Vol. 14. No. 1 January 2003

Kjell Suadicani1

Tomas Nordfjell2

Danish Centre for Forest, Landscape and Planning

Denmark

The authors are 1Senior Consultant, Danish Centre for Forest, Landscape and Planning and 2Professor,Danish Centre for Forest, Landscape and Planning, and Senior Lecturer, Swedish University of Agricultural Sciences, Department of Silviculture, Section of Forest Technology.

ABSTRACT

The aim of this study is to investigate the productivity, thinning quotient, reduction in basal area, damage rate, and costs of operation of row and selective thinning in the establishment of a shelterwood in a medium-aged Norway spruce stand. The cutting was performed with a single-grip harvester operating from existing striproads (spacing 15 m) parallel to the tree-rows. Extraction with a forwarder was studied in the same stand.

The two thinnings were more alike than expected. The thinning quotient was 0.9 and the reduction in basal area round 40% in both treatments. The time consumption for harvesting was larger in row than in selective thinning because row thinning was more difficult to perform when the harvester worked from striproads parallel to the tree-rows. No difference in forwarding productivity was found. The damage rate was higher in row than in selective thinning. It is concluded that row thinning from striproads parallel to the tree-rows has a negative influence on both productivity and quality of the work. This type of row thinning is difficult to perform because the tree-rows are difficult to identify and because the trees are more difficult to reach.

The operational aspects should be considered before a thinning method is chosen. Row thinning should preferably be carried out either by driving on removed rows or from striproads perpendicular to the tree-rows.

Keywords: Denmark, extraction, forwarder, harvesting, Picea abies, productivity, row thinning, selective thinning, single-grip harvester, stem-damages, stem-injuries, time study.

INTRODUCTION

Norway spruce (Picea abies (L.) Karst.) is the most common tree species in northern and central Europe. It has been planted far beyond its natural range, for example on the former heath areas in western Denmark [31]. Norway spruce has several advantages in these plantations on poor soil such as easy regeneration by planting after clearcutting, rapid juvenile growth and good timber quality. However some disadvantages have become apparent. The older stands are susceptible to windthrows, and root rot (caused by the fungus Heterobasidion annosum (Fr.) Bref.) has become more and more common. Because of the disadvantages objectives have been set to transform part of the heath plantations into mixed forests mainly of native broad-leaved species [7, 10]. Regeneration by clearcutting and replanting is not suitable for the introduction of species such as beech (Fagus sylvatica L.) and silver fir (Abies alba Mill.), but under a shelterwood it is possible. However, in the windy climate of western Denmark fully-grown shelterwoods are often subject to windthrows. Shorter stands are more wind-resistant, and therefore early shelterwood regeneration (height<15 meters) has been proposed [17,21, 23, 27].

The harvester-forwarder system is used for almost all softwood harvesting in Scandinavia. The system has been analysed in detail with most efforts consisting of studies of single-grip harvester productivity [9, 11, 12, 13, 19, 20, 35]. The mechanisation and rationalisation of forest-management in the Nordic countries has led to the replacement of traditional marking for felling in thinnings by machine operator tree selection based on thinning prescriptions.

Establishing shelterwoods in stands planted in rows is mainly done in two ways: row or selective thinning. Row thinning is defined as total removal of a proportion of the rows in some sequence, while selective thinning can be described as removing a proportion of the trees in every row, according to some individual selection criteria. Selective thinning is preferred if specific post stand characteristics or specific characteristics of the harvested trees are sought (thinning from below, thinning from above, thinning for quality etc.). Row thinning is preferred if accessibility to the stand is given priority for example for facilitating site preparation [28].

Establishing striproads is the most common type of row thinning, and the harvester operates from the striproad as it is established. This type of row thinning is efficient because it is easy to harvest trees directly in front of the harvester. If row thinning is to be done in stands where the distance between the tree-rows is small, the most common solution is to use a very narrow machine or to remove two adjacent tree-rows. Row thinning can also be performed the same way as selective thinning, which means that the harvester is operating from already established striproads, wide enough to drive on. This is not very common, but it can be relevant if shelterwood establishment is to be followed by site preparation with narrow drawn implements.

All thinning operations cause some damage to the remaining stand. The damage rate for single-grip harvesters in thinning and in shelterwood establishment has been decreasing [16]. In recent studies the proportion of damaged trees has been only 3% [33, 35]. Sirén [33] found variation between operators and a clear correlation between high productivity and low frequency of damaged trees. Fröding [16] found that most damage occurred during processing (90%) while Sirén [33] found that as much as 60% occurred during felling. Fröding's results [14, 15, 16] mostly go back to the situation before 1985 when mechanised thinning was something new, even though the last of these papers was published in 1992. This explains most the lower proportion of damaged trees in processing in more recent studies [33, 35]. Extraction also results in damage, with loading being responsible for most of it (up to 80%) [24].

The aim of this study is to investigate the productivity, thinning quotient, reduction in basal area, damage rate and costs of operation of two thinning methods termed row and selective thinning in the establishment of a shelterwood in a fifty year old Norway spruce stand. The harvesting was performed with a single-grip harvester operating from existing striproads (spacing 15 m) parallel to the tree-rows. Extraction with a forwarder was studied in the same stand.

MATERIALS AND METHODS

The study area was a 50 year old Norway spruce stand (4.1 ha) on a poor sandy soil located in north-western Denmark (56° 30'N, 8° 22' E). Terrain conditions for the site were class 1 for bearing capacity, surface evenness and ground slope where class 1 represents very easy conditions and 5 very difficult conditions [6].

The stand was originally planted in rows spaced at approximately 1.4 m and trees within them at the same spacing. Some silver fir (Abies alba Mill.), grand fir (Abies grandis Lindl.), Scots pine (Pinus silvestris L.) and larch (Larix decidua Mill.) were found in the stand, but 95% of the trees were Norway spruce.

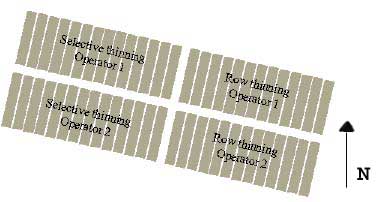

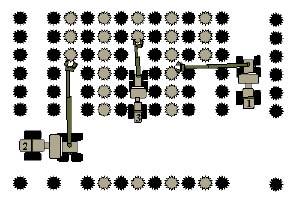

Striproads had been established, and the stand had been selectively thinned twice before the study, which had reduced the stand density from about 4000 to about 1000 trees per ha (N1 according to symbols in Table 1). A main hauling road (5 meters wide) perpendicular to the rows and 26 striproads (4 meters wide, spaced 15 meters apart) parallel to the rows divided the stand into 54 plots(approximately 0.08 ha each)consisting of approximately 9 tree-rows. The stand was divided in four parts where row thinning and selective thinning as well as the effect of the two operators was studied (Figure 1).

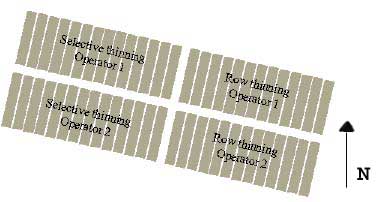

In selective thinning, the prescription was to leave 50-60% of the most vigorous trees uniformly spaced while in row thinning, it was to remove every second tree row in order to obtain easy passage for site preparation implements (normally row 2 and 4 according to Figure 2). A tree row was not to be removed if this would cause larger gaps (i.e. more than 6*6 meters) in the stand structure. If so, the adjacent tree row should be removed (i.e., shifting rows for a short distance), still bearing in mind the need for easy passage of site preparation implement. In both treatments dead, dying, recessive or damaged trees should be removed irrespective of their location, and trees of other species than Norway spruce should be preserved if possible. Saw logs of 2.2 meter length and 3.0 meter pulpwood were the target products. Saw logs were to have a minimum top diameter of 10 cm, be straight and without defects. Pulpwood should have a minimum top diameter of 7 cm and contain no rot. Treetops should be placed on the striproad because the shelterwood establishment was to be followed by site preparation and planting.

Figure 1. Study area and treatments.

Table 1: Stand mensurational data.

| Operator 1 Row thinning |

Operator 2 Row thinning |

Operator 1 Selective thinning |

Operator 2 Selective thinning |

|

| N1(ha-1) | 991 | 1088 | 953 | 975 |

| Dg1 (cm) | 17.6 | 16.7 | 18.0 | 16.6 |

| G1(m2ha-1) | 24.0 | 23.8 | 24.3 | 21.1 |

| Hg1 (m) | 14.0 | 13.7 | 14.2 | 13.7 |

| Vs1 (m3ha-1) | 182 | 178 | 186 | 157 |

| N2 (ha-1) | 417 | 508 | 425 | 433 |

| Dg2 (cm) | 16.3 | 15.9 | 17.2 | 15.3 |

| G2 (m2ha-1) | 8.7 | 10.1 | 9.8 | 8.0 |

| Hg2 (m) | 13.6 | 13.4 | 13.9 | 13.2 |

| Vs2 (m3ha-1) | 65 | 74 | 74 | 58 |

| Vm2 (m3ha-1) | 57 | 65 | 65 | 51 |

| N3 (ha-1) | 574 | 580 | 528 | 541 |

| Dg3 (cm) | 18.4 | 17.4 | 18.7 | 17.6 |

| G3 (m2ha-1) | 15.3 | 13.7 | 14.5 | 13.2 |

| Hg2 (m) | 14.3 | 14.0 | 14.4 | 14.0 |

| Vs3 (m3ha-1) | 117 | 104 | 112 | 100 |

Symbols according to IUFRO standard (extended) [2, 18]:

d: Single tree diameter at breast

height

Subscripts following symbols:

|

Figure 2. Row numbers.

For both methods a residual density of approximately 550 trees per ha after thinning was the silvicultural target.

Before establishing the shelterwood, diameters at breast height (d1 in Table 1) were measured in samples (1141 trees), while d1/h1 (where h1 is height in meters) was measured on 39 trees. After establishing the shelterwood, d3 were measured on all (2284) shelter trees and d3/h3 was measured on 159 trees. The harvested trees were counted during the time study and d2 was registered on 820 of the 1818 harvested trees. No d2/h2 were measured on harvested trees. A diameter/height function built on the same model as [26] was estimated on the basis of all d/h (h=(d*(1.20+0.360*d)-1)3+1.3). Total stem volume per hectare (vs2) was calculated from a standard total stem volume function [22]. The harvester head measured the merchantable volume (vm2) during harvesting.

The harvesting was done with a Silvatec 656 TH single-grip harvester (see Table 2 for machine details) driving on the striproads parallel to the rows. Extraction was carried out with a Valmet 820 forwarder (see Table 2). Saw logs were extracted first, followed by pulpwood. Saw logs were loaded in two tandem stacks on the forwarder in order to double the volume of each load. Harvesting was carried out between the 20th and the 22nd and the extraction between the 26th and the 28th of May 1997.

Table 2. Machine specifications.

| Harvester: Silvatec 656 TH

Engine type and power: Perkins 1006-T, 114 kW Weight: 11000 kg Width: 2.5 m Length: 6.3 m Crane type and reach: Silvatec 7570, 7.0 m. Harvester head type and weight: Silvatec 445, 750 kg Inlet diameter: 50 cm Delimbing diameter: 5-45 cm |

| Forwarder: Valmet 820

Engine type and power: Valmet 420 DW, 80 kW Weight: 9300 kg Width: 2.5 meter Length 7.9 meter Load area: 3.4 m2 Max load: 8500 kg Crane type and reach: Cranab 580, 5.4 m Grapple type and area: Cranab 280, 0.28 m2 |

Productive work time [8] was recorded in a cumulative time study using SIWORK-3 software on a Husky Hunter computer [29]. In the harvesting study, the unit of observation was the individual tree, and in the forwarding study it was the individual load. In the harvesting study the productive work time for harvesting was divided into processing time, positioning time, moving time and preparation time. In the forwarding study the productive work time for forwarding was divided into loading time, time to drive while loading, time to adjust the load, unloading time, driving time with full load, and driving time without load (Table 3).

The harvesting time-study results have been standardised to fixed conditions (tree removal rate (N2)=450 trees/ha, diameter of removed trees (d2)=15.8 cm) through the use of covariates. In the harvesting study, the analysis of processing time and positioning time was based on 820 single tree observations. For processing time, d2 has been used as covariate. For positioning time, d2 was also tested as covariate, but it had no significant effect. Moving time per ha was calculated on the basis of 46 observations each representing moving along a striproad (24 observations in row thinning and 22 in selective thinning). The areas were calculated as half the sum of the two plot areas on each side of the striproad. Analysis of moving time per ha was done using N2 as covariate. After standardising to fixed conditions (N2=450 trees /ha), moving time per tree was calculated as moving time per ha divided by 450. Preparation time per ha was calculated and analysed the same way as moving time, but without covariate.

For the extraction, the time consumption per m3m (merchantable volume) was calculated on the basis of data from 20 full loads (4 loads of pulpwood in row thinning, 6 loads of pulpwood in selective thinning, 6 loads of saw logs in row thinning, and 4 loads of saw logs in selective thinning). The time to drive while loading has been adjusted proportionally to the number of removed trees (N2) to eliminate the effect of thinning intensity (Timeadjusted=Time*N2/450). Extraction distance was standardised to 150 m on forest roads and 100 m on striproads/main hauling roads on the basis of a linear regression.

After harvesting and forwarding, the number of injured shelter trees was registered in all 54 plots. All visible wounds exposing the xylem were registered irrespective of their size, according to [15]. Damaged trees were classified in two groups: (1) visible root-damage and damage lower than one meter above the ground and (2) damage one to five meters above the ground.

All analyses were carried out in the SAS statistical package, version 6.12 [4,5]. Models have been tested for outliers, influential values, and constant variance in the guided data analysis module. Transformations have been made where appropriate in order to obtain normal distributions, but all mean values are calculated on untransformed data. Typically, variance of the residuals in time-study data is non-constant, and is characterised by the "right opening megaphone distribution" [34] i.e. there is a greater variation associated with the larger observations than with smaller. The logarithmic transformation has been found to be suitable for time study data giving the transformed observations a normal distribution and a constant variation.

The economical analyses were based on work place (i.e., scheduled) time. For both harvesting and forwarding work place time was calculated as 1.49 times the productive work time [30]. The productive work time is considered equal to E0 (Effective work-time according to [3]). Prices for saw logs and pulpwood were assumed to 38 and 23 US $ m-3m respectively. Machine costs was set to 119 US $ h-1 for the harvester and 81 US $ h-1 for the forwarder in terms of work place time [1].

RESULTS

In total 1818 trees were harvested giving 143 m3m saw logs and 87 m3m pulpwood. The ratio between Vm2 and Vs2 was calculated to 87.5% based on the total merchantable volume and the total stem volume (Table 1). The productive work time for harvesting was studied for 17.0 hours and the forwarding productive work time for 21.3 hours. The overall productivity was 13.5 m3/hour (productive work time) for harvesting and 10.8 m3/hour for forwarding.

The reduction in basal area was around 40% and the thinning quotient was approximately 90% in both row thinning and selective thinning (Table 1).

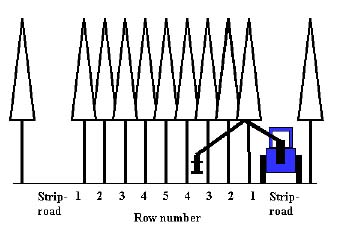

Before thinning, the density of trees decreased with increasing distance from the striproad. In selective thinning the number of removed trees decreased with increasing distance from the striproad, and therefore selective thinning resulted in quite a uniform distribution of shelter trees. In row thinning most trees were removed in tree row 2 and 4 in accordance with the prescription. Row thinning was more strictly practised in row 2 than in row 4, and row thinning resulted in a high density of shelter trees in tree row 1 (Figure 3).

Table 3: Work elements.

Operation | Work element and abbreviations | Description and demarcations | Priority |

| Harvesting | Processing time | Starts when the boom reaches the tree and the saw begins to fell the tree and ends when the harvester head releases the treetop on the striproad and the boom starts to move for the next work element. | 1 |

| Positioning | Starts when the harvester head releases the treetop, slash etc. and when the boom moves towards the next tree and ends when the saw begins to fell the tree. | 1 | |

| Preparation time | Starts when harvester head releases the treetop and the boom is used for preparation purpose and ends when the boom moves towards the next tree. | 1 | |

| Moving time | Starts when the treetop, slash etc. is released and ends when the wheels stops rolling | 2 | |

| Extraction | Loading time | Starts when the grapple starts to move for loading and ends when the grab has placed the assortments on the load and moves for the next work element. | 1 |

| Time to adjust the load | Starts when the grapple starts to move for adjusting the load and ends when the grapple starts to move for the next work element. | 1 | |

| Time to drive while loading | Starts when the grapple stops to move and the machine starts to move and ends when the forwarder stops and the grapple starts to move for the next work element. | 2 | |

| Unloading time | Starts when the grapple starts to unload. Ends when the grab stops to move and the forwarder starts to drive. | 1 | |

| Driving time with full load | Starts when the grapple stops to move and the forwarder starts to drive out of the stand. Ends when the forwarder stops moving and the grapple starts to move for unloading | 2 | |

| Driving time without load | Starts when the grapple stops to move and the forwarder starts to drive into the stand. Ends when the forwarder stops moving, and the grapple starts to move for loading. | 2 | |

Figure 3. Proportion of trees in rows. Row 1 is closest and row 5 is farthest away from the striproad.

Table 4. Harvesting productive work time in cmin tree-1 (% of total time).

| Work element | Operator 1 Row thinning | Operator 2 Row thinning | Operator 1 Selective thinning | Operator 2 Selective thinning |

| Processing time | 31.9 b* | 32.7b | 29.2 a | 28.8 a |

| Positioning time | 12.4 b | 14.1 c | 11.0 a | 11.1 a |

| Moving time | 6.6 a | 7.6 a | 6.2 a | 6.5 a |

| Preparation time | 2.1 b | 0.3 a | 2.1 b | 0.3 a |

| Productive work time for harvesting | 53.0 b | 54.7 b | 48.5 a | 46.7 a |

selective thinning |

||||

| Processing time | 32.3 (60) | 29.0 (61) | ||

| Positioning time | 13.3 (25) | 11.1 (23) | ||

| Moving time | 7.1 (13) | 6.4 (13) | ||

| Preparation time | 1.2 (2) | 1.2 (3) | ||

| Productive work time for harvesting | 53.9 (100) | 47.6 (100) | ||

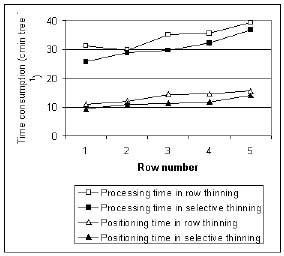

After standardisation, harvesting productivity was 10% higher in selective thinning than in row thinning because processing and positioning took shorter time. No significant difference was found between the two operators except that operator 1 used more preparation time (Table 4). Both processing and positioning took longer time if trees were harvested far away from the striproad, and in all tree-rows processing and positioning took longer time in row thinning than in selective thinning (Figure 4). Moving time per ha was strongly correlated to N2 and no significant difference between row thinning and selective thinning could be found (Table 4). The total number of working positions per ha (the number of the work element moving per ha) was also strongly correlated with N2 while moving time per position did not seem to be correlated with N2.

A full load of saw logs and pulpwood consisted of 10.5 m3m and 6.6 m3m (m3 merchantable volume) respectively for both treatments. There was no significant difference in the productive work time for forwarding between the two treatments, but significant differences were found between the two assortments. Seventy-three percent of the time consumption was used for loading, drive while loading and adjusting the load and 27% for driving with load, driving without load and unloading. Loading time and time to drive while loading took longer for pulpwood, and time to adjust the load took longer for saw logs (Table 5). A grapple contained 0.16 and 0.11 m3m saw logs and pulpwood respectively when loading. Corresponding values for unloading was 0.42 and 0.50 m3m. On basis of the observations of driving time with load and driving time without load two regressions were made (Table 5). The speed on forest roads was estimated to 11 km h-1 loaded and 13 km h-1 empty, and the speed at the striproads were estimated to 4 km h-1, both loaded and empty.

The only difference in the economic analysis is in the harvesting costs (Table 6). The reason is that no differences in mean tree-size of the harvested trees, in the distribution of assortments, or in the productive work time for forwarding was found between the treatments. This result would not be expected if the thinning prescription were to be followed more strictly.

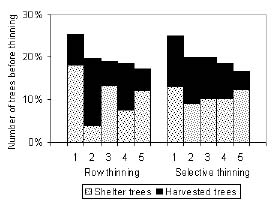

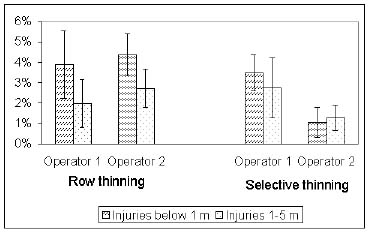

The selective thinning seems to result in lower damage rate below one meter, especially for operator 2. Row or selective thinning or operator did not seem to affect damage rate from one to five meters above ground level (Figure 5).

DISCUSSION

Shelterwoods should be established using at least two thinnings [23]. The thinning operations studied represent the shelterwood establishment for the stands studied given that the initial thinning was done five years earlier.

Harvester productivity in this study was slightly higher than found in [9] and [11]. The reason is probably the very easy conditions, the uniform stand and the dense net of striproads. It was expected that row thinning would have resulted in a thinning quotient (the quotient between breast-height-diameter for the harvested trees and breast-height-diameter for the shelterwood) near one and selective thinning round 80-90%. The study results showed no difference in thinning quotient between the two treatments. The explanations are that row thinning was not strictly adhered to, and that large trees often stand isolated and therefore are preserved to a higher degree than small trees. The operators maybe prefer to remove small trees in row thinning because a tree represents an obstruction for site preparation irrespective of its size. Another explanation could be that the operators are so used to thin from below that they do it automatically, even in row thinning.

Figure 4. Processing time and positioning time for the harvester. Row 1 is closest and row 5 is farthest away from the striproad.

Table 5. Forwarding productive work time in cmin m-3m (% of total time).

| Work element | ||||

| Saw logs Row thinning | Saw logs Selective thinning | Pulpwood Row thinning | Pulpwood Selective thinning |

|

| Loading time | 230 a | 213 a | 267 a | 258 a |

| Time to drive while loading | 79 a | 72 a | 113 b | 93 ab |

| Time to adjust the load | 97 b | 86 b | 46 a | 42 a |

| Unloading time | 88 b | 81 b | 62 a | 62 a |

| Driving time with load** | 30 | 30 | 48 | 48 |

| Driving time without load** | 25 | 25 | 40 | 40 |

| Productive work time for forwarding | 550 a | 507 a | 577 a | 544 a |

| Mean values for Saw logs | Mean values for Pulpwood |

|||

| Loading time | 222 (42) | 263 (47) | ||

| Time to drive while loading | 75 (14) | 103 (18) | ||

| Time to adjust the load | 92 (17) | 44 (8) | ||

| Unloading time | 85 (16) | 62 (11) | ||

| Driving time with load** | 30 (6) | 48 (9) | ||

| Driving time without load** | 25 (5) | 40 (7) | ||

| Productive work time for forwarding | 529 (100) | 561 (100) | ||

| Regressions: | Driving time with load = (86.59 + 0.552*FR + 1.498*SR)/load size |

| Driving time without load=(51.68 + 0.458*FR + 1.468*SR)/load size | |

| FR = meters on forest road, SR = meters on striproads | |

| Load size for saw logs: 10.5 m3m | |

| Load size for pulpwood: 6.6 m3m |

Table 6. Income and costs at roadside (US $ ha-1).

| Row thinning | Selective thinning | ||

| Income | Saw logs | 1333 | 1333 |

| Pulpwood | 495 | 495 | |

| Total | 1828 | 1828 | |

| Costs | Harvesting | 721 | 644 |

| Extraction Logs | 373 | 373 | |

| Extraction Pulpwood | 242 | 242 | |

| Total | 1337 | 1259 | |

| Net income | 491 | 568 | |

Figure 5. Proportion of damaged shelter trees with 95% confidence intervals below 1 m above the ground and 1-5 m above the ground.

Processing time increases with increasing distance from the tree to the striproad because the tree must be pulled out to the striproad. Positioning time also increases with increasing distance from the striproad to the tree because it takes more time for the boom to move the longer distance. One explanation of the higher time consumption in row thinning is therefore that the trees were, on average, harvested farther away from the striproad. Another explanation is the higher number of shelter trees in tree row 1 for row thinning (Figure 3), because these trees obstructed boom operations the most.

The increase in moving time per ha with increasing thinning intensity shows that moving time was not only determined by the driving distance, but also connected with the harvesting operation (in line with positioning time). In other words one can say that one part of the moving time per ha was used to move the harvester on the striproads, and the other part was used for micropositioning the machine in order to harvest a tree.

Time consumption for loading depends on the volume per grapple and therefore loading is faster for saw logs than for pulpwood. When unloading, the opposite is true (more volume in a grapple of pulpwood) because of the longer lengths. The time consumption to drive while loading depends on the density (m3ha-1), and was therefore shorter for saw logs than for pulpwood. Adjusting the load includes additional time for loading tandem stacks on the forwarder, and therefore time to adjust the load is longer for saw logs. On the other hand the tandem stacks double the load, which halves the driving time with and without load per unit of production. The size of the load does not seem to affect speed, but driving without load is faster than driving with load.

The damage rate was acceptably low compared with similar studies [16, 32, 35] taking into consideration that is was a result of both harvesting and extraction. The present study showed more damage below 1 m from the ground in row thinning compared to selective thinning. Fröding [14] examined the spatial distribution of injuries in thinning and found that injury rates often decrease as the distance from the striproad increases. This could explain the higher damage rate in row thinning simply because there were more shelter trees left in row 1. The larger amount of damage in row thinning can also be attributed to the different distribution of shelter trees for the two treatments. Shelter trees are quite uniformly spaced after selective thinning, which means that there is approximately four meters between the trees. The average distance between the shelter trees in row thinning depends on the orientation. The distance between the shelter trees in the tree -rows is smaller than average and the inter-row distance is larger than average. Because the trees are felled perpendicular to the tree-rows, the spacing between the trees in the tree-row determines the space for felling and thereby the level of damage.

In both treatments, the operators were to remove trees with obvious damage, providing that it did not result in an unacceptably large gap in the shelterwood. The work pattern in selective thinning might make it easier to remove damaged trees, because the damaged trees could be reached more easily.

Both operators preferred to do selective thinning. The reason might lie in this being routine practice, but the operators also pointed out that the single-grip harvester is designed in a way that the operator can see the whole tree, allowing him to assess its quality. The view from the cabin also gives the operators a good picture of the distribution of the trees, but the operators can not easily identify the specific tree-rows, because their line of sight is perpendicular to the rows. Therefore they often had to stand up or lean forward to identify the tree-rows in row thinning.

Selective thinning must be preferred from a stand vigour aspect, because vigour is a more dominant selection criterion in selective thinning than in row thinning. In a vigorous stand like the one studied, almost all trees are acceptable shelter trees. In spite of this, row thinning could not be practised strictly. In less vigorous, stands row thinning will be unacceptably restrictive. If row thinning had been done in earlier thinnings, it could have been applied more strictly.

An alternative way to do row thinning is to drive on striproads perpendicular to the rows (Figure 6, Harvester no. 2). This would make it easy for the operator to identify the tree-rows and remove every second row. The accessibility of the harvester head in the stand would be improved, and the felling would be parallel to the rows. This would increase productivity and simultaneously reduce the number of injuries.

Row thinning could alternatively be carried out using a more compact harvester being able to drive in a 2.2-2.4 m wide corridor (e.g. Sampo Rosenlew 1046X see Figure 6, harvester no. 3). There are also forwarders narrow enough to drive in such a corridor [25]. Harvester productivity would increase because of decreased positioning time. This way of doing row thinning could be of interest as younger spruce plantations in Denmark are often established with an inter-row spacing of 1.7 meters, providing a 2.8-3.0 m wide corridor after row thinning. That space makes it more realistic to drive machines there.

The way row thinning has been carried out in this study has a negative influence on the harvesting productivity and also on the damage rate, but row thinning may still be preferred if the disadvantages are compensated by advantages for the site preparation. The final conclusion must be that the two treatments can be combined. The prescription might be to leave vigorous trees on the area uniformly spaced, at the same time being aware of the accessibility requirements of site preparation equipment. Other ways of executing row thinning e.g. driving on the removed rows or driving on striproads perpendicular to the present striproads are expected to give higher productivity and lower damage rate than the method used in this study.

Figure 6. Row thinning can be performed from striproads parallel to the rows (1), or from striproads perpendicular to the rows (2), or with a narrow harvester driving in the stand (3).

ACKNOWLEDGEMENTS

The authors would like to thank Andreas Bergstedt, Dr. Dag Fjeld, and Dr. Niels Heding for valuable comments and suggestions in the writing process. Other thanks are addressed to the machine operators, and to the administration at Klosterheden State Forest for allowing the study to take place on their property and for providing machines and personnel.

This project was co-financed by The Ministry of Food, Fisheries and Agriculture and the Ministry of Environment and Energy. Further funding was received from the Nordic Forest Research Co-operation Committee through its "Forest Management for environmental services" program.

AUTHOR CONTACT

Kjell Suadicani can be reached by e-mail at --

kjs@fsl.dk

LITERATURE CITED

[1] Andersen, P. S. pers. comm. 1999. Machine station leader at Klosterheden State Forest, Gammel Landevej 35, Fabjerg, 7520 Lemvig, Denmark.

[2] Anon. 1965. The standardisation of symbols in forest mensuration. IUFRO. Technical bulletin no. 15. Maine Agricultural Experimental Station. 32 pp.

[3] Anon. 1978. Nordic forestry work-study nomenclature. Nordiska Skogarbetsstudiernes råd, Oslo. 130 pp.

[4] Anon. 1989a. SAS/STAT® User's Guide Version 6, Fourth Edition, Volume 1. SAS Institute Inc. Cary, NC. 943 pp.

[5] Anon. 1989b. SAS/STAT® User's Guide Version 6, Fourth Edition, Volume 2. SAS Institute Inc. Cary, NC. 846 pp.

[6] Anon. 1991. Terrain Classification System for Forestry Work. Forskningsstiftelsen Skogsarbeten. Kista. 29 pp.

[7] Anon. 1994. Strategi for bæredygtig skovdrift [Strategy for sustainable forestry]. Miljøministeriet. Betænkning nr. 1267. 217 pp.

[8] Björheden, R. 1995. Forest Work Study Nomenclature. Test Edition valid 1995 - 2000. IUFRO/SUAS, Dept of Operational Efficiency, Garpenberg. 16 pp.

[9] Brunberg T., A. Thelin, and S. Westerling. 1989. Basic data for productivity standards for single-grip harvesters in thinning. Forskningsstiftelsen Skogsarbeten Redogörelse 3. 25 pp.

[10] Clausen, J. T. 1995. Conversion of heath plantations into forests. In: Forfang, A.-S., P. Sørensen and P. Feilberg (Eds.). Skovbrugets grønne alternativ - en debatbog om naturnær skovdyrkning. [The forestry´s green alternative - a debate book about close-to-nature forestry]. Nepentes, Århus. 128 pp.

[11] Eliasson, L., J. Bengtsson, J. Cedergren and H. Lageson 1999. Comparison of single-grip harvester productivity in clear- and shelterwood cutting. J. For. Eng. 10(1):43-48.

[12] Fjeld, D. 1992. Snauhogst og skjermstillingshogst - en sammenligningsstudie av tidsforbruk ved mekanisert hogst [Clear-cutting and shelterwood a comparative time-study of mechanised harvesting]. Aktuelt fra Skogforsk 11. 21 pp.

[13] Fjeld, D. 1994. Time consumption for selection and patch cutting with a one-grip harvester. Communications of Skogforsk 47(4). 28 pp.

[14] Fröding, A. 1982. The condition of newly thinned stands - a study of 101 randomly selected thinnings. Swedish University of Agricultural Sciences. Dept. of operational efficiency. Report No. 144. 47 pp.

[15] Fröding, A. 1983. Status of remaining stand after partly mechanised thinning. Swedish University of Agricultural Sciences. Dept. of operational efficiency. Report No. 152. 34 pp.

[16] Fröding, A. 1992. Thinning damage to coniferous stands in Sweden. Dissertation. Swedish University of Agricultural Sciences. Dept. of Operational Sciences. Garpenberg. 49 pp.

[17] Henriksen, H. A. 1971. Betragtninger vedrørende hedeskovenes foryngelse belyst ved et par eksempler [Considerations about regeneration of the heath plantations enlightened by some examples]. Dansk Skovforen.Tidsskr. LVI: 1-29.

[18] Holten-Andersen P. 1989. Danish Yield tables in the past century. Forstl. Forsøgsv. Danm. 42:71-145.

[19] Hånell, B., T. Nordfjell and L. Eliasson 2000. Productivity and costs in shelterwood harvesting. Scand. J For. Res. 15:561-569.

[20] Lageson, H. 1997. Effect of thinning type on the harvester productivity and on the residual stand. J. For. Eng. 8 (2):7-14.

[21] Løfting, E. C. L. 1949. Regeneration of Norway spruce in the Danish heath regions. Part 1: Problems of the regeneration. Forstl. Forsøgsv. Danm. 18:327-383.

[22] Madsen, S. F. & Heusèrr, M. 1993. Volume and stem taper functions for Norway spruce. For. & Landsc. Res. 1(1):51-78.

[23] Neckelmann, J. 1995: To foryngelsesforsøg i rødgran på midtjysk hedeflade [Alternative regeneration methods in Norway spruce on poor, sand soil]. Forskningscentret for Skov & Landskab, Hørsholm. Skovbrugsserien nr. 16-1995. 212 pp.

[24] Nilsson, N. 1985. Skador vid kranarbete i gallring [Damages by boom-work in thinnings]. Swedish University of Agricultural Sciences. Department of Operational Sciences. Garpenberg. 35 pp.

[25] Nordfjell, T., E. Bøllehuus and E. J. Christensen 2001. Små hjuldrevne udkørselsmaskiner - præstationer og økonomi [Small wheel-driven forwarders - productivity and economy]. Skov & Landskab (FSL). Videnblade Skovbrug 6.4-3. 2 pp.

[26] Näslund, M. 1936. Skogsförsöksanstaltens gallringsförsök i tallskog [The Forestry Research Institute's thinning studies in pine]. Meddelanden från Statens Skogsförsöksanstalt 29. pp. 1-169.

[27] Oksbjerg, E. 1951. Rødgranplantagernes foryngelse i de jyske hedeegne. 2. del: Underplantning, selvsåning og renafdrift [Regeneration of the Norway spruce in the Danish heath plantations part 2: Planting in shelterwood, natural regeneration and clear-cutting]. Forstl. Forsøgsv. Danm. 20:165-228.

[28] Pregent, G. 1998. Thinning of plantations. Mémoire de recherche forestière n° 133 Gouvernement du Québec, Ministère des Ressources naturelles, Forêt Québec, Direction de la recherche forestière. 38 pp.

[29] Rolev, A.-M. 1988. SIWORK3, version 1.1 Work study and field data collection system based on Husky Hunter hand held computer. Danish Institute of Forest Technology, Frederiksberg. Denmark. 37 pp.

[30] Samset, I. 1995. 150 år i forsøksskogen [150 years in the research forest ].Skogforsk. Rapport 9/95. 302 pp.

[31] Schmidt-Vogt, H. 1987. Die Fichte. Ein Handbuch in Zwei Bänden [The Norway spruce a handbook in two parts]. 2.edn. Paul Parey, Hamburg and Berlin. 647 pp.

[32] Siren, M. 1999. One-grip harvester operations, silvicultural results and possibilities to predict tree damage. In Keane, M.G. and P.D. Kofman [Eds.] The thinning wood chain. Proc. IUFRO 3.09.00 Conf. on the harvesting and economics of thinning. National Council for Forest Research and Development, University College Dublin, Ireland. May 4-7, 1999. Pp. 152-167.

[33] Sirén, M. 2001. Tree damage in single-grip harvester thinning operations. J. For. Eng. 12:1. pp. 29-38.

[34] Weisberg, S. 1985. Applied linear regression. Second edition. John Wiley & Sons New York. 324 pp.

[35] Westerberg, D., Sikström, U. von Hofsten, H. & Gustafsson, L. 1996. Skärmskogsbruk [Shelterwood forestry]. In Utvecklingskonferens 1996. The Forest Research Institute of Sweden. Redegörelse nr. 1. pp. 112-122.