Vol.9 No.1 January 1998

A. Asikainen and P. Pulkkinen

University of Joensuu

Joensuu, Finland

The authors are researchers at the University of Joensuu, Faculty of Forestry.

ABSTRACT

This study is part of the ongoing national Bioenergy Research Programme in Finland. The study looked into the quality of chips made of logging residues composed predominantly of spruce wood. In addition, the productivity of the Evolution 910R chipper, the MOHA chipper truck, and the Morbark 1200 tub grinder was studied.

The three machines studied were capable of producing acceptable chips for heat generation plants. The particle-size distribution was good in all cases and the proportion of large particles and the fine fraction was small. The ash content of the chips was low due to carefulness in the handling of logging residues. The moisture content was typical for logging residues stored at the logging site for some months. The machine productivity values obtained were as follows: Evolution = 65 m3 loose/E15-h, MOHA = 23 m3 loose/E15-h, and Morbark = 50—60 m3 loose/E15-h. These results are preliminary; a follow-up study is needed for more reliable results to be obtained concerning the productivities.

Keywords: Bioenergy, chipping, chipper, crusher.

INTRODUCTION

Logging residues form the largest source of wood fuel in Finland. More than 20 million m3 of logging residues are left in the forests annually [4]. Residues consist of unmerchantable stemwood and actual lop-and-top material. In practice, the amount of recoverable residues is considerably smaller than total potential, i.e., about three million m3 for clear-cut areas [4]..

Logging residues can be comminuted in the forest, at the landing, or at the terminal. Several chippers and crushers for logging residues have been developed and tested in field conditions in the course of the Finnish Bioenergy Research Programme in order to define the productivity of these machines and the quality of the chips obtained. Chip quality is an essential factor for the trouble-free operation of power plants. Moisture content, ash content, percentage of fine particles, and particle-size distribution are the factors available in defining the quality of wood fuel [7]. It has been found that peat is the preferred fuel type for many solid-fuel plants despite the competitiveness of wood fuel. Wood fuel's low level of utilization is due to its considerable variability in quality; i.e., variability in the moisture content, ash content, and especially size distribution of wood chips. This causes problems especially with regard to the conveyors and feeding systems of power plants [3,6]. Whole tree chips can be characterized by larger variation in particle size than can stemwood chips [8]. Furthermore, the control of heating systems becomes difficult if the moisture content of the chips varies widely. Additional manual adjustment of the combustion process may be needed, which can reduce the process efficiency [7]. Therefore, the quality problems associated with wood chips must be solved in order to promote the use of wood as a fuel.

The aim of this study was to measure the quality of chips produced by two chippers (MOHA chipper truck and Evolution 910R chipper) and a tub grinder (Morbark 1200). The raw material used in the study consisted of logging-residues from spruce-dominated clear-cut areas. In addition, machine productivity was estimated.

The quantities of chips are expressed in loose measures. One m3 loose corresponds approximately to 0.4 m3 in solid measures. Effective hour (E0-h) does not include any delays and gross effective hour (E15-h) includes all delays shorter than 15 minutes.

MATERIALS AND METHODS

Description of Machines Studied

Three machines for comminuting woody raw material were examined: the Evolution 910R drum chipper, the MOHA chipper truck, and the Morbark 1200 tub grinder.

The Evolution 910R is a chipper mounted on a truck base (SISU). The chipper is fed via the rear by an RKP 8500 hydraulic crane with an operating angle of 300 degrees. The feeding device of the chipper is long and large (3.7m x 3.1m) to facilitate the feeding of logging residues. The machine weighs 25 000 kg and is 10.0 m long, 2.6 m wide, and 4.0 m high. The engine has an output of 267 kW. A belt conveyor takes the raw material to the drum, which is 100 cm wide, 90 cm in diameter, and has a rotation speed of 700 rpm. The chips are conveyed to the chip truck via a tube that blows them into the truck's container.

The MOHA chipper truck comprises a chipper mounted on an all-terrain truck bed (SISU). The engine (type 800 CT) has maximum output of 229 kW. The truck is equipped with a hydraulic power transmission that enables smooth motion in variable terrain conditions. The cabin is a VALMET forwarder and the hydraulic crane is Kesla's FORESTERI 500. The chipper (Bruks 800) is placed crossways between the cabin and the chip container. The drum has a width of 55 cm and a diameter of 45 cm, and the maximum rotation speed is 1400 rpm. The theoretical capacity of the chipper is 50 m3 loose/effective hour. The machine has a tare weight of 17 000 kg and weighs 30 000 kg when fully loaded. The machine's feeding table is relatively small as it needs to be lifted into an upward position during transportation. The feeding device is equipped with a rake conveyor. The chipper throws the chips into a 35 m3 container. The chipper truck operates as a chipper and a truck, which means that it can perform all operations from the logging site to the power plant.

The Morbark 1200 tub grinder is fed by its loading device from the top of the machine. It has a hammermill crusher unit at the bottom of the tub. Chips fall onto a belt conveyor, which takes them into the chip truck. The chip truck must be driven crossways under the conveyor and has to be moved during loading. The grinder is 11.3 metres long, 3.6 m wide, and 4.0 m high, and it weighs 24 000 kg. The engine has an output of 481 kW. The feeding funnel's diameter at the top is 360 cm and the opening at the bottom is 66 cm x 132 cm.

Processed Material and Data Collection

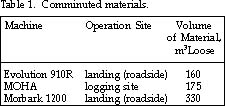

The material processed in the experiments consisted of logging residues collected from spruce-dominated final-felling sites. The logging had been carried out the previous summer. Cutting was done by single-grip harvesters, i.e., the logging residues were left scattered on the logging site. For the Evolution and the Morbark, the logging residues were forwarded to the roadside. The amounts of material processed by machine are given in Table 1. The Evolution 910R chipper and the Morbark 1200 tub grinder operated at the roadside landing, whereas the MOHA operated in the woods.

The dimensions of the load volumes of the trucks were measured. As a truck was being loaded, the surface was levelled with a shovel and the height of the load was measured with an accuracy of 5 cm. The load weights were measured using scales.

Chip samples were taken to define the particle size distribution, moisture content, and ash content of the chips. The volume of the samples taken was 10 litres and 10 to 15 samples were taken per machine. The samples were extracted from several locations in the load so that the results would be representative of the load. Each sample was stored in a plastic bag and the bag was carefully closed and marked. Later, a two-litre sample was separated for the determination of ash and moisture content. The rest of the sample was screened green.

The screening was done using an automatic screening machine. The largest screen had a mesh size of 40 mm and the next one was 8 mm. The rest of the screens had hole diameters of 13 mm, 7 mm, and 3 mm. Particles smaller than 3 mm were gathered in a slot.

The moisture content of the chips was determined by drying them in an oven. The green mass of the samples was measured and the samples were then placed in an aluminium container in an oven kept at 105° C. The samples were dried completely. The moisture content was determined by dividing the mass of water by the green weight of the sample.

In order to define the ash content, 3 to 5 samples were taken from the dried samples. The chips were burned in a steel container at 550° C for eight hours. If no carbon or wood was found in the sample, the oven was switched off. If wood or carbon was found, the sample was checked every two hours until it had burned completely. The samples were removed once the temperature of the oven had decreased to 100° C. After having cooled down, the samples were weighed and their ash contents calculated as the proportion of ash of the dry weight of the sample.

A time study was carried out using the continuous-timing method [5]. Data were collected by means of a hand-held computer (RUFCO 900). The work-site time was divided into the following elements:

In addition, operating the MOHA chipper truck had the following elements:

The MOHA chipper truck is able to transport chips to the power plant. This is done if the transport distance is shorter than 30 to 40 km. At longer distances a separate truck with a full trailer is used for transportation.

The operators using the machines had a lot of relevant work

experience. They had received several weeks of training in

operating the machines prior to the test. Each machine was driven

by a different operator and thus the conditions for a comparative

time study were not fulfilled. Therefore, the productivity

estimates obtained in this

study should be seen as being of a preliminary nature.

RESULTS

Chip Quality

The particle-size distributions of the chips produced in the course of testing the machines are presented in Figure 1. All the machines produced chips acceptable for use in heat-generation plants. The proportion of large particles (>15 cm) was small in all cases. On the other hand, the proportion of small particles was relatively high. This is due to the high percentage of needles in the raw material. Crushers are expected to produce chips of lower quality than those produced by chippers. In this study, the Morbark 1200 tub grinder was able to produce chips that were equal to those produced by the two chippers included in this study.

The moisture contents of the logging residues are presented in Table 2. The values obtained were typical for green logging residues. The ash content values (also Table 2) are typical for pure logging residues; there was no sand or other impurities in the material.

Machine Productivity and Cost of Chips Produced at the Roadside

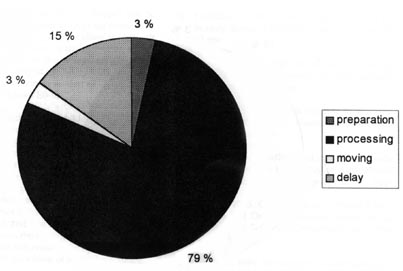

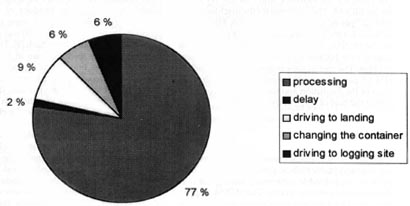

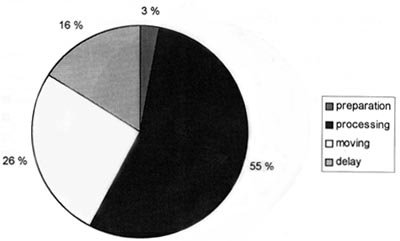

The gross effective time (E15-h) distributions of the machines are presented in Figures 2, 3, and 4.

The machine productivity figures are presented in Table 3. The productivity per effective hour (E0-h) was measured, whereas productivity per gross effective hour (E15-h) was estimated due to the shortness of the time study period. There were only a few delays (<15 min) during the time study experiment, and therefore the typical proportion of delays was estimated by the operators and entrepreneurs. The dry mass/loose volume (kg/m3 loose ) varies between machines due to differences in the particle size distribution.

Table 2. Water and ash content of chips.

Table 3. Productivities of machines.

* Productivities were estimated because there were no delays >15 min during the time study period.

Figure 1. Particle-size distributions of chips.

Figure 2. Distribution of the gross effective time, Evolution 910R.

Figure 3. Distribution of the gross effective time, MOHA.

Figure 4. Distribution of the gross effective time, Morbark 1200.

The hourly costs were estimated for the machines. Cost factors, e.g., purchase price, depreciation period, annual work hours, labour costs, and insurance were given by machine manufacturers and entrepreneurs. The hourly costs were FIM (Finnish Markka) 590 per E15-h for the Evolution, FIM 496 per E15-h for the Morbark, and FIM 354 per E15-h for the MOHA. The unit costs for the machines were FIM 10.7 per m3 loose for the Evolution, FIM 9.0 per m3 loose for the Morbark, and FIM 15.4 per m3 loose for the MOHA. It must borne in mind that the unit costs for the MOHA include terrain transportation of chips. The cost of forwarding residues, which is FIM 8.6 per m3 loose [1] must be added to the unit costs of the Evolution and the Morbark in order to obtain the cost of chips at the roadside.

DISCUSSION

All the tested machines were capable of producing chips acceptable for heat-generation plants. There were no considerable differences among the machines in terms of chip quality. The MOHA chipper truck produced the best distribution of chips there were no big particles (>40 mm) in the material. The proportion of big particles was less than 2% for Morbark 1200 and Evolution 910R.

Chipper productivity varied considerably. The Morbark and the Evolution achieved the highest productivity levels because they work at a roadside landings, whereas the MOHA chipper truck works in the woods. Tests of the Morbark 1100 tub grinder found that the productivity values obtained with fresh residues were 14 to 24 m3 loose/E0-h [2]. In another test, where the residues of a chain-flail debarking/delimbing chipper were crushed, the productivity of the Morbark 1200 was significantly higher, 100 to 150 m3 loose/E0-h [9]. The difference in results is due to difficulties in the feeding of logging residues into the tub grinder. Especially long tree crowns were difficult to process, and they had to be cut before being fed into the machine. Operation at the landing was difficult to carry out using the Morbark unit because the chip-carrying trucks need to be parked crossways during loading. Therefore, a Morbark unit should be used at terminals, where there is plenty of space. However, if a Morbark unit has to be operated at the landing, the chip conveyor should be redesigned or a second conveyor installed 90° to the tub grinder's conveyor so that trucks can be loaded at the side or at the rear of the grinder. With the chippers there were no difficulties in processing and the results were very promising.

The productivity of the MOHA chipper can be compared to that of a Chipset chip harvester [10]. Comparing their productivity values is difficult because of the differences in the operating conditions. If the distance to the unloading site is the same, the productivity of the MOHA (29 m3 loose/E0-h) is of the same order as that of Chipset chip harvester (33 m3 loose/E0-h).

The common method of roadside chipping represented by the Evolution 910R chipper and the Morbark 1200 tub grinder is "old" technology. The MOHA chipper truck is a new machine, which is also able to chip, forward, and transport the chips to the mill. It has some considerable advantages compared to chippers operating at the landing; e.g., it can move in difficult terrain, there is no interaction between machines (because there is only one machine operating), and one operator can handle the entire system. From the management point of view, it is easier to plan and control the operation of one machine than the operation of several machines.

The productivity results of this study must be considered to be preliminary because the amount of processed material was small. The machines and work methods studied are under continuous development, and a follow-up study is needed for the precise determination of the productivity and unit costs. The results concerning chip quality are, however, more reliable. Chip quality is relatively independent of the operator if the raw material is good and the machine is well serviced. To facilitate the comparison of machines, the entire wood-fuel harvesting system should be modelled. Then the interactions between machines could be taken into account and the performance of machines could be estimated in real situations. The estimation of the effect of interactions calls for extensive field studies and follow-up studies and/or the use of system simulation [1].

REFERENCES

[1] Asikainen, A. 1995. Discrete-event simulation of

mechanized wood-harvesting systems. Academic dissertation.

Research Notes 38. University of Joensuu, Faculty of Forestry. 86

pp.

[Return to text]

[1] Asikainen, A. 1995. Discrete-event simulation of

mechanized wood-harvesting systems. Academic dissertation.

Research Notes 38. University of Joensuu, Faculty of Forestry. 86

pp.

[Return to text]

[2] Desrochers, L. 1993. Recovery of residues from delimbing

and delimbing-debarking using tub grinders. FERIC. Technical Note

TN-209. 8 pp.

[Return to text]

[3] Hakkila, P. 1984. Forest chips as a fuel for heating

plants in Finland. Folia Forestalia 586. 62 pp.

[Return to text]

[4] Hakkila, P. 1992. (Ed.) Metsäenergia (Energy from

Forests). Metsäntutkimuslaitoksen tiedonantoja 422. 51

pp.

[Return to text]

[4] Hakkila, P. 1992. (Ed.) Metsäenergia (Energy from

Forests). Metsäntutkimuslaitoksen tiedonantoja 422. 51

pp.

[Return to text]

[5] Harstela, P. 1991. Work studies in forestry. Silva

Carelica 18:141. University of Joensuu Faculty of

Forestry.

[Return to text]

[6] Jirjis, R. 1995. Handling and storage of woody biomass.

Swedish University of Agricultural Sciences, Department of Forest

Products. 5 pp.

[Return to text]

[7] Jirjis, R. 1996. Optimization of Wood Chips Storage and

Drying. Swedish University of Agricultural Sciences, Department

of Forest Products. 12 pp.

[Return to text]

[7] Jirjis, R. 1996. Optimization of Wood Chips Storage and

Drying. Swedish University of Agricultural Sciences, Department

of Forest Products. 12 pp.

[Return to text]

[8] Kalaja, H. 1984. Varastointi- ja siirtolaitteiden

toimintahäriöt metsähaketta

käyttävissä lämpölaitoksissa.

(Malfunctions of storage and transport devices in the heat plants

using forest chips as a fuel). Metsäntutkimuslaitoksen

tiedonantoja 166. 24 pp.

[Return to text]

[9] Pulkkinen, P. and A. Asikainen. 1996. Hakkuutähteen,

karsijan puujätteen, sahan kuorijätteen ja kantojen

murskaaminen Morbark 1200 -murskaimella. (Comminution of logging

residues, residues from delimbing-debarking, bark and stumps

using Morbark-1200 tub grinder). Folia Forestalia -

Metsätieteen aikakauskirja 1996 (1):1726.

[Return to text]

[10] Vesisenaho, T. 1994. Chipset 536 C -hakeharvesterin

käyttö polttohakkeen tuotannossa. (Use of Chipset 536 C

chip harvester in the production of fuel chips). Keski-Suomen

metsäenergiaprojekti D 106. Bioenergy Research Programme. 35

pp.

[Return to text]