Vol. 15 No. 2, March 2004

Paula Jylhä

Finnish Forest Research Institute

Kannus, Finland

The author is a Researcher at the Kannus Research Station of the Finnish Forest Research Institute.

ABSTRACT

This paper deals with the feasibility of adapted tree section method using a conceptual bundle harvester for the integrated production of pulpwood and energy wood in first commercial thinning of Scots pine (Pinus sylvestris L.). The harvester would operate on the site, and it would be comprised of a base machine, an accumulating felling head, and a compacting device. Separation of pulpwood and energy wood fractions would take place at a pulp mill. In this experiment, the trees were topped and the top sections were left at the site.

The concept was evaluated from an ecological and economic point of view. Nutrient losses were significantly lower compared to whole-tree harvesting. The energy fraction increased by 150% compared to the cut-to-length method, in which stem bark represents the energy fraction.

In bundle transportation, the load-bearing capacity of standard trucks can be highly utilized. For short distance hauling by conventional forwarders, an expansion of the load space is required in order to improve the utilization of the load-bearing capacity.

Due to insufficient compaction capability when dealing with large trees, the bundling concept seems to be more appealing in harvesting energy wood from dense stands characterized by small stem size. In energy wood procurement, the bundling concept has several indirect advantages compared to the conventional forest chip production. Standard vehicles, with minor modifications, can be used for transportation. Machines involved in the operation can work independently, increasing the reliability of the system. Bundling with accurate real-time information about the daily production and inventories creates favourable conditions for efficient process control.

Key words: bundling, compacting, tree sections, nutrient loss, biomass balance, Pinus sylvestris L., Finland, topping, integrated harvesting, pulpwood, energy wood.

INTRODUCTION

Background

In Finland, 48% of the country's forestland is covered by advanced seedling stands and young thinning stands [4]. Thinning these stands is necessary to guarantee a good supply of industrial roundwood, especially saw and veneer logs, for the future. In recent years, the management of these stands was insufficient, mainly due to the high costs associated with the harvesting of small stem sized trees, the low yields, as well as the lower quality of the pulpwood obtained [9].

Now that wood consumption in forest industries is at a high level and the use of wood fuel is promoted in numerous ways, more emphasis is being placed on utilizing juvenile stands, which are potential sources of both energy wood and pulpwood. Their management is planned to be increased from 177,00 hectares [4] to 250,00 hectares by the year 2010 [3]. Furthermore, the use of renewable energy is to be increased by 50% from the 1995 levels by 2010, mainly by increasing the use of wood fuels. Virtually all wood processing residues are already in use. This means that any increase must be based on the recovery of unutilized biomass, such as small-sized trees [8]. When promoting both industrial and energy use of young stands, technology development plays a key role.

Energy wood procurement can be integrated with pulpwood harvesting by applying the tree-section method, in which the whole tree with intact branches is bucked into two or more parts [6]. The basic idea in this method is to reduce harvesting costs by eliminating unnecessary work phases (e.g. delimbing, dispensable bucking), and increasing the recovery in the form of branches and foliage. The tree-section method with present-day logging machinery is not competitive with the conventional cut-to-length methods in pulpwood harvesting [12]. Low bulk density in transportation is one of the main drawbacks of the method [20].

A concept of a bundle harvester comprised of a base machine, an accumulating felling head, and a compacting device has been developed. This conceptual harvester would primarily be used for energy-wood harvesting in dense young stands, but it could also be used for the integrated harvesting of pulpwood and energy wood. In the latter case, the pulpwood and energy-wood fractions would be separated in the debarking plant at a pulp mill.

The trees would be topped (Figure 1), and the tops would be left at the site to reduce nutrient losses, and possibly improve the quality of the pulpwood fraction also. The increase in the energy fraction would compensate for the costs of harvesting small-diameter stems for pulpwood. Omitting bucking and delimbing as well as applying multi-tree handling harvesting, could reduce costs even further. Savings in transportation due to load compaction are, however, estimated to be the foremost advantage of the bundling concept when compared with the conventional tree-section method. The bundling system is also considered to be more flexible than most energy-wood procurement chains, because no significant bottlenecks are expected, and conventional vehicles can be used for onward transportation.

Figure 1. Conceptual division of a tree into recovered and residual part in the tree-section method.

Aim of the Study

In order to further facilitate development of the bundling method, this study was aimed at evaluating the concept from an ecological and economic point of view. Ecological acceptability of the adapted tree-section method was assessed on the basis of biomass balance and nutrient removal. Economic consideration focused on the gain of additional raw material and bundle transportation.

The bundling operation was simulated by felling and topping the trees using a feller-buncher and forwarding the tree sections to the roadside, where they were bundled using a robust slash bundler originally designed for slash harvesting on final fellings.

MATERIAL AND METHODS

Stand Data

The data was collected from a 35-year-old Vaccinium-type Scots pine stand located in Central Finland (60°30'N, 24°20'E). For dry-mass-based above-ground biomass balances, the stand was inventoried before and after harvesting, and the bundles and bundling waste were analyzed. The biomass of the remaining stand was computed by subtracting the removal of biomass from the initial stand. In nutrient calculations, nutrient concentrations presented by Mälkönen [18] were used.

Before harvesting, twelve 200 m2 circular sample plots were systematically located on the 10.7 hectare compartment. In these plots, the diameter at breast height (DBH) of 362 tally trees was measured, and 73 systematically selected sample trees were measured as to their bark thickness, height and crown height. Stand data for both initial stand and the removal (Table 1) were computed using the KPL software [10]. The DBH distribution for the removal was reproduced after harvesting by conducting a stump inventory on ten systematically located 200 m2 circular sample plots where height and diameter of each stump were measured. The DBH of the removed trees were derived from stump measurements and sample tree data using a stem taper model [15]. Furthermore, this diameter distribution was used for estimating the effect of topping diameter on recovery.

Table 1. Stand data.

| Initial Stand | Removed Trees | |

| Number of stems ha-1 | 1508 | 735 |

| Basal area, m2ha-1 | 15.5 | 6.6 |

| Mean diameter, cm | 10.8 | 10.4 |

| Mean height, m | 9.9 | 10.0 |

| Crown height, m | 4.9 | 5.0 |

| Stem volume o.b., m3ha-1 | 90 | 40 |

Stem and bark volumes were converted into dry mass using basic densities. In conjunction with the pre-harvesting inventory, 15 sample trees representing all diameter classes were selected for the purpose of determining basic density and bark content. Sample discs were cut at points representing 10%, 30%, 50%, and 80% relative heights along the stem, and the average stemwood density and bark percentage were calculated by weighing the values obtained from these disc measurements by the volume of the corresponding stem section. These volumes were derived from stem taper-models [14] as differential volumes. The computations resulted in an average basic density of 416 kg m-3 (sd=25 kg m-3) for stemwood. The basic density applied for stem bark was of 267 kg m-3 [9].

The dry mass of living branches and foliage was computed using Hakkila's models [7]. In the case of the initial stand, the dry mass of the dead branches was assumed to be 22.2 kg per cubic meter of stemwood (incl. bark) [9] and the bark content of the branches was assumed to be 37.1% [7].

Recovery

The topped tree sections were hauled to the roadside and piled using a conventional forwarder. Most trees were cut into two sections to avoid damaging the remaining stand. At the landing, the slash bundler picked up the tree sections from the piles and placed them in the feed mechanism of its continuous bundling process. It then compressed the tree sections into cylindrical form with a calculated maximum pressure of 0.5 MPa, wrapped the bundles with a sisal string and cut them into pieces of about 3 meters (Figure 2).

Figure 2. Bundling tree sections at the roadside landing.

Out of a total of 674 bundles, 31 biomass and moisture samples were cut using the bundler's cutting device (Figure 3). These gave a mean green weight of 39 kg (sd=10 kg). Stemwood, living branches, dead branches, as well as the remaining fine fraction (5.7% of the sample dry mass), were separated, weighed, and parallel samples for the purpose of determining the foliage content of the living branches were taken. The fractions were homogenized, and samples of 2 liters each were taken from each fraction. In addition to this, 15 samples were taken to determine the foliage content of the fine fraction. In the computations, the composition of the remaining fine fraction after the removal of foliage was assumed to be as follows: stemwood 10%, stem bark 10%, living branchwood 25%, branch bark 15%, and dead branches 40%. The amount of bark in the stemwood fraction was calculated using the mean dry mass based bark content of 12.5% (sd=3.3%), which was computed from the sample discs.

Figure 3. Principle applied in sample taking.

The total recovered dry mass per hectare was derived from the bundle composition and the total mass of truckloads transported to the mill (355.2 tonnes), plus the mass of bundle samples. When converting the dry mass data of the bundle components into volume data, the following basic densities were used (in addition to the measured basic density of stemwood, 416 kg m-3): stem bark 267 kg m-3 [9], branchwood 424 kg m-3 [13], branch bark 311 kg m-3 [13], and foliage 373 kg m-3 [5].

Bundling waste at the roadside consisted of branches, foliage, bark, and short waste pieces of stemwood. In the conceptual bundling system, this residue would be classified as forest residue, and as such, was excluded from the recovery in the biomass balance. The amount of this residue was calculated tentatively by weighing all the waste from 1 of the 6 waste piles located in the bundling area, and by taking five moisture samples of the waste. Weighing this material was quite a laborious operation. Consequently, the rectangular bundling area of the following pile was divided into two equal parts, and all stem pieces were weighed, and the remaining residue in the other part was weighed. Before weighing, five samples of 10 litres each were taken along the diagonal of the entire area. These samples were divided into living branches, dead branches and into the fine fraction, which was divided into biomass components as in the case of bundle samples. The foliage content of the living branches and fine fraction were analyzed in the laboratory. Furthermore, to specify stemwood losses, all stem pieces in the bundling area of the third pile were weighed. The number of bundles produced from each pile was used for approximating the total amount of bundling residue.

When estimating the effect of minimum diameter on recovery, the longitudinal distribution of the crown mass (excl. dead branches) was calculated using Metsäteho models [21]. The minimum length of 2.7 m for the recovered trees was applied in these comparisons.

The heating value of the energy fraction was computed using figures presented by Nurmi [19]. However, the heating value of dead branches was assumed to be 75% of that of living branches. Moisture contents analyzed from the biomass samples were used for calculating heating values at delivery. For needles, a moisture content of 57% was used [5].

Forest Residue

Harvesting residue was inventoried in connection with stump measurements. The lengths of the tops were measured on each plot, as were the diameters of the butt ends. These measurements showed that the average topping diameter was 5.7 cm (sd=0.6 cm) and the average top length was 3.7 m (sd = 1.1 m).

For biomass calculations, the tops and top sections within the sample plots were delimbed and all the branches, divided into living and dead ones, were weighed, as were the stem sections of the tops. These fractions were chipped separately on the site, and the chips were homogenized by using manual stirring to facilitate moisture samples of 2 liters each. The foliage percentage of the dry mass of the living branches was determined from three randomly selected sample branches taken from each sample plot. The bark contents used for stems and branches were assumed to be the same as for the recovered fractions.

Utilization of Transportation Capacity

The tree sections were hauled to the roadside in 73.5 loads by a forwarder with a nominal load space of 12.9 m3. At the landing, the gross volumes of the piles were measured applying the method described by Kanninen et al. [11].

To determine the gross volumes of individual bundles, their lengths were measured from bundles preceding and following the samples (Figure 3), and digital photographs were taken of the bundle-end cross-sections. Cross-sectional areas of the bundles were measured from digital images using the manual functions of the Image Pro Express software [16]. The cross-sectional area of stemwood was also computed from the images.

The bundles were transported to the pulp mill in 11 truckloads each representing an approximate load capacity of 107 m3 loose volume. The load volumes were obtained from xylometric sampling, in which the mass and volume of one of the five bundle stacks of each truck were measured. The densities derived from these measurements were extended to apply also for the four other bundle stacks. All the bundle stacks of the first truck, were, however, separately measured.

The compactness of the harvested material was estimated on the basis of its space requirements at various phases of the procurement chain. The estimated solid volumes of the tree sections are mainly based on xylometric measurements. The volume of the forwarded residual biomass was, however, derived from the biomass and moisture sampling.

RESULTS

Biomass Balance

Total removal in the sample forest amounted to 19,000 kg dry matter ha-1 (Table 2), which corresponds to a total volume of 49 m3 ha-1. The thinning implemented was fairly intensive with 40% of the initial biomass being removed. Forest residue amounted to about 15% of the total removal. The amounts of dead branches in the forest residue and in the remaining stand were, however, biased, because only branches still attached to the stems were analyzed in the post-harvesting inventory. About 63% of the removed foliage remained in the stand, and 11% were left on the bundling site.

Table 2. Above-ground-level biomass balance of the study stand

| Stem | Crown | Total kg DM ha-1 |

||||

| Wood kg DM ha-1 | Bark kg DM ha-1 | Living Branches kg DM ha-1 | Dead Branches kg DM ha-1 | Foliage kg DM ha-1 | ||

| Initial stand | 31 842 | 3 607 | 6 498 | 1 999 | 2 634 | 46 579 |

| Removal | 12 447 | 1 853 | 2 412 | 1 122 | 1 171 | 19 005 |

| Recovery | 11 305 | 1 682 | 1 317 | 943 | 309 | 15 555 |

| Bundling waste | 161 | 31 | 119 | 158 | 128 | 596 |

| Forest residue | 981 | 140 | 977 | 22 | 734 | 2 854 |

| Remaining stand | 19 395 | 1 753 | 4 086 | 877 | 1 463 | 27 574 |

Nutrient Losses

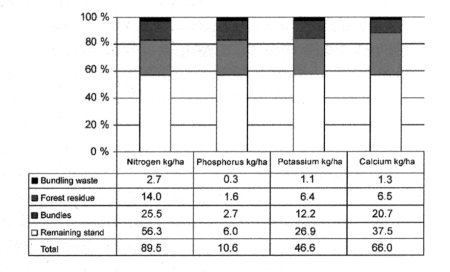

On the basis of the biomass balance, 26% of the nitrogen, phosphorus and potassium, and 31% of the calcium were removed from the stand with the bundles and bundle samples (Figure 4).

Figure 4. Above-ground-level nutrient balance of the woody biomass.

The magnitude of nutrient losses depends on the amount of biomass removed. For instance, nitrogen loss attributable to the adjusted tree-section method would be 85% greater than when using the cut-to-length method, but 40% less than in the whole-tree method (Table 3).

Table 3. Nutrient losses attributable to alternative logging methods

| Method | N (kg ha-1) | P (kg ha-1) | K (kg ha-1) | Ca (kg ha-1) |

| Cut-to-lenght | 13.6 | 1.5 | 7.5 | 14.0 |

| Adapted tree-section | 25.5 | 2.7 | 12.2 | 20.7 |

| Whole-tree | 42.2 | 4.5 | 19.7 | 28.5 |

Gain in Additional Raw Material

Debarking residue is usually combusted at the pulp mill. The yield of this energy fraction (stem bark) would have been 1 682 kg DM ha-1 for delimbed trees. For adjusted tree-section harvesting, the recovery of energy fraction was 4 251 kg DM ha-1 (+150%), and its effective oven dry heating value was 22.7 MWh ha-1. With the average moisture content of 48%, the heating value at delivery was 19.7 MWh ha-1. The final heating value of the energy fraction, however, depends on the amount of water used in wood and the capacity of dewatering devices of the debarking plant.

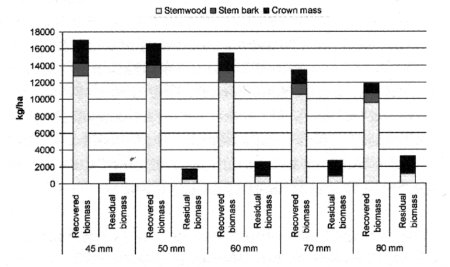

When applying the adjusted tree-section method, the recovery of pulpwood would not increase significantly by reducing the prevailing minimum top diameter of 60 mm to 45 mm (Figure 5), which is the minimum diameter allowed in the debarking drums used for processing the bundles. In regards to volume, the pulpwood gain would have increased by 2 cubic meters (o.b.) per hectare (6%). Instead, the yield of energy wood (excl. dead branches) could be tripled if the minimum top diameter of the recovered trees was reduced from 60 mm to 45 mm, and if the tree-section method was applied instead of the cut-to-length system.

Figure 5. Effect of minimum diameter on the recovery of pulpwood and energy wood in the sample stand. The minimum length of the recovered trees was 2.7 m, dead branches and undersized trees excluded.

When comparing to the conventional cut-to-length harvesting, the adjusted tree-section method results in an increase in pulpwood, since it is possible to utilize the tree up to the nominal minimum length.

Bundle Properties

The average bundle green mass of 527 kg was derived from the load weight records at the pulp mill and the total number of the bundles. The mean green density of the bundled tree sections was 871 kg m-3 (sd=19.5 kg) at the mean moisture content of 53%. The biomass composition of the bundles was as shown in Table 4.

Table 4. Average biomass composition of a bundle.

| Stem | ||

| Living branches | ||

| Dead branches | ||

| Foliage | ||

| Total |

The mean length of the bundles was 294 cm (sd=3.8 cm) and the mean diameter was 69 cm (sd=4.1 cm). The mean gross volume of the bundles was 0.982 m3 (sd=0.038 m2). With the mean green mass of a single bundle, this resulted in a mean bulk density of 537 kg m-3. The average solid content of the bundles was 62% of their gross volume. The proportion of stemwood was 49% (sd=5%-unit) of the cross-sectional area of the bundles.

Bundle Transportation

In Finland, the maximum gross vehicle weight of truck and trailer is 60 tonnes. The average carrying capacity of the trucks used in the experiment was 36.34 tonnes (sd=1.67 tonnes). The average load weight of 33.45 tonnes resulted in a 92% (sd=9.7%-unit) utilization of carrying capacity and a bulk density of 312 kg m-3 (sd=38 kg m-3). Assuming that the load height (2.6 m) remains unchanged, an increase in the average bundle length from 294 cm to 319 cm would result in a full utilization of the carrying capacity with a bulk density of 339 kg m-3.

The average load volume was 38.2 m3 (sd=4.6 m3), and the solid content of the total load space of 107 m3 was 36%. In the case of two bundle stacks in the truck and three in the trailer, the trailer's load space length (10.2 m) limits the maximum length of an individual bundle to 3.4 m. This would result in 42% solid content and a load volume of 44 m3. In this case, the total weight of truck and trailer would exceed the maximum permissable weight. Moisture content and basic density, however, markedly affect load weights.

In this study, the tree sections used in the experiment were transported to the bundling site by a conventional forwarder with a carrying capacity of 8500 kg. The estimated mean load volume was 5.8 m3, and green mass 4800 kg. When transporting slash bundles with approximately identical dimensions, load sizes of 12-13 bundles have been recorded using standard forwarders with carrying capacities of 8000-12000 kg [1]. With the average mass of the tree section bundles, this would result in a load size of 6300 - 6900 kg and 7.3 _ 7.9 m3. The actual bundle length of 2.94 m is not, however, optimal for forest haulage. A high utilization of the carrying capacity of forwarders used in thinning conditions seems possible by expanding the load space.

Compactness of the bundles is a beneficial property when storing, transporting and handling them at any stage of the procurement chain. Table 5 indicates relative space requirements of the tree sections at various forms of existence.

Table 5. Solid content of the tree sections harvested from the sample stand and their relative space requirements at various phases.

| Volume | Solid Content | Relative Space Requirement |

| Xylometric (solid) | 100% | 1.00 |

| Piled tree sections | 26% | 3.84 |

| Individual bundles | 62% | 1.62 |

| Bundle truck loads | 36% | 2.81 |

DISCUSSION

Ecological Aspects

There are concerns about removing branches and foliage as part of wood harvesting as this may decrease the growth of the remaining stand due to nutrient losses. The direct effects of slash removal on wood production are poorly known. The reaction of the remaining stand to slash removal depends significantly on site properties, the development phase of the stand, tree-species composition, the amount of slash removed, and the spatial distribution of the logging residue. We can, however, compare effects of the adapted tree-section method with alternative logging methods on the basis of nutrient removal.

Pine needles are especially rich in nutrients in comparison with the other biomass components [17]. About 63% of the foliage of the removed trees remained in the stand, and only 26% were carried away in the bundles. The total nutrient loss was small compared with the nutrient reserves of mineral soils. In Finland, nitrogen is usually the foremost growth-limiting factor on mineral soils. The total nitrogen removal was 25.5 kg ha-1, which is about 2% of the total nitrogen stores in the root layer of the mineral soil underlying Vaccinium-type forests stands in Southern Finland [22]. The recovery of fuel fractions, i.e. branches and foliage, increased nitrogen removal by 11.9 kg. Nitrogen deposition compensates for these nutrient losses. The average annual deposition of nitrogen available to forest vegetation is 10 kg ha-1 in Southern Finland [18].

Nutrient losses attributable to the adapted tree-section method were significantly lower than those caused by the whole-tree system. The losses accredited to the whole-tree method may, however, be overestimated in this study since in mechanized harvesting a fraction of the crown mass will inevitably drop off at various phases.

System Evaluation

The estimated mean bulk density of individual bundles was 537 kg m-3. In a Swedish study using laboratory equipment, a bulk density of 600 kg m-3 was reached when dealing with fresh pine crown mass and applying a compaction pressure of 0.5 MPa [2]. The compaction capability of the conceptual bundler cannot be fully utilized when processing trees with heavy stem sections, which themselves compact loads by breaking and crushing the branches. Sometimes it might be more rational to convert the butt ends of this kind of trees into small logs applying single-tree harvesting. This sets more requirements for the felling head of the conceptual bundle harvester. Consequently, the bundling concept seems more favorable in harvesting energy wood from dense stands composed of small-diameter trees than in integrated harvesting of pulpwood and energy wood from conventional thinning sites as was done in the present study. In the case of integrated harvesting, the disadvantages caused by mixed tree species in debarking and pulping also have to be considered [23].

From the economic point of view, bundling can be expected to be profitable if the savings in transportation exceed the compaction costs. The bundle concept should be compared especially with the conventional tree-section method in which the gain in additional raw material is approximately equal to that of the bundling system.

The present study indicated that the carrying capacity of the trucks could be highly utilized in bundle transportation. The average bulk density of bundle truckloads (312 kg m3) was about the same as in other Scandinavian studies, in which tree sections were transported by trucks equipped with load compaction devices [2, 20]. Increasing bundle length could further increase bulk density of bundle loads. When comparing bulk densities, one should, however, consider varying moisture content and basic densities.

For safety reasons, the trucks should be equipped with side and rear walls in order to prevent short stem bolts and other loose particles to drop down. For the forest haulage of bundles, a modification of the forwarder's load space is necessary in order to maximize the utilization of their load-bearing capacity. When optimizing the bundling system, one should consider forest haulage and long-distance transportation, as well as bundle handling. It seems that optimal transportation efficiency is achieved when hauling the bundles over long distances.

In energy production, bundling has several indirect advantages as described by Hakkila [8]. Compared with conventional production chains of forest chips, the conceptual bundle harvester operates independently of the other machines involved in the operation. This makes the system less vulnerable. The integration of bundle production in the procurement of industrial roundwood is simple, as off- and on-road transportation can be performed with conventional equipment through minor modification. Storage of the bundles is simple, and the storage space requirement is reduced, which is an important factor at cramped landing sites. Compared to conventional procurement chains, large landing areas are not needed for comminution either. Since bundles are crushed by efficient stationary equipment, the transfer of chippers is avoided, and the noise, dust and litter problems occurring at a landing are reduced. There is only little loss or deterioration of the biomass, and long-term buffer storage is possible. Bundling also reduces the probability of raw materials becoming contaminated by stones and soil. In addition, the bundles are relative uniform in size and composition. Thus, the bundler can produce real-time information about the daily production and inventories. This creates good conditions for efficient process control.

From the contractor's point of view, the bundle harvester concept seems appealing due to its versatility. It could be used for both energy wood and pulpwood harvesting, and with interchangable grapple, the bundle harvester might also be applicable for slash bundling on final fellings. Logging sites often comprise of several compartments, and this kind of multi-functioning machine might reduce the need for machine transfers.

AUTHOR CONTACT

Paula Jylhä can be reached by e-mail at --

Paula.Jylha@metla.fi

REFERENCES

[1] Backlund, C. 2003. UPM-Kymmene Forest Department. Telephone conversation 8.9.2003.

[2] Danielsson, B-O, J. Marks, and H-O. Säll. 1977. Komprimering av klena träd och träddelar [Compaction of small trees and tree sections]. Skogshögsk. Inst. Rapp. Upps. 119. 47 p (in Swedish). Cited in: Hakkila, P. 1989. Utilization of Residual Forest Biomass. Springer-Verlag. Berlin. 568 p.

[3] Finland's National Forest Programme 2010. 1999. Finnish Ministry of Agriculture and Forestry. Publications 2/1999. 40 p.

[4] Finnish Statistical Yearbook of Forestry 2002. Finnish Forest Research Institute. 378 p.

[5] Gislerud, O. 1974. Heltreutnyttelse. II. Biomasse og biomasseegenskaper hos tynningsvirke av gran, furu, bjork og or. [Whole tree utilization. II. Biomass properties of trees from thinnings of spruce, pine, birch and alder]. Rapp. Norsk Inst. Skogsforskn. 6/74:1-59. (in Norwegian).

[6] Hakkila, P. 1989. Utilization of residual forest biomass. Springer-Verlag. Berlin. 568 p.

[7] Hakkila, P. 1991. Hakkuupoistuman latvusmassa. [Crown mass of trees at the harvesting phase]. Folia Forestalia 773. 24 p. (in Finnish).

[8] Hakkila, P. 2003. Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999-2003. Interim Report. Technology Programme Report 5/2003. Tekes. 54 p.

[9] Hakkila, P., H. Kalaja, and P. Saranpää. 1995. Etelä-Suomen ensiharvennusmänniköt kuitu- ja energialähteinä [Scots pine harvested from first thinning sites in Southern Finland as sources of pulpwood and energy wood]. Metsäntutkimuslaitoksen tiedonantoja 852. 93 p. + 6 app. (in Finnish).

[10] Heinonen, J. 1995. Koealojen puu- ja puustotunnusten laskentaohjelma KPL. Käyttöohje. [Software for computing tree and stand characteristics for sample plots. Users' manual]. Metsäntutkimuslaitoksen tiedonantoja 504. 80 p. (in Finnish).

[11] Kanninen, K., O. Uusvaara, and P. Valonen. 1979. Kokopuuraaka-aineen mittaus ja ominaisuudet. [Measuring and properties of whole tree raw material]. Folia Forestalia 403. 53 p. (in Finnish).

[12] Korpilahti, A., Varhimo, A., Backman, M. and Rieppo, K. 1998. Karsimattoman puun korjuu ensiharvennuksilta. [Harvesting tree-sections from first thinning]. Bioenergian tutkimusohjelma. Puupolttoaineiden tuotantotekniikka. Loppuraportti 9.12.1998. Metsäteho. Helsinki. 33 p. (in Finnish).

[13] Kärkkäinen, M. 1976. Puun ja kuoren kuiva-tuoretiheys ja kosteus sekä kuoren osuus koivun, kuusen ja männyn oksissa. [Density and moisture content of wood and bark, and bark percentage in the branches of birch, Norway spruce, and Scots pine]. Silva Fennica 10(3): 212-236. (in Finnish).

[14] Laasasenaho, J. 1982. Taper curve and volume functions for pine, spruce and birch. Communicationes Instituti Forestalis Fenniae 108. 74 p.

[15] Lappi, J. 2002. A stem curve model based on nonparametric regression and a multivariate mixed model. Manuscript.

[16] Media Cybernetics. http://www.mediacy.com/ipe45features.htm. Accessed on September 30, 2003.

[17] Mälkönen, E. 1974. Annual primary production and nutrient cycle in some Scots pine stands. Communicationes Instituti Forestalis Fenniae 84.5. 87 p.

[18] Mälkönen, E. 1990. Effects of nitrogen inputs on forest ecosystems. In: Kauppi, P., Anttila, P. and Kenttämies, K. [Eds.]. Acidification in Finland. Springer-Verlag. Berlin. pp: 325-347.

[19] Nurmi, J. 1993. Heating values of the above ground biomass of small-sized trees. Acta Forestalia Fennica 236. 30 p.

[20] Oijala, T. 1991. Osapuun autokuljetuksen ajanmenekki ja kuormien koot Pohjois-Suomessa. [Time consumption and load sizes in tree-section transportation by trucks in Northern Finland]. Raportti 30.12.1991 Metsäteho. Helsinki. 9 p. (in Finnish).

[21] Poikela, A. 1997. Latvusmassan pituussuuntainen jakaantuminen. [Longitudinal distribution of crown mass]. Metsätehon raportti 10. Metsäteho. Helsinki. 28 p. (in Finnish).

[22] Tamminen, P. 1998. Maaperätekijät. [Soil factors]. In: Mälkönen, E. [Ed.]. Ympäristömuutos ja metsien kunto. Metsäntutkimuslaitoksen tiedonantoja 691:64-75 (in Finnish).

[23] Virkola, N-E. and U. Klemetti. 1986. Kotimaisesta havu- ja lehtipuusta valmistetun kemiallisen massan laatuun ja prosessoitavuuteen vaikuttavat tekijät. [Factors affecting processing and the quality of chemical pulp made of domestic softwood and hardwood]. INSKO B 215-86 I. Insinöörijärjestöjen koulutuskeskus. Helsinki. 39 p. (in Finnish).