Vol. 16, No. 2 July 2005

Han-Sup Han

University of Idaho

Moscow, ID, USA

Chad Renzie

University of Northern British Columbia

Prince George, BC, Canada

The authors are, respectively, Assistant Professor, Department of Forest Products, College of Natural Resources, and Graduate Research Assistant, Forestry Program.

ABSTRACT

Stump heights were measured on six clear-cut blocks in the central interior of British Columbia using a systematic sampling method. Felling method, ground slope, species and stump diameter were analyzed to determine their effect on stump height. Mechanized felling with a feller-buncher resulted in lower stumps by 5.5 cm on average than those from manual felling with a chainsaw. The wide range (9.6 cm to 23.4 cm) of the average stump heights sampled from six clear-cut units indicates that other factors such as slope, species and stump diameter may influence stump height. When considering tree species, the feller-buncher left lower stump heights for subalpine fir and white spruce, while chainsaw felling resulted in lower stumps for Douglas-fir. Average stump and feller-buncher stump heights tended to increase as percent slope increased up to 45%, but the opposite trend was found in chainsaw felled sites with slopes greater than 45%. Both feller-buncher and chainsaw felling methods resulted in lower stumps as the average stump diameter increased. On ground slopes less than 30% and stump diameters between 30 and 70 cm, our analysis suggested that feller-buncher felling resulted in lower stump heights than chainsaw felling. Chainsaw felling can cause stump-pulls, slabs, and unevenness at the bottom of the tree being felled, requiring a further reduction of wood that could potentially be used for solid wood products. Feller-buncher felling, however, results in greater wood volume waste as the result of a thicker saw blade kerf than does chainsaw felling.

Keywords: mechanical felling, chainsaw, wood utilization, log quality.

INTRODUCTION

Feller-bunchers are the most typical felling machine for mechanized, ground-based harvesting systems in the interior of British Columbia (BC), often teaming with grapple skidders for off-road skidding and a processor for central processing at a landing. Feller-bunchers are highly productive machines for felling on gentle slopes, and are occasionally used on steeper ground for skyline and helicopter yarding. While feller-bunchers effectively control felling direction and bunch felled trees, large trees (>70 cm diameter at breast height (DBH)) may require multiple cuts from two or more cutting directions instead of cutting through a tree with a single-cut. Rocky ground conditions in harvesting sites can cause damage to tracks, felling teeth, and felling discs.

In general, chainsaw felling has no tree size or ground slope limitations while maintaining a reasonable production rate. It was often observed in BC that feller-bunchers leave large trees (>70 cm DBH) uncut for chainsaw felling in a mechanized harvesting operation because chainsaw felling can be more productive with such large trees. Chainsaws can also be effectively used to cut a tree at the ground level on a rocky ground with minimal concerns for equipment damage. Beside tree size and ground surface conditions, chainsaws are the primary tool for felling on steeper ground where skyline or helicopter yarding is considered for the primary transport of logs. When ground-based skidding is used, a cable skidder equipped with a winch is often teamed with chainsaw felling. Chainsaw felling in a high density stand filled with small-diameter trees, however, may not be as productive as feller-buncher felling and can raise safety concerns for chainsaw fellers because trees being felled often catch on the standing trees, instead of falling onto the ground. This situation can be severe in a light thinning treatment (i.e., smaller number of trees removed).

A conventional chainsaw felling method that uses face and back cuts is commonly used in BC. This method leaves an uneven cut at the bottom of a tree felled, which is then removed during tree processing at the landing or log processing at the mill. When the chainsaw is used for felling, stump-pull (hinge wood left in the middle of the stump) and slabbing (wood on the outside portion of the log left at the edge of the stump) may result. These uneven cuts and felling defects affect the process of manufacturing solid products such as lumber. Ryan and Han [4] found that 17% of stumps left by chainsaw felling contained stump-pull, or slabbing or both.

Ryan and Han {4] also stated that mechanized felling methods display a significantly lower average stump height than manual felling. Measured stump heights from mechanized felling were found to be 8.8 cm lower than those from manual felling (13.1 vs. 21.9 cm). Boston and Dysart [2] observed a similar trend: they found that chainsaw felling left higher stumps (21.1 cm average) compared to five other mechanized felling methods (averages of 4.6 to 14.0 cm). An average stump height of 17.7 cm was also found in three mixed forests felled using continuous disk sawheads in Virginia [6]. Boston and Dysart's' observations on leaving high stumps with mechanized felling were primarily due to the machine operator's concerns over cutting disk damage and the desire to achieve high production rates.

Under-utilization of wood fiber due to high stumps, poor bucking practices, and log breakage often occurs during harvesting operations. Wood waste can be significant if we consider the accumulative effects of such poor logging practices occurring on many harvesting sites [2, 5]. The bottom of a tree also contains the most valuable portion of each tree unless defects such as decay, butt swell, and crook are present. Lowering stump heights contributes to the maximum use of this high quality material.

High stumps are considered to be the result of poor felling practices, and BC's logging residue and waste standard requires stump height to be lower than 30 cm for all harvest sites [1]. Unless there are physical obstructions or safety precautions, waste in stumps is classified as avoidable waste that is subject to a fine if it exceeds the maximum allowable waste. Woody materials left on harvesting sites, including high stumps are considered as "under-utilized". The current BC waste standard states for the dry interior of BC that the waste per hectare has to be less than 4 m3 on each harvest unit to avoid financial penalty [1]. Based on authors' observations on felling operations in the interior BC, stump heights of less than 15 cm can be easily achieved when using a feller-buncher on gentle slopes (<30%).

Potential value loss and poor utilization of the available wood resources due to high stumps have been cited often to emphasize the importance of leaving low stumps for better utilization of wood [2, 4, 5, 6]. For example, Murphy and Buse [5] noted that approximately 30% of the value lost during the felling process is due to wood loss in high stumps. The loss is highly variable: US $30/ha (mechanical felling; [6]) to US $1,038/ha (chainsaw felling; [2]). Then-current values for sawlogs or wood chips and sensitivity analysis over several average stump heights were often used to estimate potential financial impacts due to high stumps.

High stumps can also cause negative effects on harvesting equipment, worker safety, and tree planting. There are a few exceptions that require high stumps. For example, high stumps are used as guyline anchors for skyline yarding. However, leaving low stumps normally results in benefits that include the following:

· Higher productivity of primary transport (stump-to-landing). Low stumps provide smooth surface of trails for skidding or forwarding, and allows faster turns and a more comfortable ride to the operator.

· Less machine damage to equipment and low maintenance cost. High stumps may cause high centering or stretching of equipment tracks due to the track cleats catching on high stumps.

· Reduced stand damage in partial cutting. Skidder or forwarder operators tend to avoid the high stumps within a skid trail to reduce possible hang-ups and for operator comfort (a smoother ride). This widens skid trails and can cause damage to residual trees near skid trails.

· Facilitation of the mechanical site preparations for tree planting. Forestry equipment can more efficiently move around the harvested units as low stumps do not hinder operations such as mechanical site preparations and tree planting. Site preparation cost could be reduced by as much as $US148/ha [3].

· Tree breakage during felling. Tree breakage may occur when trees are felled across or on high stumps.

· Operational efficiency during winching and yarding phases. Hang-ups due to high stumps often cause delay in skyline yarding or skidder winching.

· Promoting improved forest health. Mountain pine beetle is highly destructive insect in BC, and preventive or salvage harvesting of infested trees requires that the stumps be cut low to avoid leaving the insects in the stumps.

To lower stump height in any timber harvesting operations, it is important to clearly understand how harvesting attributes can affect final stump height. These attributes include felling methods (chainsaw vs. mechanized felling), slope, tree size, species and ground conditions. A number of previous studies investigated average stump height and potential wood waste associated with high stumps resulting from chainsaw and mechanized felling, but did not effectively evaluate other variables determining stump height . The objective of this study was to compare two felling methods, namely chainsaw and feller-buncher, in relation to stump height through the relationship between the response variable (stump height) and the independent variables (ground slope, stump diameter, and species). These outcomes should help maximize potential benefits that can accrue from leaving lower stumps.

STUDY METHODS

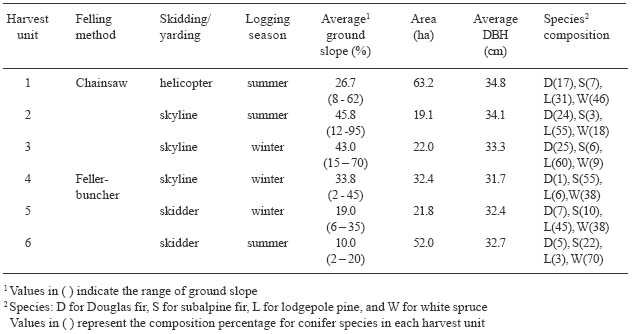

Six clearcut sites were randomly selected near Prince George located in central BC, based on availability for the study, felling methods used, and logging season (Table 1). Conifer species including white spruce (Picea glauca (Moench.) Voss.), lodgepole pine (Pinus contorta Douglas var. latifolia Engelmann), subalpine fir (Abies lasiocarpa (Hook.) Nutt.), and Douglas-fir (Pseudotsuga menziesii (Mirb.) Franco) were the major component (>95%), mixed with some hardwood species such as paper birch (Betula papyrifera Marsh.) and cottonwood (Populus trichocarpa Torr. & A. Gray). Ground slopes varied and affected equipment selection for felling and primary transport (stump-to-landing). There was little (<20 cm) or no snow accumulation on the ground due to high crown closure and little snow falling during the winter harvesting period. Snow data for winter logging sites was not collected. Depending on depth, snow levels can become an important factor affecting stump height, but were considered to be insignificant in this study. Stems were felled with a Madill 3200B feller-buncher equipped with a 61-cm hot saw and by two chainsaw felling crews. Both machine operator and chainsaw fellers had more than one year of felling experience.

Table 1. Six study site descriptions and harvesting systems used.

Fixed, 0.1 ha-circular sampling plots were systematically located over each of the study sites. Slope was taken in both uphill and downhill directions, from the plot center. Twenty sampling plots were distributed across each study site, but some plots located on landings and unit boundaries were removed (Table 1). Total area sampled per harvest site ranged from 1.7 to 2.0 ha. The sample size was determined using the following equation and guidelines explained by Sokal and Rohlf [7]:

Where, n = number of sampling plots

ó = true standard deviation (ó = 10 cm)

ä = the smallest true difference to be detected (ä = 10 cm)

í = degrees of freedom of the sample standard deviation

á = significant level (á = 0.05)

p = the intended power of the test (p = 0.8)

On each sample plot, stump height was measured to the nearest centimeter from the ground level to the highest portion of the cut face of the stump on the high side (Figure 1). Species were identified by looking at the bark on stumps. Stumps cut purposely high for anchors for skyline yarding and creating snags for wildlife were disregarded. Average stump diameter was calculated to the nearest centimeter based on two measurements, the widest and the narrowest face of the stump surface. Stumps smaller than 15 cm in diameter were excluded from the study as they were not considered to be commercial trees. Two log defects were also observed: slab (wood left on the outside of the stump; Figure 3) and stump-pull (wood left in or cross the middle of the stump; Figures 2 and 3). Slab and stump-pull height measurements were taken for the highest points beyond the cut face of the stump. Both slabs and stump-pulls less than 10 cm in length and 2 cm in width and thickness were not recorded because they had negligible impacts on log quality.

Figure 1. Feller-buncher felled stump with no stump-pull and slab. A researcher shows the method measuring stump height.

Figure 2. Chainsaw felled stump showing uneven cut with stump-pull. Rocks near the stump can cause higher stump and make feller-buncher felling more difficult.

Figure 3. Potential wood losses from felling.

Stump height data was evaluated for outliers and normality by reviewing residual plots, scatter plots and histograms before implementing statistical data analysis. Examination of the residuals from a general linear model revealed a considerable non-constant variability across levels of species, slope and stump diameter, and thus natural logarithm transformation of stump height data was taken to stabilize variance. A General Linear Model (GLM) analysis using the SAS program version 8.02 (©1999-2001; SAS Institute) was performed to compare the average stump height between feller-buncher and chainsaw felling. The interaction between felling method and each of the other three independent variables (species, slope, stump diameter) was also examined. The effects of slope, average stump diameter, and species on stump height were assessed through Tukey-Kramer multiple comparisons, along with an analysis of covariance for each variable.

Feller-buncher felling has a higher volume of wood waste associated with the thickness of the saw blade kerf than does chainsaw felling. Based on a survey on the felling head of feller-bunchers and harvesters during the event of harvesting equipment exhibition (Forest Expo 2000) in Prince George, BC, the kerf thickness for nine models of feller-buncher ranged from 5 to 6 cm, compared to 0.75 cm to 1 cm for 7 models of chainsaw. This inherent difference (5 cm on average) of kerf thickness between feller-buncher and chainsaw was used to estimate the wood volume waste associated with each harvesting method.

RESULTS AND DISCUSSION

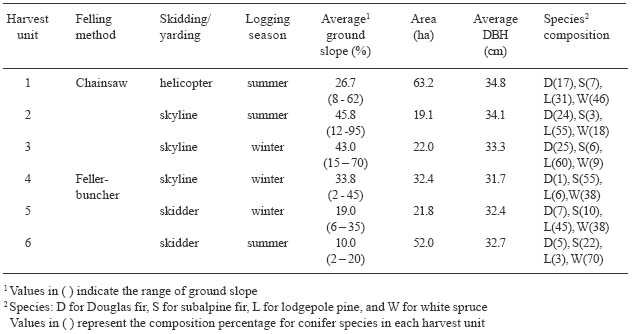

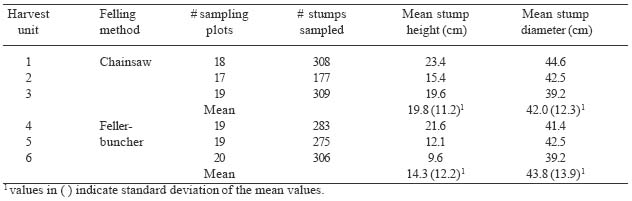

In total there were 1,658 stumps measured from six harvest units (Table 2). The average stump height (19.8 cm; n = 794) from chainsaw felling was significantly higher than the one (14.3 cm; n = 864) from feller-buncher felling (p<0.05). This study confirmed the results of a high stump study conducted by Ryan and Han [4], which indicated that chainsaw felling left higher stumps than mechanical felling. However, the difference of the average stump height between felling methods in their study (8.8 cm) was larger than the result from this study (5.5 cm).

The wide range (9.6 cm to 23.4 cm) of the average stump heights sampled from six clear-cut units indicates that other factors such as slope, species and stump diameter may influence stump height. The visual examination of the residuals from a general linear model revealed non-constant variability across three independent variables (slope, species and stump diameter) between two felling methods. The natural logarithmic transformation of the response variable (stump height) was performed to stabilize the variability. The final outcomes of the analyses were converted back to the original scale for interpretation.

SPECIES VS. TWO FELLING METHODS

Examination of the profile plot showed the feller-buncher having a lower mean stump height for the species of white spruce, lodgepole pine, and subalpine fir, but the chainsaw had the lower mean stump height for Douglas-fir (Figure 4). Two species variables were not well represented in the data set: cottonwood (n = 1) and birch (n = 3 for chainsaw felling and n =11 for feller-buncher felling). These two species were removed from the analysis data since the stump height comparison between felling methods would not be much value due to lack of observations.

Table 2. Average stump heights and diameter for six study units.

Figure 4. Mean stump heights for four species between two felling methods.

There was no significant effect of species on stump height (p = 0.0590), but an analysis of the model (ln_height = felling method + species + felling method*species) yielded a significant F-test for the interaction term of felling method*species (p<0.0001). The coefficient of determination (R2) was low at 0.082. As the interaction term is significant in this model, Tukey-Kramer multiple comparisons of the mean values were performed and showed that the differences in the mean ln_height between the two felling methods were significantly large for spruce (p<0.0001) and subalpine fir (p<0.0001), but not for lodgepole pine (p = 0.9392) and Douglas-fir (p = 0.1166). This result can be explained by butt flare that is a swell of the main stem near the ground contact area. Notable butt flare in a log can cause processing problems at an automated sawmill and is typically removed during the log preparation process. Spruce and subalpine fir are known to have a butt flare while Douglas-fir and lodgepole pine are not. A chainsaw feller intentionally cuts a tree above the obvious swelling portion as they are aware of this sawmilling requirement. A feller-buncher operator, however, cannot see well the base of the stem and swell and as a result cuts the tree at the lowest possible height given machine and cutting head constraints. The relationship between chainsaw felling and species may be explained by the market value of each species. Chainsaw fellers make additional efforts to leave low stumps when falling Douglas-fir trees because commercial value of this species is higher in BC than pine, spruce, and subalpine fir.

GROUND SLOPE VS. TWO FELLING METHODS

There was a notable difference in slope on which stump data were collected for the two felling methods; chainsaw felling stump data were collected from ground slopes ranging from 8% to 95% while stump data for feller-buncher occurred on 2 to 45% slopes with 94 percent of the data being observed at slopes of 30% or less (Figure 5). We observed that on steep slopes, chainsaw fellers often positioned themselves at the downhill side of the tree to be cut. This allows the feller to cut a tree at or close to the ground level without physically bending to a great degree (i.e., 90 degree), assisting the feller in cutting stumps low. Flat ground often requires chainsaw fellers to increasingly bend to cut a tree at ground level, resulting in stress on a feller's arms, back, and legs.

We examined the effect of felling method and slope on stump height using the second model (ln_height = felling method + slope + felling method*slope). The profile plot of the interaction term showed consistently lower mean stump heights for the feller-buncher felling for 2 to 32.5% slopes (Figure 5). Four exceptions to the trend occurred at 10, 17.7, 22.5 and 27.5%. A multiple comparison analysis with Tukey adjusted significance levels was performed to evaluate a statistical difference between two felling methods over a wide range of ground slope. Comparisons over the range of 2 to 17.5% showed that there was no significant difference between the two felling methods (p>0.05). The mean stump height for chainsaw felling, however, was significantly higher than those of the feller-buncher felling for 20 to 28.5% slopes (p <0.0066). At 45% slope, the reverse of the trend occurred, where chainsaw felling left a significantly lower mean stump height than feller-buncher felling (p<0.0001). There were no other observations for feller-buncher felling data beyond a 45% slope.

Figure 5. Mean stump heights between two felling methods over a range of ground slope

Applying the method of analysis of covariance over an interval of 2 to 30% slope allowed further interpretation of the relationship between the felling method and ln_height. This analysis method essentially was to fit regression lines to the data, and the slopes of these lines were then compared to determine the presence of interaction between two felling methods over the interval of interest. The interaction between two felling methods was not significant (p = 0.1710), indicating that the regression lines were parallel. In the presence of parallelism, a test for the main effects of two felling methods was significant (p<0.0001). Significance of the test for main effects indicated that the expected mean stump height resulting from chainsaw felling was 1.68 cm higher than the one that resulted from feller-buncher felling over a slope range of 2% to 30%.

STUMP DIAMETER VS. TWO FELLING METHODS

Both feller-buncher and chainsaw felling methods tended to leave lower stumps as the average stump diameter increased (Figure 6). This trend was more significantly noticeable with feller-buncher felling (p<0.05), but no significant relationship was found between the average stump size and stump height for chainsaw felling (p>0.05). The overall average stump diameter inside bark (n = 1658) was 43.2 cm with a standard deviation of 14.6 cm.

Figure 6. Mean stump heights between two felling methods over a range of stump diameter.

In implementing the model (ln_height = felling method + diameter + felling method*diameter), the interaction term between felling method and diameter was significant at a 0.036 level. Comparisons were conducted by assessing the presence of overlap between confidence intervals computed for the two felling methods at each diameter value. Bonferroni correction was used to control the Type I error rate at 0.05. The results of these comparisons indicated that there were no statistically significant differences in mean values between two felling methods for stump diameter (p>0.05).

Further inspection of the profile plot revealed a diameter interval between 30 to 70 cm where mean ln_height was consistently lower for the feller-buncher felling over chainsaw felling (Figure 6). An analysis of covariance over this interval allowed for the fitting of separate regression lines to each of the felling methods. A test for interaction over the diameter interval of interest was insignificant (p = 0.5313), indicating that two separate lines were parallel to each other. A subsequent test of felling method effect also indicated that there was a significant difference between two felling methods at a difference of 1.44 cm over the diameter interval of interest (p<0.0001).

WOOD WASTE DUE TO KERF THICKNESS AND POOR FELLING PRACTICES

On average, the feller-buncher uses cutting teeth 5-cm thicker than the one used on chainsaws. This inherent difference of kerf thickness translates to an additional 0.44 m3 of wood waste per hectare from feller-buncher felling, compared to chainsaw felling if the average stump diameter is 43 cm and 650 stems per hectare are removed. Wood volume waste associated with the thickness of the kerf can be significant when considering the number of trees that are cut by a feller-buncher during it's life and that feller-bunchers are one of the most common types of felling equipment being used on gentle grounds. Chainsaw felling, however, often used a face-cut to control felling direction, resulted in the uneven bottom of a felled tree. This may require an additional cut to remove the unevenness at the landing or during the process of lumber manufacturing. The potential wood losses are illustrated in the Figure 3.

For chainsaw felling, wood was ripped away from the center (stump-pull) or the side (slab) of the tree and remained attached to the stump as it falls. Stump-pulls and slabs higher than 10 cm appeared on 4.1% (20 out of 485) of the manually felled stumps with an average height of 38.2 cm. Our field observation during data collection indicates that large size trees tend to have a higher proportion of stump-pull, as saws may not have been able to cut cleanly through the tree. This can cause a length reduction of boards produced from the wood volume affected by stump pull and slab.

CONCLUSION

Mechanical felling resulted in lower stumps, by an average of 5.5 cm, relative to chainsaw felling, but stump height was significantly affected by species, slope, and average stump diameter. Feller-buncher felling left lower average stump heights for the species of subalpine fir and white spruce. For the analysis of average stump height over a range of ground slope, the feller-buncher felling method produced lower average stump heights between 2 to 30% slope. Similarly the average stump heights resulting from feller-buncher felling were lower than those from chainsaw felling for diameters between 30 and 70 cm. Thus, feller-buncher felling would be a better choice than chainsaw felling for ground slopes less than 30% and stump diameters between 30 and 70 cm. Additionally, when considering the harvesting of subalpine fir and white spruce, the feller-buncher left lower stump heights, although changing felling method between chainsaw and feller-buncher in a mixed confer stand may not be practical.

Felling defects (stump-pull, slab and uneven cut) from chainsaw felling cause additional wood waste to the value loss due to high stumps. Feller-buncher felling, however, results in more wood volume waste associated with the thickness of saw blade kerf than does chainsaw felling. Harvesting trees close to the ground level helps not only improve potential value recovery, but also allows higher operational efficiency for the follow-up tasks such as log extraction and planting activities. Besides the few exceptions, the operational and economic benefits of lower stump heights outweigh that of high stumps.

AUTHOR CONTACT

Prof. Han can be reached by e-mail at --

hanh@uidaho.edu

REFERENCES

[1] BCMOF (British Columbia of Ministry of Forestry). 1994. Provincial Logging Residue and Waste Measurement and Procedures Manual. British

[2] Boston, K. and G. Dysart. 2000. A comparison of felling techniques on stump height and log damage with economic interpretation. West. J. Appl. For.15(2):59-61.

[3] Dubois, M. W.F. Watson, T.J. Straka, and K.L. Belli. 1991. Costs and cost trends for forestry practices in the South. For. Farm. (Manual Ed.) 50(3):26-32.

[4] Hall, R. and H.-S. Han. 2004. A comparison of mechanized and manual felled stump heights in north-central British Columbia. A manuscript submitted to West. J. Appl. For. for review. 19 p.

[5] Murphy, G. and J.D. Buse. 1984. How to reduce felling related butt damage. LIRA Tech. Release. 6:6.

[6] Shaffer, R.M. and R.S. Taumas. 1992. A comparison of sheared and sawhead-felled stump heights on six nonindustrial private timber sale in southeastern Virginia. South. J. Appl. For.16(3):140-142.

[7] Sokal, R.R. and F.J. Rohlf. 1995. Biometry: the principles and practices of statistics in biological research. Third edition. W. H. Freeman and Company, New York. pp. 261-265.