Vol. 15 No. 2, March 2004

Kalle Kärhä

Metsäteho Oy

Helsinki, Finland

Esa Rönkkö

University of Helsinki

Helsinki, Finland

Seppo-Ilmari Gumse

TTS Institute

Rajamäki, Helsinki

The authors are, respectively, Senior Research Specialist in the sectors of wood procurement and wood handling technology, and resources and productivity at Metsäteho Oy, Researcher at the Department of Forest Resource Management, Faculty of Agriculture and Forestry at the University of Helsinki and external Researcher at the Department of Forestry at the TTS Institute.

ABSTRACT

High harvesting costs are the main problems in first thinnings. Machines with lower operating costs could be one potential solution for cost-efficient first thinnings. The research investigated the productivity of the four most widely used small harvesters, i.e. thinning harvesters, and their cutting costs. Data were also collected on the productivity relationships between working methods and the differences between operators. In the time studies involving thinning harvesters, the Nokka Profi and Timberjack 770 represented the larger, more expensive machines, while the Sampo-Rosenlew 1046X and Valtra Forest 120 represented the more compact, less expensive thinning harvesters.

The productivity per operating hour (E15 including delay times shorter than 15 minutes) of the thinning harvesters was found to be 5.6-10.3 m3/ E15 (stem size 50-100 dm3) in first thinnings and 9.1-12.7 m3/ E15 (100-150 m3) in second thinnings. The productivity figures of the individual machines were similar. The differences were mainly attributable to the operators. The time study showed that the differences between operators using the same machines were as great as 40%.

The cutting costs for the thinning harvesters were 7.5-14.2 US$/m3 (50-100 dm3) in first thinnings when using the Nokka/Timberjack machine group. The corresponding costs for the Sampo/Valtra machine group were 5.7 and 10.5 US$/m3. It would appear that thinning harvesters can be operated at the same productivity level of medium-sized harvesters in thinnings and, consequently, they can be run at cutting costs lower than those of medium-sized harvesters.

Keywords: thinnings, harvesters, productivity, cutting costs, operators, time study, Pinus sylvestris, Finland.

INTRODUCTION

In Finland, forest management and wood production are based on thinnings. There are usually two or three commercial thinnings before final cutting. The first thinning is carried out when the age of the stand is 25-45 years [4]. According to the National Forest Programme, the estimated need for first thinnings is 250,000 hectares per year in Finland [1]. However, during the past five years only 125,000 - 177,000 hectares have been thinned per year [26-30]. Moreover, first thinnings are running late on a total area of 400,000 hectares [25]. High harvesting costs are the main problems in first thinnings. Small stem size, low removal per hectare, high number of remaining trees and dense undergrowth mean low productivity and high harvesting costs.

Nowadays, nearly 90% of first thinnings in Finland are mechanized [31]. The majority of first thinnings are made with medium-sized, single-grip harvesters, like Ponsse Beaver, Timberjack 1070 and Valmet 901. The operating hour costs of medium-sized harvesters are more than 75 US$/h. Machines with lower operating costs could be one potential solution for cost-efficient first thinnings. In 2002, the average cutting costs in mechanized first thinnings carried out by the forest industries and the Finnish Forest and Park Service were 12.2 US$/m3 [31]. The first-thinning cuttings amounted to 3.2 million m3 in 2002. More than half of the volume of first-thinning cuttings came from Scots pine (Pinus sylvestris L.) stands.

Thinning harvesters, i.e. small harvesters, are cheaper than larger, medium-sized ones. Lower harvester prices and lower operating costs mean lower cutting costs than those of medium-sized harvesters, unless the productivity of thinning harvesters is significantly lower than that of medium-sized harvesters. There are approximately 200 thinning harvesters in use in Finnish forests.

The aims of the study were:

The research project was carried out as a part of the HARKO research and development project "The Possibilities of Special Machines in the Harvesting Thinnings Wood". This sub-project was carried out by the TTS Institute and funded mainly by TEKES, the National Technology Agency, and the machine manufacturers. In the HARKO Project, the Finnish Forest Research Institute conducted a follow-up study of thinning harvesters and investigated the silvicultural result of the thinning harvesters. The results presented in the following concerning the productivity and costs of thinning harvesters have previously been presented in the publishing series of TTS Institute [9, 18].

MATERIAL AND METHODS

Harvesters

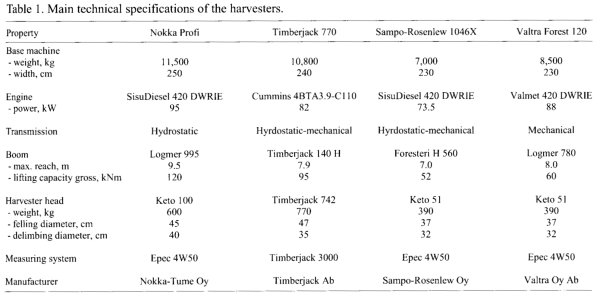

The time studies were mainly conducted in Scots pine thinning stands during the snowfree period in the fall (November 1999 at Keuruu (62o16'N, 24o42'E) in Central Finland), and also in winter conditions (February-March 2000 at Janakkala (60o52'N, 24o36'E)in Southern Finland). The thinning harvesters studied were Nokka Profi, Timberjack 770, Sampo-Rosenlew 1046X and Valtra Forest 120 (Figure 1). The Nokka Profi and Timberjack 770 represented the larger, more expensive machines, while the Sampo-Rosenlew 1046X and Valtra Forest 120 represented the more compact, less expensive thinning harvesters. Technical data about the harvesters are given in Table 1.

Figure 1. Thinning harvesters included in the study: Nokka Profi (top left), Timberjack 770 (top right), Sampo-Rosenlew 1046X (bottom left), and Valtra Forest 120. Photos: Esa Rönkkö.

Study Stands

The stands investigated in November 1999 were 33-year-old first-thinning Scots pine stands growing on dry upland sites, and 45-year-old Scots pine-dominated second-thinning stands, containing a high proportion of Norway spruce (Picea abies L. Karst.), on moist upland sites. The stands investigated during February-March 2000 were 30- to 40-year-old fresh upland Scots pine thinning stands on moist upland sites. In order to determine the technically most appropriate application areas for the harvesters, each machine also performed last thinnings and final cuttings. The stand data are given in Table 2.

Table 2. Stand data of the stands included in the time study.

| Season / Stand type | Initial stand, trees/ha | Removal, trees/ha | Average stem size, dm3 | Removal, m3/ha | Plots, no |

| Fall | |||||

| - first thinning | 1,665 | 642 | 69 | 44 | 28 |

| - second thinning | 1,073 | 349 | 124 | 44 | 14 |

| Winter | |||||

| - first thinning | 1,594 | 693 | 87 | 59 | 24 |

| - second thinning | 1,258 | 529 | 142 | 72 | 24 |

| - last thinning / final cutting | 648 | 187 | 289 | 54 | 10 |

The terrain in the marked stands was relatively easy, and the work was performed during daylight hours. All the plots with undergrowth that would affect harvesting were pre-cleared. The effect of undergrowth pre-clearance on the productivity and silvicultural harvesting result was investigated in a separate pre-clearance study [23].

A total of 100 plots, from which 14,078 trees were removed, were studied . There were 52 first-thinning plots, 38 second-thinning plots, and 10 last-thinning or final-cutting plots. There were 17-34 plots per machine. Each plot was determined on the basis of the tree stand and other factors such that at least 100 trees could be removed from each plot. The average removal per plot was 137 trees.

Operators and Working Methods

There were a total of 11 operators, some of which worked both in the fall and winter. The operators selected for the time study had to be well-skilled at thinning work. Except for one of the two Timberjack operator (Timberjack/ Operator 1), all the operators had at least three years experience in thinning work. However, some of them had not worked with cutting strips. Timberjack operator 1 had more than 10 years experience in final cutting work. There was no snow during the fall. In winter, the ground was covered with 40-50 cm of wet snow. The target length for pulpwood was 5 m, and the shortest length was 2.7 m.

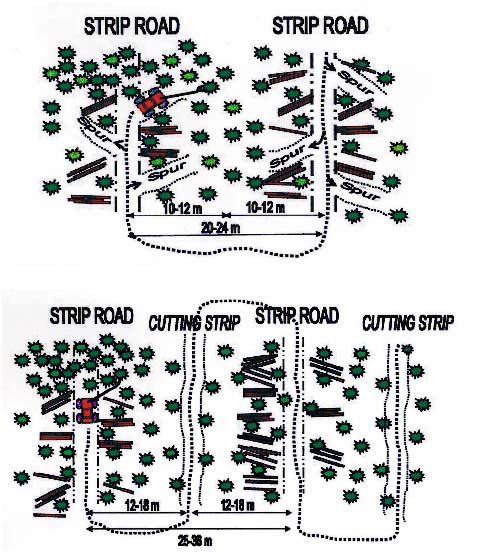

The basic method applied was thinning using a strip-road spacing of about 20 m (strip-road method) (Figure 2). Strip roads and cutting strips were not marked in advance; they were planned by the operators between cutting work. The comparison comprised thinning using one strip-road and one cutting-strip parallel with the strip-road (cutting-strip method). The minimum spacing was 20 m. The strip-road spacing averaged 25-36 m depending on the machine. Three operators also operated the Sampo-Rosenlew harvester in first thinning using a strip-road consisting of two cutting strips between two adjacent strip-roads. Thus, the strip-road spacing increased to 30-40 m.

Figure 2. Working methods used in the study: strip-road method (strip-road for harvester and forwarder (top)) and cutting-strip method (cutting-strip only for harvester). Photos: Arto Mutikainen.

Time Study

The same researcher collected all the time study material with a KTP 84 data logger using a continuous time study method (cmin). In the time study, the work cycle (i.e. all the work elements for processing one tree) was divided into the following elements:

The felled stems were measured by the measuring system of the harvester (see Table 1) to an accuracy of 0.1 dm3. The measuring systems were checked and calibrated by means of a Masser 2000 GR caliper before each study period.

Cost Calculations

The operating costs were calculated using the Metsäteho Oy machine calculation program. Operating costs include both time-dependent costs (capital depreciation, interest expenses, labor costs, insurance fees, administration expenses) and variable operating costs (fuel, repair and service, machine transfers). A currency conversion rate of 1 € = 1.172 US$ was used in the cost calculations. The harvester price was 262,170 US$ (VAT 0%) for the Nokka/Timberjack machine group and 164,530 US$ (VAT 0%) for the Sampo/Valtra machine group. Annual working hours were 2,570 operating hours. A machine utilization value of 80% was used in the calculations. The proportion of thinnings was 90% in the calculations. Average stem size was 97 dm3 in thinnings and 290 dm3 in final cuttings. The productivity per operating hour (E15 including delay times shorter than 15 minutes) was 8.2 m3/h for the Nokka/Timberjack machine group and 7.9 m3/h for the Sampo/Valtra machine group in thinnings. The productivity in final cuttings was 16.4 m3 per operating hour. The depreciation period for the base machine in the cost calculation was 4.7 years, and for the harvester head 2.3 years. An interest rate of 6.2% was applied.

The operator's salary was 10.0 US$/h with indirect salary costs (65.2%) added, and the amount of compensated work trips 41,400 km/a. The fuel consumption was 11 liters per operating hour (0.37 US$/l), and the chain oil consumption 0.7 liters per operating hour (1.62 US$/l). The chain plate costs and chain costs were estimated to be 3,180 US$/a for the Nokka/Timberjack machine group, and 3,070 US$/a for the Sampo/Valtra machine group.

Repair and service costs (including oil and lubricant costs) were estimated to be 10.1 US$ per operating hour, administration and maintenance costs 6,740 US$/a, and insurance fees 2,130 US$/a for the Nokka/Timberjack machine group, and 1.420 US$/a for the Sampo/Valtra machine group. The transferring expenses of the Nokka/Timberjack machine group were 6,560 US$/a, and the transport costs of the Sampo/Valtra machine group 6,330 US$/a in the cost calculations.

Data Analysis

Stem-specific effective times were modelled by working method, by operator, and by machine group by applying regression analysis with the volume of the merchantable section of the stem as the independent variable in most of the cases. The suitability of the models with respect to the data was numerically assessed on the basis of the degree of explanation and the statistical significance.

RESULTS

Distribution of Time Consumption

The proportion of the moving phase in first thinning using the strip-road method was 20-24%, 17-21% in the one cutting-strip method, and 22% of the effective time in the two cutting-strips method using the Sampo-Rosenlew harvester. On the other hand, the proportion of moving in second thinning was larger due to the lower density of removal: 21-27% in the strip-road method and 17-27% in the one cutting-strip method.

The share of the boom out and felling phases in first thinning using the strip-road method was 40-44%, in the one cutting-strip method 43-47%, and in the two cutting-strips method 42% of the effective time using the Sampo-Rosenlew harvester. The share of the boom out and felling in second thinning was 35-41% in the strip-road method and 35-41% of the effective time in one cutting-strip method.

Stem processing (i.e. delimbing, cross-cutting and bucking) took perceptibly less time than the time of boom out and felling. Its proportion in first thinning using the strip-road method was 25-31%, in the one cutting-strip method 26-31%, and in the two cutting-strips method 29 %. In second thinning, the proportion of processing was 29-37% in the strip-road method and 31-38 % in the one cutting-strip method.

The share of the clearing phase in first thinning by machine and by working method was 0-3% and 1-8% of the effective time in second thinning. This proportion was surprisingly high compared to the pre-clearance of the sample plots. The share of miscellaneous times by machine and by working method was 0.1-3.3% of the effective time in the time study.

PRODUCTIVITY

Stem Size

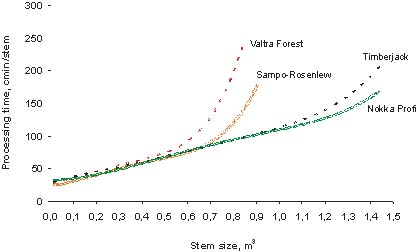

Figure 3 illustrates the processing time (boom out, felling, delimbing, and cross-cutting) per stem with different harvesters. The processing time per stem grew linearly for all harvesters up to a stem size of 0.5 m3. Processing using the Sampo-Rosenlew and Valtra Forest harvesters clearly slowed down with larger stem sizes. Thus, these machines are best suited for thinning operations. On the other hand, stem processing with the Nokka Profi and Timberjack harvesters began to slow down markedly when the stem volume exceeded 1 m3. Thus their operational range extends to last thinnings and small-sized final cuttings.

Figure 3. Stem-specific processing times (boom-out, felling, delimbing, and cross-cutting) for the different harvesters.

The effective time (moving to stem, boom out, felling, delimbing, cross-cutting, bucking, cleaning, and miscellaneous times) (E0 excluding delay times) was converted into operating time (E15 including delay times shorter than 15 minutes) using the coefficient of 1.393, which is based on time studies and follow-up studies on thinning harvesters conducted by Metsäteho Oy.

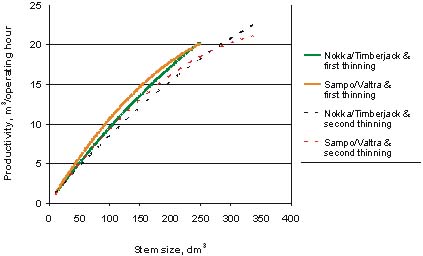

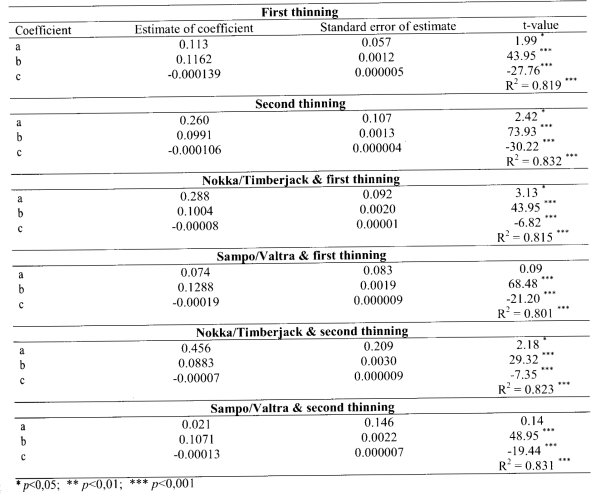

The graphs of productivity per operating hour in first and second thinnings as a function of the stem's merchantable section for the Nokka/Timberjack and Sampo/Valtra machine groups are presented in Figure 4 and Table 3. The productivity per operating hour (E15) of the thinning harvesters was 5.6-10.3 m3/h (stem size 50-100 dm3) in first thinnings, and 9.1-12.7 m3/h (100-150 dm3) in second thinnings. The productivity of the thinning harvesters was, on the average, 18.7 m3 per operating hour (290 dm3) in last thinnings. The productivity figures of the individual machines were similar.

Figure 4. Productivity per operating hour (E15) in first and second thinnings as a function of the stem's merchantable section for the Nokka/Timberjack and Sampo/Valtra machine groups.

Table 3. Overall regression models for the productivity in first and second thinnings, and regression models for the productivity of the Nokka/Timberjack and Sampo/Rosenlew machine groups in first and second thinnings.

y = a + bx + cx2 (1)

where

y = productivity, m3/operating hour

x = stem size, dm3

a = constant

b and c = coefficients of the variables

The productivity of the Nokka/Timberjack and Sampo/Valtra machine groups was slightly higher in first thinnings than in second thinnings. Low removal per hectare in second thinnings partly explains this result (see Table 2). In addition, Figure 4 shows that when the volume of trees removed was below 250 dm3, the productivity of the Sampo/Valtra machine group was higher than that of the Nokka/Timberjack machine group.

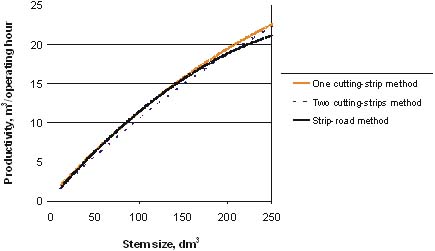

Working Methods

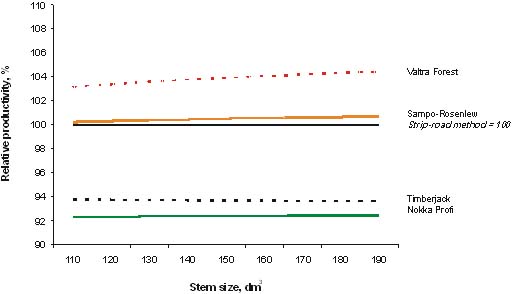

All the working methods - strip-road method, one cutting-strip method and two cutting-strips method - were used only with the Sampo-Rosenlew harvester. The productivity per operating hour in first thinnings by working method for the Sampo-Rosenlew harvester is given in Figure 5 and Table 4. There were no significant differences between the methods.

Figure 5. Productivity per operating hour in first thinnings by working method for the Sampo-Rosenlew harvester.

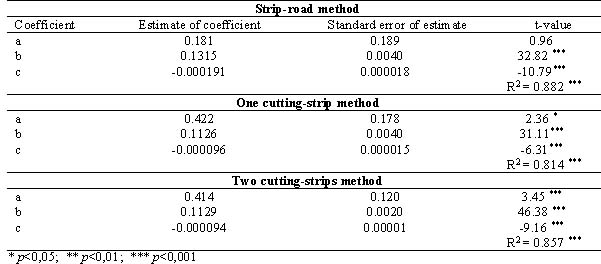

Table 4. Regression models for the productivity of the Sampo-Rosenlew harvester in the working methods used.

y = a + bx + cx2

where

y = productivity, m3/operating hour

x = stem size, dm3

a = constant

b and c = coefficients of the variables

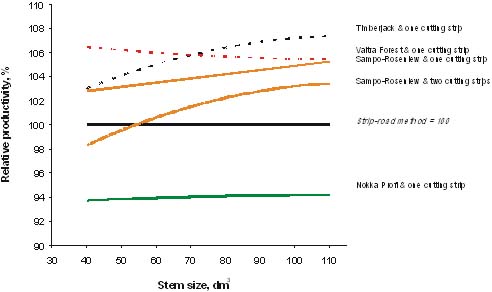

Figure 6 shows the relative productivities by working method with different harvesters as an operator average in first thinnings, and Figure 7 shows the corresponding values in second thinnings. The productivity value is set at 100 for each harvester when using the strip-road method. According to Figures 6 and 7, the harvesters cannot be compared with each other because the comparison level (100) is specific for each harvester. There were only very slight productivity differences between the working methods: in first thinnings the difference was 0-7%, and in second thinnings 0-8%.

Figure 6. Relative productivity by machine in first thinnings using the cutting-strip methods, with the productivity value set at 100 for each machine when using the strip-road method.

Figure 7. Relative productivity by machine in second thinnings, with the productivity value set at 100 for each machine when using the strip-road method.

The Nokka Profi was more efficient in thinning when operating from strip-roads instead of cutting-strips. The difference in productivity in first thinnings was 6 % and in second thinnings 8%. As the reach of the Nokka Profi's boom was 9.5 m, thinning work was efficient using strip-roads. There was no need to make spurs to catch the trees in the center stand when the interval of the strip-roads was about 20 m. The other harvesters achieved slightly better productivity values when operating along cutting strips. Short booms (8 m) required spurs to harvest the trees in the center stand.

The productivity of the Sampo-Rosenlew harvester using the cutting-strip method in first thinnings was better than that using strip-roads. The advantage of the one cutting-strip method over the strip-road method was, on the average, 3-6% and for two cutting-strips slightly less. When the stem volume was below 50 dm3, thinning using the strip-road method was more efficient than the two cutting-strips method. There was no significant difference between the strip-road and cutting-strip methods in second thinnings.

In first thinnings, the productivity of the Timberjack harvester using cutting strips was 3-7% larger than that using strip-roads. On the other hand, the situation in second thinnings was reversed; the strip-road method was approximately 6% higher. When using the Valtra Forest harvester and the cutting-strip method, the productivity in first thinnings was, on the average, 5-6% higher and in second thinnings 3-4% higher than when using the strip-road method.

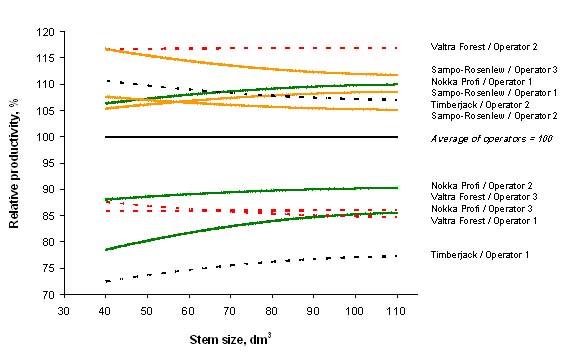

Operators

The productivity difference by operator in first thinnings using the strip-road method is presented in Figure 8. The strip-road method was the basic working method for the operator. In second thinnings, the differences between the operators were clearly smaller than in first thinnings. The differences in the operators' skill levels were especially emphasized in dense, first-thinning stands.

With the operators of Nokka Profi harvesters, the productivity differences in first thinnings using the strip-road method were 2-20% and using the cutting-strip method 3-30%. The productivity difference between Timberjack operators in first thinnings using strip-roads was 35-40% and using the cutting-strip method 30-35%. In second thinnings, the corresponding differences were 10-15%. The main reasons for the marked differences were insufficient experience in thinning work of the Timberjack Operator 1, and the use of a brand new Timberjack harvester when working in the fall.

The productivity differences between Sampo-Rosenlew harvester operators in first thinnings using the strip-road method were 0-15%, using the one cutting-strip method 15-20%, and using the two cutting-strips method 25-30%. In second thinnings, the productivity difference between operators when using the strip-road method was about 20% and with the cutting-strip method about 15%. With the operators of Valtra Forest harvesters, the productivity differences using the strip-road method were 0-35% and using the cutting-strip method clearly smaller, 0-15%.

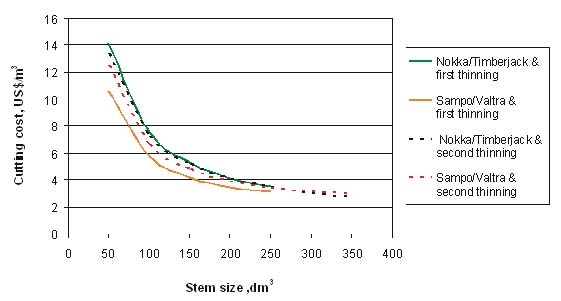

Costs

The operating hour cost amounted to 72.1 US$/h for the Nokka/Timberjack machine group and to 63.3 US$/h for the Sampo/Valtra machine group. The cutting costs of first and second thinnings are given in Figure 9. The cutting costs for the thinning harvesters were 7.5-14.2 US$/m3 (stem size 50-100 dm3) in first thinnings for the Nokka/Timberjack machine group. The corresponding costs for the Sampo/Valtra machine group were 5.7 and 10.5 US$/m3. In second thinnings, the cutting costs for the Nokka/Timberjack machine group were 5.9-8.5 US$/m3 (100-150 dm3), and the corresponding costs for the Sampo/Valtra machine group 4.7-6.7 US$/m3.

Figure 8. Relative productivity by machine and by operator in first thinnings, with average productivity for the operators set at the value 100 when using the strip-road method.

Figure 9. Cutting costs by machine group in first and second thinnings.

DISCUSSION

The time study identifies the factors that affect the work productivity. Thus, the productivity in the time studies cannot be applied directly to practical work. Especially on harvesting sites where there are several machines of competing machine manufacturers, there may be competition between the operators. In addition, the rather short working periods in the time study by no means represent practical working situations. A follow-up study gives a more reliable picture of the productivity in everyday work. In the HARKO Project, Sirén and Aaltio studied the long-term productivity of thinning harvesters [21].

The material of the study was relatively extensive. It consisted of 100 plots and about 14,000 trees harvested. Earlier studies have shown that the operator has a decisive influence on the productivity and silvicultural result in harvesting work [15, 19]. Therefore, for instance, small productivity differences in the harvesters may be caused by the operator rather than by the machine. The time study showed that the differences between operators using the same machines were as great as 35-40%.

When working with the Sampo-Rosenlew and Valtra Forest harvesters, stem processing slowed down markedly when cutting stems over 0.5 m3. The processing of larger trees required delimbing and cross-cutting to be carried out with the butt part of the stem on the ground. This is because these harvesters are light machines designed solely for thinnings. On the other hand, Nokka Profi and Timberjack 770 harvesters are slightly heavier and more expensive, and they can also be used for final cuttings. Although, stems over 1 m3 were processed in the time study, in everyday harvesting work the processing of 0.5 m3 stems is already a very slow process with these harvesters. Harvesting of large trees also sets a significantly strain on the structure of a small harvester, particularly the boom.

On the basis of the results of this study, it would appear that thinning harvesters can operate at the same productivity level as medium-sized harvesters in thinnings [e.g. 2, 3, 6, 7, 10-12] and, consequently, they could be operated to achieve cutting costs lower than those of medium-sized harvesters. The results of the follow-up study of Sirén and Aaltio are similar [21]. The high capacity and all the other properties of medium-sized harvesters cannot be fully utilized in thinnings. In 2002, the average cutting costs in mechanized first thinnings were 12.2 US$/m3 when the average stem size was 84 dm3 and the average removal 44 m3/ha [31]. As a consequence, the average cutting costs in this study were 3-5 US$/m3 lower than the aforesaid average costs.

Even though the thinning harvesters are productive and cost-efficient machines, Mäkinen [13] concluded that the profitability of thinning-harvester enterprises (i.e. enterprises operating small harvesters) is inferior in comparison with conventional forestry contracting enterprises (i.e. enterprises operating medium-sized and/or large harvesters and/or forwarders). The main reasons for the lack of profitability of the thinning-harvester enterprises are probably the degree of utilization of the machines, the low productivity of the machines in relation to the level of contracting rate, and also the relatively short experience of the entrepreneurs [8]. According to the survey of the Trade Association of Finnish Forestry and Earth Moving Contractors, thinnings are usually an unprofitable operating area for all forest machine contractors and not only for the thinning-harvester enterprises [5].

The productivity of the thinning harvesters in the follow-up study [21] was lower than that obtained in the time study. There are a number of possible explanations for the differences between the results of the follow-up and the time studies [8]. When several machines participate in comparative time studies, all the work must be carried out under the same conditions. For this reason these studies are often carried out in high volume stands with minimum undergrowth in relatively easy terrain. A comparative study can also lead to competition between the makes of machine. High productivity can also be the result of poor quality in the silvicultural result and in the size of the bundles. Time studies are often based on sample plots, while at actual work sites the whole stand is harvested. These issues could explain the differences in productivity between the follow-up and time studies.

Tahvanainen [23] investigated the effects of the pre-clearance of undergrowth on the productivity and silvicultural result of mechanized thinning in the HARKO Project. In the summer, the clearing of undergrowth was found to increase the productivity of cutting work by 13-38%. A large number of trees were damaged on the uncleared sample plots in the summer test. Approximately 9.0% of the trees left in the stand were damaged. The corresponding figure on the cleared sample plots was 5.3%. In winter, only conifer undergrowth caused a significant hindrance to cutting work. The clearing of conifer undergrowth was found to increase productivity by a maximum of about 25%. The silvicultural result proved to be good on all the winter sample plots. The average damage proportion was 0.4% on the cleared sample plots and 1.4% on the non-cleared ones.

In this research, there was no great difference in productivity between the working methods . However, the cutting-strip method was the most efficient working method in thinnings using harvesters with short booms (Sampo-Rosenlew, Timberjack and Valtra Forest) and, correspondingly, the strip-road method was most efficient when working with harvesters with long booms (Nokka Profi). In previous time studies, the productivity of cutting work using strip-roads has been 9-30% higher than that using cutting-strips [e.g. 17, 22, 24].

The Finnish Forest Research Institute investigated the silvicultural result in a sub-project [20]. The silvicultural harvesting result with all the machines and working methods was good. Damage caused by harvesting to retention trees varied within the range of 1.2 - 1.8% in first thinnings when using the strip-road method, 2.3 - 4.7% when using the one cutting-strip method, and 0.8 - 6.1% with the two cutting-strips method. When using cutting-strip methods the damaged trees were mainly concentrated near to cutting strips. In second thinnings, the damage to retention trees varied within the range of 3.7 - 4.3% when using the strip-road method, and 0.4 - 1. % when using the one cutting-strip method. According to the norms of the Forestry Development Centre Tapio, thinning is carried out well with respect to tree damage when the damage percentage is at the most 5% [14]. In Finland, the damage percentage in thinnings has been 2.2 - 3. % during the past five years [16].

The use of cutting strips appeared to increase the number of damaged trees in first thinnings. Sirén and Tanttu [22] obtained similar results when harvesting in the first thinning of a pine bog. In their time study, the amount of tree damage incurred using the cutting-strip method was more than double that of the strip-road method. Cramped working space along narrow cutting strips and the considerable need for shifting the felled trees in order to bring the prepared timber within reach of the forest-haulage machine probably explains the greater risk of damage [22].

When using a strip-road spacing of 20 m for the thinning-harvester chain, the number of remaining trees increased with increasing distance from the strip-road [20]. When applying the cutting-strip method, the distribution of the remaining trees was more even. This observation is also supported by the results obtained by Sirén and Tanttu [22]. Terävä [24] reported that the trees in the retention stand were more evenly spaced when using strip-roads when than using cutting strips.

In dense first-thinning and uneven-quality first-thinning Scots pine stands, the cutting-strip method is well justified on the grounds of the productivity of the cutting work, as well as the spatial arrangement of the trees forming the retention stand [8]. In Norway spruce stands, the risk of tree damage and poor visibility restrict the use of the cutting-strip method. Also, when using the cutting-strip method there is more timber per haulage route density because the strip-road interval is greater. Thus, forest haulage costs are lower when the route density is higher. Working with narrow cutting-strips sets great demands on the operators' skills. Therefore, the pretentiousness of harvesting work sets its own challenges for the training of operators in the future.

AUTHOR CONTACT

Kalle Kärhä can be contacted by e-mail at -

kalle.karha@metsateho.fi

REFERENCES

[1] Anon. 1999. Finland's National Forest Programme 2010. Ministry of Agriculture and Forestry, Publications 2/1999. 40 pp.

[2] Brunberg, T. 1997. Basic data for productivity norms for single-grip harvesters in thinning. The Forestry Research Institute of Sweden, Report 8/1997. 18 pp.

[3] Brunberg, T., A. Thelin, and S. Westerling. 1989. Basic Data for Productivity Standards for Single-Grip Harvesters in Thinning. The Forest Operations Institute of Sweden, Report 3/1989. 25 pp.

[4] Hakkila, P., H. Kalaja, and P. Saranpää. 1995. Etelä-Suomen ensiharvennusmänniköt kuitu- ja energialähteenä. [First thinning stands of Scots pine in Southern Finland as a source of fibre and energy]. Finnish Forest Research Institute, Research Papers 582. 100 pp. (in Finnish).

[5] Jaakkola, S. 2003. Ajokoneen tuotto harvennnushakkuissa vain 35 euroa tunnissa. [The profit of forwarder in thinnings only 35 euros per hour]. Koneyrittäjä 5/2003: 10-12.(in Finnish).

[6] Kuitto, P-J., S. Keskinen, J. Lindroos, T. Oijala, J. Rajamäki, T. Räsänen, and J. Terävä. 1994. Mechanized cutting and forest haulage. Metsäteho, Report 410. 38 pp.

[7] Kuitto, P-J. and M. Mäkelä. 1988. Boom-mounted harvester in first and second thinnings. An NSR-Project. Metsäteho, Review 7/1988. 4 pp.

[8] Kärhä, K., P. Mäkinen, K. Rieppo, and M. Sirén. 2001. Tarkastelu ja johtopäätökset HARKO-projektista. [Discussion and conclusions of HARKO Project]. In: Kärhä, K. [Ed.]. Alternative Harvesting Systems in Mechanised Thinning. Final Report of HARKO Project (1999-2001). TTS Institute, Publications 382. pp. 74-82. (in Finnish).

[9] Kärhä, K., S. Ryynänen, and E. Rönkkö. 2001. Productivity and felling costs when using thinning harvesters. TTS Institute, Forestry Bulletin 640. 6 pp.

[10] Lilleberg, R. 1990. Kuormainharvesteri avo- ja harvennushakkuissa. Maksuperustetutkimus. [Boom-mounted harvester in final cuttings and thinnings. Cost base study]. Metsäteho, Monisteita 28.3.1990. 21 pp. (in Finnish).

[11] Mäkelä, M. 1989. Mechanical harvesting in first thinning of pine stands. Metsäteho, Review 2/1989. 6 pp.

[12] Mäkelä, M. 1989. Mechanical harvesting in first thinning of spruce stands. Metsäteho, Review 10/1989. 6 pp.

[13] Mäkinen, P. 2001. Harvennusharvesteriyrittämisen taloudellinen kannattavuus. [Economic profitability of thinning-harvester enterprises]. In: Kärhä, K. [Ed.]. Alternative Harvesting Systems in Mechanised Thinning. Final Report of HARKO Project (1999-2001). TTS Institute, Publications 382. pp. 69-73. (in Finnish).

[14] Niemelä, H., R. Ranta, and S. Hartikainen. 1997. Hakkuiden ja metsänhoitotöiden tarkastaminen. [Control of logging and silvicultural works]. Metsätalouden kehittämiskeskus Tapio, Moniste 26.6.1997. 16 pp. (in Finnish).

[15] Rajamäki, J. 1997. Kuljettaja ratkaisee harvennushakkuun tuottavuuden. [The productivity of cutting in thinnings dependent on operator]. Koneyrittäjä 2/1997: 10-11. (in Finnish).

[16] Ranta, R. 2003. Metsänkäyttöilmoitusten ja hakkuiden tarkastukset vuonna 2002. [Inventories of forest utilization reports and loggings in 2002]. Metsätalouden kehittämiskeskus Tapio, Moniste 21.3.2003. 12 pp. (in Finnish).

[17] Ryynänen, S. 1993. Fendt farm tractor and Keto cutting device in first thinning of pine stand. TTS Institute, Forestry Bulletin 509. 6 pp.

[18] Ryynänen, S. and E. Rönkkö. 2001. Productivity and expenses associated with thinning harvesters. TTS Institute, Publications 382. 67 pp.

[19] Sirén, M. 1998. One-grip harvester operation, it's silvicultural result and possibilities to predict tree damage. Finnish Forest Research Institute, Research Papers 694. 179 pp.

[20] Sirén, M. 2001. Harvennusharvestereiden korjuujälki. [Silvicultural result of thinning harvesters]. In: Kärhä, K. [Ed.]. Alternative Harvesting Systems in Mechanised Thinning. Final Report of HARKO Project (1999-2001). TTS Institute, Publications 382. pp. 54-56. (in Finnish).

[21] Sirén, M. and H. Aaltio. 2003. Productivity of Costs of Thinning Harvesters and Harvester-Forwarders. International Journal of Forest Engineering 14(1): 39-48.

[22] Sirén, M. and V. Tanttu. 2001. Pienet hakkuukoneet ja korjuri rämemännikön talvikorjuussa. [Small one-grip harvesters and a harvester-forwarder in winter harvesting of pine bog]. Metsätieteen aikakauskirja 4/2001: 599-614. (in Finnish).

[23] Tahvanainen, M. 2001. On the effects of advance clearing of undergrowth when applying mechanised thinning. TTS Institute, Forestry Bulletin 638. 4 pp.

[24] Terävä, J. 1991. Using the FMG 0470 Motokärppä small-sized harvester for first thinnigs. Metsäteho, Review 5/1991. 6 pp.

[25] Tomppo, E. and H. Henttonen. 1996. Suomen metsävarat 1989-1994 ja niiden muutokset vuodesta 1951 lähtien. [Finnish forest resources 1989-1994 and their changes since 1951]. Finnish Forest Research Institute, Forest Statistical Bulletin 354. 18 pp. (in Finnish).

[26] Västilä, S. and H. Herrala-Ylinen. 2000. Metsänhoito- ja perusparannustyöt, vuosi 1999. [Silvicultural and forest-improvement works, 1999]. Finnish Forest Research Institute, Forest Statistical Bulletin 555. 31 pp. (in Finnish).

[27] Västilä, S. and H. Herrala-Ylinen. 2001. Metsänhoito- ja perusparannustyöt, vuosi 2000. [Silvicultural and forest-improvement works, 2000]. Finnish Forest Research Institute, Forest Statistical Bulletin 596. Official Statistics of Finland, Agriculture, forestry and fishery 2001:41. 32 pp. (in Finnish).

[28] Västilä, S. and H. Herrala-Ylinen. 2002. Metsänhoito- ja perusparannustyöt, vuosi 2001. [Silvicultural and forest-improvement works, 2001]. Finnish Forest Research Institute, Forest Statistical Bulletin 646. Official Statistics of Finland, Agriculture, forestry and fishery 2002:41. 38 pp. (in Finnish).

[29] Västilä, S., H. Herrala-Ylinen, I. Kulju, and K. Linna. 1998. Metsänhoito- ja perusparannustyöt, vuosi 1997. [Silvicultural and forest-improvement works, 1997]. Finnish Forest Research Institute, Forest Statistical Bulletin 461. 32 pp. (in Finnish).

[30] Västilä, S., H. Herrala-Ylinen, I. Kulju, and K. Linna. 1999. Metsänhoito- ja perusparannustyöt, vuosi 1998. [Silvicultural and forest-improvement works, 1998]. Finnish Forest Research Institute, Forest Statistical Bulletin 510. 31 pp. (in Finnish).

[31] Örn, J. 2003. Timber harvesting and long-distance timber transportation costs in 2002. Metsäteho, Statistics.