Vol. 15 No. 2, March 2004

Jean-François Gingras

Forest Engineering Research Institute of Canada

Quebec, Canada

The author is Program Leader at the Forest Engineering Research Institute of Canada (FERIC).

ABSTRACT

Thinnings are not as common in Canada as they are in most European countries for a variety of reasons, not the least being the high treatment costs. In recent years, FERIC has proposed a host of strategies to reduce the costs of thinnings and thus increase the attractiveness of this treatment. One of these strategies is to use multi-tree handling harvester heads because the use of single-grip harvesters often results in high wood costs when harvesting small stems typical of commercial thinning treatments. Recently introduced harvester heads such as the Waratah HTH-470 HD provide multi-stem felling and processing options that can increase harvester productivity in small trees. This paper describes the early results from FERIC studies of multi-stem heads working in eastern Canada.

During FERIC studies, the ability to handle more than one stem at a time increased machine productivity by an average of 21 to 33% compared with handling stems one at a time. On average, multi-stem work cycles were longer than single-stem cycles, but the ability to process more than one stem at a time in 30 to 40% of the cycles lowered the mean harvesting time per stem. The delimbing quality and the length-measurement accuracy for sawlogs were comparable to those of conventional heads currently on the market.

This technology is thus well suited to final felling of small trees and to commercial thinning because its productivity is less affected than with conventional heads by the small tree volumes. The accumulator that keeps felled stems vertical also provides benefits, since it lets the operator control the fall of the felled stems and thus may reduce the risk of damaging residual stems.

Keywords: Multi-stem harvester head, Waratah HTH-470HD single-grip head, thinning, cut-to-length system, productivity, Picea marianna, Abies balsamea, Pinus banksiana, Canada.

INTRODUCTION

Processing more than one stem per cycle, also known as multi-tree handling (MTH), offers potential productivity increases under small stem conditions typical of thinnings, and thus, reduced costs. The objectives of this paper are to describe the first results from FERIC studies conducted on multi-stem heads operating in eastern Canada, to quantify the productivity gains, assess any impact on the quality of the logs produced and identify the potential use of this concept in thinnings and final fellings.

Multi-stem processing with harvester heads was initially proposed in Scandinavia in the late eighties. One of the first products designed with multi-stem features was the FMG 756 described by Lilleberg [9, 10]. At around the same time, the Norwegian company Forest Machine Technologies Ltd., in cooperation with NISK, developed a head capable of processing two stems at a time, the FMT 45 [2]. In Denmark, Kofman [8] describes how the Danish Forest and Landscape Institute tested a modified Silvatec 454 harvester head in the felling and processing of two stems per cycle. In all of these trials, multi-stem capabilities were demonstrated but problems existed with delimbing quality, length measuring accuracy and volume calculations. In conjunction with the fact that early thinnings were on the decline in Europe because of poor pulpwood markets, these multi-stem concepts were not actively pursued until fairly recently.

The multi-stem harvester heads discussed in this paper are multi-function heads capable of felling, delimbing, measuring and bucking to length; thus, they should not be confused with simple accumulating felling heads that are only designed to fell and bunch trees for further processing by another machine. Examples include standard circular saw feller-buncher heads or the chain saw or shear heads designed for energy wood harvest like the AM230 [5], the Haka 110 [11] or the Naarva-Grip [7]. The cycle time savings of multiple-tree felling with these concepts were discussed at length in Johansson and Gullberg [6].

Gingras [3] described the first trials in Canada of a dedicated multi-stem single-grip head, the Timberjack 745, manufactured by a Finnish company called Outokommun Metalli Oy. After these field trials, the head was modified and improved, and is now being sold in Canada by Waratah Forestry Attachments as the HTH-470HD model [4].

INTEREST FOR MULTI-STEM HARVESTING IN CANADA

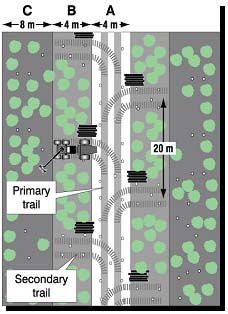

Multi-tree handling (MTH) provides an opportunity to reduce harvesting costs in final felling and for increasing the amount of wood harvested with thinnings in eastern Canada. Thinnings have not been used nearly to the same extent in Canada when compared with most European countries for a variety of reasons including public ownership of forest lands, high costs and until recently, lower fiber procurement costs from accessing overmature stands in previously unmanaged areas. In recent years, FERIC has proposed a host of strategies to reduce the costs of thinnings. For example, the use of widely spaced extraction trails concurrently with a network of secondary trails permits the use of larger equipment traditionally used in clearcuts, thus avoiding the need to purchase specialized equipment (Figure 1).

Figure 1. Network of main and secondary trails for use in commercial thinning.

Regardless of operating techniques, FERIC studies have shown that using single-grip harvesters in commercial thinning operations in natural boreal stands results in high wood costs compared with final felling. Multi-tree handling is seen as a viable approach for reducing costs in thinnings, assuming it can produce logs at near-equivalent quality levels as single-tree handling.

TECHNOLOGICAL FEATURES OF THE MULTI-STEM HARVESTER HEAD

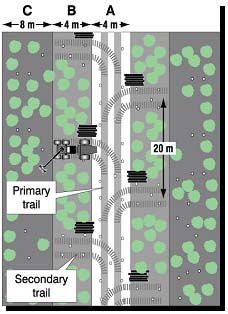

The only proven multi-stem harvester head currently available in Canada is the Waratah HTH-470HD. The key elements that let this head efficiently process several stems at a time are the accumulator arms, which keep the cut stems vertical during felling; the four hydraulically or mechanically linked feed rollers, which prevent the stems from slipping during processing; and the extra-wide measuring wheel, which ensures constant contact with the tree bundles (Figure 2).

Figure 2. The Waratah HTH-470HD multi-stem head.

FIELD STUDIES OF MULTI-STEM TECHNOLOGY

FERIC conducted three different field studies of the multi-stem technology in eastern Canada (two in 2001 and one in 2002). In two studies, the head was mounted on a Timberjack 608L tracked carrier; in the third, it was installed on a Timberjack 1270B harvester. Large tracked carriers are well suited to final felling of mature stands on soft or hilly ground, whereas wheeled carriers are best suited to rocky sites and thinning applications. For the field studies, FERIC conducted short-term productivity evaluations using hand-held field computers and an in-house time study program called TS-1000. Complete work cycles were recorded, including time elements, the number of logs produced per assortment type, and the number of trees per cycle. The harvested stands were cruised prior to harvesting, and a sample of logs from each assortment type was scaled. Where possible, log pairs or triplets produced during multi-stem cycles were marked with paint so their lengths could be measured separately and compared with the average length of all sampled logs in the same assortment. The delimbing quality for these and other logs was assessed visually.

Table 1 describes the results of FERIC's productivity studies in three different operations where the head was clear felling natural softwood stands (no results yet available in thinnings). The productivity without multi-stem processing was estimated by using the mean positioning and cutting times for single-stem cycles to replace the recorded positioning and cutting times in cycles that combined felling and multi-stem processing, and by reducing the number of stems per cycle to one. The average processing time was also reduced by 10% to account for occasional difficulties encountered when processing multiple stems. All other work-cycle time elements such as moving, brushing, and miscellaneous delays were spread uniformly among all cycles.

Table 1. Productivity and quality results from the three field studies (MTH = multi-tree handling, STH = single-tree handling).

| Site 1 (Spring 2001) | Site 2 (Summer 2001) | Site 3 (Fall 2002) |

|

| Stand and terrain conditions | |||

| Stand | Fir (Abies balsamea) - spruce (Picea Marianna) | Spruce - jack pine (Pinus banksiana) | Spruce - jack pine |

| Density (stems/ha) | 1600 | 1300 | 1300 |

| Volume/stem (m³) | 0.10 | 0.10 | 0.10 |

| Volume/ha (m³) | 160 | 130 | 130 |

| Terrain | Rough and hilly | Flat and soft | Flat and firm |

| Productivity | |||

| Proportion of multi-stem cycles (%) | 40 | 31 | 40 |

| Stems/PMHa | 157 | 154 | 155 |

| Volume/PMH (m³) | 16.0 | 15.1 | 15.4 |

| Calculated productivity STH (m³/PMH) | 12.0 | 12.5 | 12.4 |

| Effect of MTH (% productivity increase) | +33 | +21 | +24 |

| Length-measurement accuracy | |||

| Proportion of logs within ±5 cm of target length (%) | 80 | 88 | 92 |

a PMH: productive machine-hours (productive time minus non-operational delays and operational delays exceeding 15 minutes).

The ability to handle more than one stem at a time increased productivity by an average of 21 to 33% compared with harvesting similar stems one at a time. This is in the same range though slightly higher than the 18% gain reported by Bergkvist [1]. The trees in the Swedish study were likely larger than the FERIC studies, thereby reducing the potential gains of MTH. Lilleberg reports gains of 20 to 30% in thinnings [10] and 15% in the larger trees of final felling [9].

On average, multi-stem work cycles were longer than single-stem cycles, but the ability to process more than one stem at a time in 30 to 40% of the cycles lowered the mean harvesting time per stem. Obviously, such productivity gains cannot always be guaranteed, since they depend on several factors, including the operator's skill, the spatial distribution of the stems within the stand, and the mean stem volume. The smaller and more clustered the trees, the more opportunities exist for multi-stem felling and processing. In thinnings, it is possible that the obstruction from residual stems will hamper accumulation potential, thus productivity gains might be lower.

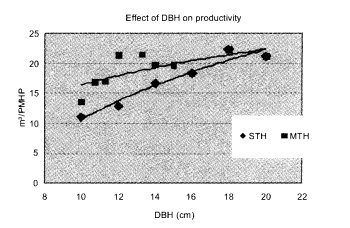

Figure 3 illustrates the effect of DBH on the productivity with and without multi-stem processing over the observed range of study conditions. It's clear that as mean diameter increases, the advantage offered by multi-stem processing decreases. At a DBH of around 20 cm, the two lines meet, since it becomes difficult to process more than one stem at a time with larger trees.

Figure 3. The effect of stem diameter on productivity with single stems and with multi-stem handling.

The usual concern with multi-stem processing relates to the quality of the logs produced, and particularly to the delimbing quality and length-measurement accuracy. Bergkvist [1] reports that 6% of logs produced with MTH did not meet the mill quality specifications because of excessive residual limbs or inadequate diameter. In the field, we observed no difference in delimbing quality between logs produced by processing one stem at a time or with multi-stem processing. The five knives and four feed rollers of the Waratah head seem to provide excellent contact with the stem surface during processing. The length accuracy for logs produced during multi-tree handling cycles was not significantly lower than those produced in single-tree handling cycles. It should be noted that the accuracy data measured during these studies are comparable to those obtained in other operations studied by FERIC that used conventional STH heads [12].

DISCUSSION AND CONCLUSIONS

Our studies clearly demonstrated the benefits of multi-stem technology, particularly the increased harvesting productivity with small trees typical of thinning operations.

It was found that unlike with conventional heads, it's not essential to handle stems of the same dimensions (DBH or length) during multi-stem processing cycles, especially if pulpwood is the main assortment produced from the small stems. However, large differences in DBH (more than 4 cm) can create problems during processing of the top-end logs, since the point at which the minimum utilization diameter arises may not occur at the same position on the stem.

Multi-stem processing does present a higher risk of quality losses compared with STH, particularly in terms of length measurement; thus, operators should remain vigilant and conduct frequent quality checks of the logs produced especially if multi-stem cycles are common and sawlogs represent a large proportion of the product basket.

Operators should avoid attempting multi-stem cycles under unfavorable conditions such as in difficult delimbing situations. As well, little time is saved by trying to harvest widely scattered stems within the same work cycle.

One problem with the MTH concept is the imprecise volume measurements of the heads when multi-tree handling. This can prevent widespread use of this technology in certain countries like Finland where machine volume measurements are officially used for wood and contractor payments. New measuring systems will need to be developed for multi-stem applications.

Overall, the greater productivity of multi-tree handling compared with single-tree handling in small trees makes it an attractive concept for commercial thinning or other partial cuts. The accumulator that keeps felled stems vertical on the Waratah head also provides benefits, since it lets the operator control the fall of the felled stems and possibly reduces the risk of damaging residual stems. It is not known yet if residual stems encountered in thinning operations will reduce the accumulation potential, and thus the productivity gains, of the multi-stem concept. While most heads sold so far in Canada have been applied in clearcutting, it is expected that a growing number will be implemented in commercial thinning applications in the future.

AUTHOR CONTACT

Mr. Gingras can be reached by e-mail at --

jfg@mtl.feric.ca

REFERENCES

[1] Bergkvist, I. 2003. Multitree-handling increases both productivity and profitability in smallwood thinning. Skogforsk Resultat no. 5, Upsala, Sweden.

[2] Dale, O. and O. Sorhagen. 1994. Handling of multiple trees in early thinnings. In: Harvesting Small Trees and Forest Residues: 1994 IEA Workshop held in Norway June 6-9, 1994. For. Eng. Res. Inst. Canada Internal Report IR-1995-01-02, Pointe-Claire, Que.

[3] Gingras, J.-F. 1999. Evaluation of the Timberjack 745 single-grip head with multi-stem capability. For. Eng. Res. Inst. Can. (FERIC), Pointe-Claire, Que. Tech. Note TN-291. 4 pp.

[4] Gingras, J.-F. 2002. Evaluation of the Waratah HTH-470HD multi-stem harvester head. For. Eng. Res. Inst. Can. (FERIC), Pointe-Claire, Que. Advantage Rep. 3(3). 4 pp.

[5] Ihonen, M. 1994. Maataloustraktorin kerräävä am 230 - Kaatlaite kokopuuhakkuussa. [Agricultural tractor-mounted AM 230 multi-tree felling head in whole-tree harvesting]. Työtehoseuran Metsätiedote 000536, Helsinki, Finland. 4 pp. (in Finnish).

[6] Johansson, J. and T. Gullberg. 2002. Multiple tree handling in the selective felling and bunching of small trees in dense stands. Int. J. For. Eng. Vol. 13(2): pp. 25-34.

[7] Kärhä, K., A. Jouhiaho, A. Mutikainen and S. Mattila. 2002. Joukkokasitteleva Naarva-Koura energiapuun hakkuussa. [The multiple-tree processing Naarva-Grip in energy wood harvesting]. Tyotehoseuran-Metsatiedote. 2002, No. 655, 4 pp. Työtehoseura Ry; Helsinki, Finland. (in Finnish).

[8] Kofman, P.D. 1994. Multiple tree handling in Denmark. In Harvesting Small Trees and Forest Residues: 1994 IEA Workshop held in Norway June 6-9, 1994. For. Eng. Res. Inst. Canada Internal Report IR-1995-01-02, Pointe-Claire, Que.

[9] Lilleberg, R. 1994a. A multi-tree harvester in final cuttings in northern Finland. Metsäteho Katsaus 1994/0002. Helsinki, Finland.

[10] Lilleberg, R. 1994b. A multi-tree harvester FMG 990/756H in first thinning of pine. Metsäteho Katsaus; 1994/0008. Helsinki, Finland.

[11] Natt, M.H. 1995. Haka 110-kourasaha nuoren metsan kasittelyssa. [Haka 110 grapple-mounted saw in tending and amelioration cutting of young stands]. Työtehoseuran Metsätiedote 000539, Helsinki, Finland. 4 pp. (in Finnish).

[12] Plamondon, J.A. 1999. Log-length measurement errors with six single-grip harvester heads. For. Eng. Res. Inst. Can. (FERIC), Pointe-Claire, Que. Tech. Note TN-297. 6 pp.