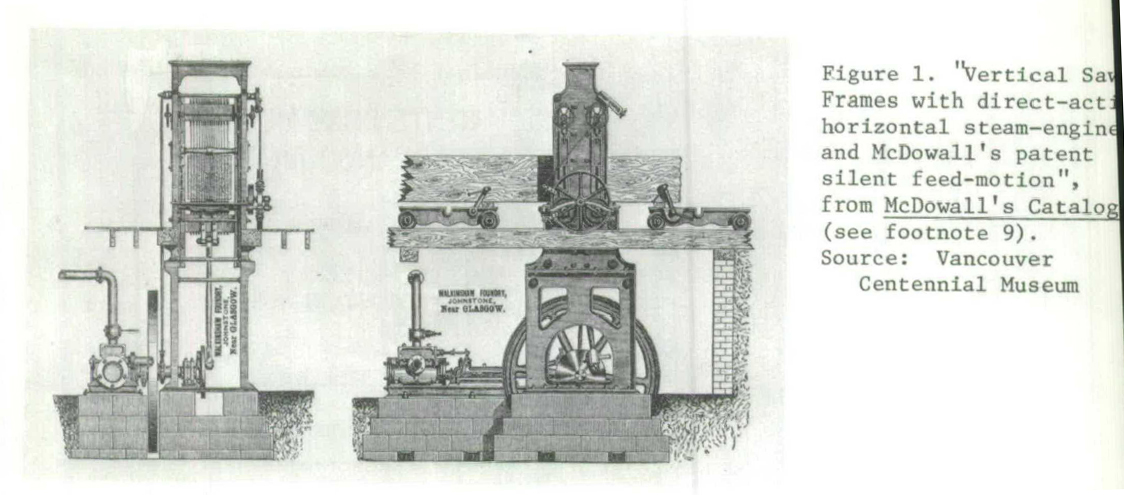

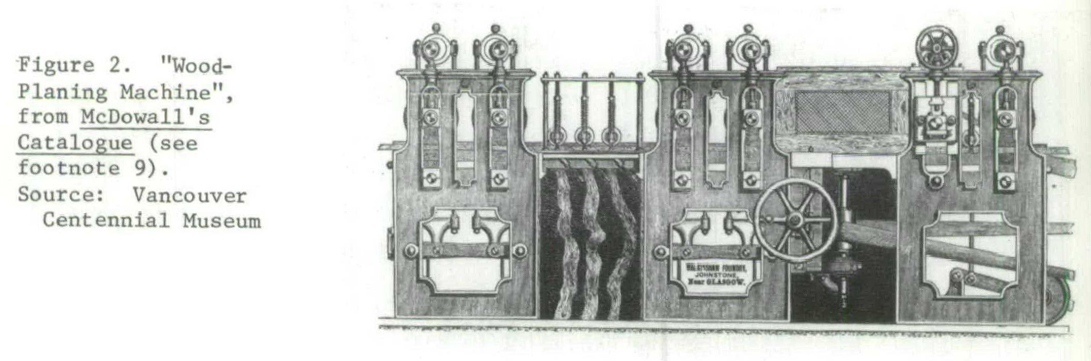

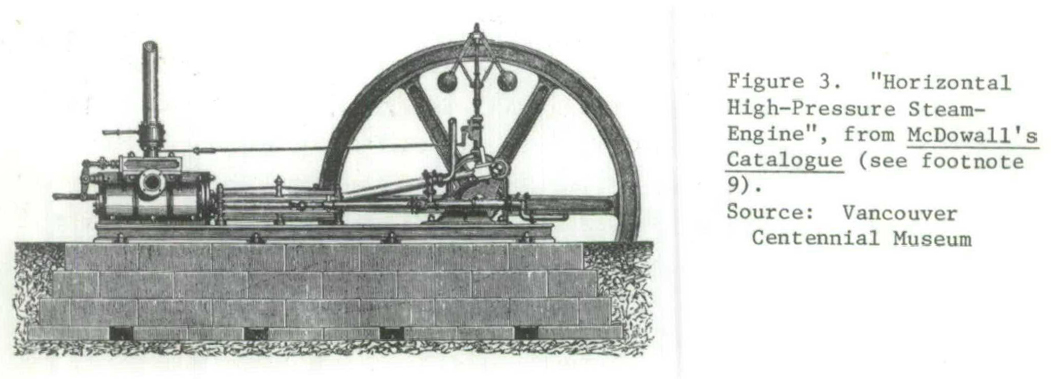

10 In spite of this, however, the catalogues do provide some legitimate visual information. If we cannot claim that the exact make of machine is correct they are at least closely representative of what British manufacturers in the 1860's offered for sale. In the McDowell catalogue of 1865 we find a combined gang and engine, a vertical drilling machine, a tongue and groove planing machine and saws which closely approximate the double circular and the edger circular (see figures 1 and 2). There is also a horizontal high pressure steam engine (see figure 3) made in sizes which relate to the machines mentioned in the inventory.9 The 1867 catalogue put out by Robinson contains lathes, a gang and engine, a vertical boring machine and a horizontal high pressure engine although cylinder bore and stroke specifications do not match exactly.10 It will be apparent that not all the machinery listed on the inventory can be accounted for, even an approximate way, with reference to these catalogues. Unfortunately, no information has been located yet to explain the two "brand" names the Wordworth and Woodbury patents. There is a possibility that some machines were modified from parts machines from parts purchased from defunct concerns in the area.11

11 In any case it was not necessary to track down every detail about each machine listed in the inventory in order to proceed with the development of the gallery. Using the inventory and the floor plan of the Hastings Mill taken from the 1885 fire insurance atlas of Granville, B.C. [Granville became Vancouver on 6 April 1886],12 the curator and designer created scale drawings for mill as we believe it existed in 1870. These drawings are now being used to build a large working model of the mill which will be one of the central interpretive features of the first part of the gallery. Inevitably we had to take some guesses as to the inventory and the plans were silent on several points, especially with regard to methods of construction. However, without the inventory it would have been virtually impossible to recreate the mill with any degree of detail and accuracy.

12 It should perhaps be mentioned that reconstruction, in model form, was our only option apart from a very limited scheme of panels with photo reproductions and text. Even if a considerable number of artifacts had existed, available space, amounting to just over 600 square feet, would have permitted use of only a few. As it turned out there was no such "embarras de richnesse" of artifacts. To date I have been unable to locate any of the machines listed in the inventory. In fact, I have not found any piece of sawmill equipment that can be identified as having been used in British Columbia prior to 1880 or even any representative pieces. The single artifact, perhaps the sole remaining survivor of the early forest industry in the province, is a circular saw made by Spears and Jackson in England about 1867 or 1868 which was shipped around the Horn to a small mill at Barkerville.13 It is now owned by Spear and Jackson (B.C.) Limited and is being loaned to the Centennial Museum for the duration of the new exhibition.

13 As a curator I am now confident that given the scarcity of appropriate artifacts our solution about how to interpret this early portion of Vancouver's history has been the correct one. I am also greatly relieved about the question of accuracy since the discovery of inventory has placed us on much more solid historical ground than we would otherwise have been. Finally, I am hopeful that by using the inventory we may somewhere eventually locate a few of the listed machines. Such finds would help to fill some very large gaps in the material history of this part of Canada.