Vol. 16 No. 2 January 2005

Fuel From Early Thinnings

Pentti Hakkila

VTT Processes

Espoo, Finland

ABSTRACT

The fight against climatic change has introduced a new dimension to Finnish forestry. Renewable forest fuels play an important role in the national climate strategy, which is aimed at reducing the greenhouse gas emissions in accordance with Finland's international commitments. According to the Action Plan for Renewable Energy Sources, 5 million solid m3 forest chips or 0.9 Mtoe energy is to be derived annually from low-quality forest biomass by 2010: two thirds from logging residues from final fellings and one third from small trees from early thinnings.

The production of fuel chips from early thinnings is a challenge, but provides the opportunity to improve the tending of young forests. To make the use of chips competitive, the cost of harvesting must be reduced, and the yield of biomass per hectare must be increased. Therefore, in industrial operations the chips are produced from whole trees rather than delimbed stems. The intensive recovery of biomass can result in the accelerated loss of nutrients from forest soils, and this has to be taken into account in site selection and system development.

In 1999, the National Technology Agency Tekes launched a five-year Wood Energy Technology Program to develop efficient procurement systems for large-scale production of forest chips from residual forest biomass. The ongoing program is reviewed in this paper from the viewpoint of early thinnings. Among the topics discussed are the resource and its biomass composition, background problems, cost of production, silvicultural impacts, benefits from the program, and future prospects.

Keywords: early thinnings, forest fuel, whole-tree chips, wood energy, Finland.

WOOD IN THE FINNISH ENERGY STRATEGY

Because of its harsh climate, high standard of living, long transport distances and the predominance of process-type industries, the per capita consumption of energy in Finland is high, 6 tonnes of oil equivalent (toe) per annum. There are no deposits of fossil fuels, but the country is rich in forests.

The Finnish forests are managed for the production of industrial raw material, but they are increasingly seen also as a source of clean renewable energy. Annual fellings amount to 12 m3 per capita, and in addition, 3 m3 of timber per capita per annum is imported. The total consumption of wood is thus 15 m3 per capita. The corresponding average figure for the EU countries, Finland excluded, is only 0.7 m3 [2].

It follows that wood continues to play an important role in energy management. About 20 % of the total consumption of primary energy and 11 % of electricity production is derived from wood-based fuels, primarily from solid and liquid processing residues from the forest industries [8]. These proportions are higher than in any other industrialized country, and the goal is to increase them further.

Renewable energy sources play a key role in the national climate strategy. In the Action Plan for Renewable Energy Sources of the Ministry of Trade and Industries, wood-based fuels have a dominant role. The largest source of additional wood for fuel is the processing residues from expanding forest industries, but another significant source is biomass residues from forestry operations. According to the Action Plan, 0.9 Mtoe or 5 million solid m3 wood fuel is to be derived directly from low-quality forest biomass in 2010 in the form of chips [6].

REDUCTION OF PRODUCTION COSTS

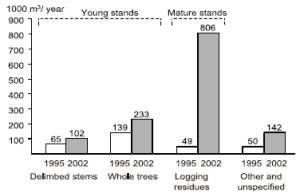

The chip utilization capacity of heating and power plants will soon exceed the target level of 5 million m3 per annum, as new wood fuelled plants are being established and old plants are being modified to receive, handle and burn chips. The availability of unmerchantable forest biomass is not a limiting factor either, since the potential greatly exceeds the target. As shown by Figure 1, three major sources of unutilized forest biomass are available:

Presently, the real limiting factor is the production of chips at a competitive cost, i.e. about USD 10 per MWh (USD 20 per m3 solid) at the plant. The problem is that the use of forest fuels is beneficial to the national economy and environment, but it is not necessarily profitable business. To improve the competitiveness of forest fuels, either the cost of other fuels must be increased by means of taxation, or the cost of forest chips must be reduced. In fact, a considerable cost reduction has taken place since the mid 1990s as a result of many changes in the operating environment:

Figure 1. Biomass residues technically harvestable from the Finnish forests annually [5].

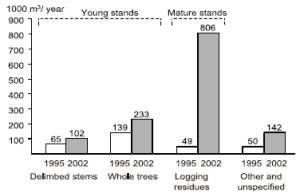

However, progress was mainly limited to operations in regeneration areas, where only a nominal cost has to be allocated to the cutting and bunching of residues. In small-tree thinnings, on the other hand, the cost burden of cutting makes the chips uncompetitive, unless the production is subsidized from public funds. Consequently, during the last few years, growth in the use of small-tree chips was slow, but rapid in the use of logging residue chips (Figure 2). Costly small-tree chips were partly replaced by logging residue chips. Chips produced from logging residues from final harvest are presently competitive against alternative fuels, but cost pressures are accumulating as demand grows. Pressures arise as:

Figure 2. The use of commercial forest chips in Finland in 1995 and 2002 [5, 9].

It is agreed, therefore, that the biomass base of forest chips must be broadened and production of forest chips from early thinnings must be increased to control cost development and to ensure sufficient availability. This presents an opportunity for promoting good forest management practices in young stands.

The National Wood Energy Technology Program of Tekes (the National Technology Agency) supports research and development to reduce the production cost of forest chips, as well as improving the quality of chips [3]. Among the specific small-tree topics being studied by enterprises and research institutes are:

FIBER OR ENERGY FROM SMALL TREES?

From the national economy point of view, wood should be used for industrial raw material rather than as a source of energy. This guarantees a higher stumpage price for the forest owners as well. However, in addition to the high cost of harvesting, the use of small trees for pulp or composite boards is constrained by the technical properties of the raw material.

Small trees contain a high proportion of juvenile wood, which means short fiber and low basic density. Furthermore, the percentage of bark tends to be high, and the loss of wood in drum debarking is excessive due to the breakage of thin logs.

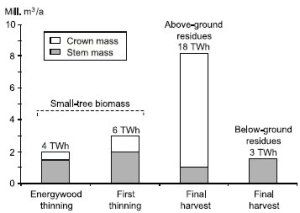

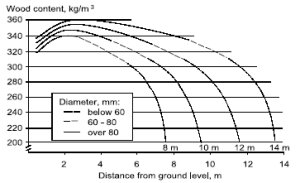

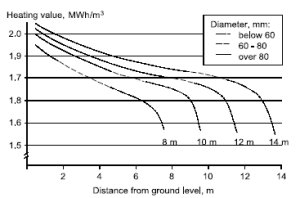

Figure 3 shows the wood content of de-barked Scots pine wood from early thinnings. Decreasing tree size and increasing distance from the tree butt both result in steeply decreasing wood content and high wood consumption in pulping. Therefore, thin logs from early thinnings are an inferior raw material for pulping. Unfortunately, due to the low basic density of the wood and bark they are inferior in energy production as well (Figure 4). However, the effects of tree size and distance from the butt are not as critical when the wood is used for fuel.

Figure 3. Wood content (dry mass) of de-barked Scots pine from first commercial thinnings (unpublished material, FFRI).

Figure 4. Heating value of de-barked Scots pine wood from early thinnings [unpublished material, FFRI].

In the traditional first commercial thinning, pulpwood is normally the main product. However, if the yield of pulpwood does not exceed 25-30 m3 solid per hectare, the stand to be thinned is not merchantable. In any case, 20-30 % of the stemwood removal is typically unsuitable for pulping because of its small size, and it is left unutilized.

This traditional first commercial thinning is typically preceded by a pre-commercial thinning where all biomass is left unutilized in the forest because of the small tree size and the insufficient yield of pulpwood-sized material. Parts of these early thinning sites are suitable for fuel production. The tending operation is then called energywood thinning. Thus, in conjunction with early thinnings fuel can be recovered from first thinnings as a by-product and from energywood thinnings as primary product.

It is estimated that if the production target of forest chips (5 million m3 solid in 2010) is met, two thirds of the chips will be produced from above- and below-ground residues from final harvest and one-third from early thinnings. At the moment, the total annual yield of industrial wood and firewood from the Finnish forests is about 55 million m3 [6]. Thus, the production of forest chips would increase the removal from the Finnish forests by almost 10 %. Chips from early thinnings alone would mean a 3 % increase in the present removal.

If small trees are delimbed prior to comminution, a large part of the fuel potential is lost and the cost of chips is increased. Large-scale production of small-tree chips therefore requires the adoption of the principle of whole-tree chipping rather than stem-only chipping. The quality of chips is then reduced, but it is not a critical issue for large CHP plants. A more difficult problem is the accelerated loss of nutrients from forest soils, and this must be taken into account during site selection and method development. Under Finnish conditions, the effects of whole-tree recovery, compared with the stem-only recovery, are roughly as follows:

| Change, % | |

| - Increase in fuel yield | 15-50 |

| - Increase in the productivity of logging | 15-40 |

| - Reduction in the cost of chips | 20-40 |

| - Increase in the loss of nutrients | 50-150 |

BENEFITS FROM THE USE OF SMALL-TREE CHIPS

The primary driving force behind the promotion of forest fuels in Finland is the reduction of greenhouse gas emissions. If the forest fuel target is achieved, and one third of the chips can be produced annually from small-tree material from early thinnings, production of whole-tree chips will help to reduce Finland's greenhouse gas emissions about 1 million tonnes per annum, depending on whether oil or coal is replaced.

Early thinnings are a particular problem for forest owners as long as the demand for small-sized wood is weak. Increasing the demand for low-quality biomass improves the economic conditions of tending young stands. While the need for precommercial thinnings is some 200 000 ha per year, the planned chip production could cover up to 30 000 - 40 000 ha or 20 % of the total area with little cost to the forest owner, thus greatly promoting the management of young stands.

The production and use of forest chips also helps to create urgently required rural jobs. Table 1 shows that the use of forest chips, especially when the chips are produced from small trees, have a positive effect on local employment. However, the effect is somewhat smaller in large-scale operations. Furthermore, the employment effect will be reduced when the productivity of chip procurement gradually increases through the development of cutting and logistics,

Table 1. Employment effect of a 4 MW rural heating plant depending on the fuel used [1].

| Fuel | Production of fuel | Production of heat | Total | Local jobs |

| Employment effect, h/MWh | % |

|||

| Imported heavy fuel oil | 0.09 | 0.09 | 0.18 | 22 |

| Sod peat | 0.21 | 0.20 | 0.41 | 56 |

| Chips from final harvest | 0.41 | 0.20 | 0.61 | 69 |

| Chips from early thinnings | 0.63 | 0.20 | 0.83 | 77 |

Small-tree chips will be produced in the future mainly from undelimbed trees. This practice will accelerate the loss of nutrients from forest soil at a time when the annual growth of a stand reaches its maximum level. Based on joint Nordic studies [7] it can be concluded that the removal of one tonne of absolutely dry crown mass results in a total growth loss of 0.6 m3 stemwood per hectare for Scots pine and 1.1 m3 per hectare for Norway spruce during a period of 10 4]. Under Finnish conditions, the removal of crown mass is in reality about 4 tonnes of dry matter per hectare from young Scots pine stands and 7 tonnes from Norway stands, when the removal of stemwood is 40 m3 per hectare. In 2010, the total growth reduction effect of nutrient loss would thus be roughly 100 000 - 150 000 m3 per annum.

This loss would waste only a fraction of the quantitative and qualitative growth benefits from the intensified tending of 300 000 - 400 000 ha of forest. Nevertheless, there is an obvious need to develop harvesting practices so that the harmful loss of nutrients can be minimized.

AUTHOR CONTACT

Professor Hakkila can be reached by e-mail at --

Pentti.Hakkila@vtt.fi

REFERENCES

[1] Ahonen, A. 2003. Unpublished data from an ongoing project of the Finnish Wood Energy Technology Program.

[2] Finnish Forest Research Institute 2002. Finnish statistical yearbook of forestry. SVT Agriculture, forestry and fishery 2000: 45.

[3] Hakkila, P. 2002. Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999-2003. Interim Report. Tekes. Technology Programme Report 5/2003.

[4] Hakkila, P. 2003. Mistä metsähake tehdään [The sources of forest chips]. Bioenergia 1/2003: pp. 10-13. (In Finnish).

[5] Hakkila, P. and T. Fredriksson. 1999. Metsämme bioenergian lähteenä [Our forests as a source of bioenergy]. Metsäntutkimuslaitoksen tiedonantoja 613. (In Finnish).

[6] Ministry of Trade and Industries 2000. Action Plan for Renewable Energy Sources. Publication 1/2000.

[7] Mälkönen, E., M. Kukkola, and L. Finér. 2001. Energiapuun korjuu ja metsämaan ravinnetase [Harvesting of energy wood and the nutrient balance of forest soil]. Metsäntutkimuslaitoksen tiedonantoja 816: pp. 31-52. (in Finnish).

[8] Statistics Finland 2001. 2002. Energy Statistics.

[9] Ylitalo, E. 2003. Puupolttoaineen käyttö energiantuotannossa vuonna 2002 [Use of wood fuels for the production of energy in 2002]. SVT Maa, metsä- ja kalatalous 2003: 670. (in Finnish).

The author is a Professor at VTT Processes, Finland.