Articles

The Archeological Investigation of Two Huron County, Ontario, Earthenware Potteries

1 The study of the history and technology of Ontario's earthenware potteries in the nineteenth century is a topic of considerable interest to the historical archaeologist, the industrial historian, and the collector of Canadiana. This broad base of interest in the results of archaeological investigation makes the work of the archaeologist relevant both in a theoretical and practical sense. At the Royal Ontario Museum we have been involved for the past ten years in a programme of field study and excavation of Canadian earthernware and stoneware potteries. Two published reports have already been issued by the Museum1 and five more are in various stages of preparation. The purpose of this short note is to report on the excavation of two potteries located in Huron County, Ontario, and to indicate the contribution of archaeological excavation to the study of the material history of Canada.

2 The earthenware pottery industry in Ontario went from infancy to old age within a time span of slightly more than 125 years.2 This was due in part to the fact that the industry itself, for the most part, never developed far beyond the craft stage in rural Ontario. Most of the potters arrived in Canada with previous training in either England, Germany or the United States. They moved to newly-established settlements where there was a ready demand for containers. The abundance of inexpensive or free clay suitable for potting made numerous local pottery businesses feasible.

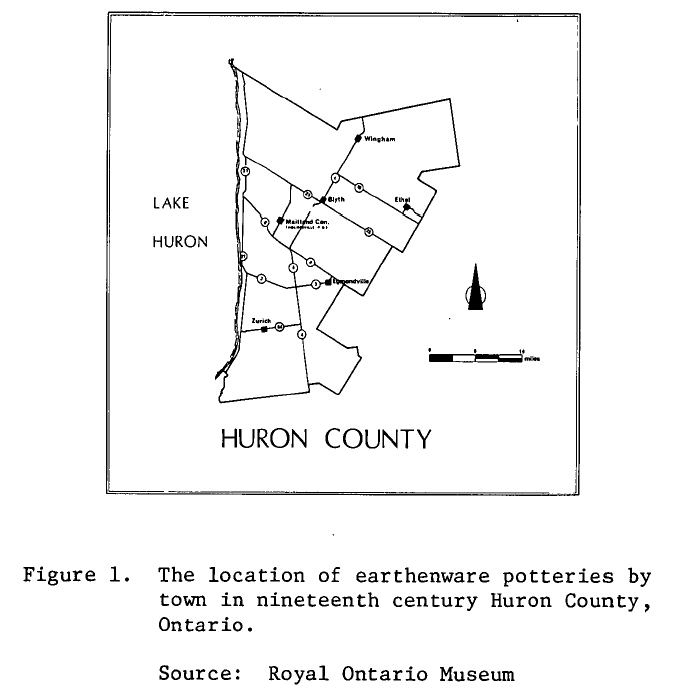

3 By the time of the 1880-81 census there were five potteries reported operating in Huron County alone,3 and a search of directories, historical atlases, tax assessment records and other documentary sources enables us to locate the potteries, shown by town in figure 1.4 The story of the potteries of Huron County, Ontario, begins with Valentine Boehler, an immigrant from Germany who established the Huron Pottery in 1852. Boehler spent his first two years in Canada at his brother's pottery in New Hamburg, Waterloo County, Ontario, before moving further west to Egmondville, Huron County. He started his business on lots 2 and 3 on the north side of Stanley Street. This land he later purchased from C.L. Van Egmond for £20.5 Some ten miles west of Egmondville, David Burns established a small pottery on a ten-acre parcel of lot 46, Maitland Concession, in the early 1860's.6

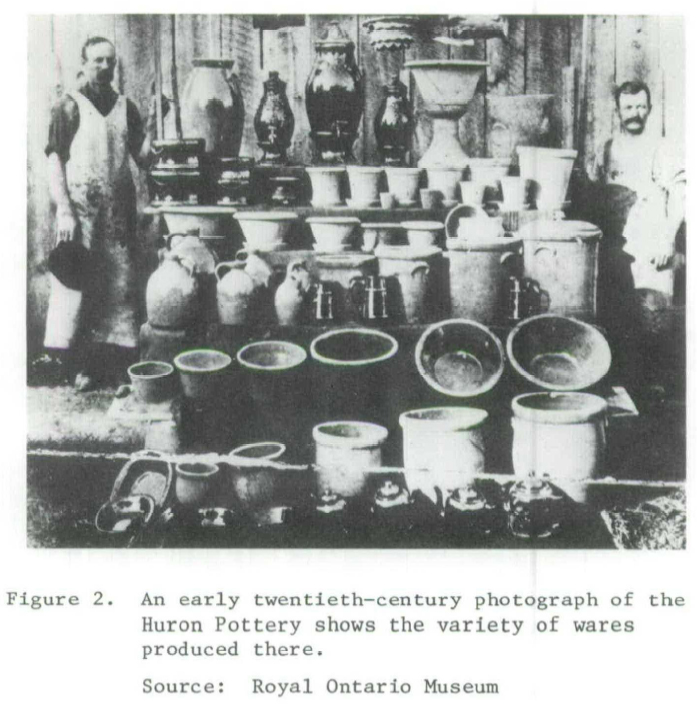

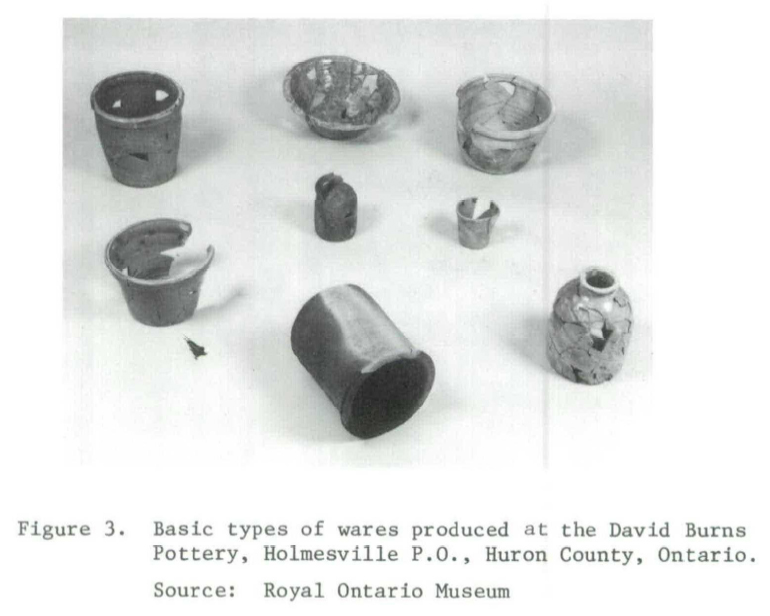

4 The surviving documentary evidence on the two potteries presents an interesting contrast, not unlike what must have existed in other parts of Ontario at the time. The Huron Pottery produced a wide range of vessel shapes and sizes, including water coolers, spittoons and flower pots (figure 2). The pottery employed four or five men all year long in the 1880's, distributing wares widely throughout Huron and Perth Counties.7 One newspaper report indicates that pottery was shipped as far as Manitoba.8 In comparison, the David Burns pottery produced a limited number of different shapes and sizes of containers, mainly milk pans, bowls, preserve jars, flower pots and drain tiles (figure 3). The David Burns pottery appears to have been primarily a one-man, seasonal operation with the potter farming during the summer and 'throwing' pots during the fall and winter months. The Burns pottery received few notices in the local newspaper and it does not appear in directories or contemporary atlases.

5 The excavations at each of the sites concentrated on three main areas: the kiln remains, artifacts in stratified materials associated with the pottery building architecture, and the exploration of part of the extensive waster dumps. The information obtained from these objectives includes hundreds of sacks of pottery sherds, architectural plans, section drawings of all baulks and a sizeable collection of intact vessels. After the study of these materials is completed it will be possible to determine the archaeological phasing of each site. This information, used in conjunction with the documentary record and specialists' reports, should enable us to provide a detailed, comparative study of two geographically related sites. A brief description of some of these comparative studies now in progress and an account of the retrieval of pottery-making tools may be of interest to those who study the material history of Canada.

6 One of the most immediate results of the excavations at the two sites will be the information obtained from comparing types and styles of pottery manufactured by the potters. Since the Huron Pottery displays a 'German' tradition, and the Burns pottery an 'English' tradition of pottery manufacture, the distinctive styles of pottery shapes retrieved from each site may help to clarify the use of the terms 'Germanic tradition' and 'English tradition' which are frequently applied in popular literature to Ontario earthenware pottery.9

7 The excavation of two potteries in the same geographical area provided an opportunity to determine if marked and unmarked wares found at each site could be distinguished from that produced at other sites. The preliminary study of a number of sherds from the Huron Pottery, the David Burns Pottery, and the Morganville, N.Y., Pottery, was conducted by Mr. Lowa Katz and Dr. R.M. Farquhar, of the Department of Physics, University of Toronto.10 The slowpoke reactor was used to irradiate twenty powdered samples of sherds and the concentration of thirteen elements was determined for each sherd, using a computer programme written for this purpose. As of yet no significant differences in elemental concentrations were found between marked and unmarked pottery at a particular site and graphs relating elements for sherds from the three sites failed to show discrete scattering patterns. Similarities between clays used at the Egmondville and David Burns sites could be expected if the clay beds were similar in composition, but the use of shards from the Morganville pottery as a check showed a uniformity of clays extending beyond Western Ontario to upper New York State. A more comprehensive study of trace elements in Ontario earthenware pottery is planned in 1976 in an effort to determine whether unmarked earthenware sherds from a particular site can be distinguished from other sites. The study should help to determine if unmarked pottery found at historical sites can be trace to its place of manufacture.

8 A number of other studies involving the materials retrieved from the two potteries are planned. These include the study of kiln construction methods, kiln 'furniture' and how it was used in stacking pottery for firing, and the problems faced by the potters when 'throwing', glazing and firing their wares.

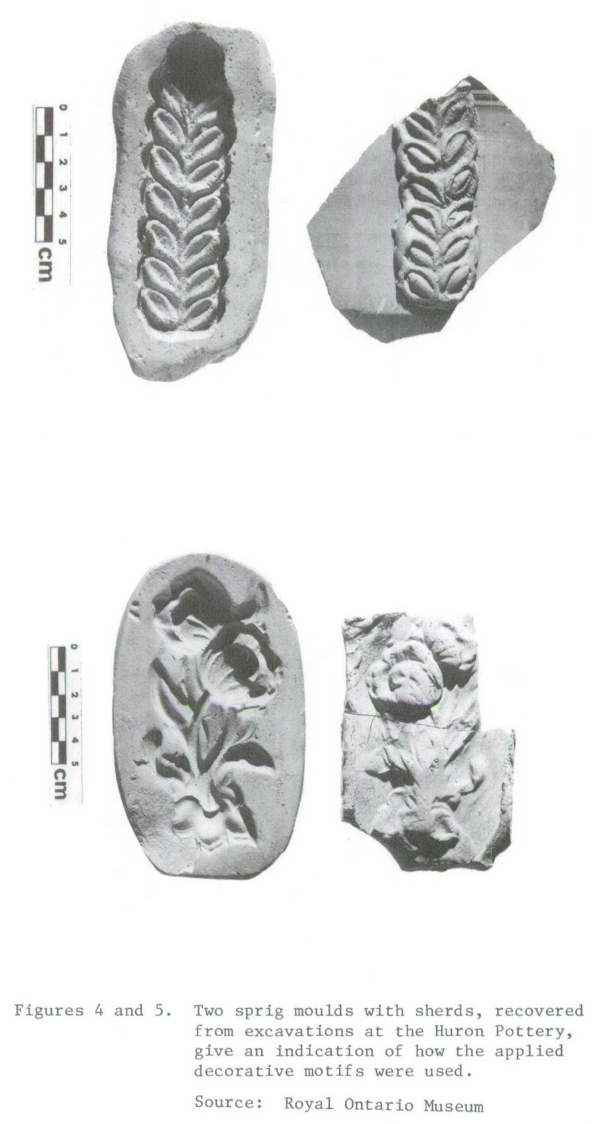

9 The most unusual group of artifacts recovered in the 1975 field season at the Huron Pottery were twenty-two sprig moulds, a number of plaster of paris forms for slip-moulding of lids and jelly dishes, a plaster of paris coggle wheel for making decorative bands on the outside of the rims of flower pots, and glaze grinding wheels. More tools remain in the ground, some visible in baulks left for the next season. Of special interest is the sprig mould with the initials of Xavier Boehler, founder of the New Hamburg Pottery, Waterloo County, Ontario, and brother of the first potter at Egmondville. Two moulds, and sherds showing sprigging, were among the objects recovered from the cellar of the pottery building and are shown as figures 4 and 5.

10 The spring moulds could be made by the potter himself, using plaster of paris or unglazed clay. Motifs from existing patterns could be copied, or original designs could be formed by inscribing a negative impression in the clay or plaster of paris. The potter could use the sprig moulds in one of two ways: first, he could press a small quantity of soft clay into the mould, scrape off any surplus with a knife, and remove the positive impression or 'sprig'. The sprig could then be attached to the surface of the pot with a small amount of slip. The second, and possibly more common, procedure would be for the potter to press the soft clay into the mould and then peel the sprig directly onto the pot. This procedure prevented damage to the sprig and required less time. Two of the Egmondville sprig moulds have a slightly curved surface, suggesting this latter procedure might have been used. Unlike the fashion in England at the time, there is no record of the Huron Pottery ever producing sprigs in different coloured clay from the body of the vessel.

11 The sprig moulds provide a dated series of decorative motifs that can be attributed to an operating Ontario earthenware pottery of the nineteenth century. The other pottery-making tools excavated at the Huron Pottery in the summer of 1975 comprise the first known collection of tools attributed to a Canadian pottery operating in the nineteenth century. The only other comparable collection of sprig moulds was obtained by the Smithsonian Institution c. 1895 from a pottery in Morgantown, West Virginia, that had ceased to operate c. 1890.11

12 It is hoped that further excavations of early Ontario potteries will continue to provide controlled and reliable material for future studies aimed at exploring pottery-making traditions of Ontario and the techniques used by the potters to produce their wares.

Display large image of Figure 1

Display large image of Figure 1 Display large image of Figure 2

Display large image of Figure 2 Display large image of Figure 3

Display large image of Figure 3 Display large image of Figure 4

Display large image of Figure 4