Vol. 15 No. 2, March 2004

K. Suadicani

The Danish Centre for Forest,

Landscape and Planning

Hoersholm, Denmark

The author is Senior Consultant at the Danish Centre for Forest, Landscape and Planning.

ABSTRACT

Close-to-nature forestry may contribute to fulfil the objective of sustainable forestry. In western Denmark conversion of even-aged monocultures of Norway spruce to more stable stands has high priority, and must be done before close-to-nature forest management systems such as selection management can be implemented. Shelterwood regeneration in medium-aged Norway spruce stands seems to be the most promising method for conversion. Time consumption and damages were studied on the different harvesting methods in the establishment of the shelterwood. The traditional cut-to-length system gave higher net income than the fuel chip harvesting systems, but changes in price relations or lower stand quality might reverse this. The damage rate of remaining trees seems to be negatively correlated with the productivity of the logging/chipping operation.

Keywords: harvesting systems, productivity, thinning, time study, work quality, Picea abies L., Denmark

INTRODUCTION

In the temperate forests of Europe Norway spruce (Picea abies L.) has been planted far beyond its natural range, because is has been considered economically superior to other species [22]. Unfortunately many of these stands have shown symptoms of ecological instability, and many efforts are made in order to convert such Norway spruce stands to other types of stands. [e.g. 16, 19, 20]. Although not indigenous, Norway spruce dominates the heath-land plantations in western Denmark. Here, it also shows symptoms of ecological instability. It is susceptible to windthrows, to root and butt rot (mostly Heterobasidion annosum (Fr.) Bref. and Armillaria mellea (Vahl ex Fr.) Kumm.), to drought, warm winters, and to air pollution [4, 10]. A conversion of parts of the heath plantations is therefore highly prioritised in Denmark. Shelterwood regeneration is the most promising system [12], but little knowledge of operational aspects exists.

In the windy climate of western Denmark shelterwoods in mature stands are often subject to windthrows. Less tall stands are more wind-resistant, and therefore shelterwood regeneration in medium-aged stands (height <15 meters) has been proposed [9, 15, 18]. Neckelmann [17] demonstrated that the stability was good in such stands, and the diameter increment on the shelter trees was high, provided the stand was vigorous. Because of the smaller size of the individual trees, shelterwoods in medium-aged stands must consist of more trees as compared to shelterwoods in fully-grown stands.

Establishment of shelterwoods in medium-aged stands can be achieved by cut-to length harvesting of industrial round wood, as whole-tree chipping of fuel-chips or as integrated harvesting (combined production of industrial round wood and fuel-chips). In stands without too much root rot, the cut-to length system is expected to give the best economic result, while the whole-tree chipping system is an option in stands of poor quality. Integrated harvesting might be superior if high quality saw logs can be produced in the butt end, while the top end is not suitable for production of round wood assortments. The cut-to length system is quite well known. The system has been analysed in detail with most efforts laid in studies of single-grip harvester productivity [3, 5, 6, 7, 11, 14]. In operational terms, the establishment of a shelterwood is a thinning. Some other selection criteria might be chosen, especially if site preparation follows, but the cut-to length system is well known in such thinning operations. The widely used in-terrain whole-tree chipping system [8] is developed for thinning in younger stands and must be adapted to the larger tree size than it was originally designed for. A consequence of introducing chipping systems in stands with larger tree-size is that integrated harvesting might become an alternative to whole-tree chipping.

The aim of the study was to determine productivity, costs, and damage rate in the establishment of a shelterwood in a medium-aged Norway spruce stand. Conventional cut-to-length harvesting, three whole-tree-chipping systems and one integrated harvesting system were analysed.

MATERIALS AND METHODS

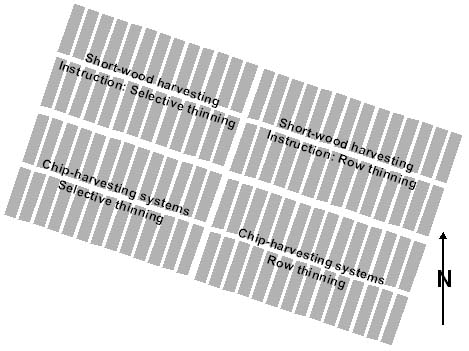

The study took place in north-western Denmark. Terrain conditions for the site were very good, but the soil was poor and sandy and covered by a layer of raw humus. Ninety five percent of the trees were Norway spruce, but some silver fir (Abies alba Mill.), grand fir (Abies grandis Lindl.), Scots pine (Pinus Silvestris L.) and larch (Larix decidua Mill.) were also found. A striproad system divided the stand into 108 plots (57´15m) each consisting of approximately 9 tree rows. Cut-to length harvesting (two thinning methods termed row and selective thinning) was performed in one part of the stand. In the other part, three whole-tree-chipping systems and one integrated-harvesting system were studied. The harvesting studies resulted in one part of the stand where site preparation implements had easy access to the stand (row thinning), and one part of the stand where the distribution and quality of the shelter trees was given priority (selective thinning) (Figure 1).

Figure 1. Study design.

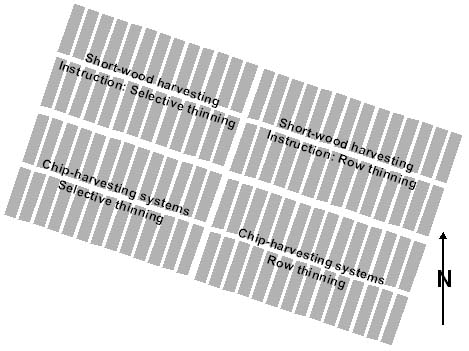

A Silvatec 656 TH harvester and a Valmet 820 forwarder did the cut-to length harvesting operating from striproads parallel to the tree rows. In selective thinning, the instruction was to leave 50-60% of the most vigorous trees uniformly spaced. In row thinning, the instruction was to remove every second tree row in order to obtain easy passage for site preparation implements (row 2 and 4 in Figure 2). A tree row was not to be removed, if this would cause larger gaps in the stand structure. If so, the adjacent tree row should be removed (shifting row for a distance), still having in mind easy passage for site preparation implement [25].

Figure 2. Cut-to-length harvesting from the striproads.

The whole-tree chipping systems had different felling operations (1) Motor-manual felling, (2) felling and bunching at the striproads with a Silvatec 854 TH feller-buncher and (3) felling in herringbone pattern with a Silvatec 656 TH harvester. The integrated harvesting (4) was also performed by felling in herringbone pattern with the Silvatec 656 TH harvester, but the felling included production of a piece of saw log in the butt end when possible. All chipping was performed in the stand with a Fendt Favorit 614 LSA/TP-960 chip-harvester, and a Fendt 308/Spragelse did the terrain transportation. As with the cut-to-length system no trees were marked prior to felling [24].

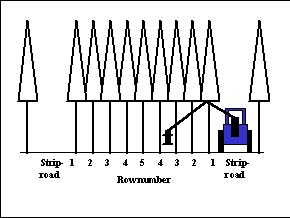

The feller-buncher could not handle trees if the boom was overly extended. Therefore the feller-buncher felled tree row number 2 closest to the striproad, while motormanual felling was conducted in tree row 4 further away from the striproad (Figure 3). Felling in herringbone pattern and integrated harvesting was done as selective thinning.

Figure 3. Tree rows felled with feller-buncher (FEBU) and motormanually (MOMA).

The stands were measured both before and after harvesting. Productive work time for harvesting and extraction were recorded in continuous time studies using SIWORK3 software and a Husky Hunter computer. All analyses were done in SAS version 6.12 [1, 2]. Work place time was calculated according to Samset [21]. Damages to the remaining trees were recorded after both harvesting and extraction.

RESULTS

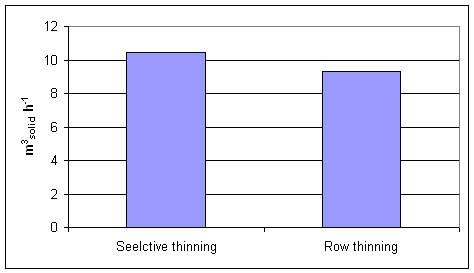

The cut-to-length system resulted in lower productivity if trees were harvested far away from the striproad, and productivity was lower in row thinning compared to selective thinning (Figure 4).

Figure 4. Productivity of the cut-to-length system in row and selective thinning.

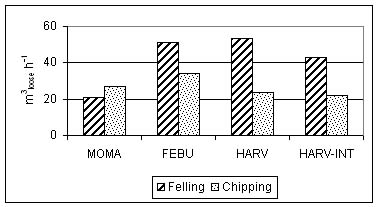

The highest chipping productivity was found in the feller-bunched areas, while the productivity was low where the harvester did the felling in the herringbone pattern. Felling productivity was approximately the same for the feller-buncher and the harvester, while integrated harvesting took longer time. Motor-manual felling was the most cost-effective felling method (Figure 5)

Figure 5. Felling and chipping productivity. (MOMA=felled motormanually, FEBU= Felled with a feller-buncher, HARV=Felled in herringbone pattern with a harvester, HARV-INT= Felled in herringbone pattern with a harvester and a piece of industrial roundwood was cut off from the butt end if possible).

The income was higher for the cut-to-length harvesting and integrated harvesting than for whole-tree chipping, while the costs were higher for integrated harvesting and whole-tree chipping after felling in herringbone pattern with a harvester than for whole-tree chipping of trees in lines and cut-to-length harvesting. Cut-to-length harvesting therefore gave the highest net-income (Table 1).

Table 1. Income and costs at roadside ($ ha-1).

| Cut-to-length harvesting | Whole-tree chipping | Integrated harvesting |

||||

| Row thinning | Selective thinning | Motor-manual felling | Feller-buncher felling | Harvester felling | ||

| Income at roadside | 1828 | 1828 | 1512 | 1512 | 1512 | 1796 |

| Costs at roadside | 1337 | 1259 | 1255 | 1247 | 1708 | 1664 |

| Net income | 491 | 568 | 257 | 265 | -196 | 132 |

In the analyses of injuries to the shelter trees, it was found that the most efficient systems seems to cause the least damage to the remaining trees. Difficulties in the work (as seen in row thinning in cut-to-length harvesting and in chipping of trees in herringbone pattern) resulted in more injuries on the shelter trees (Figure 6).

Figure 6. Rates for damages on shelter trees.

Display large image of Figure 6

DISCUSSION

Cut-to-length harvesting productivity was as expected by Brunberg et al. [3]. Cut-to-length harvesting productivity was lower in row thinning as compared to selective thinning because residual trees obstructed the harvesting more (more trees were left in tree row 1 closest to the striproad).

The absence of root rot was the principal reason why cut-to-length harvesting turned out to be more economical than whole-tree chipping. If root rot had been present, time consumption would have increased, and yield of sawlogs and pulpwood would have decreased resulting in a lower net income in cut-to-length harvesting. If only pulpwood were produced (the saw-logs prices were reduced to pulpwood prices), the income would decrease with more than 500 $ ha-1 reducing the net income to round zero, and whole-tree chipping would be more economical than cut-to-length harvesting. Integrated harvesting would also be negatively affected by root rot, while it would have little influence on whole-tree chipping.

Since the study, prices on industrial roundwood have decreased 15-20% in Denmark. Using the lower prices would also equalise the economic outcome from cut-to-length and whole-tree chipping.

The productivity in motormanual felling and felling with feller-buncher was in line with former studies of harvesting smaller trees. Chipping productivity is also in line with former studies [13].

The feller-buncher was too small to handle large trees in an upright position especially if the boom was overly extended. If the feller-buncher were to be used on the whole area it would have been necessary to add an extra striproad between the original striproads to reach all the trees. Alternatively a larger feller-buncher should have been used. Felling in herringbone pattern did not work well because the trees were not placed properly for chipping, but a chipper able to feed trees lying more angled to the striproad might have changed the conclusion. Chipping costs comprised at least 70% of the harvesting costs at roadside, and therefore easy feeding of the chipper must be given priority.

There seems to be a lower damage rate where the harvesting systems worked well. Siren [23] came to the same conclusion when he studied damages from harvesting with a single-grip harvester.

CONCLUSION

If prices on industrial round wood happen to be low, it might be relevant to produce whole-tree chips in medium-aged Norway spruce. Anyhow, in good quality stands the cut-to-length system is expected to give the best outcome, while whole-tree chipping might be relevant in stands affected by root rot and in stands of poor quality.

AUTHOR CONTACT

Kjell Suadicani can be reached by email at --

kjs@fsl.dk

REFERENCES

[1] Anon. 1989a. SAS/STAT® User's Guide Version 6, Forth Edition, Volume 1. 943 pp. SAS Institute Inc. Cary, NC. ISBN 1-55544-376-1.

[2] Anon. 1989b. SAS/STAT® User's Guide Version 6, Forth Edition, Volume 2. 846 pp. SAS Institute Inc. Cary, NC. ISBN 1-55544-376-1.

[3] Brunberg T., A. Thelin, and S. Westerling, 1989. Underlag för prestationsnormer för engreppsskördare i gallring. [Basic data for productivity standards for single-grip harvesters in thinning]. Forskningsstiftelsen Skogsarbeten Redogörelse 3: 25 pp. ISSN 0346-6671 (in Swedish).

[4] Clausen, J. T. 1995. Fra hedeplantage til skov. [Conversion of heath plantations into forests]. In Forfang, A.-S., P. Sørensen, and P. Feilberg [Eds.] 1995. The forestry's green alternative. A debate book about close-to-nature forestry. Nepentes Forlag, Århus. pp. 37-42 pp. ISBN 87-89519-11-6. (in Danish).

[5] Eliasson, L., J. Bengtsson, J. Cedergren and H. Lageson, 1999. Comparison of single-grip harvester productivity in clear- and shelterwood cutting. J. For. Eng. 10:1 pp. 43-48. ISSN 0843-5243.

[6] Fjeld, D. 1992. Snauhogst og skjermstillingshogst - en sammenligningsstudie av tidsforbruk ved mekanisert hogst. [Selective cutting and shelterwood cutting. A comparative study of time consumption in mechanical harvesting]. Aktuelt fra Skogforsk 11: 21 pp. ISBN 82-7169-518-5 (in Norwegian).

[7] Fjeld, D. 1994. Time consumption for selection and patch cutting with a one-grip harvester. Communications of Skogforsk 47.4: 28 pp. ISBN 82-7169-691-2.

[8] Hakkila, P. 1990. Comminution in conjunction with integrated biomass harvesting. - In Hudson, B. [Ed.] 1990. IEA/BA TASK VI activity 2 Integrated harvesting systems workshop. Copenhagen, Denmark May 30, 1990. Forestry Research Paper 1990:2 Aberdeen University. pp. 22-31. ISBN 1 873502-05-2.

[9] Henriksen, H. A. 1971. Betragtninger vedrørende hedeskovenes foryngelse belyst ved et par eksempler. [Reflections on the regeneration of the heath plantations illustrated by some examples]. Dansk Skovf. Tidskr. 1/71: 1-29. (in Danish).

[10] Hviid, A. 1957. Dyrkning af rødgran på mager bund. [Silviculture of Norway spruce on poor soils]. Dansk Skovf. Tidsskr. 42: 73-132. (in Danish).

[11] Hånell, B., T. Nordfjell and L. Eliasson, 2000. Productivity and costs in shelterwood harvesting. Scand. J For. Res. 15:561-569 ISSN 0282-7581.

[12] Jakobsen, M. K. and J. Emborg, 2000. Transformation of spruce monocultures to mixed stands with heterogenous structure on nutrient poor soils in Denmark. - In Klimo, E., H. Hager, and J. Kulhavý [Eds.] 2000. Spruce monocultures in central Europe - Problems and prospects. pp. 53-61. EFI Proceedings 33/2000 ISSN 1237-8801.

[13] Kofman, P. D. 1993. Flishugning. Dokumentation af nuværende systemer [Chipping. Documentation of existing systems]. Maskinrapport 12 Miljøministeriet, Skov- og Naturstyrelsen. København. 39 pp. ISBN 87-601-3947-1 (In Danish).

[14] Lageson, H. 1997. Effect of thinning type on the harvester productivity and on the residual stand. J. For. Eng. 8:2 7-14 ISSN 0843-5243.

[15] Løfting, E. C. L. 1949. Rødgranplantagernes foryngelse i de jyske hedeegne. 1 del: foryngelsesproblemerne. [Regeneration of Norway spruce in the Danish heath regions. First part: Problems of the regeneration]. Forstl. Forsøgsv. Danm. 18: 327-383. (in Danish).

[16] Matthes, U. and U. Ammer, 2000. Conversion of Norway spruce (Picea abies L.) stands into mixed stands with Norway spruce and beech (Fagus sylvatica L.) - Effects on the stand structure in two different test areas. - In Klimo, E., H. Hager and J. Kulhavý [Eds.] 2000. Spruce monocultures in central Europe - Problems and prospects. pp. 71-80. EFI Proceedings 33/2000 ISSN 1237-8801.

[17] Neckelmann, J. 1995: To foryngelsesforsøg i rødgran på midtjysk hedeflade. [Alternative regeneration methods in Norway spruce on poor, sandy soil]. Forskningscentret for Skov & Landskab, Hørsholm. Skovbrugsserien nr. 16-1995. 212 s. ill. ISBN 87-89822-52-8. (In Danish.) English summary in: Heding, N. [Ed.] 1995: Forest Operations in Multiple-Use Forestry - A NSR Project. Danish Forest and Landscape Research Institute, Denmark. 103 pp. ISBN: 87-89822-54-4.

[18] Oksbjerg, E. 1951. Rødgranplantagernes foryngelse i de jyske hedeegne. 2. del: Underplantning, selvsåning og renafdrift. [Regeneration of Norway spruce in the Danish heath regions. Second part: Planting under shelterwood, natural regeneration and clearcutting]. Forstl. Forsøgsv. Danm. 20: 165-228 (in Danish).

[19] Otto, H. J. 1995a. Standörtliche Veraussetzungen, Ziele und Waldbautechnik in Fichten-Buchen-Mischbeständen des Harzes. Teil I: Leistungsstruktur und Geschichte der Mischbestände von Fichte un Buche im Harz. [Site conditions, aims and silviculture of mixed spruce/beech stands in the Harz mountains. Part 1: Sites, structure and history of mixed stands of spruce and beech in the Harz Mountains]. Allg. Forst-u. J.-Ztg 157. Jg., 10: pp. 188-196. (in German).

[20] Otto, H. J. 1995b. Standörtliche Veraussetzungen, Ziele und Waldbautechnik in Fichten-Buchen-Mischbeständen des Harzes. Teil II: Möglichkeiten und Waldbautechnik von Mischbeständen der Fichte und Buche im Harz. [Site conditions, aims and silviculture of mixed spruce/beech stands in the Harz mountains. Part 2: Aims, possibilities and silviculture in mixed stands of spruce and beech in the Harz Mountains]. Allg. Forst-u. J.-Ztg 157. Jg., 11: pp. 214-1222. (in German).

[21] Samset, I. 1995. 150 år i forsøksskogen. [150 years in the research forest]. Skogforsk. Rapport 9/95: 302 pp. ISBN 82-7169-736-6. (in Norwegian).

[22] Schmidt-Vogt, H. 1987. Die Fichte. Ein Handbuch in Zwei Bänden. [The spruce. A handbook in two parts]. 2nd edition. Paul Parey, Hamburg and Berlin. 647 pp. ISBN 3-490-09916-8 (in German).

[23] Sirén, M. 2001. Tree damage in single-grip harvester thinning operations. J. For. Eng. 12:1 pp. 29-38. ISSN 0843-5243.

[24] Suadicani, K. 2003. Production of fuel chips in a 50-year old Norway spruce stand. Biomass and bioenergy 25:1 pp 35-43. ISSN 0961-9534.

[25] Suadicani, K. and T. Nordfjell, 2003. Operational aspects of row and selective thinning in the establishing of a shelterwood in a medium-aged Norway spruce stand. J. For. Eng. 14:1 pp. 25-37. ISSN 0843-5243.