Vol. 14 No. 2 July 2003

Albert J. Lefort, Jr.

Louisiana Department of Wildlife & Fisheries

Louisiana, USA

Cornelis F. de Hoop

Louisiana State University Agricultural Centre

Louisiana, USA

John C. Pine

Brian D. Marx

Louisiana State University

Louisiana, USA

The authors are, respectively, Biologist, Louisiana Department of Wildlife and Fisheries; Associate Professor, Louisiana Forest Products Development Center, School of Renewable Natural Resources; Professor, Institute for Environmental Studies; and Professor, Department of Experimental Statistics.

ABSTRACT

Characterizing injuries and their trends will allow safety managers to concentrate their resources on the areas of safety that will be most effective in the workplace. Injuries reported to the Louisiana Office of Workers' Compensation Administration for 1986 to 1998 were characterized according to the part of the body affected, the nature of the injury, the source of the injury, and the type of accident for the timber harvesting industry. Many of the injuries in the logging sector were sprains / strains to the knees. Injuries resulting from falling onto structures and surfaces were common and rising. Although the number of accidents in each category is generally decreasing, some trends should be of concern. There was no significant linear trend in overall accident rates since 1991. While the proportion of cuts and lacerations declined, the proportion of fractures increased. This coincided with a time period when logging operations in Louisiana experienced rapid mechanization and insurance companies started enforcing the use of personal protective equipment. The proportion of transportation accidents rose more than any other category. Some suggestions on focusing and improving current safety programs are given. The need for continued and improved training of managers and employees seems to be most critical.

Keywords: forestry accidents, injuries, logging safety, Louisiana, safety training.

INTRODUCTION

The forest products industry is perhaps one of the most dangerous industries in the United States [6 , 24 , 37 , 38 , 41] and throughout the world [9 , 18] . The U.S. Bureau of Labor Statistics [5] reported that logging has 26 percent more injuries than general industries, and loggers are 19 times more likely to be killed on the job. The average fatality rate was 11.5 times higher for forest industries than the overall work force in New Zealand [9 , 32] . Although very dangerous, the forest products industry is of major importance throughout Louisiana, representing the largest segment of the agricultural economy in the state [35] .

Injuries and illnesses resulting from accidents and exposures in the workplace cost industry billions of dollars each year. Of 596 closed logging industry accident cases in the state of West Virginia in 1989-1990, payments averaged US$1903 in medical expenses plus US$1216 in disability payments per workers' compensation insurance claim [29] . In a logging industry study in Louisiana, sprains and strains averaged US$20,000 per claim, neck injuries averaged US$38,500 per claim, and injuries to the lower extremities averaged US$10,800 per claim [13 , 16] (only closed cases over seven days' of disability were included in the study). The French Mutual Social Insurance System reported that the total direct cost of accidents in that country was 79,000,000 French Francs in 1996, or FRF 26,600 (approx. US$ 5,165) per lost-time accident.

The above costs reflect only the direct costs of injury. One major forest products company in the USA performed an in-house study and concluded, "For every dollar spent on injuries, there is another US5 to $7 of hidden costs," such as reduced productivity and finding substitute workers [36] . Employees can experience loss of wages, poor workplace morale, extensive personal grief and extended losses to the entire family. Accidents and exposures in the workplace can impose significant financial burdens on employers through employee health and workers' compensation programs.

One way to reduce workers' compensation costs is to reduce the number of accidents and injuries in the workplace. This can be accomplished through the improvement of safety programs. Any program aimed at reducing the number of accidents will require analyzing the accidents to develop a sound plan to educate workers and managers and to design safer worksites and equipment.

OBJECTIVE

The objective of this research is to characterize accidents and injuries in the logging industry according to the nature, type, source, and frequency of the injuries and demographics of the workers. This information will provide a basis for improving safety programs in the logging industry.

LITERATURE REVIEW

Workers' compensation claims may be one of the few reliable sources of data for the analysis of accidents and injuries in the workplace. A study by the French Mutual Social Insurance System stated that the logging accident rate for 1996 was 142 lost time accidents per 1,000,000 worker-hours (approximately 28 lost time accidents per 100 workers), down 14% from 1976 [19] . About 16% of these accidents are "serious." Pine et al. [44] conducted a study based upon information from workers' compensation claims to characterize injuries in the logging industry in Louisiana. The data were based on injuries that resulted in more than seven days of disability for the years 1985 through 1990. This paper provides an update of that study. The authors found that the number of reported workers' compensation injuries in Louisiana decreased at a time when the work force increased slightly. New employees were found to have the most injuries. Cuts and lacerations were the most common injury during the mid-1980s, but sprains and strains were the most common by 1990. This trend is probably attributable to the mechanization of felling activities. The plurality of the injuries occurred to the lower extremities of the body. This may be caused in part by cuts from chainsaws on the feet, legs, and thighs. Axelsson [2] determined that accident rates in Sweden among chainsaw operators were four times higher than among machine operators.

Several other studies concluded that the plurality of accidents occurred to the lower extremities. A German study of accidents in the years 1994-1995 found that about 40% of all injuries to forestry workers (including loggers) occurred to the lower extremities and that 15% of all injuries were the direct result of chainsaws [28] . A Polish study of 1986-1995 accidents found that 44% of forest worker (including logging) accidents occurred to the lower extremities [40] . A Brazilian study of 1985-88 accidents pointed out that the most severe accidents occur to the feet [23] . A continuing study in New Zealand of all reported accidents found that most of these occurred to a foot. In particular, these injuries usually occurred to the left foot at the base of the big toe, directly behind the steel toe of the boot [42 , 43] . Leg protection (saw chaps) works relatively well to prevent chainsaw cuts, but foot protection development is lagging because the long strings of textile that make leg protection effective cannot be incorporated into footwear [10] .

Hassler et al. [29] examined the West Virginia wood products industry's workers' compensation claims over two fiscal years, 1989-90. For the logging industry, the most common part of the body injured was the limbs. They also found that sprains, open wounds, contusions, and fractures accounted for nearly 75 percent of all reported injuries in the logging industry sector.

Shaffer and Milburn [46] analyzed injuries on skidder logging operations in the southeastern United States. A random sample of 303 from 2,000 injury claims in 1997 from three workers' compensation insurance providers was taken. Forty percent of the injuries occurred to those who had been working for less than one year with the same company. Manual chainsaw delimbing was the most hazardous activity in partially mechanized operations, whereas repairing equipment was the most hazardous in fully mechanized operations. Falls incurred by operators while mounting or dismounting equipment were also a significant source of injury. Many of the injuries that occurred on mechanized operations occurred when the individuals were performing non-routine tasks. This included operators manually felling trees in fully mechanized operations. These workers have fewer opportunities to maintain their physical strength and chainsaw operating skills; thus, they are more likely to have an accident.

Most of the literature points out that nationwide statistics are available to determine overall trends, but such studies rarely go much beyond determining accident rates and trends. Much of the literature that reviews accident databases focuses on accidents to the extremities and to chainsaw accidents. In the USA, Shaffer and Milburn [46] went beyond the generalities and identified some points that are not readily obvious from a typical accident database. Other than this, detailed studies at the state level are lacking.

MATERIALS AND METHODS

Data for this research came from claims reported to the Louisiana Department of Labor, Office of Workers' Compensation Administration (state level agency). These claims are the initial report of injury, which employers or insurance companies must submit to the Office of Workers Compensation Administration.

Claims for injuries and accidents were reported on the Employer's Report of Occupational Injury or Disease Form (LDOL-WC-1007), which is similar to the OSHA 101 (and 301) form of the federal Occupational Safety & Health Administration (OSHA). The narrative description of the accident or exposure from the form was coded by a staff member of the Office of Workers' Compensation Administration and categorized by nature of injury, source of injury, part of body affected, and type of accident. The codes for this classification were defined by the American National Standards Institute [1] method of recording basic facts relating to the nature and occurrence of work injuries.

The data are based on reportable claims (fatality, permanent disability, and temporary disability resulting in more than seven days of disability) received between 1986 and 1998, inclusive, for SIC 2411 - Logging [20] . Only the data, after entry by Office of Workers' Compensation Administration personnel, were accessible. Thus, it was not possible to verify the interpretation by the data entry personnel nor to read the prose descriptions of the accidents.

Tests of homogeneity were conducted to determine if the proportion of a certain category of injury was consistent throughout the study period. The data were classified into a two-way contingency table according to two criteria: the injury characteristic and the year. To test the null hypothesis that the rows and columns of the contingency tables represent homogenous classifications, p-values were obtained for a significance level a = 0.05. This test helps in determining individual elements within a particular injury category that caused significant deviations from a homogeneous pattern of injury or illness occurrence. When categories of injuries exhibited non-homogeneous patterns, Poisson residuals were used to identify departures from homogeneity (+/- 2).

To further determine whether overall trends were statistically significant, analysis of variance was tested on the major categories over the years, especially those categories identified in the contingency tables as having significant departures from homogeneity.

RESULTS

The number of workers' compensation claims in Louisiana peaked in 1987 at 566 (Table 1). It dropped dramatically in 1991 to 246 and has generally remained in the mid 200s since then. The number of employees in logging operations, according to the Louisiana Department of Labor, fell from 3348 in 1985 to 2784 in 1986, but then increased to 3491 in 1998. The dramatic drop in employment in 1985 is reflective of a recession in the logging industry and generally tough times for Louisiana during that year.

Incidence rates (the number of accidents per 100 full-time employee equivalents or 200,000 worker-hours) are used to compare the safety records of multiple-sized operations in a single industry. Overall, the incident rates showed a significant linear decline from 1986 to 1995 (p=0.0001, R2=0.88). The decline is better described as a linear decline through 1990 (p=0.003, R2=0.97), followed by a non-significant linear trend for 1991-1995 (p=0.36, R2=0.28) that averaged 8.1 accidents per 100 workers. In comparison to the incidence rates for the United States, the incidence rates for Louisiana were lower (Table 2).

Table 1. Number of Injuries > 7 days of disability in the Logging sector (SIC 2411) according to the Louisiana Office of Workers' Compensation Administration for 1986 to 9/30/1998, and Number of Employees according to the Louisiana Department of Labor. Counts for the last three years could be low due to late reporting.

| 1986 | 1987 | 1988 | 1989 | 1990 | 1991 | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | |

| Case | 547 | 566 | 506 | 474 | 448 | 246 | 257 | 287 | 279 | 268 | 188 | 161 | 121 |

| Emp | 2784 | 2934 | 2966 | 3101 | 3189 | 2960 | 3214 | 3371 | 3434 | 3434 | 3371 | 3469 | 3491 |

| Rate | 19.6 | 19.3 | 17.1 | 15.3 | 14.0 | 8.3 | 8.0 | 8.5 | 8.1 | 7.8 | — | — | — |

Table 2. Incidence Rates for all Recordable Accidents in the Logging Sector of the Forest Products Industry for the United States and Louisiana according to the U.S. Bureau of Labor Statistics 1986-1998 [5] .

| 1986 | 1987 | 1988 | 1989 | 1990 | 1991 | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | |

| U.S. | 19.1 | 19.3 | 19.8 | 19.5 | 18.1 | 15.9 | 14.6 | 13.8 | 11.0 | 10.5 | 9.1 | 10.1 | 8.4 |

| LA | 8.2 | 9.8 | 11.0 | 10.0 | 10.8 | 9.9 | 5.2 | 6.3 | 4.9 | 8.0 | 5.6 | 4.7 | 4.4 |

Tables 1 and 2 are used to compare the number of serious injuries obtained through the Louisiana Office of Workers' Compensation Administration (OWCA) with the incidence rates obtained by the Bureau of Labor Statistics (BLS) [5] . There are some differences in the development of these data of which the reader should be aware. One is that the BLS data are based on all OSHA recordable injuries, whereas the data from the Louisiana OWCA are injuries that exceed seven days of disability. Another is that the data from the OWCA are based on legally required reports, whereas the BLS data are based on a sample of companies [8] .

In theory, Table 1 represents accidents that are a subset of the accidents represented in Table 2. Therefore, the incidence rates in Table 1 should be lower than those in Table 2. This is often not the case. In conversations with personnel responsible for both databases, the authors were unable to deduce plausible reasons for the discrepancy.

From Tables 1 and 2, it is notable that the incidence rate for Louisiana made a dramatic drop around 1991, but that the national incidence rate dropped more gradually. Many other states experienced mechanization and workers' compensation problems similar to Louisiana, but not always at the same time.

Part of Body Affected

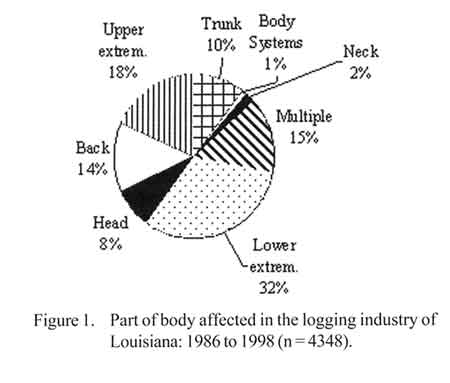

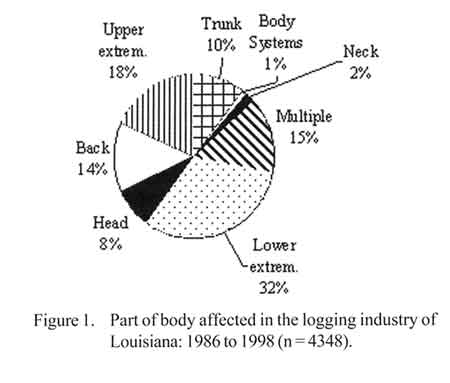

The part of the body affected identifies the part of the injured or ill employee's body directly affected by the injury or illness (Figure 1). The greatest portion of all claims occurred to the lower extremities (32%) and to the upper extremities (18%). Of those claims to the upper extremities, most of the injuries occurred to the fingers (49%) and hand (25%). Of the claims to the lower extremities, 28% of the injuries occurred to a knee (Figure 2).

Nature of Injury

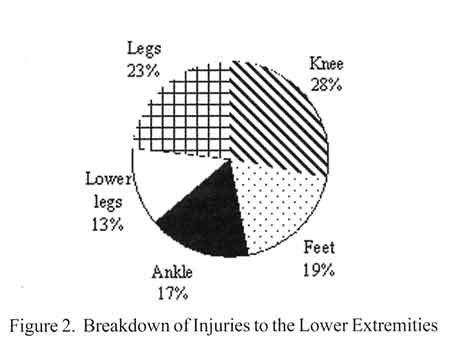

The nature of the injury names the principal physical characteristic of an injury. In the 1980s, cuts and lacerations accounted for the greatest portion of claims (Figure 3). These included all open wounds and many chainsaw injuries. By the early 1990s, sprains and strains accounted for the greatest portion of the total claims [44] . These claims included torn ligaments, ruptured muscles, and muscle tears. Traumatic injuries to the bones, which included fractures and dislocations, were responsible for a relatively small portion of the total claims in the 1980s, but were about equal to the portion of sprains and strains by the mid- and late 1990s.

Source of Injury

The source of the injury is the object, substance, exposure, or bodily motion that directly produced or inflicted the injury. Animals/Plants/Minerals (31%) were the most common source of injury. This category includes trees and limbs. Tools and equipment (including chainsaws) were responsible for 19% of the injuries. Other major categories were parts & materials (15%) and working structures and surfaces (13%).

Type of Accident

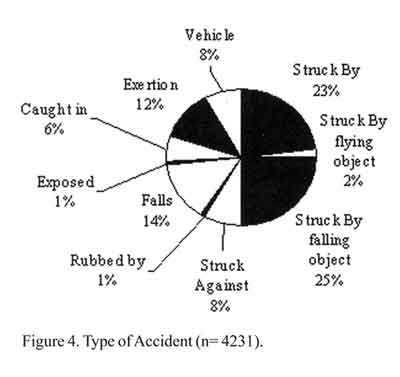

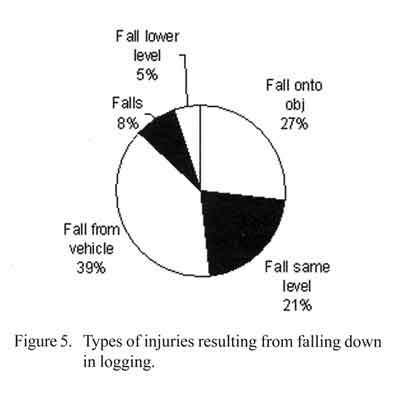

The type of accident or exposure identifies the event that directly resulted in an injury or illness (Figure 4). Most claims resulted from being struck by or against an object (58%). The plurality of claims resulted from employees being struck by a falling object (25% of all claims), which would include falling trees and limbs. Falls (14%) and exertion (12%) accounted for smaller portions of claims. Exertion includes injuries sustained while lifting, pushing, holding, carrying, turning, throwing objects, awkward from bending, climbing, crawling, twisting, reaching, or slipping. Most falls occurred from vehicles onto the working surfaces (39% of falls) (Figure 5). Falling onto an object (27% of falls) and falling down on the same level (21% of falls) accounted for many of the falls.

Display large image of Figure 3

Selected Detailed Combinations of Injuries

Finger Injuries

Finger injuries are 49% of upper extremity claims. Cuts and lacerations accounted for nearly 58% of these claims, fractures for 20%, amputations for 10%, and bruises for 12%. Of the cuts and lacerations, 15% resulted from contact with parts and materials, 69% from contact with various tools and 13% from contact with some type of machinery. Nearly 90% of all finger lacerations resulted from being struck by/against an object, while 9% resulted from the fingers getting caught in something.

Hand Injuries

Injuries to the hands were also significant, being 25% of upper extremity claims. Cuts and lacerations accounted for 70% of the claims that resulted in hand injuries. Bruises accounted for 18% of the claims, and fractures accounted for 12%. Of the lacerations to the hand, about 16% of the injuries resulted from contact with parts and materials, 66% from contact with tools, and 12% from contact with machinery. About 90% of the lacerations resulted from the hands being struck by/against an object.

Knee Injuries

Injuries to the knee were a major part of the total claims, being 28% of lower extremity claims. Sprains and strains accounted for 40% of the claims, cuts and lacerations for 31%, bruises for 20%, and fractures for 8%. Of the knee injuries that resulted in sprains and strains, 44% resulted contact with structures and surfaces and 42% from contact with trees or logs. Almost 44% of all knee injuries resulted from falling down, 32% resulted from a worker being struck by/against an object, and 24% were a result of bodily reaction or exertion, which included pushing, moving, or pulling an object.

Foot Injuries

Foot injuries were 19% of lower extremity claims. Cuts and lacerations accounted for 50% of these claims, bruises for 23%, and fractures for 19%. Of the foot injuries that resulted in cuts and lacerations, 71% resulted from contact with various tools, possibly chainsaws. Nearly 90% of the foot fractures resulted from workers getting a foot struck by/against an object, while 10% resulted from workers falling down.

CHI-SQUARE TESTS FOR ANALYZING THE HOMOGENEITY OF THE INJURIES

Tests of homogeneity were conducted to determine if the proportion of a certain category of injury was consistent throughout the years of the study period. The hypothesis requires homogeneity within each injury category across all years. For part of body (p=0.002), nature of injury (p=0.001), source of injury (p=0.001), and type of injury (p=0.001), there were indications of some statistically significant non-homogenous patterns. Tables 3-6 highlight the departures from homogeneity by identifying cells with observed and expected counts that produced large standardized chi-square residuals (greater than two in absolute value). In Table 3, for example, in 1986 and 1987 we found more injuries to the upper extremities than expected under the homogeneity assumption (observed 129, 121; expected 97, 99, respectively), and in 1994 and 1995 there were fewer injuries to the upper extremities than expected (observed 34, 33; expected 50, 47, respectively).

DISCUSSION

There are several reasons that may account for the drop in incidence rates for Louisiana during the study period. First, the logging industry in Louisiana became more mechanized. The felling process was becoming mechanized at a very rapid rate, especially in pine logging operations around the turn of the decade. Second, this included a period during which the workers' compensation insurance situation in Louisiana was very critical (all workers' compensation insurance in Louisiana is covered by private companies which are regulated by the state). The assigned risk pool had risen to 65%. That is, only 35% of the companies were able to obtain workers' compensation insurance, so the remaining employers were assigned insurers by the state for three year periods, resulting in little incentive to improve premium rates. The Louisiana Legislature created a private company, the Louisiana Workers' Compensation Corporation (LWCC), with the mandate that it insure any employer desiring to do business with the LWCC, without regard to risk. The LWCC opened for business in 1992, and the assigned risk pool was eliminated by 1994. It is not known to what extent this activity was a factor in the accident claim rates, but it seems plausible to have been at least a small factor. An overall improvement in the insurance coverage system may result in better claims management and fewer serious injury claims, but it could also result in more complete reporting.

Table 3. Part of body - main contributors to heterogeneity.

| Head | More 1988 (observed 55; expected 41) |

Fewer 1991 (obs. 8; exp. 20) |

| Upper Extremities | More 1986, 1987 (obs. 129, 121; exp. 97, 99) |

Fewer 1994, 1995 (obs. 34, 33; exp. 50, 47) |

| Trunk | Fewer 1986 (obs. 43; exp. 56) |

|

| Back | All standardized chi-square residuals were less than 2 | |

| Lower extremities | All standardized chi-square residuals were less than 2 | |

| Multiple injuries | All standardized chi-square residuals were less than 2 | |

Analysis of variance revealed no statistically significant linear trends in the proportions of these categories (p values ranged from 0.19 to 0.92), with the exception of a marginal upward trend in multiple body parts (p=0.043, R2=0.32).

Table 4. Nature of injury - main contributors to heterogeneity.

| Lacerations | More 1986, 1987 (obs. 174, 190; exp. 133, 153) |

Fewer 1990, 1991, 1994 (obs.90, 47, 38; exp. 107, 60, 51) |

| Sprains/Strains | Fewer 1986 (obs. 112; exp. 134) |

More 1990 (obs. 130; exp. 107) |

| Fractures | Fewer 1986 and 1987 (obs. 77, 85; exp. 95, 110) |

More 1994, 1995, 1996, 1997 (obs. 48, 52, 39, 39; exp. 37, 41, 28, 27) |

| Analysis of variance revealed a significant negative linear trend in the percentage of cuts and lacerations (slope=-1.4, p=0.0005, R2=0.69). The category sprains/strains has no significant linear trend (p=0.26, R2=0.12). Fractures increased significantly (slope=0.6, p=0.0001, R2=0.76). | ||

Table 5. Source of injury - main contributors to heterogeneity.

| Contact with Trees/logs/limbs/plants | Fewer 1986, 1988 (obs. 146, 132; exp. 174, 153) |

More 1994 (observed 102; expected 81) |

| Contact with Machinery | Fewer 1988 (obs. 13; exp. 31) |

More 1991 (obs. 33; exp. 15) |

| Contact with Parts and materials | More 1986, 1990 (obs. 129, 87; exp. 86, 68) |

Fewer 1994, 1997, 1998 (obs. 18, 14, 8; exp. 40, 25, 17) |

| Contact with Structures and Surfaces | Fewer 1987 (obs. 55; exp. 71) |

More 1997 (obs. 29; exp. 20) |

| Contact with Tools | More 1987, 1988 (obs. 160, 131; exp. 107, 93) |

Fewer 1990-91, 1993-94 (obs. 62, 21, 36, 34; exp. 83, 45, 49, 49) |

| Vehicular injuries | Fewer 1986, 1990 (obs. 31, 29; exp. 52, 41) |

More 1994, 1996-98 (obs. 34, 29, 27, 22; exp. 24, 17, 15, 11) |

| The proportion of vehicular accidents rose at a particularly steady and alarming rate, from 6% of cases to 18% (p<0.0001, R2 = 0.82) of cases, but the actual number of cases declined from roughly 40 annually to about 25 (p=0.0062, R2 = 0.51). | ||

Table 6. Type of accident — main contributors to heterogeneity.

| Transportation | Fewer 1986, 1990 (obs. 23, 24; exp. 43, 36) |

More 1994, 1996-98 (obs. 38, 28, 24, 19; exp. 22, 15, 13, 9) |

| Falls | More 1997 (observed 34; expected 22) |

|

| Struck By/Against | More 1986, 1987 (obs. 343, 344; exp. 313, 320) |

Fewer 1994, 1996-98 (obs. 135, 88, 72, 55; exp. 161, 107, 92, 68) |

| Exertion | All standardized chi-square residuals were less than 2 | |

| The proportion of falls rose linearly (slope=0.55, p=0.0027, R2=0.57), while the proportion of struck by/against declined (slope=-1.6, p<0.0001, R2=0.81). | ||

A third factor that may have influenced the accident rates is requirements by insurance companies. In the late 1980s and early 1990s, workers' compensation insurers started requiring minimal safety standards of loggers, such as mandatory use of personal protective equipment, and enforced these requirements by sending inspectors to the logging jobs. These inspectors also served as safety advisors to the logging companies.

For the part of the body, the extremities were the most affected. This is not too surprising because the extremities are actively used in work areas. This is especially true of finger injuries. Fingers are much used in work and receive the most injuries. Knee injuries are more common than ankle and foot injuries. This may seem counterintuitive but could be because feet and ankles are usually protected with personal protective equipment (sturdy work boots). This level of protection is rarely applied to the knees.

The decline in cuts and lacerations corresponds with the same time that manual felling (with chainsaws) was being replaced by mechanized felling (machines with shears or saw heads). This resulted in fewer employees being exposed to the potential danger of chainsaws. Mechanized felling also requires fewer employees for the same production level, and these employees are enclosed in a protective cab.

For the major categories, we modeled linear trends of the proportions of injuries. By definition of proportions, as one category decreases (increases) then others must increase (decrease).

We found a significant negative relationship (p=0.0005, R2=0.69) in the proportion of cuts and lacerations over time. In Pine et al. (1994), the category sprains/strains was found to be significantly increasing during years 1986-1992; however, this trend has now reversed and is non-significant over the extended period through 1998 (p=0.26, R2=0.12). Fractures, on the other hand, are significantly increasing (p=0.0001, R2=0.76). Unfortunately, these are also the most costly and require longer recovery times [15] . This is evidence that the logging industry is following the classical safety pattern that, as an industry gets more mechanized, the accident rates decline, but the severity of the injuries increases. Cost and recovery time data indicated that sprains and strains are slightly more severe than fractures. It would be interesting to see how a current cost analysis would compare these three categories.

The category Animals/Plants/Minerals continues to be a major source of injury with no discernable trend (p=0.83, R2=0.005). This includes trees and logs. However, two other categories increased in proportional significance: vehicles (p<0.0001, R2=0.82) and, to a mild extent, machinery (p=0.13, R2 =0.20; A spike in 1991 prevented these numbers from being stronger). This is logical, since the industry is becoming more mechanized. Also, travel distances of 80 to 180 km are common in Louisiana, both to the mills and to the homes of loggers. Many areas are experiencing increases in traffic without corresponding increases in highway construction.

It is important to note that a major proportion of accident types involved exertion (Figure 4), which can be prevented by proper work techniques. Workers must be trained in the proper techniques of lifting, pulling, pushing, carrying, etc. Good housekeeping will also help prevent these events.

The percentage of falls increased (slope=0.55, p=0.0027, R2=0.57). Falls are simple and preventable accidents, yet they can create very serious injuries. The plurality of falls occur from vehicles onto working surfaces. As mentioned previously in the Literature Review, Shaffer and Milburn [46] found in their study that many of the fall injuries occurred while mounting or dismounting equipment. Preliminary data from a developing source within the Louisiana Logging Council also indicate that mounting/dismounting is a common type of accident [12] . Further study of this issue is needed. Ergonomic checklists for forest machines [25, 26] could be helpful in such studies. For example, many skidders do not to meet the ergonomic lists' specifications of 35 to 70 cm for height of first step above ground. This problem is compounded by the fact that steps are often damaged during normal woods use.

Many of the knee injuries resulted from falling down or bodily exertion. Often, this indicates a work technique problem rather than a direct exposure to an unsafe condition. Safety programs should include job task analyses of even the most mundane tasks, followed by training in proper techniques in common, everyday activities. Such tasks may include lifting, carrying, reaching, dismounting equipment, and accessing unusual areas of the equipment for repairs and maintenance.

Almost one-half of the hand/finger injuries are struck by/against accidents involving contact with tools resulting in lacerations. Since more than half of these injuries are cuts and lacerations, gloves should be considered as an essential prevention item. Many of the hand/finger injuries are bruises and fractures. Like sprains and strains, these injuries can be much more serious than first suspected.

The amount of finger amputations (10% of all finger claims) could be considered an indicator of the severity of finger injuries. This number is striking in light of the fact that loggers are not subjected to continuously running saws as are employees in sawmills and woodshops. Thus, the amputations are more likely to involve crushing or mangling rather than clean-cut amputations.

Lacerations to the foot continue to be a problem. Many of these are chainsaw accidents despite the developments of saw-resistant boots and chaps. It is not known whether the proper protective equipment was worn in these cases. Although the wearing of safety chaps is common today in Louisiana, their acceptance was with reluctance. A major reason for this has to do with hot weather (for six months of the year, the weather in Louisiana is very similar to any very humid tropical region). The use of chaps decreases worker comfort and appears to decrease worker productivity. There is a critical need for cooler personal protective equipment. Several researchers have studied worker productivity and metabolism in hot weather [17 , 50 , 51] , but the modification or development of personal protective equipment that is suitable for hot weather is limited. At least one researcher is attempting to develop a helmet system with cooling elements [30] , and another group has proposed specific changes to cut-resistant clothing [3] .

As the mechanization of logging increases, the exposure of the remaining chainsaw operators is changing. Rather than being exposed to falling trees, many chainsaw operators stand in landings and have the skidders bring the logs by for trimming. Thus, saw operators now face greater exposure to shifting logs and moving machinery. A safe overall workflow is essential - one wherein workers are separated safely apart and the movement of wood and machinery does not put anyone at risk.

The lack of enforcement of good safety programs by management is a major problem in the industry. Of the 107 American logging fatalities summarized in an OSHA report, 92% were caused by human factors and involved violations of safe operating procedures [48] . The most frequently cited violation of federal safety standards was logging operations training. Since nearly all logging in most parts of the USA is performed by small businesses, motivating and educating the business owners to develop and enforce good safety programs requires a major effort from both within and without the industry. In Louisiana, OSHA is attempting a tactic that is different from its traditional enforcement effort. It is developing a "Strategic Partnership" that includes federal government, state government, the logging industry, industry associations, and academia [12] .

CONCLUSIONS OF INTEREST TO PRODUCTION PERSONNEL

Accident Rates and Severity

While accident rates appear to have made a dramatic decline around 1991-1992 (as approximately verified by BLS data), it would be difficult to conclude they declined much since then. There does appear to be a decline in rates from 1995 to 1998, but this can only be verified when late reports for those years are obtained. Any improvements in accident rates are believed to be attributed to the following reasons:

While it appears that overall accident rates may be declining in Louisiana, the severity of the accidents is increasing. Logging is following the classical safety pattern in that, as an industry becomes more mechanized, the number of accidents decreases, but the severity of the accidents increases. Thus, while some loggers stated that they "solved" their accident problem by replacing chainsaws with mechanized felling, this is clearly not the case. Comprehensive safety programs are still needed.

Lacerations

Cuts/lacerations account for most of the finger and hand injuries, half of the foot injuries and many knee injuries. Lacerations can often be prevented by proper use of personal protective equipment (PPE). Cut-resistant legwear and footwear was not in common usage in Louisiana during the early part of this study period, but has become more popular at the insistence of insurers. However, the authors still learn of injuries that could have been prevented by the proper use of PPE, so education in the use of PPE is important.

Falls

It is difficult to imagine a more basic type of accident than falling, yet falls account for 14% of injuries and are increasing. Many of these falls occur from vehicles. Riding policies, mounting/dismounting procedures and the condition/location of steps and handholds deserve attention. Ergonomic checklists [25 , 26] could help loggers determine proper modifications to their equipment for cab entry/exit and for maintenance access.

Transportation

With the long distances from home and mills that loggers commonly work, it is not surprising that 8% of the accidents are transportation accidents. The importance of defensive driving education is obvious. In addition, anything that the loggers, foresters and timber companies (mills) can do to minimize travel distances will, in theory, reduce the risk of transportation accidents. It would also reduce logging costs.

Exertion

Injuries from exertion (12%) include the activities of lifting, pushing, holding, carrying, turning, throwing, bending, climbing, crawling, twisting, reaching and slipping (without falling). Education, such as training in proper lifting techniques, can prevent many of these types of injuries. Another tactic to prevent these injuries is to develop equipment (or modifications to equipment) that eliminates the need to lift heavy objects or perform some of these exertion activities.

Training

It is clear that the plurality of accidents still occur in relation to some sort of contact with trees, limbs or logs. Since nearly all active logging equipment in Louisiana meets the federal standards for rollover and falling object protection, it appears that better establishment and enforcement of safe working procedures within each company is needed. Since the industry consists almost entirely of small contracting companies, the owners and employees of these companies have not had the benefit of the safety training common in large corporations. Effective safety education is going to require the combined efforts of wood consumers (mills), foresters, loggers, industry associations, government and academia [31 , 49] . The framework for this mechanism was established in Louisiana in 1993 through the Sustainable Forestry Initiative and the Louisiana Logging Council [11 , 13 , 14] .

The desire on the part of logging contractors for better safety training exists. In a survey of Irish logging contractors, "enhanced safety training and education" was identified most frequently as a suggestion for improvement in logger health and safety [39] .

Other studies have shown that, to be most effective, training and education should be combined with experience in a realistic work setting; follow-up training of experienced workers is also important [4] . Since the operator learning curve on some equipment can take months, formal training of a work force pool would be particularly helpful in mechanized logging to help overcome inefficiencies in employee turnover relating to low production during training [32] .

Some of the more critical training needs identified through this research, combined with a review of the literature are (most important first, in the judgment of the authors and according to frequency of accident/injury):

CONCLUSIONS PERTAINING TO FUTURE RESEARCH NEEDS

Database

Accidents classified in the database as "multiple body parts" have been of little value to this study. It would be more useful to understanding logging accidents if the person classifying the accidents into the database would simply make a judgment as to which injured body part is most serious and classify the accident accordingly. This would actually result in less detail being lost. When the classification "multiple body parts" is used, all details about body parts are lost and effectively unavailable for analysis.

In the forest products industry, there needs to be a convention of standards about additional sub-classifications specific to the industry, such as specific occupations and types of machinery. In the future, representatives of the forest products industry may want to petition the BLS to have these new classifications incorporated into the Occupational Injury and Illness Classification Manual. These new classifications would allow for even more meaningful analyses of injuries in the forest products industry in the future. A document developed at a round-table meeting of several ergonomists with knowledge of the logging industry might be an appropriate place to start this type of change.

Another concern arises from the employers who submit the reports to the Louisiana Office of Workers' Compensation Administration. In many instances, reports are submitted incomplete. Feedback needs to be given to those who fill out the reports on how the information is used and why the information that they report is important.

The above changes are difficult and would still yield only marginally improved results. A system wherein detailed descriptions of the accidents can be obtained would be more useful. This would make it possible to discern the specific activity being performed at the time of accident. One such effort is already underway in Louisiana [12] .

Personal Protective Equipment

There is still a need to improve the personal protective equipment (PPE) used in logging. The most critical need seems to be the development of improved footwear for chainsaw operators. Properties of particular concern would be: better saw-resistance; traction in flat, wet terrain (very high heels are not needed and add to risk of twisting ankles); water resistance; breathability; weight (especially when wet); and economy. There is also a need for economical footwear that is not bulky and that is designed for the occasional chainsaw user.

Hot Weather PPE

In addition, much of the available logging PPE is extremely uncomfortable in hot weather, exacerbating heat exhaustion and dehydration problems. This is especially true of helmets, leg protection and saw-resistant footwear [21] . Korhonen pointed out that legislation and standards focus on the protective efficiency of PPE, but not on the thermal and comfort properties. Thus, development in thermal properties is lagging [34] . Research should focus on new materials, new designs, new technology, accident prevention in hot weather, and training [21] .

Repetitive Stress Injuries

Repetitive stress injuries were not discerned in this study. However, a study in Sweden, where logging is highly mechanized, found that about half of the logging equipment operators were experiencing repetitive stress injuries, but that the injuries were largely unreported [2] . A Norwegian survey concluded that 88% of machine operators suffered from musculoskeletal disorders [27] , especially neck and shoulder complaints [52] . With the increased mechanization of logging operations in Louisiana and many other parts of the USA, it is likely that the Scandinavian experience is not unique. Better understanding of the extent of this problem is needed.

Many loggers have been observed working long hours in addition to commuting long distances. More needs to be known about the status of fatigue, rest, sleep and diet of loggers in the southern USA. Radocha and Kocianova have begun to lay the groundwork for measuring the psychological strain of logging workers in Slovakia [45] .

Training

Many of the conclusions in the previous section of this paper focused on the need for more and better training. However, the effectiveness of such training is not well known. Studies on the effectiveness of any current and proposed logger education programs should be performed to assess their economic and social impacts [47] .

Overall, the analysis of injuries will benefit not only the individual companies but also the employees of these companies. The analysis of injuries should help logging companies focus their safety programs on the most critical needs and help manufacturers design safer equipment and supplies. This should help portray a positive message to the employees, who, in turn, may enjoy a better morale and be more productive in the work setting.

ACKNOWLEDGMENTS

The authors wish to thank the personnel of the Louisiana Office of Workers' Compensation Administration, especially Assistant Secretary Dan Boudreaux, J.D., and Karen Bevan, for making the accident database available and for their immense effort in compiling the accident data. Direct financial support for this analysis was provided by USDA McIntire-Stennis funds and the Louisiana Forest Products Development Center.

AUTHOR CONTACT

Professor de Hoop can be reached by e-mail at -- cdehoop@Isu.edu

REFERENCES

[1] American National Standards Institute. 1979. Recording basic facts relating to the nature and occurrence of work injuries. ANSI 216.2-1962.

[2] Axelsson, S. 1998. The Mechanization of Logging Operations in Sweden and its Effect on Occupational Safety and Health. J. For. Eng. 9(2):25-31.

[3] Bartels, V.T, and K.-H. Umbach. 1999. Bekleidungsphysiologische Optimierrung von Schnittschutzkleidung (Physiological optimisation of cut resistant protective clothing). ISBN 3-89701-404-1. Wirtschaftsverlag NW, Bremerhaven. 84pp.

[4] Brook, J., and R. Brook. 2000. Safety Training for New Zealand Loggers. COHFE Report Vol. 1, No. 3. 7pp. http://www.cohfe.co.nz .

[5] Bureau of Labor Statistics. 1988 (and annually). Survey of Occupational Injuries and Illnesses, 1986. U.S. Dept of Labor, Washington, D.C.

[6] Bureau of Labor Statistics. 1984. Injuries in the Logging Industry. Bulletin 2203. U.S. Dept of Labor, Washington, D.C.

[7] Bureau of Labor Statistics. 1990. Occupational Injuries and Illnesses in the United States, Bulletin 2366, U.S. Dept of Labor, Washington, D.C.

[8] Bureau of Labor Statistics. 1989. SDS Operating Manual, Office of Survey Processing, U.S. Dept of Labor, Washington, D.C.

[9] Cryer, C., and C. Fleming. 1987. A review of work-related fatal injuries in New Zealand 1975-84 — Number, rates, and trends. New Zealand Medical J. 100(816):1-6.

[10] Cyr, P. 2001. Unpublished testing of chainsaw-resistant footwear. Occupational Safety & Health Adm., US Dept. of Labor, Washington, DC.

[11] de Hoop, Cornelis F. 2000. An Overview of Logging Safety Programs in the USA. Working Paper #43. Louisiana Forest Products Devel. Ctr.; School of Renewable Natural Resources; Louisiana Agricultural Experiment Station, Louisiana State University Agricultural Center. 8 pp. Presented at the International Union of Forestry Research Organisations (IUFRO), 3.07 - Ergonomics, 9 August 2000, Kuala Lumpur, Malaysia.

[12] de Hoop, C.F., and A.J. Lefort, Jr. 2003. Loggers and Bureaucrats: A Strategic Partnership Creates Better Accident Summaries and Safety Education. In: Yoshimura, T., ed., Proceedings of the International Seminar on New Roles of Plantation Forestry Requiring Appropriate Tending and Harvesting Operations, September 29 - October 5, 2002, Tokyo, Japan. Organized by The Japan Forest Engineering Society and IUFRO 3.04/3.06/3.07. Tokyo. P.376-384.

[13] de Hoop, C.F., J.C. Pine and B.D. Marx. 1997. What's being done About Logging Accidents in Louisiana? Louisiana Agriculture 40(2):22-24.

[14] de Hoop, C., J. Pine and B. Marx. 1994. Injuries in Louisiana's Logging Woods, and What's Being Done About It. In: Kellogg, L., and J. Sessions, eds. Advanced Technology in Forest Operations: Applied Ecology in Action. Council on Forest Engineering 17th Annual Meeting and International Union of Forestry Research Organizations Division 3: Forest Operations & Techniques Proceedings. Corvallis, OR. Pp. 99-108.

[15] de Hoop, C.F., J.C. Pine, B.D. Marx and A.J. Lefort. 2000. Major Logging Injuries in Louisiana: Nature and Trends 1985-1998. Louisiana Forest Products Development Center Working Paper # 44. Louisiana State University Agricultural Station, Baton Rouge, LA.

[16] de Hoop, C.F., J.C. Pine, B.D. Marx and C. Vellala. 1995. Cost of Logging Injuries to Loggers in Louisiana. In: Hassan, A.E., J. Sherar and J. Swanner, Eds. 1995 Proceedings of the 18th Annual Meeting of the Council on Forest Engineering, Corvallis, OR. P. 251-155.

[17] de Sousa, A.P., L.J. Minette, C.C. Machado and N.C. Fiedler. 1998. Analysis of Ergonomic Factors in Timber Cutting Operations Using Chainsaws. In: Staudt, F.J., ed., Caring for the Forest: Research in a Changing World, Proceedings of the ergonomic papers and posters presented during the XXth IUFRO World Congress held from 6 - 12 August 1995 in Tampere Finland. P. 125-126. Wageningen, Netherlands.

[18] Driscoll, T.R., G. Ansari, J.E. Harrison, M.S. Frommer and E.A. Ruck. 1995. Traumatic work-related fatalities in forestry and sawmill workers in Australia. J. of Safety Research 26(4):221-233.

[19] Estève, M.L. 1999. Roles des Agents d'Assurance de Accidents du Travail pour Promouvoir le Professionalisme parmi les Entrepreneurs (The Role of Industrial Accident Insurance Providers in Promoting Professionalism among Employers). Seminar Proceedings Improving Working Conditions and Increasing Productivity in Forestry held in Banská Štiavnica, Slovakia, 9-13 September 1998. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.171-201 (Summary in English and Russian).

[20] Executive Office of the President. 1987. Standard Industrial Classification Manual. Office of Management and Budget, Washington, D.C.

[21] FAO/ECE/ILO. 1994. Report of the Seminar. Proceedings of the Seminar on Clothing and Safety Equipment in Forestry held in Kuopio, Finland June 27 - July 1, 1994. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.1-75 (English, French and Russian).

[22] FAO/ECE/ILO. 1997. Report of the Seminar. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.9-74 (English, French and Russian).

[23] Fenner, P. 1997. Job Accidents in a Brazilian Forest Company. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.173-181 (Summary in French and Russian).

[24] Fosbroke, D.E. 1993. Regional Variability in Logging Fatalities. American Society of Agricultural Engineers International Winter Meeting. Paper # 937522.

[25] Gellerstedt, S., R.. Almqvist, M. Attebrant, D. Myhrman, B.-O. Wikström, J. Winkel, T. Vik, H. Tapola, E. Bøllehus, G. Frumerie and A. Marconi. 1999. Ergonomic Guidelines for Forest Machines. SkogForsk, Uppsala, Sweden. 85pp.

[26] Golsse, J.-M. 1994. Revised FERIC Ergonomic Checklist for Canadian Forest Machinery. FERIC Special Report SR-100. Pointe-Claire, PQ, Canada. 38pp.

[27] Hagen, K.B. 1997. New Troubles for Old? Health and Safety Hazards in Highly Mechanized Operations. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.153-172 (Summary in French and Russian).

[28] Hartfield, J. 1997. First Standardized Federal Accident Statistic - Analysis of Accident Data of the State Forest Services in Germany. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.105-126 (Summary in French and Russian).

[29] Hassler, C.C., R.W. Wright and H.C. Sims. 1993. Analysis of West Virginia Workers' Compensation Records for the Wood Products Industry (1989-1990). West Virginia University Agricultural and Forestry Expt. Sta. Misc. Pub. 24. Morgantown, WV.

[30] Holz, E. 1999. Cooling elements for safety helmets. In: Poschen, P., ed., FORWORKNET Update. November 1999. FAO/ECE/ILO, Geneva. Available on internet at http://www.ilo.org/public/english/dialogue/sector/newsletr/fwknet/index.htm .

[31] Jokiluoma, H. 1997. Experiences of Safety Programmes in Forestry Work in Finland. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.287-297 (Summary in French and Russian).

[32] Kirk, P.M., J.S. Byers, R.J. Parker and M.J. Sullman. 1997. Mechanisation Developments Within the New Zealand Forest Industry: The Human Factors. Int. J. For. Eng. 8(1):75-80.

[33] Kolb, J. Undated. NORTIM Corporation Jobsite Stretching. Pittsburgh, PA. 26pp.

[34] Korhonen, E. 1994. European Requirements on the Design and Use of Personal Protective Equipment. Proceedings of the Seminar on Clothing and Safety Equipment in Forestry held in Kuopio, Finland June 27 - July 1, 1994. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.163-172.

[35] Louisiana State University Agriculture Center. 2002 and annually. Annual Agricultural Statistics. Louisiana Agricultural Experiment Station, Baton Rouge, LA.

[36] Manz, J. 2000. Unpublished address to the American Logging Council held in Beaumont, Texas, USA. September 28.

[37] Myers, J.R., and D.E. Fosbroke. 1994. Logging Fatalities in the United States by Region, Cause of Death, and Other Factors-1980 to 1988. J. Safety Research 25(2):97-105.

[38] National Safety Council. 1991. Accident Facts. Itasca, Ill. 108 pp.

[39] Nieuwenhuis, M., and M. Lyons. 2002. Health and Safety Issues and Perception of Forest Harvesting Contractors in Ireland. Int. J. For. Eng. 13(2):69-76.

[40] Olszewski, A. 1997. Description of Risks to the Life and Health of Forestry Workers in Poland and Trends in Preventive Measures. Proceedings of the Seminar on Safety and Health in Forestry are Feasible held in Konolfingen, Switzerland October 6-11, 1996. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P.95-104 (Summary in French and Russian).

[41] OSHA. 1988. "Selected Occupational Fatalities Related to Logging as Found in Reports of OSHA Fatality / Catastrophe Investigations." United States Dept of Labor, Washington, D.C.

[42] Parker, R., L. Ashby and T. Evanson. 2002. Analysis of Lost Time and Minor Injuries - 2001, Logging. COHFE Report Vol. 3, No. 4. 8pp. http://www.cohfe.co.nz .

[43] Parker, R., and M. Sullman. 1996. Chainsaw Injuries to Loggers' Feet. Proceedings, 7th Conference of the New Zealand Ergonomics Society, Wellington. P.225-231.

[44] Pine, J.C., B.D. Marx, and C.F. deHoop. 1994. Characteristics of Workers' Compensation Injuries for logging operations in Louisiana: 1985-1990. Southern J. Applied For. 18(3):110-115.

[45] Radocha, M., and K. Kacoianova. 1999. Possibilities of the Role of Ergonomy and Psychology in Forest Operations. Seminar Proceedings Improving Working Conditions and Increasing Productivity in Forestry held in Banská Štiavnica, Slovakia, 9-13 September 1998. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P. 286-296 (Summary in French and Russian).

[46] Shaffer, R.M., and J.S. Milburn. 1999. Injuries on feller-buncher/grapple skidder logging operations in the Southeastern United States. For. Prod. J. 49(7/8):24-26.

[47] Staudt, F., and M. Lipoglavsek. 1999. Ergonomic Research in a Changing World. Seminar Proceedings Improving Working Conditions and Increasing Productivity in Forestry held in Banská Štiavnica, Slovakia, 9-13 September 1998. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P. 276-275 (Summary in French and Russian).

[48] Vance, E.L., P. Cyr, C.N. Jeffress, C. Greenaugh and J. DuBois. 2000. A Review of Logging Fatalities Investigated by the Occupational Safety and Health Administration in FY 1996 and FY 1997. US Dept. of Labor, Occupational Safety & Health Adm., Directorate of Info. Tech., Office of Statistics, Washington, DC. 435pp.

[49] Vik, T. 1999. Improving Working Conditions in Forestry - An Example from Norway. Seminar Proceedings Improving Working Conditions and Increasing Productivity in Forestry held in Banská Štiavnica, Slovakia, 9-13 September 1998. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P. 51-65 (Summary in French and Russian).

[50] Yovi , E.Y., and Y. Takimoto. 2003. Workload of Physical Work Analysis of Manual Logs Transporting at Log Yard in Indonesia. In: Yoshimura, T., ed., Proceedings of the International Seminar on New Roles of Plantation Forestry Requiring Appropriate Tending and Harvesting Operations, September 29 - October 5, 2002, Tokyo, Japan. Organized by The Japan Forest Engineering Society and IUFRO 3.04/3.06/3.07. Tokyo. P.520-535.

[51] Yoshimura, T. 1999. Work System for Forestry Work under Hot and Humid Conditions in Summer Season. Seminar Proceedings Improving Working Conditions and Increasing Productivity in Forestry held in Banská Štiavnica, Slovakia, 9-13 September 1998. Joint FAO/ECE/ILO Committee on Forest Technology, Management and Training. P. 161-169 (Summary in French and Russian).

[52] Østensvik, T. 1997. Arbeidsmiljøets og mestringsstrategiers betydning for nakke- og skulderplager hos skogsmakinførere (Worker Environment and Management Strategy Significance for Neck- and Shoulder Complaints of Forest Machine Operators). Hovedfagsoppgave I Fysioterapiviten-skap. Universitetet I Bergen. 64pp + 10pp annex.