Vol. 16, No. 2 July 2005

D. Ligné

T. Nordfjell

A. Karlsson

Swedish University of Agricultural Science

Umeå, Sweden

The authors are, respectively, Associate Professor, Associate Professor, and PhD student, Swedish University of Agricultural Science, Umeå, Sweden.

ABSTRACT

High costs, increasing density and height of young stands at the time of pre-commercial thinning, and difficulty in attracting personnel to do motor-manual work have called for the development of new techniques for pre-commercial thinning. In the study reported here a new motor-manual and mechanized pre-commercial thinning technique was compared to the conventional brush saw technique in terms of time requirements and damage caused to crop trees. The motor-manual tools tested were a hacksaw and two pole saws with modified chainsaw blades. The mechanized machine prototype was built especially for pre-commercial thinning, and was equipped with a new type of crane tip-mounted device based on a cutting-squeezing technique. Our expectations were that, compared to the brush saw, themechanized approach would be less time-demanding in dense and/or large diameter stands, but more main stems would be damaged. Furthermore, a motor-manual device with a larger cutting area than the conventional brush saw blade should allow faster operation in dense and large diameter stands, without damaging higher numbers of main stems.

To test these beliefs, a rig was built that enabled the tools to be compared in experimental stands with different densities and diameters of secondary stems.

One of the pole saws and the mechanized prototype machine were competitive with the conventional brush saw in terms of both time requirements and frequency of damage to main stems, especially in dense (i.e. >15000 stems ha-1) and large diameter (>4 cm) stands. The pole saw was competitive despite having a less powerful engine. The mechanized prototype showed more homogenous time consumption, with lower variation than the other tools. Further field studies are needed to compare the tools in economic terms.

Keywords: cleaning, experimental design, Husqvarna, mechanized, pct, motor-manual, Sweden, time study, Vimek.

INTRODUCTION

Almost all pre-commercial thinning (PCT) in Sweden today is carried out using brush saws; little work has been done to modify the technique since it was first introduced 50 years ago [13, 34]. However, the cost of PCT has been accounting for an increasingly large proportion of total forestry costs. Recent figures show that the cost of PCT is in the range of 23-27% of the cost of harvesting and extraction (100 m³sob, solid volume over bark) or total regeneration investment ha-1. Corresponding figures for the year 1985 were 10-13% (Figure 1).

Figure 1. The average cost of pre-commercial thinning of one hectare relative to the average cost of harvesting and extraction of 100 m3sob (solid volume over bark) and average regeneration costs ha-1 in Sweden 1981-2001 [1, 2, 3, 4, 5, 7].

In addition in Sweden today PCT tends to be performed in older stands than in the early 1990's, so the stems to be cut tend to be taller and have a larger diameter [6, 37] (Figure 2a). Furthermore, stands tend to be denser at the time of PCT nowadays because regeneration methods are more efficient, there is an increased abundance of broad-leaved trees (for environmental reasons and to meet forest certification standards), and PCT-treated areas have declined in recent decades [6, 37] (Figure 2b). In all, these developments have reduced productivity of PCT with a brush saw, and may cause operations to be even more expensive in the future. The diameter and number of stems are the two major factors affecting productivity of PCT using a brush saw [9]. There are also problems in attracting personnel to do this type of motor-manual work in Sweden today [16]. Overall, the lack of technical development and the changes in conditions call for the introduction of new techniques [22, 41].

Figure 2. a) Average tree-height when pre-commercial thinning was carried out in Sweden 1983-2001 [38]. b) Total number of stems per hectare in young pine-dominated stands and young spruce-dominated stands before and after pre-commercial thinning in Sweden 1952-2001 [38].

A search among available PCT related patents revealed more than 2300 possible approaches [29]. A majority of the patents concern mechanized tools, and the others describe motor-manual approaches. Mechanized PCT has been tested (mainly in Scandinavia and North America) more or less continuously since the late 1940´s [15, 41]. The mechanized apaproaches can be divided into three groups: selective PCT, geometric PCT and a combination of these two options [8].

Scandinavian efforts to build PCT-machines have so far involved the use of boom-mounted felling devices with rotating flexible flails or saw teeth for selective cutting [8, 39]. The latest machines to be introduced were based on standard harvesters with increased ground clearance, and were not specifically designed for PCT [22, 26]. The basic idea was to carry out the operation when the main stems (potential crop trees) were lower than two metres tall to allow the machine to straddle plants [22]. Today, almost no PCT-machines of this type are in practical use in Sweden because of their poor economy [26], adverse biological effects [27] and the high frequency of damage to main stems they cause [18, 33, 43].

Earlier studies on mechanized PCT state that conditions are unfavourable for motor-manual approaches when trees are tightly grouped, and when the density and/or diameter of stems is high [18, 19, 22]. Shortages of labour are also disadvantageous for motor-manual PCT [30, 41]. The situation in Sweden today should therefore favour a mechanized approach.

Several motor-manual alternatives to the brush saw, e.g. hydraulic shears [25] and saw chains [32, 34], have been developed and tested in recent decades, but none seems to be competitive. Generally, saw chains productivity is low in dense young forests, increasing time requirements and costs, although they seem to be competitive in large diameter stands [32, 34]. Hydraulic shears are generally too slow because of the time required for positioning and cutting capacity limitations, at least as long as single stems are cut [14, 25]. The brush saws used today are generally lighter and more ergonomically sound than earlier models, but they are not significantly more productive [13].

A recently tested method for pre-commercial thinning, top-cutting, could facilitate the development of efficient new tools. This approach involves cutting stems at a higher level above the ground [28] where there are fewer obstacles, thinner stems, and operator visibility is likely to be better [12]. Under such conditions, new tools and cutting techniques are required. Moreover, a large number of stems ha-1 should favour a multi-stem cutting device.

The objective of this study was to examine the time requirements for the new motor-manual and the mechanized pre-commercial thinning techniques, and the damage they cause to main stems in comparison with the conventional brush saw.

MATERIALS AND METHODS

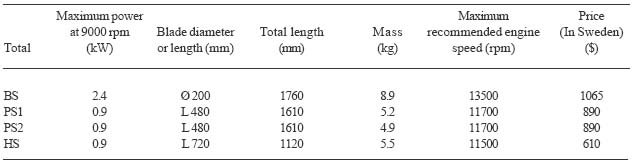

Prototypes for the four new approaches were developed together with Husqvarna AB and Vimek AB in 2000. The three motor-manual tools were built by Husqvarna AB, and the one mechanized tool (ME) was built by Vimek AB. The Husqvarna prototypes included a hacksaw (HS) (Figure 3a), a pole saw with an angled brush saw shaft together with a modified chainsaw blade and chain (PS1) (Figure 3b) and a pole saw with a modified straight shaft together with a modified chainsaw blade and chain (PS2) (Figure 3c). The same type of cutting head, with chain lubrication, was used on PS1 and PS2 (Figure 3d). A conventional brush saw (BS), a Husqvarna 252 RX model, was also included in the study (Figure 3e) (Table 1). All motor-manual tools had a mass of 4.9 _ 8.9 kg and were powered by two-stroke engines. They were carried in a standard brush saw harness, except for HS which was carried by hand and supported by a belt worn around the neck. The engine power of all of the motor-manual prototypes was 38% of that of the BS.

(a)

(b)

(c)

(d)

(e)

Figure 3. The motor-manual tools tested in this study: a) the hacksaw (HS) b) the pole saw with angled brush saw shaft together with modified chainsaw blade and chain (PS1) c) The pole saw with modified straight shaft together with modified chainsaw blade and chain (PS2) d) The cutting head with chain lubrication used on PS1 and PS2 e) The brush saw (BS).

Table 1. Technical specifications for the motor manual tools, abbreviations as in Figure 3.

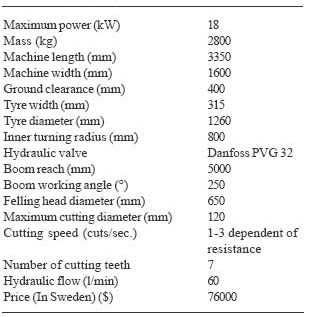

The mechanized tool (Figure 4) was designed to be driven between main stems. The front part (cab), diesel engine, and articulated steering were identical to that of the Vimek model 606 forwarder [36]. The rear part had a single-axle with Ackerman-steering and a parallel crane. The two steering systems gave the machine an unusually small turning radius (Table 2). A new type of cutting device was developed by Vimek based on a cutting-squeezing technique that can be geared up and down depending on resistance (Table 2) (Figure 4) [20].

Figure 4. The mechanized prototype (ME) tested in this study with its cutting device [20].

Table 2. Technical specifications for the mechanized prototype (ME)

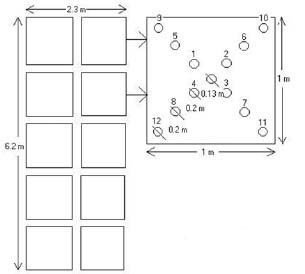

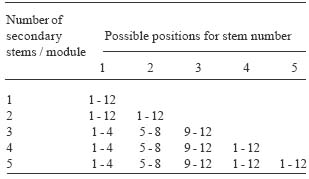

An experimental resting rig was built that enabled identical stands to be constructed [25, 34]. Ten identical modules, each with 13 holes in a specified pattern, were connected to complete the rig in order to simulate a small stand (Figure 5). In each center hole a Scots pine (Pinus sylvestris L.) was placed as a main stem, and secondary stems of downy birch (Betula pubescens Ehrh.) were then placed in some of the other twelve holes. Each tool was

tested with three different diameters and five densities of secondary stems, in all 15 permutations. The diameters tested were 2, 4 and 6 cm diameter at the butt end of the tree. The HS could only be tested on 2 cm trees since its maximum cutting diameter was 22 mm. Variation of 15% in diameter was accepted. The densities tested were 1, 2, 3, 4 and 5 stems per module, giving 10 _ 50 stems in toto. The holes for the stems were numbered 1 _ 12 in each module (Figure 5), and the positions of the stems were randomly distributed under the specified restrictions given in Table 3 to spread them. Each combination of tool, diameter and number of stems was tested four times.

Figure 5. The experimental rig and numbered positions for stems on one of the modules.

Table 3. Possible positions for secondary stems before drawing lots for the positions used, see Figure 5.

For each tool, 100 stems of each diameter were randomly selected. Height, diameter and number of branches were recorded in order to assess possible differences in the morphology and size of the trees. Differences between the chosen stems were evaluated by analysis of variance. The model used was:

Yij = ì + Ti + 0ij (1)

where Yij is the response variable (diameter in mm, height in cm or number of branches), ì is the grand mean, Ti is the specific population effect for the respective tool, and 0ij the error term. No differences at all between the populations were found (p=0.118). The stems were not frozen at any point of time during the study, and carried no leaves. Average tree height for the diameters 2, 4 and 6 cm were 3.1, 4.6 and 5.5 m, respectively.

In each case, the total time for cutting all the stems in the rig was measured. Recording, for the motor-manual tools, began when the operator stepped into the rig, and stopped when he stepped out (i.e. when his first foot entered or left it). For ME recording began when the cutting head was lifted from the ground and stopped when it was placed on the ground again. The ME machine did not change position during the test. After cutting, all visible damage to the remaining main stems was registered. A stem was recorded as being damaged when the sapwood could be seen, regardless of the size of the wound. If any problems with the tools occurred during cutting, the operation was terminated and a completely new round was started. The same person operated all the motor-manual tools and another well-trained driver operated the ME. Before the actual test, the operators were given a three-week training period regarding PCT in young forest stands to familiarize them with the equipment.

The effects of the tools on time consumption were evaluated using analysis of variance, for each combination of stand density, diameter and tool. The model used to describe effects of the tools on time consumption was:

Yij = ì + Ri + 0ij (2)

where Yij is time consumption, ì the grand mean, Ri the fixed tools effects and 0ij the error term.

The model used to describe the effects of diameter and number of stems on time consumption for each of the tools was:

Yijk = ì + Di + Nj + DNij + 0ijk (3)

where Yijk is time consumption, ì the grand mean, Di the fixed diameter effect of stems, Nj the fixed effect of number of stems, DNij the fixed interaction term and 0ijk the error term.

Evaluation of the residuals by plotting [42] and by the Anderson-Darling test for normality [40] showed that assumptions of normality and constant variance of the residuals were fulfilled in models (1) and (2), but violated in model (3). Therefore, for model (3) the variables were transformed to enable analysis of variance. Logarithmic transformation was used in this case, as it gave a good distribution of the residuals [42, 45]. To identify statistically significant differences, Tukey's studentised range test was used.

Differences between the tools with respect to damage caused to main stems were analysed with the Friedman's rank test since the assumptions of normality were violated [40, 45]. If significant interaction effects occurred, in model (3), they were investigated with graphical methods [45]. All statistical analyses were done using Minitab 13.1 [40].

RESULTS

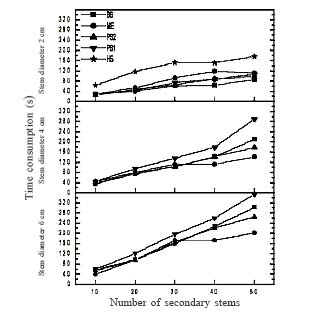

Time consumption for all tools was affected by the number and diameter of stems and the interaction term, number of stems × diameter of stems (p<0.001). The interaction term was significant for all tools (p<0.05), probably (in all cases except ME) because variance increased as the number and/or diameter of stems increased (Figure 6).

In all cases, again except for ME, time consumption increased as stem diameter increased, and it was significantly higher both for the 4 cm diameter trees compared to the 2 cm trees, and for the 6 cm compared to the 4 cm trees (p<0.0001). For all tools, again except ME, time consumption also increased as the number of stems increased, and in all cases for BS, PS1 and PS2 there were significant differences in time consumption between the different densities of stems tested (p<0.0001). For ME there were significant differences in time consumption between all densities of stems tested (p<0.05), except between 30 and 40 stems, for which no significant difference was detected (p=0.1305). In one case (ME), the mean values for time consumption for the tested diameters "crossed" as more time was consumed for 40 stems at 2 cm diameter than for 40 stems at 4 cm diameter (Figure 6).

Figure 6. Effects of butt end diameter (2, 4 and 6 cm) and number of secondary stems on time consumption for the four tested tools: Brush saw (BS), Mechanized prototype (ME), Pole saw with straight shaft (PS2), Pole saw with angled brush saw shaft (PS1).

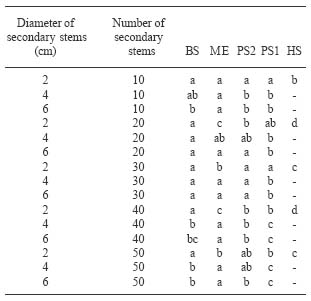

The time requirements for the different tools significantly differed in all combinations of diameter and number of stems (Table 4, Figure 7). Generally, the relationships between the tools were broadly similar for the 4 and 6 cm diameters, but there were greater differences for the 2 cm trees (Table 4, Figure 7). For the 4 and 6 cm diameters, ME was the fastest, or one of the fastest, tools at all densities.

Table 4. Dependence of time consumption for the different tools on diameter and number of secondary stems. Significant differences in time consumption between the tools, according to Tukey´s studentized range test (p<0.05), are indicated as follows: a<b<c<d (cf. Figure 7). Abbreviations for tools as in Figure 3.

Figure 7. Effects of butt end diameter (2, 4 and 6 cm) and number of secondary stems on time consumption (abbreviations as in Figures 3 and 4).

However, for 2 cm diameter trees, ME was one of the slowest of all the tools, at all densities except the lowest, and HS was the slowest tool at all densities (Table 4, Figure 7). Time requirements for the BS and PS2 were similar. The only statistically significant differences between these two tools appeared at the lowest diameter for densities 20 and 40 stems, where BS was the faster tool (Table 4, Figure 7). PS1 consumed about the same amount of time as PS2 at the lowest diameter. For the other two diameters, 4 and 6 cm, PS1 was the slowest or one of the slowest tools at all densities (Table 4, Figure 7).

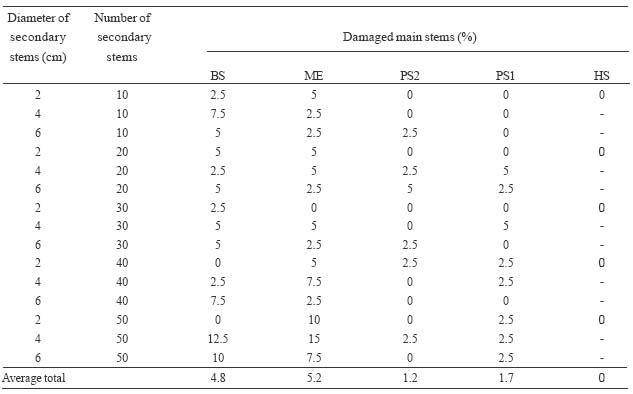

In total, 4.8% of the main stems were damaged during PCT with BS, 5.2% with ME, 1.2% with PS2 and 1.7% with PS1 (Table 5). Damage frequencies during PCT with ME were not significantly different than during PCT with BS (p=0.564). There were significant differences in damage frequencies between BS compared to both PS1 and PS2 (p<0.008). No damage to main stems at all was recorded with HS (Table 5), but no comparisons with the other tools were made since HS was only tested on 2 cm diameter trees.

Table 5. Number of damaged main stems (%) after pre-commercial thinning, per tool, for each permutation of diameter and number of secondary stems. Abbreviations as in Figure 3.

DISCUSSION

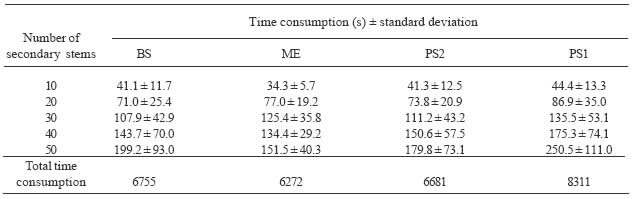

The significant interaction term, number × diameter of stems, affecting the time consumption for the tools, is typical for time-study data [43]. "Right-opening megaphone distributions" are caused by the positive correlation between variation and the magnitude of independent variables. Time consumption for all of the tools increased as either the diameter or number of stems increased, as expected and thoroughly described in earlier studies [9, 17, 23, 25, 32, 34] (Table 6). However, the relationships between time consumption, diameter of stems and number of stems differed somewhat for the different tools. The relationships for the motor-manual tools were almost identical and linear, although the time requirements varied in absolute terms (Table 6, Figure 7). These results are in accordance with earlier studies, and the time consumption figures obtained for the BS seem to be normal [9]. A tendency for the time requirements per stem to be lower for the higher density class (50 stems) than for the other density classes was detected for PS2, especially for trees of the two higher diameters. This may reflect the point at which the possibility to cut more than one stem at the same time starts to significantly affect the time requirements.

Table 6. Average time consumption ± standard deviation for the tools for each number of secondary stems, including all three diameters (2, 4 and 6 cm). Total time consumption for all tested diameters and numbers of secondary stems also included.

The relationships for the ME were somewhat different, and there seemed to be a kind of threshold at densities around 30 stems, beyond which the time consumption rose significantly more slowly with further increases in density. This is consistent with earlier studies on selective mechanized PCT-equipment [11, 18, 21, 35]. At densities around 10000-15000 stems ha-1 (corresponding to approximately 20-30 stems in this study) the felling head has to be moved over almost all the treated area and the number of stems that are cut will probably not significantly affect the time consumption. The time consumption is therefore probably more closely correlated to the area that needs to be covered with the boom and felling head than to the number of stems that are cut. Therefore, a cutting head with a larger cutting area than the one tested here could prove to be more efficient, provided it could avoid damaging the main stems.

The HS could not compete in terms of time consumption, since its maximum cutting diameter and the tooth depth of its blade were too small. The operator also complained that such a large cutting device (blade, Table 1a) was hard to control. For the two pole-saws (PS1 and PS2) the time consumption differed significantly. Since the two tools' motors and cutting devices were identical, the reason for PS2's lower time requirements must be the configuration of the saw. PS2 had a different configuration for the handles, enabling the operator to go sideways more easily in the stand, and thus granting more flexibility of action. To balance the PS1 a larger part of the tool had to be behind the handles (and thus behind the operator) than for the PS2, making it more difficult to control.

In terms of damage to main stems, the pole saws were better than the BS, probably partly because of the better visibility they allowed at a higher cutting-level and partly because of the protective hook at the tip of the blade attached to PS1 and PS2 (Figures 3b, 3c, 3d). This feature enabled the operator to pull stems away from nearby main stems while cutting them. In addition, a chain will not give kickbacks to the same extent as a circular saw, and this might also result in somewhat lower damage to main stems compared to BS.

ME was believed to cause more damage to main stems than could be assessed in this study, since the machine did not move around in the stand so damage caused by the wheels and chassis of the moving machine could not be evaluated. However, damage caused by the boom and felling head were lower than in earlier studies of mechanized PCT-equipment [23, 31, 39]. Although no statistically significant difference in damaged main stems after treatment with BS and ME was recorded, it is likely that some difference would occur in real stands when damage caused by the machine's movements was added. Earlier cutting devices on PCT-machines often had rotating, flexible flails [22, 26], resulting in some damage to main stems from cutting debris [36, 44]. This problem, as well as the earlier rigorous safety distances (200 metres), should be eliminated with this new type of felling head.

The PS1 and PS2 require somewhat different silvicultural regimes, which may have both advantages and disadvantages. The results so far indicate that the approach of cutting stems at a higher level can give several benefits, e.g. higher quality in main stems and attractive fodder for browsers, which should add further value to the method [24]. There is probably also some value in the scope it allows to vary the tools and methods used between, or even within, stands. So far, forest practitioners have had very little scope to choose among different methods and tools for PCT, and the ability to do so would most likely leave the operators and landowners with a more complex range of options. A comment from the operator was that the PS2 was also suitable for operations in stands where pruning or trimming of stems browsed by moose could be of interest, something also mentioned in earlier studies [34].

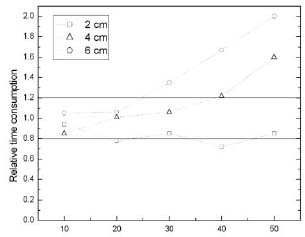

Although this study provided a lot of information about the correlations between the time requirements for the different tools with the diameter and number of stems, and the relative capacities of the tools, one should be cautious about extrapolating the results to production norms for real stands in the field. A comparison between the time consumption for the conventional brush saw in this study and the productivity targets from Bergstrand et al. (1986) [9] resulted in a relatively constant relationship (horizontal line) for small diameter trees (2 cm) and for the other diameters in not too dense stands (Figure 8) (less than 30 - 40). The reason for this is probably poor representation of high diameter stands in Bergstrand et al. (1986) [9], bias in this study, or a combination of both of these factors. To investigate this further, field studies are needed.

Figure 8. Time consumption for the brush saw (BS) relative to the productivity targets set by [9] at 2, 4 and 6 cm butt end diameter.

Further field studies are also needed to investigate the way the tools handle larger diameters trees, and variations in densities and diameters of stems within the stand. Studies are also needed to evaluate machine performance in practice, and to enable economic comparisons between them. This study did not allow economic analysis of the tools, or determination of possible thresholds where, for example, the ME might be preferred economically. The ME is a more expensive investment than a conventional brush saw, so higher productivity is needed in order for it to be economically viable. Earlier studies suggest that a combination of mechanized PCT-equipment and motor-manual workers may provide the best option, both economically and qualitatively [10, 21, 35], and nothing in this study indicated that this should not be the case for the ME too. Since the ME seemed to be most competitive in dense and large diameter stands, the choice of stands for its use would also be very important. To further evaluate the difference in time consumption between the pole saws and BS, new pole saws are needed with the same engine power as BS.

AUTHOR CONTACT

Mr. Ligné can be reached by e-mail at --

Daniel.Ligne@ssko.slu.se

ACKNOWLEDGEMENTS

This work was financially supported by the Forest owners' association, Norrskogs research foundation (NFS), the Nordic Forest Research Co-operation Committee (SNS) and INTERREG IIIA in the Kvarken-MidtSkandia region. We thank Sören Holm for statistical advice and Dr. John Blackwell for revising the language.

REFERENCES

[1] Anon. 1983. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[2] Anon. 1985. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[3] Anon. 1990. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[4] Anon. 1995. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[5] Anon. 2000. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[6] Anon. 2002. Forestry Statistics 2002, Theme: Young Forests. Department of Forest Resource Management and Geomatics, Swedish University of Agricultural Science, Umeå, Sweden.

[7] Anon. 2003. Statistical Yearbook of Forestry. Official Statistics of Sweden. National Board of Forestry, Jönköping Sweden.

[8] Berg, H., P-O. Bäckström, R. Gustavsson, and B. Hägglund. 1975. Systems analyses of cleaning of young stands. Forestry Research Institute of Sweden. Report Nr. 1E.

[9] Bergstrand, K-G., J. Lindman, and E. Petré. 1986. Instruments for use in setting productivity targets for motor-manual cleaning. Forestry Research Institute of Sweden. Redogörelse nr. 7. In Swedish with English summary.

[10] Bjurulf, A. and N. Nilsson. 1988. Samverkansformer vid maskinell röjning. [Co-operation standards with mechanized pre-commercial thinning]. Forskningsstiftelsen Skogsarbeten. Stencil 1988-10-12.

[11] Brunberg, T. 1991. Preliminärt underlag för produktionsnorm för maskinell röjning. [Preliminary basis for productivity norms for mechanized pre-commercial thinning]. Forskningsstiftelsen Skogsarbeten. Stencil 1991-02-06.

[12] Bulley, B., C. Bowling, and G. Niznowski. 1997. Jack pine leader clipping trial: fifth-year results. Ont. Min. Natur. Resour., Northwest Sci. & Technol., Thunder Bay, Ont. TR-106.

[13] Bäckström, P-O. 1984. Ungskogsröjning och lövbehandling. [Pre-commercial thinning and treatment of deciduous trees]. Sveriges Skogs-vårdsförbunds Tidskrift 3-4: 5-14.

[14] Christensen, P. 1989. Afsluttende rapport over kemikalieforsog T28. Biologisk effekt af "Selektiv"- metoden på Valbygård skovdistrikt. [Report from chemical trial T28. Biological effects of the "Selektiv" _ method on Valbygård forest management district]. Skovteknisk Institut, Stencil 1989-12-18.

[15] Crossley, D. I. 1952. Discing in overdense lodgepole pine reproduction. Can. For. Branch, Dept. Res. Devel., Div. For. Res., Silv. Leaflet Nr. 66.

[16] Davner, L. 2002. Skogsarbetare, var är ni? [Forest workers, where are you?]. Skogen, 11:02, p. 8-14. Stockholm.

[17] Eickhoff, K. and J. Lindman. 1986. Studie av prestation och arbetsmönster vid maskinell röjning med litet aggtregat i lövat och olövat bestånd. [Study of productivity and work pattern in mechanized pre-commercial thinning with a small cutting device in leafed and deleafed stands]. Forskningsstiftelsen Skogsarbeten Stencil 1986-09-19.

[18] Eickhoff, K. 1987. Beståndsval vid maskinell röjning. [Choice of stand for mechanized pre-commercial thinning]. Forestry Research Institute of Sweden. Resultat nr. 3. In Swedish with English summary.

[19] Eickhoff, K. 1988. Maskinell röjning. [Mechanized pre-commercial thinning]. Forskningsstiftelsen Skogsarbeten. Handledning.

[20] EP 1 157 605. http://l2.espacenet.com/espacenet/viewer?PN=EP1157605&CY=se&LG=se&DB=EPD 2003-08-20.

[21] Freij, J. and A. Tosterud. 1990. Maskinell röjning med rätt instruktion. [Mechanized pre-commercial thinning with the right instructions]. Forestry Research Institute of Sweden. Resultat nr. 21.

[22] Freij, J. 1991. Pre-commercial thinning technique. Forestry Research Institute of Sweden. Redogörelse nr. 2. In Swedish with English summary.

[23] Fries, C., J. Lindman, and P. Olsson. 1985. Vad styr prestationen vid mekaniserad röjning? Studie av Bruunett Mini med kranspetsmonterat aggregat. [What influences productivity of mechanized pre-commercial thinning? Study of Bruunett Mini with boom mounted cutting device]. Skogsarbeten Stencil 1974-11-12.

[24] Fällman, K., D. Ligné, A. Karlsson, and A. Albrektson. 2003. Stem quality and height development in a Betula-dominated stand seven years after precommercial thinning at different stump heights. Scand. J. For. Res. 18: 145-154.

[25] Gabrielsson, L. 1989. Pre-commercial thinning with the Selektiv. Sveriges Lantbruksuniversitet, Department of Forest Operations Research. Uppsatser och Resultat nr. 142. In Swedish with English summary.

[26] Glöde, D. and I. Bergkvist. 2003. Mechanized cleaning down and out and back again? Proceedings technique and methods, 2nd forest engineering conference. Arbetsrapport nr. 535, p. 25-37. Forestry Research Institute of Sweden.

[27] Johansson, T. 1991. Mekaniserad röjning _ biologiska resultat och val av röjningsmetod. [Mechanized pre-commercial thinning _ biological results and choice of method]. SLU, Uppsala. Skogsfakta nr. 7.

[28] Karlsson, A. and A. Albrektson. 2000. Height development of Betula and Salix species following precommercial thinning at various stump heights: 3-year results. Scand. J. For. Res. 15: 359-367.

[29] Ligne´, D. 1999. Compilation of patents and principles concerning cleaning. Department of Silviculture, Section of Forest Technology, SLU Umeå. Studentuppsatser nr. 24, 1999. In Swedish with English summary.

[30] Lindman, J. 1987a. Maskinell röjning införs på en skogsförvaltning _ ett beräkningsexempel. [Mechanized pre-commercial thinning introduced on a forest management district _ an economic calculation]. Forskningsstiftelsen Skogsarbeten. Resultat nr. 4. In Swedish with English summary.

[31] Lindman, J. 1987 b. Studie av Bruunett Mini på Älvsbyns revir. [Study of the Bruunett Mini on Älvsbyns forestry district]. Forskningsstiftelsen Skogsarbeten. Stencil 1987-02-02.

[32] Lounasvuori, J. 1989. Applicability of chain bladed brush saws in the tending of young stands. Arbetseffektivitetsföreningens skogsmeddelande 3 (451). In Finnish with English summary.

[33] Magnusson, S. 1987. Slutrapport röjningsmaskin Mini Brunett 678F. [Report cleningmachine Mini Brunett 678F]. Domänverket, Södra regionen, Tekniska sektionen. Intern rapport 1987-05-15.

[34] Marntell, T. 1989. Pre-commercial thinning with the Algoma K12. Sveriges Lantbruksuniversitet, Department of Forest Operations Research. Uppsatser och Resultat nr. 143. In Swedish with English summary.

[35] Mattsson, S., G. Andersson, and J. Freij. 1991. Kombinerad maskinell och motormanuell röjning. [Combined mechanized and motor-manual pre-commercial thinning]. Forskningsstiftelsen Skogsarbeten. Stencil 1991-02-06.

[36] Nilsson, F. and A. Strömgren. 1998. Economy with small-scale forwarders in the class of two and three tons and a conventional 8-ton thinning forwarder. Department of Silviculture, Section of Forest Technology, SLU Umeå. Studentuppsatser nr. 15, 1998. In Swedish with English summary.

[37] Nilsson, P. and K. Gustafsson. 1999. Skogsskötseln vid 90-talets mitt _ läge och trender. [Silviculture in the middle 1990´s _ current situation and trends]. Institutionen för Resurshushållning och Geomatik, SLU Umeå. Arbetsrapport nr. 56.

[38] Nilsson, P. (pers. com.) 2003. Swedish National Forest Inventory. Department of Forest Resource Management and Geomatics, Swedish University of Agricultural Science, Umeå, Sweden.

[39] Petré, E. 1984. Maskinell röjning med kranspetsmonterat aggregat. [Mechanized pre-commercial thinning with boom mounted felling device]. Forskningsstiftelsen Skogsarbeten. Redogörelse nr. 4, 1984. In Swedish with English summary.

[40] Ryan, B.F. and B. L. Joiner. 1994. Minitab Handbook. Duxbury Press, Belmont.

[41] Ryans, M. 1988. Mechanized precommercial thinning methods: experience to date. Forest Engineering Research Institute of Canada. Special Report Nr. 56.

[42] Sabin, T. E. and S. G. Stafford. 1990. Assessing the need for transformation of response variables. Oregon State Univ. Forest Research laboratory, Corvallis, Special publication 20.

[43] Weisberg, S. 1985. Applied linear regression. Second Edition. John Wiley & Sons New York.

[44] Wästerlund, I. 1990. Damage to the ground and the stand after mechanized cleaning. Sveriges Lantbruksuniversitet, Department of Forest Operations Research. Uppsatser och Resultat nr. 193.

[45] Zar J. H. 1999. Biostatistical analysis. 4th edition. Prentice-Hall, Upper Saddle River, New Jersey. ISBN 0-13-081542-X.