Vol. 16 No. 2 January 2005

Mechanized Energy Wood Harvesting from Early Thinnings

Kalle Kärhä

Metsäteho Oy

Helsinki, Finland

Aki Jouhiaho

TTS Institute

Helsinki, Finland

Arto Mutikainen

TTS Institute

Rajamäki, Finland

Salla Mattila

TTS Institute

Helsinki, Finland

ABSTRACT

The felling and bunching of small diameter trees in Finland is still largely carried out manually using a chain saw and clearing saw. The felling of small diameter trees has been developed and mechanized. In addition to the high felling costs of small trees, the move towards mechanized harvesting is also caused by a shortage of professional lumberjacks, the possibility of all-year-round mechanized energy wood harvesting, and an increasing demand for energy wood.

The research investigated the productivity, costs and silvicultural result of the guillotine blade equipped, multi-tree-processing Naarva-Grip 1600-40, for small diameter energy wood harvesting. Work-studies were carried out in six young stands at the first thinning stage.

In mechanized energy wood harvesting with the Naarva-Grip 1600-40, an average of 73% of the trees felled were multi-tree-processed. The multi-tree-processed proportion increased to 96% in dense Scots pine (Pinus sylvestris L.) sites with small trees. One bunch consisted of approximately 3.2 trees. The average density and volume of removal had the greatest effect on the productivity of the felling-bunching work. Felling-bunching was carried out on the sites at a rate of 106-422 trees per effective hour (E0, excluding delay times). Productivity on the different sites varied from 3.0 to 7.2 m3/E0, giving an average of 4.7 m3/E0 (weighted by felling volume) with an average tree size on the site of 32 dm3.

When the size of the felled trees was under 20 dm3, the felling-bunching costs were over 20 US$/m3. When the average tree size on the site increased to 50-70 dm3, the felling-bunching costs approached the 10 US$/m3 level. During the research, the Naarva-Grip 1600-40 proved to be competitive compared to the other multi-tree-processing, energy wood felling heads on the market. In order to keep the felling-bunching costs at a reasonable level, mechanized harvesting should be targeted at sites where the average size of the trees removed is over 30 dm3, and the energy wood volume at felling over 30 m3/ha.

Keywords: energy wood, early thinnings, multi-tree processing, felling heads, Naarva-Grip 1600-40, felling-bunching, productivity, costs, Finland

INTRODUCTION

Proper management of young stands increases the proportion of valuable tree species, accelerates growth, reduces the risk of damage, increases the volume of merchantable roundwood, and improves the profitability of first thinning [26]. In Finland, during the past five years the tending of seedling stands and improvement of young stands has been carried out on 152,000 - 239,000 hectares per year [28]. According to the National Forest Programme, 250,000 hectares of young stands need to be improved per year up until the year 2010 [1]. Furthermore, the area of young stands lagging behind in relation to the recommendations covers approximately 460,000 ha [1].

According to estimates, improving young stands can produce an annual volume of 1.8 million m3 of wood for energy purposes [1]. One of the aims of the Programme Promoting Renewable Energy Sources and the National Forest Programme is to increase the annual use of wood for energy production by 5 million m3 per year [1, 2]. However, only 1.7 million m3 of forest chips was used in 2002, and these were predominantly logging residue chips [29]. In the mid-1990s, the majority of commercial forest chips came from the small diameter wood produced in tending seedling stands and improving young stands [14]. The production volumes of commercial forest chips originating from young stands have not increased during the past ten years.

The main reason for the stable production volumes of small diameter whole tree chips, and in particularly chips from delimbed stems, is their high production costs and low cost competitiveness compared with other raw material sources, i.e. bark, sawdust, industrial wood chips, and logging residues. When the average price of forest chips at the plant was 20.9 US$/m3 (VAT 0%) (10.4 US$/MWh) in 1999, the price of whole tree chips was 24.0 US$ and for chips from delimbed stems 32.3 US$ [15]. Meanwhile, the price of logging residue chips coming from final cuttings was 17.3 US$/m3. Therefore, whole tree chips were almost 40%, and chips from delimbed stems over 80% more expensive as delivered to the plant than logging residue chips. The felling costs of small diameter wood are the largest cost component of both whole tree chips and chips from delimbed stems. In 1999, the felling costs of whole trees were one third (8.3 US$/m3) and delimbed stems about one half (15.8 US$/m3) of the total production costs of chips.

Nowadays, the felling and bunching of small diameter trees in Finland is still largely carried out manually using a chain saw and clearing saw [18]. Therefore, the felling of small diameter trees has been developed and mechanized. In addition to the high felling costs of small trees, the move towards mechanized harvesting is also caused by a shortage of professional lumberjacks, the possibility of all-year-round mechanized energy wood harvesting, and an increasing demand for energy wood.

Productivity remains low and felling-bunching costs become higher when the trees felled are small in size (5-40 dm3 with branches), the energy wood volume per hectare is small (20-40 m3/ha), and the number of remaining trees is high. Processing more than one stem per work cycle, also known as multi-tree processing or accumulating, can improve the productivity of harvesting small diameter trees [e.g. 3, 5, 6, 8-10, 17, 23]. Felling-bunching heads intended for energy wood harvesting do not have a delimbing attachment because the branches and needles can be utilized as energy wood. The multi-tree-processing, energy wood felling heads available on the Finnish market (Kone-Meskus' AM 230, Pentin Paja Oy's Naarva-Grip 1600-40, and Timberjack's Timberjack 720 and Timberjack 730) cut the stems either with a splitting ellipse or guillotine blade. As the splitting blade is not affected by sand or other abrasive material, the repair and service costs of a felling head with a splitting blade are considerably less than those of a felling head using a chainsaw.

The productivity of the AM 230 and Timberjack 720 felling heads has been studied earlier [16, 22], but no investigations have so far been carried out on the productivity and work costs of the Naarva-Grip 1600-40 which first came onto the market at the beginning of 2002. This research investigated the suitability of the Naarva-Grip 1600-40 felling head for small diameter energy wood harvesting on the basis of its productivity, costs and silvicultural result. The research was carried out as a part of the TTS Institute's KEMERA-funded research project entitled "Technology in Tending of Young Stands" (2001-2003).

MATERIAL AND METHODS

Felling Head and Base Machines

The Naarva-Grip 1600-40, manufactured by Pentin Paja Oy (www.pentinpaja.fi), is an energy wood felling, bunching and bucking head equipped with a multi-tree-processing function and three guillotine blades (Figure 1). The lowermost grapple on the grab, the so-called cutting grapple, has guillotine blades that open to 69 cm. Above the cutting grapple there is a three-jawed grapple with a maximum opening of 93 cm. The collecting grapple is located at a distance of 125 cm from the cutting grapple. The collecting grapple opens to 94 cm. The felling head can cut a 50 cm-thick tree bunch, in which the biggest individual stem is 32 cm in diameter. The weight of the grab without rotator is 530 kg, and the height at the felling position is 164 cm. At the time of writing this article, during fall 2003, about 20 Naarva-Grip 1600-40 felling heads were in operation.

Figure 1. The multi-tree-processing, Naarva-Grip 1600-40 energy wood felling head. Photo: Arto Mutikainen.

The data in the Naarva-Grip time study was collected in 2002 using three different-sized base machines (Fendt 380 GTA, Valmet 901-4, and ProSilva 810) (Table 1). Of these base machines, the Fendt 380 GTA is an agricultural tractor type, light harvesting machine for seasonal contracting, the Valmet 901-4 is a medium-sized harvesting machine, and the ProSilva 810 is a relatively light harvesting machine.

Table 1. Base machine information.

| Property | Fendt 380 GTA | Valmet 901-4 | ProSilva 810 |

| Base machine | |||

| - engine power, kW | 59 | 124 | 114 |

| - mass, kg | 6,700 | 14,000 | 10,000 |

| - width, cm | 225 | 265 | 250 |

| Boom | Mowi 675 | Cranab 998 | Foresteri H1195 |

| - max. reach, m | 7.5 | 10.0 | 9.3 |

| Manufacturer | Agco Corporation / Mefor Oy | Valmet Oy | ProSilva Oyj |

Sites

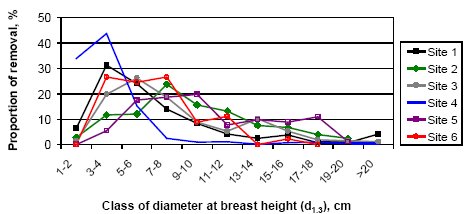

The work-study data was collected in six young stands at the first thinning stage (Table 2). The target was to have large range in the density of removal and in the volume of removal. These factors were assumed to have an effect on both the productivity and the multi-tree processing [cf. 3, 8-11, 16, 17, 22-24]. The time study plot size was 800 - 1,600 m2 (width 20 m and length 40-80 m), and there were 17 sample plots in all. A strip road runs through the middle of the sample plots and was marked beforehand using marking tape. The machine operator selected the trees to be felled. No pulpwood was produced from the felled trees; everything was used for energy wood. The target length of the bucked energy wood bundles was about 5 m on every study plot. The smallest single trees felled had a diameter at breast height of 3-4 cm. Smaller trees were also felled, but they were groups of sprout trees. Most of the trees felled had a breast height diameter of 3-10 cm (Figure 2).

The sites studied in the winter were located at Polvijärvi (62o51'N, 29o22'E) in Eastern Finland. The main tree species on Site 1 was Norway spruce (Picea abies L. Karst.). In addition to spruce, there was a high proportion of broadleaves - mainly downy birch (Betula pubescens Ehrh.) and grey alder (Alnus incana Moench, Willd.). The trees had naturally regenerated on abandoned agricultural land, and the trees were grouped along the old ditches between two strips of cultivated land. The age of Site 1 was about 40 years. Site 2 at Polvijärvi was an approximately 30-year-old Scots pine (Pinus sylvestris L.) site, which had a dense broadleaved shrub layer. Site 3 was an approximately 30-year-old, naturally regenerated downy birch site. The snow cover at the time of harvesting in February was approximately 55 cm thick. At the Polvijärvi sites, the Naarva-Grip was fitted to the Fendt 380 GTA agricultural tractor based harvester. One person, who had one month's experience with the Naarva-Grip, operated the machine.

Table 2. Harvesting conditions on the study sites.

| Base machine / Site | Plots, no. | Initial site, stem/ha | Average density of removal, stems/ha | Average height of removal, m | Average size of removal, dm3 | Energy wood volume, m3/ha |

| Fendt 380 GTA (Polvijärvi) | ||||||

| - Site 1 | 4 | 2,354 | 1,648 | 10.3 | 28 | 46 |

| - Site 2 | 2 | 3,102 | 1,681 | 11.3 | 39 | 65 |

| - Site 3 | 4 | 3,440 | 1,600 | 12.0 | 24 | 39 |

| Fendt 380 GTA (Polvijärvi) | ||||||

| Valmet 901-4 (Harjavalta) | ||||||

| - Site 4 | 3 | 5,889 | 4,659 | 4.9 | 7 | 33 |

| Fendt 380 GTA (Polvijärvi) | ||||||

| ProSilva 810 (Ruovesi) | ||||||

| - Site 5 | 3 | 1,828 | 889 | 9.9 | 69 | 61 |

| - Site 6 | 1 | 2,839 | 1,851 | 8.1 | 24 | 45 |

| Fendt 380 GTA (Polvijärvi) | ||||||

| Average | ||||||

| (weight by felling volume) | 3,128 | 1,983 | 10.0 | 32 | 48 | |

Figure 2. The stem frequency distribution series of removal on the study sites.

The data for May was collected in a Scots pine site at Harjavalta (61o19'N, 22o08'E), Western Finland that had been planted approximately 25 years ago. The site had not been cleaned and was covered with a dense birch thicket. At the Harjavalta site, the Naarva-Grip was fitted to the Valmet 901-4 harvester. The operator had used the grab on his harvester for one month.

The data for August was obtained from two sites in Ruovesi (61o59'N, 24o05'E), Southern Finland. The first-thinning Scots pine site (No. 5) had been planted approximately 30 years ago, and thinned more than ten years ago. The other site (No. 6) had been planted 20 years ago with Scots pine. This site had not been uncleaned, and had a high proportion of broadleaves. At the Ruovesi sites, the Naarva-Grip was fitted to the ProSilva 810 harvester. The operator had used the grab on his harvester for a couple of months.

Silvicultural Result and Volume of Removal

The silvicultural result to the surrounding forest was measured using the inventory method developed by Sirén [27]. Two silvicultural result sample plots were located on each time study plot. The sample plots were 10 m long in the direction of the strip road, and extended to a distance of 10 m on both sides of the strip road. The silvicultural result inventory sample plots were divided into six 3.33 m wide zones, parallel to the strip road. The number of trees in each zone was counted, and the breast height diameter measured before and after harvesting. In addition, the number of damaged trees and their quality, location, size and estimate of the cause of damage was studied after harvesting.

The strip road width was measured using the SLU method, in which the distances to the nearest trees are measured at right angles from the middle of the strip road, along a distance of 10 m on both sides. The measurement point on the trees is the cutting level. The width of the strip road was the sum of these distances [4].

Sample trees were also measured on each harvesting site. Diameter at breast height and height were measured on sample trees at each site. The stem volume of the harvested trees was calculated using the volume functions of Laasanenaho [21]. The volume of the tree branches and needles was determined using the oven dry mass models of Hakkila [13] and the basic densities of Hakkila [12].

Time Study

The same researcher collected the whole time study material using a KTP 84 data logger employing a continuous time study method (cmin). In the time study, the work cycle (i.e. all the work elements for processing one tree or several trees in one bunch) was divided into the following elements:

Moving: Begins when the harvester starts to move, and ends when the harvester stops moving to perform some activity.

Boom-out: Begins when the boom is moving towards the tree, and ends when the felling head is one meter from the stem. In addition to the time consumption, the sector and distance were recorded.

Felling and collecting: Begins when the felling head is one meter from the tree, and ends when the last tree of the bunch falls. The tree species, number of trees in the bunch, and estimation of the diameter at breast height were also recorded by a researcher.

Bunching: Begins when boom-in starts, and ends when the bunch drops from the felling head. The sector was also recorded.

Bucking: Bucking the trees at the pile.

Miscellaneous times: Other activity in harvesting work, e.g. planning work, preparation. The reason for the activity was recorded.

Delays: Time not related to the productive harvesting work, e.g. personal breaks, repairing or maintenance of harvester. The reason for interruption was recorded.

Cost Calculations

Total operating machine costs included both time-dependent costs (capital depreciation, interest expenses, labor costs, insurance fees, administration expenses) and variable operating expenses (fuel, repair and service, machine transfers). A currency conversion rate of 1 € = 1.172 US$ was used in the cost calculations. Cost calculations were prepared for the machine units using the following given values: the price of the Fendt 380 GTA agricultural tractor harvester was 117,200 US$ (VAT 0%), of which the Naarva-Grip's price was 19,924 US$ (VAT 0%). The price used for the Valmet 901-4 harvester was 328,160 US$ (VAT 0%) and for the ProSilva 810 harvester 210,960 US$ (VAT 0%). Annual working hours were 2,500 operating hours. A machine utilization value of 80% was used in the calculations. The productivity per operating hour (E15, including delay times shorter than 15 minutes) was 4.5 m3/h for energy wood harvesting. The depreciation period for the base machine in the cost calculation was 5 years and for the felling head 2.5 years. An interest rate of 6% was applied.

The operator's salary was 10.0 US$/h with indirect salary costs (67.4%) added, and the amount of compensated work trips at 25,000 km/a. Fuel consumption of the Fendt was 10 liters per operating hour, of the Valmet 12 l/h, and of the ProSilva 11 l/h (0.38 US$/l). Repair and service costs (including oil and lubricant costs) were estimated to be 7.0 US$ per operating hour, insurance fees 2,110 US$/a, and administration and maintenance costs 6,800 US$/a. The transferring expenses of the Valmet and ProSilva in the cost calculations were 6,798 US$/a. As transfer of the Fendt does not always require a truck and trailer, the transport costs of the Fendt were half those of the Valmet and ProSilva.

Data Analysis

In the research, the proportion of multi-tree processing was estimated by applying a regression analysis in which the harvesting conditions (density, height, and size of removal) were independent variables. The productivity (stems per effective hour, and m3 per effective hour) models of the felling-bunching work were based on the harvesting conditions, the proportion of multi-tree processing, and the number of trees in the bunch.

RESULTS

Distribution of Time Consumption

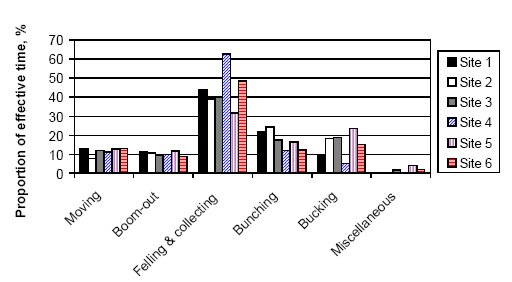

At every site, the felling and collecting of trees took most of the effective time (E0, excluding delay times) (Figure 3). In a small-stemmed (average tree volume removed 7 dm3) pine site (Site 4), nearly two-thirds of the effective time consumed was in felling and collecting. Both moving the grab to the tree stumps (boom-out), and moving from one work location to another, took approximately 10% of the effective time. There was no significant difference between the sites in the time consumed in these work stages. Bunching trees along the strip road took approximately one fifth of the effective time. Bucking the trees at the pile with a transport length of about 5 m took, on the average, 15% of the effective time per site. At the first thinning pine site (Site 5) (average tree volume removed 69 dm3), bucking took almost one quarter of the effective time. Correspondingly, the bucking phase took only 5% of the effective time at Site 4 because the majority of the felled trees were less than 5 m in length (Table 2). On the average, miscellaneous time took 1% of the effective time.

Figure 3. The proportion of effective time for the energy wood harvesting stages at the different sites.

Table 3. Regression model for the proportion of multiple processing out of the total stem processing with the Naarva-Grip 1600-40.

y = a + b×LN(x) (1)

where

y = proportion of multiple processing, %

x = density of removal, stems/ha

a = constant

b = coefficient of variable

| Coefficient | Estimate of coefficient | Standard error of estimate | t-value |

| a | -101.1520 | 38.024 | -2.66 |

| b | 23.3672 | 5.062 | 4.62** |

| R2 = 0.842 ** | |||

* p<0,05; **p<0,01; *** p<0,001

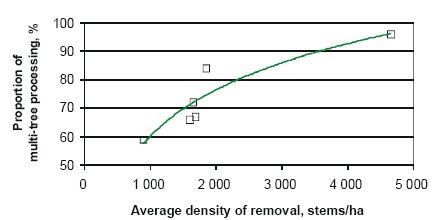

Figure 4. The multi-tree-processing percentage as a function of the tree density removed.

Table 4. The number of trees per bunch and felling-bunching productivity at the different sites.

| Base machine / Site | Proportion of multi-tree processing, % | Number of trees, stems/bunch | Productivity, stems/effective hour | Productivity, m3/effective hour |

| Fendt 380 GTA | ||||

| - Site 1 | 72 | 2.5 | 175 | 4.9 |

| - Site 2 | 67 | 2.3 | 137 | 5.3 |

| - Site 3 | 66 | 2.5 | 149 | 3.6 |

| Valmet 901-4 | ||||

| - Site 4 | 96 | 7.9 | 422 | 3.0 |

| ProSilva 810 | ||||

| - Site 5 | 59 | 1.9 | 106 | 7.2 |

| - Site 6 | 84 | 3.3 | 147 | 3.6 |

| Average | ||||

| (weight by felling volume) | 73 | 3.2 | 188 | 4.7 |

Figure 5. The distribution of trees in the bunch at the different sites.

Productivity

An average of 73% of the trees were harvested by multi-tree-processing. The multi-tree-processing percentage increased significantly as the density of the trees removed increased (Table 3, Figure 4). The other independent variables had no significant effect on multi-tree-processing percentage. At a dense small-stemmed pine site, the multi-tree-processed proportion increased to 96% (Table 4). An average of 3.2 stems was collected in one bunch. Bunches containing the highest number of trees were on the small-stemmed site (Site 4), where there were more than 15 stems in the largest bunches (Figure 5).

The number of trees felled per effective hour varied by site from 106 to 422 stems/effective hour. Productivity weighted by felling volume was on the average 4.7 m3/effective hour, when the sites average stem size was 32 dm3. The highest productivity (7.2 m3/effective hour) was achieved at the first thinning pine site (Site 5). At the small-stemmed pine site (Site 4) the productivity per effective hour was 3.0 m3/h. Considering the harvesting conditions, the different base machines had no significant effect on productivity.

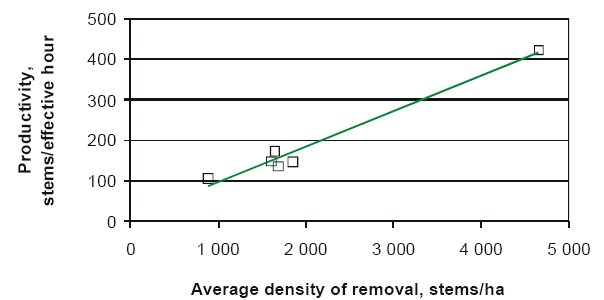

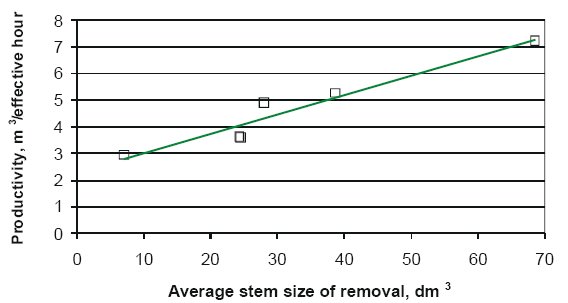

The models for the effective hour productivity (stems per hour, and m3 per hour) of felling-bunching work were determined using regression analysis. The average density of removal had the biggest influence on the productivity (stems per hour) of felling-bunching work (Table 5, Figure 6). The other variables (e.g. the average size of removal, the proportion of multi-tree processing, and the number of trees in the bunch) did not affect significantly to productivity (stems/h). Correspondingly, the average size of removal of the stand had the greatest effect on the productivity (m3 per hour) of felling-bunching work (Table 6, Figure 7). The other independent variables - for instance the average density of removal, the proportion of multi-tree processing, and the number of trees in the bunch - did not have significant influence on productivity (m3/h).

As can be seen in Figure 7, productivity on the small-stemmed (the average size of trees removed was below 20 dm3) sites was fairly low, less than 4 m3/effective hour. At the same time, there were no signs of productivity leveling out or decreasing when the size of the trees removed was 60-70 dm3.

Table 5. Regression model for the productivity (stems/h) of felling-bunching work with the Naarva-Grip 1600-40.

y = a + b×x (2)

where

y = productivity, stems/effective hour

x = average density of removal, stems/ha

a = constant

b = coefficient of variable

| Coefficient | Estimate of coefficient | Standard error of estimate | t-value |

| a | 10.8137 | 17.162 | 0.40 |

| b | 0.0869 | 0.007 | 145.35*** |

| R2 = 0.973*** | |||

* p<0,05; ** p<0,01; *** p<0,001

Table 6. Regression model for the productivity (m3/h) of felling-bunching work with the Naarva-Grip 1600-40.

y = a + b×x (3)

where

y = productivity, m3/effective hour

x = average stem size of the stand, dm3

a = constant

b = coefficient of variable

| Coefficient | Estimate of coefficient | Standard error of estimate | t-value |

| a | 2.3052 | 0.341 | 6.76 ** |

| b | 0.0721 | 0.009 | 7.85 ** |

| R2 = 0.939 ** | |||

* p<0,05; ** p<0,01; *** p<0,001

Figure 6. The effective hour productivity (stems/h) of energy wood felling-bunching as a function of the average density of removal.

Figure 7. The effective hour productivity (m3/h) of energy wood felling-bunching as a function of the average stem size of the stand.

Silvicultural Result

At sites 1-3, the remaining trees were quite severely damaged because the Fendt agricultural tractor type harvester used for felling was too light (approx. 6,500 kg) for the more than 500 kg Naarva-Grip. Control of the grab was difficult, and this was clearly evident in the silvicultural result. According to the norms of the Forestry Development Centre Tapio, thinning related to tree damage is satisfactory when the damage percentage (percentage of damaged trees out of the number of trees remaining after thinning) is at most 5% [25]. At Sites 1, 2, and 3 the damage percentage was 6.6%, 6.7% and 1.7%, respectively. The silvicultural result was excellent with all the other base machines. At Site 4, the damage percentage was 0.4%, and at Sites 5 and 6 0.5 and 0.2%, respectively.

All the damage was stem damage, primarily surface damage. Damage where only a certain amount of bark had been removed was counted as surface damage. Deep damage extended down to the wood. The average size of the damage varied by site from 8 to 30 cm2. The damage was located near the strip road. On the average, the distance between the damaged trees and the center of the strip road varied by site from 3.0 to 4.1 m. At all the sites, the felling head and the tree being processed caused most of the damage. At Sites 1-3 the width of the strip road was the narrowest (3.0 - 3.4 m), which partly influenced the amount of damaged trees. On the other sites, the width of the strip road was 3.5 - 4.0 m.

Costs

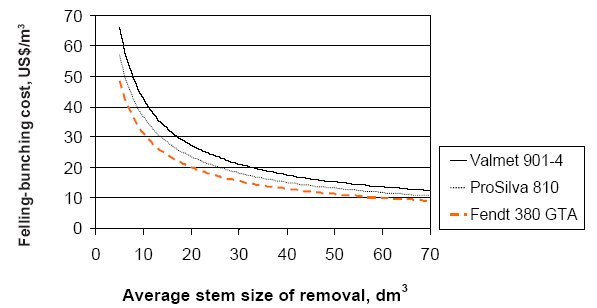

Based on the given cost values, the operating hour costs for the Fendt were 56.8 US$/h, for the Valmet 77.2 US$/h, and for the ProSilva 66.6 US$/h. The operating hour productivity (E15, including delay times shorter than 15 minutes) equation for harvesting work was obtained by adding 20 % under 15-minute interruptions to the effective time (E0). Figure 8 presents the energy wood harvesting costs of the machine units. According to the figure, when the size of the felled trees was under 20 dm3, the felling-bunching costs were over 20 US$/m3. When the average size of a tree at the site rose to 50-70 dm3, the felling-bunching costs approached the 10 US$/m3 level.

DISCUSSION

In addition to the Pentin Paja Naarva-Grip 1600-40, there are currently three other multi-tree-processing, energy wood felling heads on the market in Finland (AM 230, Timberjack 720 and Timberjack 730). In comparison with these heads, the Naarva-Grip proved to be efficient and competitive [7, 11, 16, 22, 24]. Only the Timberjack (EnHar) 720 energy wood felling head has reached a productivity level of over 5 m3/effective hour when the tree size was 20-30 dm3 [7, 22, 24]. The effective hour productivity with the Naarva-Grip was 4.7 m3/h when the average size of the tree size was 32 dm3.

At the time when the research was carried out, the Naarva-Grip was still at the development stage. Improvements have since been made, e.g. the speed of the guillotine blade has increased. In addition, the operators in the study had only been using the new grab for a few tens of hours prior to the research. As a result, the productivity level reached in the study may be lower than that achievable with regular use of the head. Further time studies, and especially long-term follow-up studies, are still needed.

Figure 8. The felling-bunching costs of energy wood with the Fendt 380 GTA agricultural tractor harvester, the ProSilva 810 and the Valmet 901-4 harvesters, as a function of the average stem size of the stand.

According to the results, the average density and volume of removal had the greatest effect on the productivity of felling-bunching work. This observation is supported by the results obtained in earlier productivity studies [e.g. 3, 5, 6, 8, 10, 16, 17, 22, 23]. Correspondingly, the other factors (e.g. number of trees in the bunch, and the proportion of multi-tree processing) had no significant influence on productivity in this research. The linear productivity functions (equations 2 and 3) described well the productivity level measured in the time study. The coefficient of determination (R2) of the function of multi-tree processing was lower than the productivity functions. In the research, 73% of the trees felled were, on the average, multi-tree-processed. The multi-tree-processed percentage increased to over 90% on a dense, small-stemmed pine site. The results revealed that the multi-tree-processing function of the Naarva-Grip was well designed. Naturally, all the trees felled cannot be processed in bunches because there are always a number of larger felled trees that are easier to process individually.

On the basis of the results, the Naarva-Grip is well suited for installation on 9- to 12-tonne harvesters. This guarantees the stability of harvesting work, thus reducing the risk of damaging residual trees (cf. the tree damage caused by Fendt). However, the base machine cannot be heavier or more expensive because the felling-bunching costs then become too high (cf. the costs of Valmet in Figure 8). The Naarva-Grip can also be mounted on forwarders, harvester-forwarders, and excavators.

Especially in cases where the machines have unused capacity, it is worth for the machinery contractor to invest in the Naarva-Grip. Thus, harvesters and forwarders can be utilized in summertime when there is only little harvesting of roundwood. On the other hand, excavators can be utilized in wintertime when there is relatively little ditching work. The harvester-forwarder has been considered to be best suited for harvesting sites where the number of timber assortments is small [20]. It could thus be assumed that the Naarva-Grip, fitted to a harvester-forwarder, would be a competitive machine unit in harvesting energy wood where only one "timber assortment" is harvested [18].

The Naarva-Grip is likely to be particularly well suited for first thinning sites where the average size of the stems is 50-100 dm3, and where there is a relatively dense broadleaved shrub layer. This kind of site should be pre-cleared manually before the first thinning. Harvesting the site primarily for energy wood with the Naarva-Grip will avoid the need for pre-clearance and provide clearance-sized wood, thus improving the profitability of first thinning.

Today, mechanized energy wood felling-bunching is usually more expensive than manual felling-bunching work. In the study of Kärhä and Häkkinen [19], when the average size of the removal was 20 dm3 the costs of manual felling-bunching was 10 US$/m3. In the study in hand this level could only be achieved when the average size was 50-70 dm3. On the other hand, Laitila and Asikainen [22] have calculated that when harvesting energy wood with a harvester costing about 170,000 US$ (VAT 0%) (64.5 US$/operating hour), mechanized felling-bunching is more expensive than manual work when the average size of the removal is under 21 dm3. If the operating hour costs of a harvester are 76.2 US$/h (harvester price about 310,000 US$), then mechanized energy wood harvesting is more expensive than manual work in all harvesting conditions [22].

Development work on the machines has to be more strongly directed at decreasing the costs of mechanized felling-bunching work to the level of manual work. In addition, means of estimating the harvested energy wood volume have to be developed. For instance, a more reliable, real-time balance has to be constructed for the grab for measuring the harvested energy wood volume. In this research, evaluation of the volume of the felled trees was carried out using mathematical equations. In practical energy wood harvesting work, measurement of the harvested trees is performed a few months later when the trees are chipped.

In the future, the harvesting and tending of young stands will become more mechanized. The move towards mechanized harvesting is primarily due to the promising productivity results obtined in studies on mechanized harvesting work, a shortage of professional lumberjacks, the possibility of all-year-round mechanized energy wood harvesting, and an increasing demand for energy wood. However, the harvesting sites suitable for mechanized harvesting have to be chosen carefully. Mechanized harvesting is expensive on sites where the average size of the stems to be removed is under 30 dm3 and the energy wood volume is less than 30 m3/ha.

AUTHOR CONTACT

Kalle Kärhä can be contacted by e-mail at -

kalle.karha@metsateho.fi

REFERENCES

[1] Anon. 1999. Finland's National Forest Programme 2010. Ministry of Agriculture and Forestry, publications 2/1999. 40 pp.

[2] Anon. 1999. Uusiutuvien energialähteiden edistämisohjelma. [Programme promoting renewable energy sources.] Ministry of Trade and Industry, publications 4/1999. 33 p. (in Finnish).

[3] Bergkvist, I. 2003. Multitree-handling increases both productivity and profitability in smallwood thinnings. Skogforsk, Resultat 5/2003. 4 pp.

[4] Björheden, R. and A. Fröding. 1986. A new routine for checking the biological quality of thinning in practice. The Swedish University of Agricultural Sciences, Department of Operational Efficiency, Research Notes 48. 14 pp.

[5] Brunberg, B., B. Nordén, and G. Svenson. 1989. Flerträdshanterande engreppsskördare kan sänka kostnaderna. [Single-grip harvester with multi-tree processing head can reduce costs.] Skogsarbeten, Resultat 18/1989. 4 pp. (in Swedish).

[6] Brunberg, B., B. Nordén, and A. Tosterud. 1989. Flerträdsupparbetning efter maskinell fällning-sammanföring - en alternativ metod för engreppsskördare? [Multi-tree processing after mechanical felling-bunching - Alternative method for single-grip harvester?] Skogsarbeten, Resultat 19/1989. 4 pp. (in Swedish).

[7] Eriksson, P. and B. Nordén. 1999. Bioenergy fuel extraction from stand with cleaning backlog. Skogforsk, Resultat 7/1999. 4 pp.

[8] Gingras, J.-F. 1988. The effect of site and stand factors on feller-buncher performance. FERIC, Technical Report 84. 18 pp.

[9] Gingras, J.-F. 1999. Evaluation of the Timberjack 745 single-grip head with multi-stem capability. FERIC, Technical Note 291. 4 pp.

[10] Greene, W.D., B.L. Landford, and E.F. Mykytka. 1987. Stand and Operating Effects on Feller-Buncher Productivity in Second Thinnings of Southern Pine. Forest Products Journal 37(3): pp. 27-34.

[11] Gullberg, T., J. Johansson, and J.-E. Liss. 1998. Studie av system EnHar vid uttag av skogsenergi i unga bestånd - Hamrestudien. [Study of EnHar in harvesting energy wood from young stands - A harvesting study.] Högskolan Dalarna, Skogsindustriella Institutionen, Arbetsdokument 9/1998. 24 pp. (in Swedish).

[12] Hakkila, P. 1978. Harvesting small-sized wood. Folia Forestalia 342. 38 pp.

[13] Hakkila, P. 1991. Crown mass of trees at the harvesting phase. Folia Forestalia 773. 24 pp.

[14] Hakkila, P. 2003. Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999-2003. Interim Report. National Technology Agency, Technology Programme Report 5/2003. 54 pp.

[15] Hakkila, P., I. Nousiainen, and H. Kalaja. 2001. Use of forest chips in Finland. Position paper for 1999. VTT Research Notes 2087. 39 pp.

[16] Ihonen, M. 1994. Agricultural tractor-mounted AM 230 multi-tree felling head in whole-tree harvesting. TTS Institute, Forestry Bulletin 536. 4 pp.

[17] Johansson, J. and T. Gullberg. 2002. Multiple Tree Handling in the Selective Felling and Bunching of Small Trees in Dense Stands. International Journal of Forest Engineering 13(2): pp 25-34.

[18] Kärhä, K. (Ed.). 2002. Small-Scale Technology in Tending of Young Stands. TTS Institute, Publications 387. 82 pp.

[19] Kärhä, K. and P. Häkkinen. 2003. New handle solutions for felling and piling. Teho 1/2003: 10-14, 46 pp.

[20] Kärhä, K., P. Mäkinen, K. Rieppo, and M. Sirén. 2001. Tarkastelu ja johtopäätökset HARKO-projektista. [Discussion and conclusions of HARKO Project.] In: Kärhä, K. (Ed.). Alternative Harvesting Systems in Mechanised Thinning. Final Report of HARKO Project (1999-2001). TTS Institute, Publications 382. pp 74-82. (in Finnish).

[21] Laasasenaho, J. 1982. Taper curve and volume functions for pine, spruce and birch. Communicationes Instituti Forestalis Fenniae 108. 74 pp.

[22] Laitila, J. and A. Asikainen. 2002. Koneellinen energiapuun korjuu harvennusmetsistä. [Mechanized energy wood harvesting from thinning stands.] PuuEnergia 3/2002: pp 8-9. (in Finnish).

[23] Lilleberg, R. 1994. A multi-tree harvester FMG 990/756 H in first thinning of pine. Metsäteho, Review 8/1994. 6 pp.

[24] Liss, J.-E. 1999. Studie av system EnHar vid uttag av skogsenergi i unga bestånd - L:a Främsbacka. [Study of EnHar in harvesting energy wood from young stands - L:a Främsbacka.] Högskolan Dalarna, Skogsindustriella Institutionen, Arbetsdokument 8/1999. 28 pp. (in Swedish).

[25] Niemelä, H., R. Ranta, and S. Hartikainen. 1997. Hakkuiden ja metsänhoitotöiden tarkastaminen. [Control of logging and silvicultural works.] Metsätalouden kehittämiskeskus Tapio, Moniste 26.6.1997. 16 pp. (in Finnish).

[26] Salminen, O., S. Valkonen, and M. Varmola. 1997. Taimikonhoito. [Tending of seedling stands.] In: Mielikäinen, K. & M. Riikilä. (Eds.). Kannattava puuntuotanto. [Profitable wood production.] Finnish Forest Research Institute, Tapio, and Metsälehti Publishing. pp. 52-64. (in Finnish).

[27] Sirén, M. 1998. One-grip harvester operation, it's silvicultural result and possibilities to predict tree damage. Finnish Forest Research Institute, Research Papers 694. 179 pp.

[28] Västilä, S. 2002. Silviculture. In: Peltola, A. (Ed.). Finnish Statistical Yearbook of Forestry 2002. Finnish Forest Research Institute. Official Statistics of Finland, Agriculture, forestry and fishery 2002:45. pp. 101-147, 364 pp.

[29] Ylitalo, E. (Ed.). 2003. Puupolttoaineen käyttö energiantuotannossa vuonna 2002. [Use of wood fuels for the production of energy in 2002.] Finnish Forest Research Institute, Forest Statistical Bulletin 670. Official Statistics of Finland, Agriculture, forestry and fishery 2003:15. 7 pp. (in Finnish).

The authors are, respectively, senior research specialist at the sectors of Wood Procurement and Wood Handling Technology, and Resources and Productivity, Metsäteho Oy, and researchers at the Department of Forestry, TTS Institute.