Articles

British Columbia's Experience with Early Chain Saws

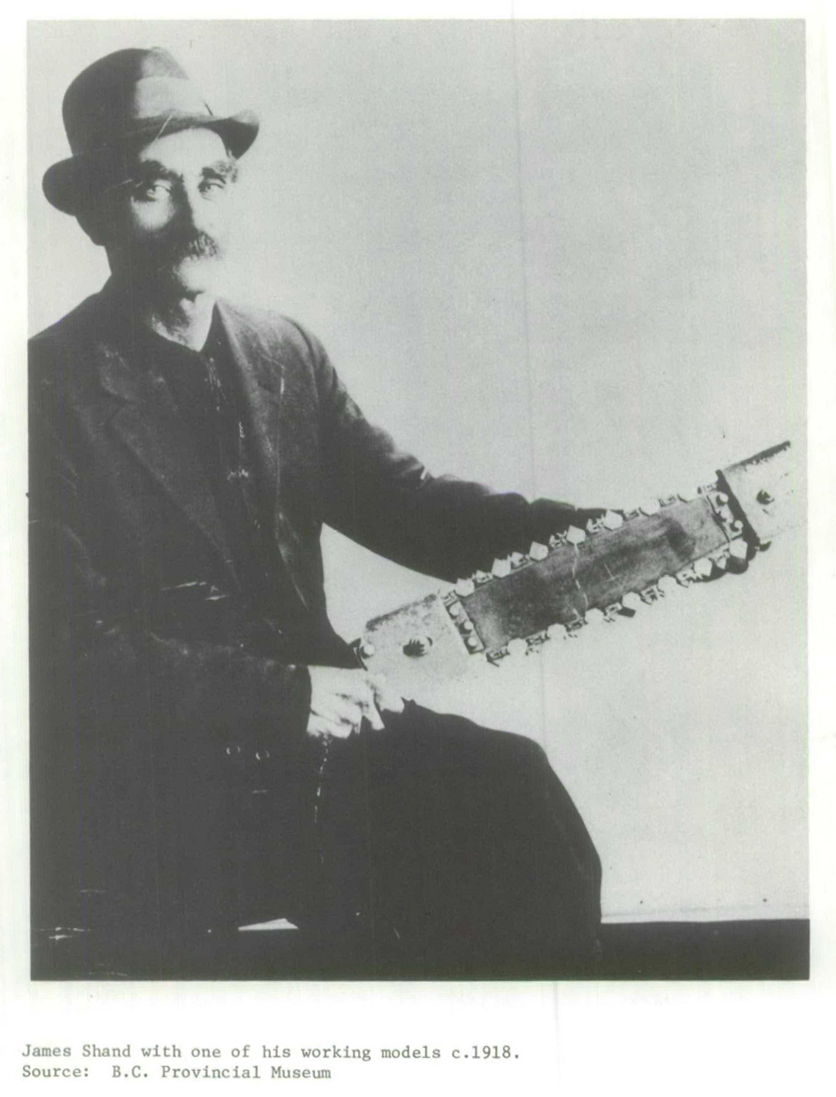

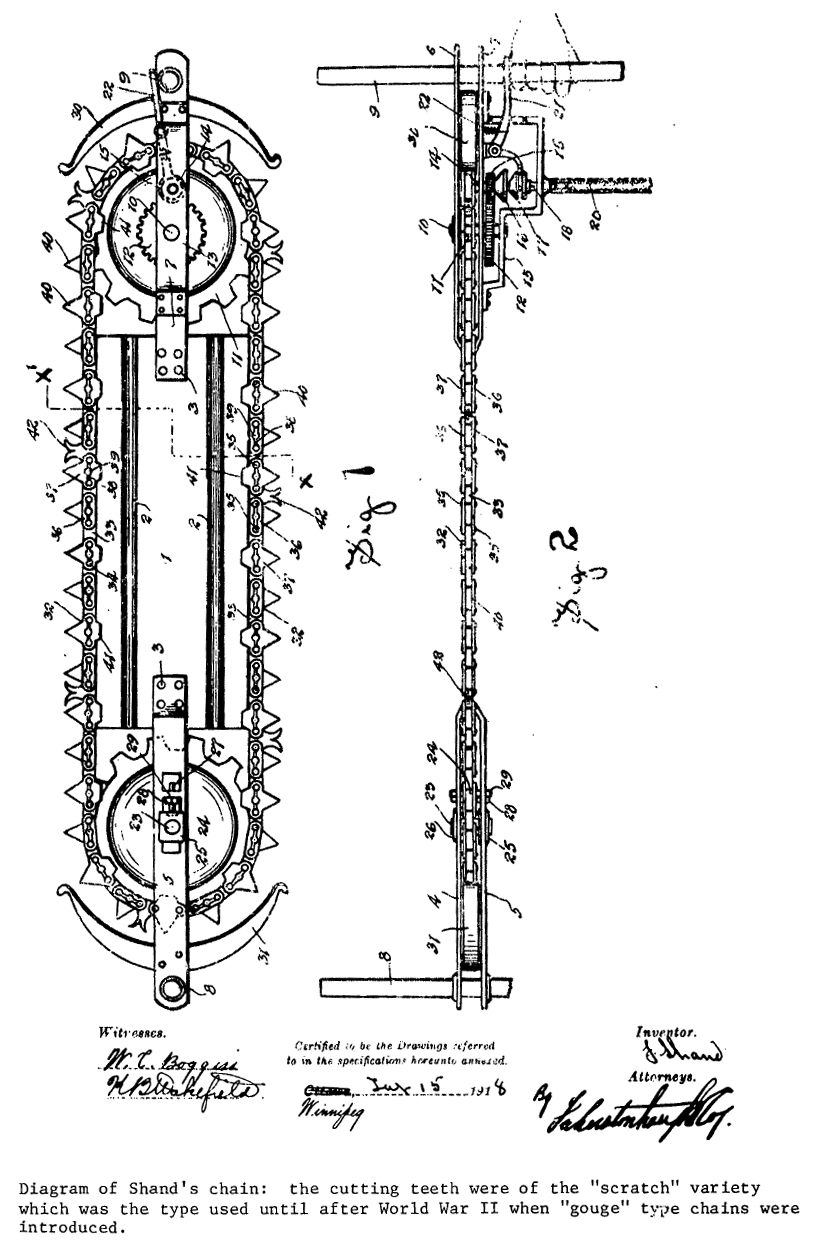

1 The British Columbia Provincial Museum recently came into possession of the original patent papers and two photographs of a chain saw which is possibly the first developed in Canada.1 James Shand, millwright and farmer in Dauphin, Manitoba, patented his "endless" chain saw in 1918. The idea came to him while he was fencing his quarter-section of land and discovered that the barbed wire, drawn by horses, had sawn through a seven-inch oak post.2 Working in his shop and using his son's bicycle chain with cutting teeth inserted, Shand produced two working models.3 Shand used one saw for a short time while in the employ of Manitoba Bridge and Iron Works4 and in 1919 he took both working models to British Columbia, hoping to spark interest in chain saw production.

2 Although the models were small with perhaps a 24" blade (small for west coast timber), Shand did grapple with the problem which had previously thwarted chain saw development — a relatively lightweight source of power. He used a small gasoline motor, commonly called a "one-lunger", which transmitted power to the chain through a Bowden cable. Progressive as the machine was, the industry showed no interest in its production, and after a second 6-year term for the patent, Shand allowed his rights to lapse in 1930.

3 The idea of a chain saw was not new. Inventive minds had been at work since 1858 when Harvey Brown of New York City patented his "endless section sawing mechanism", the first device to utilise moving saw bits on a guide bar Further inventions followed during the 19th and early 20th centuries hut none was easily portable as they were powered by large gasoline or steam engines.5 What was to become the final event in the mechanization of the woods was surprisingly slow to develop.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 24 The answer to a practical chain saw was one in which the gasoline engine was a light yet integral part of the chain saw. In 1929 the Reed-Prentice Corporation of Worcester, Mass., began development and by 1939 had produced 10 models which were far too heavy as they were powered by cumbersome 4-cycle engines.6 As the Depression wore on, the lead in the field was taken by a German industrialist, Andreas Stihl, whose headquarters were in Stuttgart. He produced for use by the German Army a much improved, light and powerful, 2-cycle motor which overcame the problem of so many early gasoline motors — high weight to horsepower ratio.

5 1936 was the pivotal point in the development of chain saws in British Columbia. The logging industry was recovering from the restrictions of he Depression but per man fallage rates were dropping as loggers, depleting easily accessible big timber stands, were forced to cut smaller trees on more rugged terrain. At the same time logging companies were having increasing difficulty finding workers willing to use the traditional cross-cut saw at a time when other sectors of the industry had become mechanized. This situation was especially critical with companies like Bloedel, Stewart and Welch which had to import the more sophisticated labour of metropolitan areas to work their isolated logging operations; these men were less willing to use hand-falling methods than were their rural counterparts.7 The time was propitious for experiments with new techniques and new equipment.

6 The potential of the power saw in the woods was becoming known in 1936. Progress had been made in the California redwoods with large gasoline-driven drag saws. However, this development was not suitable for British Columbia. A California logger would be content to haul this large machine through the redwoods when he had to cut only one or two trees a day; but in British Columbia up to forty or fifty trees had to be felled to achieve the same economy in terms of board feet dropped.

7 In 1936 the Pacific Logging Congress in Eureka, California, made the development of a practical chain saw a priority. Reports of the successful use of a Dow chain saw in California in 1933-34 were encouraging.8 The successful demonstration of the German Stihl saw prompted the assembly to predict enthusiastically that the "day of the faller and the bucker, some of the most skilful and picturesque figures in the woods will be over except in small operations".9

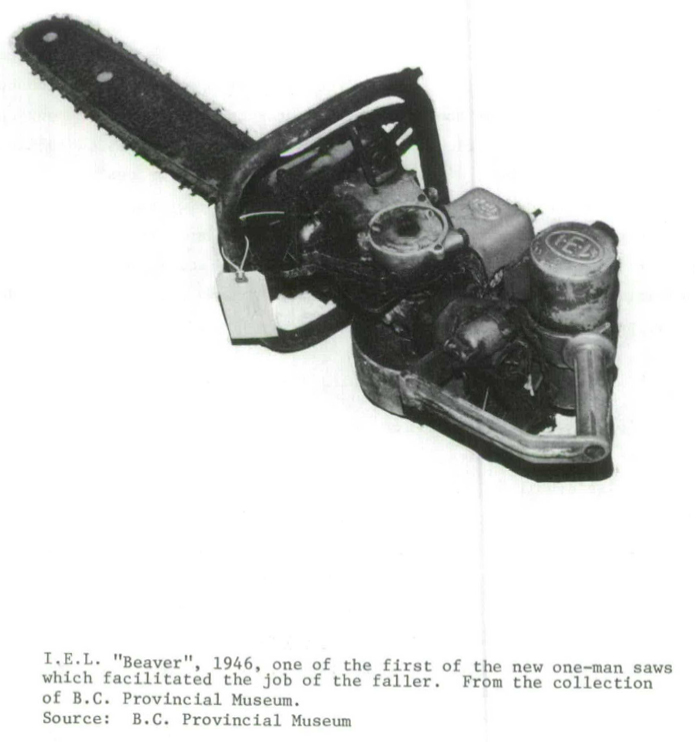

Display large image of Figure 3

Display large image of Figure 3 Display large image of Figure 4

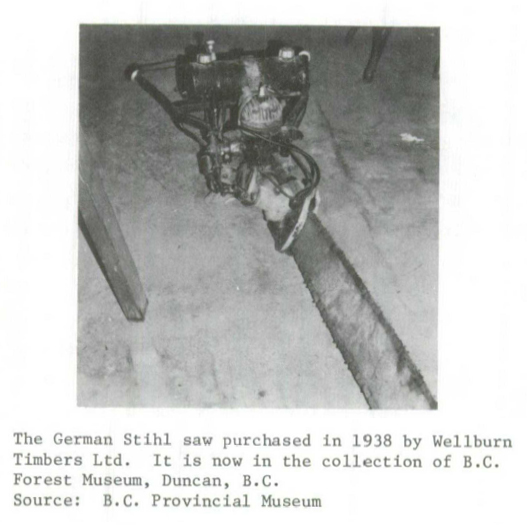

Display large image of Figure 48 As a result of a resolution passed at the Congress, Bloedel, Stewart & Welch experimented with two chain saws at their Vancouver Island Franklin River operation: the American Dow saw and the German Stihl saw.10 Soon other companies were trying out a wide variety of saws, with Stihl being the most preferred.11 In 1938 Donald J. Smith opened a dealership for Stihl saws in Vancouver and one of his first customers was Wellburn Timbers on Vancouver Island.12 Although the "Hitlers", as they were known to west coast loggers because of their German origin, were available in both gasoline and electric models, the former were more practical for forest operation.13

9 Experimenting with the best saw available, the Stihl chain saw, the logging companies continued their quest for a better, more durable machine. The largest user of power saws, Bloedel, Stewart & Welch, sent machinist Bob Shade from their Franklin River camp to Stihl's factory in Germany. On his return Shade set up a small workshop, with company assistance, on Granville Island in Vancouver. Shade Engineering Limited produced the "Forest King" until 1943 when it sold out to Dick Burnett of Burnett Power Saws & Engineering Limited.14

10 Despite its trials and tribulations the chain saw had proved its worth by 1939. Production figures for power saw fallage in one company went from 6 million board feet in 1937 to 100 million in 1939.15 Just as demand was growing for the new saws, however, the outbreak of World War II cut off Canadian customers from Stihl, the main source for components and units. As a result a number of Vancouver-based industries sprang up.

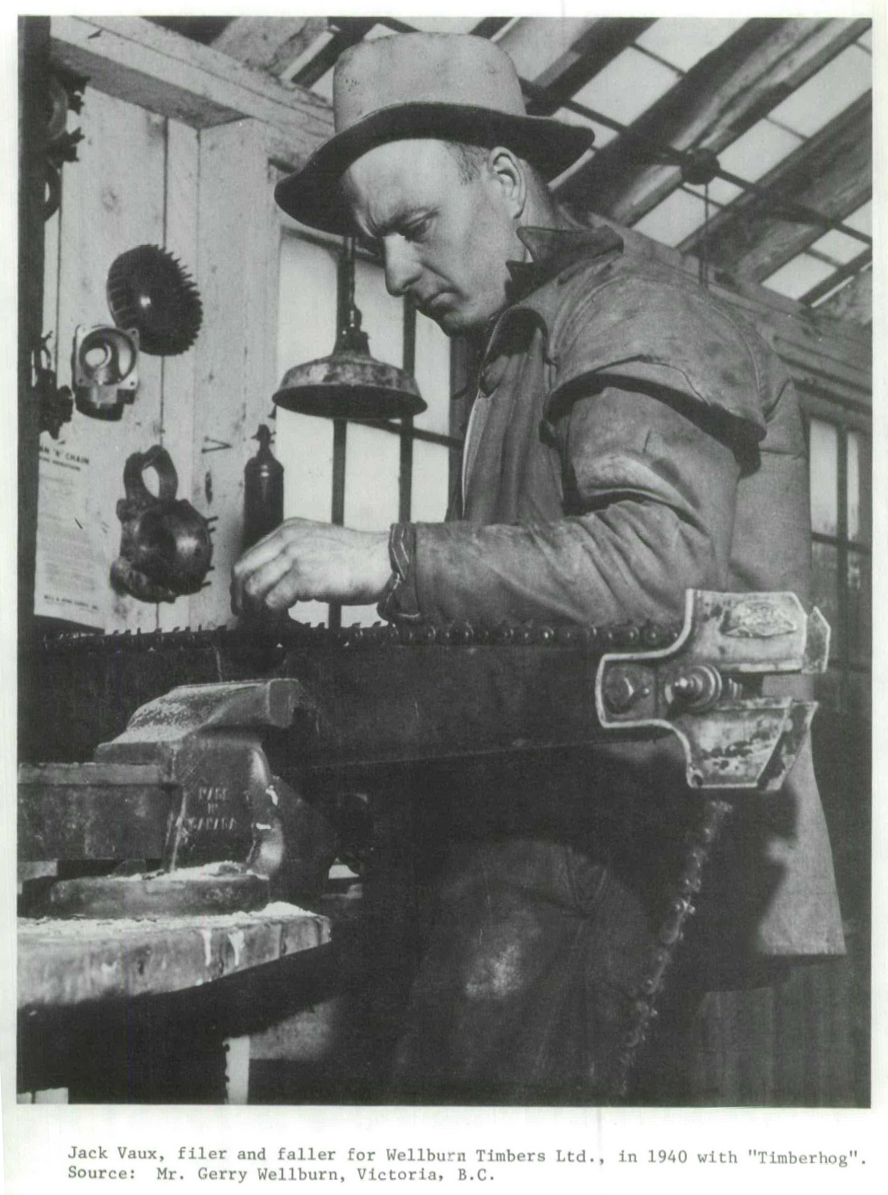

11 D.J. Smith Equipment Company, the original distributor of the Stihl saw, produced a very close copy of the German saw.16 In 1940 Reed-Prentice purchased the Smith concern and produced large quantities of the popular "Timberhog" until they in turn were bought out by a group of local investors who renamed the company Industrial Engineering Limited (I.E.L.) in 1943.17 By 1941 the well-known saw manufacturer Spear & Jackson (B.C.) Ltd. was also manufacturing a chain saw but apparently there were early design problems; one customer was lost when Wellburn Timbers Ltd. informed the firm that they were returning the saw as it had broken down "so often that we have no confidence in it ".18

12 Although there was no doubt that these early chain saws were replacing the cross-cut saws in the woods, they were real bone-shakers and mechanical nightmares.19 As a result of war-time shortages operators had to mix fish oil with gasoline and consequently the spark plugs were continually clogging up and stopping the machines.20 Parts were so hard to get that even the manufacturers were jury-rigging the component pieces and adding further grief for the fallers.21 The constant "monkey-wrenching" meant the crew had to have two saws at their disposal, "packing one in [to the woods] and the packing the other out".22

13 Because of the 120-pound weight of the two-man saws, Bloedel, Steward & Welch insisted all prospective power saw operators be over 5'10" and 175 pounds.23 But smaller companies tended to hire any man who could handle the saw. The noise or the machine led to a new appreciation of safety in the woods. The operators could not hear warning shouts or falling limbs so it became mandatory after June 1941 for all power saw crews to wear hard hats.24 It was some time before other workers in the forest industry were similarly protected.

14 Despite the draw-backs of the power saw the operator who was on contract could make better wages than the hand-faller as his production was normally upped by one-third. And the saw's value was especially evident when the men had to cut a pitchy tree; the chain saw easily went through whereas the cross-cut saw would almost certainly bind. Overall the loggers were enthusiastic about power saws They were working "harder to make life easier" as one of them said; the cross-cut saw was a thing of the past and the chain saw would become the highly efficient falling machine of the future.

Display large image of Figure 5

Display large image of Figure 5