Rien J.M. Visser and Karl Stampfer

Bodenkultur University

Vienna, Austria

The authors are, respectively, doctorate student on leave from the New Zealand Logging Industry Research Organisation and Lecturer at the Department of Forest Engineering.

ABSTRACT

A time study of the cable extraction of thinnings in short corridors was carried out in the Neuberg an der Mürz forest area, Austria. Both the yarder and the choker-setter(s) were studied. Six options were compared. For the "standard" option the timber was felled, cut to length, and pre-bunched by the harvester on a 20-meter-wide corridor, and was yarded downhill. Two choker-setters were employed. The five variations included: (1) "larger" bundles, (2) in-creased lateral hauling distance, (3) one choker-setter, (4) the harvester cutting-to-stem length and the timber yarded uphill with only one choker setter, and (5) trees in a 30-meter-wide corridor felled and bucked by motor-manual methods. The harvester used was a Skogsjan 687 XL with a 601 head; the medium-sized yarder was a Syncrofalke with a Sherpa U3 carriage.

The time study results showed that the corridors felled and cut to length by the harvester, in comparison to the motor-manually cut corridor, provided a significant improvement in the cable extraction cycle times: 3.7 min compared to 4.6 min. Additionally, an average turn volume increase of 26% was achieved by the improved presentation of the timber. A 20-meter lateral-hauling distance increased the cycle time by only 7%. The use of one choker-setter increased the delay-free cycle time by just 10%, however it significantly decreased the work-related waiting time for the choker-setter to just 5%. Uphill stem extraction using one choker-setter had the same cycle time as the downhill cut-to-length extraction using two choker-setters, although a 5% greater average turn volume was recorded.

Keywords: Harvester Skogsjan 687, thinning operations, cable extraction, Syncrofalke, time study.

INTRODUCTION

Harvesters have slowly been introduced into the Austrian forestry sector. In 1996 an estimated 50 were in operation, 25 in Austrian ownership and a further 25 by foreign contractors. Improved productivity and flexibility, a reduction in the physical forestry work component, as well as reduced overall costs are cited as being the main advantages over motor-manual operations. In Austria the cost-saving potential is particularly important: companies are struggling with low timber prices and forestry labour costs have reached US$30 per hour.

The use of harvester technology in Austria is limited by steep terrain and the forest ownership structure. Almost half (46.5%) of the forest area has slopes of over 40%. Approximately 70% of the forests are owned in parcels of less than 200 hectares and most of these are on favourably sloped land [1]. In such small forests, operations are typically carried out by the owners themselves or by part-time helpers.

The most productive system for thinning operations is likely to be a harvester together with a skidder or perhaps a forwarder. However, many poor or damaged stands in Austrian forest areas are very susceptible to both beetle and fungal attack. In thinning operations particular attention is paid to minimizing damage to the soil and to the remaining stand. Cable extraction is a desirable alternative to either a skidder or forwarder on a sensitive site.

If cable is the extraction option chosen, then a harvester has advantages over motor-manual systems that include the clear presentation of the cut timber (timber lying on top of the branches instead of underneath), and the ability to pre-bundle by cutting to length one or more trees at the same spot. The harvester's impact can be minimal if it only makes a single pass and places branches in front of its tires to minimize soil compaction and other disturbances. To provide some quantitative information on the productivity advantages of using a harvester prior to cable extraction, a time study investigation was carried out.

TIME STUDY METHODOLOGY

Corridors

Six similar corridors were chosen within the forest. Each corridor was between 120 to 140 meters in length, and were located on 10-to-15-degree slopes on smooth and firm ground. Approximately 30 m3 was extracted in each 20-meter wide corridor equating to 150 m3/ha. The stand density was reduced from 900 to 450 stems per hectare. The timber extracted was almost exclusively spruce trees with an average DBH of 21 to 25 cm. The stand was the first generation after converting back from pasture, with subsequent poor form. The corridors were marked out before the arrival of the harvester. A tail tree was rigged to a height of five meters, and no intermediate supports were used.

Harvester

The harvester was a Skogsjan 687 XL with a 601 head (Figure 1), capable of handling trees up to 55 cm in diameter. The harvester remained on the marked corridor. The Swedish operator was very experienced, having already completed three years of similar work in Austria.

Figure 1. The Skogsjan 687 XL harvester.

Yarder

A Syncrofalke medium-sized truck-mounted yarder manufactured by the Mayr-Melnhof-Saurau company was used (Figure 2). The Syncrofalke has a 10-meter tower, drums that are hydrostatically driven, and computerized carriage controls. The skyline was 18 mm in diameter, the mainline and haul-back lines were both 11 mm diameter. A Sherpa U3 carriage was used in a three-rope configuration, with both the skyline and the mainline clamps operated by radio control.

The yarder driver sits in a rotating cab that has a knuckle-boom mounted grapple. The operator can clear the chute and stack timber within a reach of nine meters. The computerised system allows the operator to return the carriage to the point it last came from at the push of a button. This means that after the carriage has commenced its travel outwards, the operator is free to operate the loader arm. Equally, the choker-setter who has a radio control unit for operating the carriage can send the carriage with the turn back towards the yarder, where it will stop for safety reasons 20 meters before the tower until the operator once again takes control.

Extraction Variation

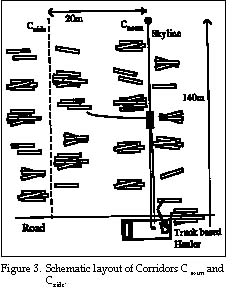

Table 1 shows a summary of the corridor variations. The corridor width was set to the "typical" width of 20 meters for the harvester (a single pass) and 30 meters for motor-manual felling. In variation 2 (Cnorm+) the harvester driver was to make an additional effort at creating larger bundles and improving their presentation. The third "corridor" (Cside) ran parallel and next to the first (Cnorm). This timber was also extracted from the first skyline corridor to create the lateral hauling situation for variation three (Figure 3). The preparation for the fourth corridor did not vary from Cnorm, except the extraction was carried out with just one choker-setter.

The fifth corridor (Cstem) was felled and delimbed by the harvester with the stems positioned so that, if possible, the tops would be under the skyline. Downhill extraction of stem length timber in Austria is not common because of the resulting damage to the remaining stand. Therefore extraction for Cstem was uphill and the stems were cut to length by the harvester at the roadside. Corridor 6 (Cm-m) was felled and cut to length by motor-manual methods.

Figure 2. The Syncrofalke yarder.

Figure 3. Schematic layout of corridors Cnorm and Cside.

The Timber

During operations the mid-diameter and the length of each piece (two to five meter lengths) was recorded and the pieces assigned to the turn. This could be carried out without interfering with the operation. Both the lateral hauling distance (estimated to the nearest five meters) and the carriage distance from the yarder were recorded for each turn. The latter was carried out by marking trees along the corridor at 10 meter intervals prior to the commencement of operations.

For stem extraction, each piece was numbered before operations. The length, the large end diameter, and the mid-diameter were recorded for each piece. During operations, the piece numbers for each turn were recorded, along with the lateral hauling and carriage distance from the yarder.

Time Study

The activities of the yarder and the choker-setters were recorded using "Latschbacher" portable time-study computers during the cable extraction, and by using a stop-watch when necessary. The work was divided into tasks for the yarder (Table 2) and the choker-setter (Table 3).

RESULTS

Table 4 shows summary information from the various corridors. Because of the 30-meter width of the corridor, which was felled by motor-manual methods, approximately 40% more total volume was extracted from this corridor. The average cycle times combined with average drag volume gives an indication of the hourly (delay-free) productivity.

The miscellaneous times have not been considered because of the large variation between the corridors. For example: during the extraction of ConeB the tailspar broke and took an hour to repair, and in Cnorm a triple-leader tree was felled and delimbed by the choker-setters. Rest breaks were mainly taken before and after the corridor extraction, but only three times during the operations.

Yarder Results

The attempted improved bundling by the harvester (Cnorm+) did not improve the delay free cycle time over Cnorm (Table 5). This was confirmed by the harvester operator who stated that only about two or three trees could be processed at the same spot without a lot of extra driving around. The opportunity to create larger bundles was therefore limited.

Much of the potential productivity advantage through using two choker-setters and the timber bundled next to the skyline (Cnorm and Cnorm+) was lost because the yarder operator was "holding up" the system while still clearing the chute with the loader arm (Task 8). Therefore using just one choker-setter increased the average cycle time by only about 10% over corridors Cnorm and Cnorm+.

Stem extraction (Cstem) with one choker-setter had the lowest delay-free cycle time. The carriage travel component was particularly small due to uphill extraction and the average haul distance being reduced to 50 meters, compared to the 60 to 70 meters for the cut-to-length corridors. The main disadvantage of this variation was that the harvester first felled and delimbed the trees in the stand and then had to return after the cable-extraction operations to cut the timber to length.

In corridor Cm-m which was felled by motor-manual methods, the cycle time is considerably higher than all the others. The most significant change is to the task of hooking up the drag. This task was made difficult by the fact that the timber pieces were spread out as well as often being under slash. This made building drags difficult and also resulted in significantly smaller drag volumes, a reduction of 20% (Table 4).

Analysing just the choker-setter "dependent" tasks of the yarder cycle (sum of Tasks 2, 3, and 4) showed Cnorm and Cnorm+ to be considerably smaller than all the others. This indicated the benefit of having two choker-setters and the timber being next to the corridor.

Cnorm and Cnorm+ had the greatest Task 8 (loader arm) components. Most of this occurred during the initial phases, that is, within the first 20 meters of the corridor. This was partially system-dependent since the operator had to operate the carriage controls in this segment of the corridor. The landing and unhooking time for Cm-m (Tasks 6 and 7) was relatively high compared to Cnorm, Cnorm+, Cside, and Cstem. Observations from the field indicated this was due to slash caught up in the drags (which the operator removed before unhooking), more strops used per drag, and the logs within the drag often being twisted.

Choker-Setter Results

Table 6 shows the breakdown of the results from the choker-setter(s) as a percentage of the total work time. The total cycle times were approximately the same as for the yarder. These differences have already been discussed.

The most physically strenuous activities are hooking up and pulling out the rope [2]. With one significant exception, these activities made up between 26% and 46% of the total work time. These activities totalled 67% of the time for the extraction of cut-to-length timber with just one choker-setter. The single choker-setter in ConeB spent 63% of his time hooking up, which includes the carrying of chokers to the logs and the pre-chokering, which was carried out while the carriage was underway.

This choker-setter had just 5% work related waiting time during operations to recover without causing a cycle delay. Since there was no slack in this system, any rest break taken by the choker-setter contributed directly to a loss in productivity. Ergonomically, a choker-setter should have at least 20% waiting time to avoid being above the generally accepted endurance limit [2]. However these corridors were short and this may not have presented such a big problem. For all other corridors the work- related waiting time was above the 25% level.

Owing to the care taken by the choker-setters, visual observations showed that damage to the remaining stand was minimal for all extraction variations. Only on three occasions were trees seriously damaged: one that was left too close to the skyline and the other two through operator error with the radio-controlled carriage. The spread of the timber in the motor-manually-prepared corridor meant more effort had to be made, such as moving the carriage or rehooking the timber, to avoid damaging the stand.

DISCUSSION

The harvester effectively carried out the task of felling, delimbing, and cutting to length in this stand. By making a slash bed in front of the harvester's tires, soil compaction was kept to a minimum. Twenty-meter-wide strips were thinned in a single pass, and the intended skyline corridor can be cleared at the same time if it has been marked out properly.

Considering just the results from this time study, the yarder would optimally extract three passes (60- meter width) from the harvester. Increased lateral hauling distance to extract the neighbouring corridor increased the cycle time by 7%. The rigging-up time and down time for this yarder for a short corridor takes about two hours. If the two harvester "corridors" on each side are also extracted from the central corridor, then an increase of 32 minutes extraction time will be incurred for the lateral hauling (80 turns with an average increase of 0.4 minutes per turn). However, four hours of rigging-up time and down time will be saved.

The extraction of stems was carried out easily with just one choker-setter. However this system had the disadvantage of the timber having to be cut to length on the roadside. A yarder variation with a cutting head on the loader arm of the yarder would be ideal for this task. This would save either the harvester returning or having to carry this task out motor-manually.

Cost optimization has not been carried out, since the harvester itself was not studied in detail. Harvester costs and productivity, yarder and worker costs, relocation and rigging times, operational and personal delay time, and timber prices would all need to be taken into consideration. In future, more extensive studies on the productivity of this harvester and on cable extraction in different settings will provide the information necessary for comparative cost calculations.

CONCLUSIONS

A time study was carried out to investigate the benefit of felling the timber by harvester on subsequent cable extraction. Five system variations were tried in additional to one corridor felled by motor-manual methods.

The results from the study showed the benefit of carrying out thinning operations with a harvester relative to this task being carried out using motor-manual methods. The timber was well presented for simplified breaking out, and larger turns were formed, improving productivity.

The average turn in the cut-to-length timber contained 0.95 m3 and took between 3.65 and 4 minutes per cycle to be broken out and stacked at the roadside. The timber felled motor-manually took on average 4.60 min to break out, with a turn size of 0.75 m3. Lateral hauling of 20 meters increased the average delay-free cycle time by just 7%, and using just one choker-setter increased the cycle time by 10%.

ACKNOWLEDGEMENTS

Sincere thank to Johannes Loschek of the forestry company Mayr-Melnhof-Saurau for his assistance in both organising and carrying out this study. We would also like to thank Erwin and Johannes Stampfer for their diligence in helping to carry out the time study.

LITERATURE CITED

[1] Austrian Ministry of Land and Forestry. 1995. Österreichischer Waldbericht. Published by the Bundesministerium für Landund Forstwirt-schaft, A-1010 Vienna. 103 pp.

[Return to text]

[2] Stampfer, K., S. Piechl, E. Stampfer, and A. Trzesniowski. 1996 (In Prep.). Belastung und Beanspruchungen bei der Holzernte im Gebirge. Report of the Forest Engineering Institute of the Bodenkultur University, Vienna. 59 pp.

[Return to text]

[2] Stampfer, K., S. Piechl, E. Stampfer, and A. Trzesniowski. 1996 (In Prep.). Belastung und Beanspruchungen bei der Holzernte im Gebirge. Report of the Forest Engineering Institute of the Bodenkultur University, Vienna. 59 pp.

[Return to text]