July, 1998, vol.9 no.2

Rolf Björheden

Swedish University of Agricultural Sciences

Garpenberg, Sweden

The author is a Researcher at the Department of Operational Efficiency.

ABSTRACT

This paper presents results from comparative studies of conventional Scandinavian shortwood processing vs a differentiated processing method. The latter signifies processing only sawlogs at the logging site. Pulpwood and forest fuel are transported off the site as undelimbed tree sections. The objective of the studies was to contribute to the development of new methods suitable for integrated harvesting of forest fuel and conventional forest products for industrial use. Study methods include direct measurement of workpiece and output and a precise indirect time measurement and working pattern evaluation, both by using videogrammetry.

Both a motor manual and a mechanized system was studied. For motor manual logging, differentiated processing was found to be recommendable for ergonomical, economical, and efficiency reasons. For the studied mechanized system - single-grip harvester in thinning - the productivity of differentiated processing did not match conventional logging. The main reason for this seems to be that crane handling and not processing is the weak point of the harvester system. According to the study, the amount of crane handling increased when differentiated processing was applied in mechanized logging. The output of forest fuel was markedly lower than that of the motor manual version.

Keywords:work study methodology, performance study, time study, integrated harvesting, wood fuel, forest fuel, operator influence.

INTRODUCTION

The renewed interest in forest fuel has brought about a new assortment of products on the Swedish forest product's market [17]. An example of this is tree sections, denoting undelimbed parts of trees bucked into convenient transport lengths, generally between 4.5 and 5.5 metres. Tree sections are normally made from the pulpwood part of harvested trees. Processing into pulp wood and forest fuel is carried out later, at a landing, terminal, or industry plant using efficient, large scale bunch or drum delimbers. Sawlogs are processed at the logging site by conventional methods, according to the Scandinavian tradition.

The systems and methods of Swedish forestry are developed for shortwood logging. When tree sections were introduced as a sort, a number of experiments with new technology and methods were started with the purpose of finding efficient ways of producing and handling the new sorts [15]. One such experiment was the use of motor manual crews in a modified shortwood method - differentiated processing[3]. After felling, only sawlogs are processed by the cutter. The bulk assortments, pulp and energy wood, are left for subsequent mechanized bucking, transportation, processing, and sorting. This method utilizes the most competitive sides of human work - the cost efficient felling and the skill of manufacturing logs from the most valuable stem segments. The heavy, risky, monotonous, and increasingly expensive work of delimbing, bucking, and piling pulpwood is excluded and left for mechanized system components, including grapple saw forwarders and bunch delimbers [8]. This layout also makes it possible to harvest forest fuel sorts in a simple way since tops and most branches were left attached to the stem. A fully mechanized version of the method, where a harvester in a similar way left the pulp wood undelimbed, was also studied. Here, the main idea was to make harvesting of forest fuel sorts more efficient. Also, as in the motor manual version, the hypothesis was that the operations would become cheaper by avoiding the processing of small dimension wood in single stem units [9].

The objectives of the studies were to investigate:

MATERIAL AND METHODS

Motor manual harvesting

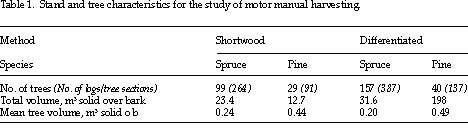

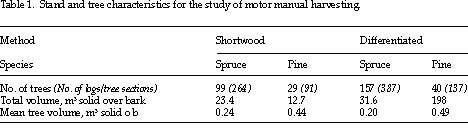

The study of motor manual harvesting was carried out in Västmanland county, in central Sweden. The logging took place in a spruce-dominated, mixed coniferous (Pinus silvestris and Picea abies), final felling stand. Tree data are presented in Table 1 and in Figure 1. The stand was normal for the region, and had been thinned several times prior to final felling.

A pilot study was used to develop study methods, previously described by Björheden, [3, 4, 5]. Fairly detailed tree and log data were recorded in the hope that statistical models built on such data would account for more of the variation of time consumption than simple 'dbh-based' logging studies. Prior to logging, dbh, and green and live crown height was measured and all trees were numbered with tags.

After logging, top diameters of processed logs were callipered, and the stump was cross-callipered. The length of all logs and residual tops was measured with a loggers tape. Tree height was calculated adding all measured lengths per tree. The delimbing difficulty of each log was rated subjectively, using three classes (easy, intermediate and difficult) making use of a system developed for piece rate agreements. Tree sections were divided in two classes: undelimbed and partially delimbed (> 1/10 length delimbed).

Table 1. Stand and tree characteristics for the study of motor manual harvesting.

Figure 1. Distribution of diameter, dry and live crown height, and tree height by species

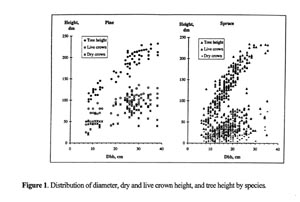

Statistical treatment of the collected data included analyses of variance used to check for covariation of independent variables such as method, cutter, and tree characteristics. Regression analysis was then used to explore the influence of these variables on time consumption in logging. The logs were classified with reference to their relative position in the trunk of the tree as shown in Figure 2.

Figure 2. Definition of log types used in the study of motor manual processing.

Four cutters were chosen for the study. The Instructor was a very skilled logger with many years of experience as a logging instructor. The Trained logger was highly productive, with good formal training and several years of experience. The Skilled logger was productive well beyond the average, with many years of experience but without formal training. The Unskilled logger was an older man who had been working in forestry all his life with infield extraction by horse and machine operation. He had no formal training and very little experience as a motor manual cutter. The choice of cutters was motivated by a wish to investigate if differences in their response to the new processing method could be attributed to their different levels of skill and training.

An alternative to motor manual bucking in differentiated processing requires the pulpwood section to be left for subsequent mechanized bucking, e.g., by a forwarder equipped with a grapple saw. To examine how this would affect the productivity of logging, videogrammetric analyses were conducted on all four cutters.

Mechanized logging

Differentiated processing in mechanized logging was studied in a final thinning operation in Jämtland, north-central Sweden. The stand was two storied with older pines and a rich understory of spruce. This stand type is common within the region, and has been identified as particularly interesting for the harvest of additional biomass through tree section logging [11]. The system studied was an ÖÖSA 735 single grip harvester mounted on a shortened ÖÖSA 250-EVA base vehicle. Before the actual study, 100 trees were felled, thoroughly measured and marked with spray paint in 1 m sections. These data were used to create local functions over stem taper, necessary for volume calculations. The trees were then processed by the harvester as a test of the differentiated processing method, using the harvester head as a boom tip processor.

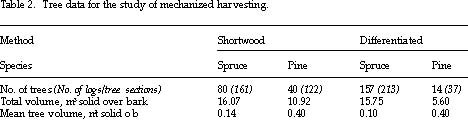

For the subsequent full scale study, all trees within crane reach from a marked strip road in the stand were measured at breast height and numbered. Of the measured trees, 291 trees were felled and included in the study. Some tree data are summarized in Table 2.

The operator of the studied machine had several years of experience as a logging contractor and of operating the actual machine. Apart from the 100 trees felled prior to the study, he had no previous experience of the differentiated processing method. The study was performed with the single tree as the observation unit.

The collected material was analysed by statistical procedures, including analysis of variance to ensure that the material could be analysed without interference by covariation between independent variables and regression analysis. Since the average stem size differed between the methods, normative calculations were performed to ensure comparability between the methods.

A videogrammetric study method was developed to enable detailed time and work measurements with high accuracy. The equipment used was a standard VHS videocam recorder that was fitted with a digital timer display with an accuracy of 1/10 second.

The method is described in detail by Björheden [6].

Time concepts and other terms used in this paper adhere to the IUFRO test edition of a 'Forest Work Study Nomenclature' [7].

Table 2. Tree data for the study of mechanized harvesting

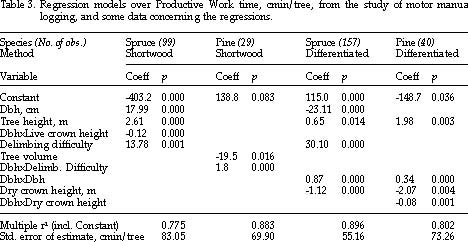

Table 3. Regression models over Productive Work time, cmin/tree, from the study of motor manual logging, and some data concerning the regressions.

RESULTS

Motor manual logging

According to the Tukey HSD test, time consumption per m3 was significantly (***) lower for the differentiated processing method than for conventional logging. On the average, Productive Work time consumption, PW, decreased by 40%, but the increase in productivity differed between species and tree size. Regression models for prediction of productive time by method and species are shown in Table 3. It needs to be pointed out that the studied loggers were not chosen to represent the normal population of loggers.

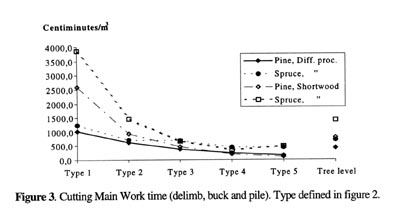

Tree diameter measures proved to be useful as explanatory variables on tree level. The many other predictors tested, alone or in combinations, normally contributed relatively little to the explanatory power of the models. For the log level, diameter, delimbing difficulty class, species, and log type all proved to be useful as predictors, with the two first variables as the strongest. The Main Work time per m3 s o b for different log types and on tree level is shown in Figure 3. Notably, the differences between the methods are generated in the pulpwood segment (log types 1 and 2). The absolute difference between the methods is fairly insensitive to tree size. As shown in Figure 3, log types 3 to 5 are almost exclusively processed into sawlogs in both methods. Log types 1 and 2 will constitute a fairly homogenous 'small tree' group of potential tree sections of which some are 'attached' to a sawlog.

Evaluation of work patterns

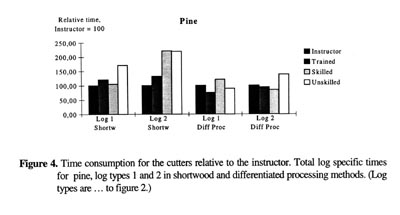

The Tukey HSD test showed several cases of significant differences between cutters. Further analyses supported the hypothesis of a pattern in the varying adaptation to the respective method, depending on level of training. This is exemplified, in Figure 4, by the performance relative to the Instructor for the other three cutters in the processing of pine and log types 1 and 2. Note that the relative differences between the cutters, strongly indicated for shortwood logging, is less pronounced in differentiated processing.

Figure 3. Cutting main work time (delimb, buck, and pile). Type defined in Figure 2.

Figure 4. Time consumption for the cutters relative to the instructor. Total log specific times for pine, log types 1 and 2 in shortwood and differentiated processing methods. (Log types are defined in Figure 2.)

Mechanized bucking of tree sections

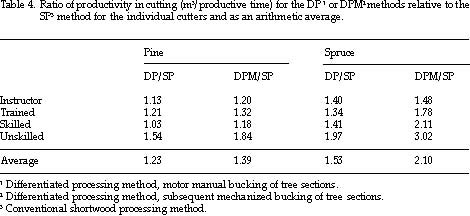

The results from the videogrammetric method study of motor manual sawlog processing followed by mechanized bucking of tree sections indicate that time consumption may decrease another 15 to 60% under the conditions prevailing under this study, depending of species and tree properties (Table 4).

Table 4. Ratio of productivity in cutting (m3/productive time) for the DP1 or DPM2 methods relative to the SP3 method for the individual cutters and as an arithmetic average.

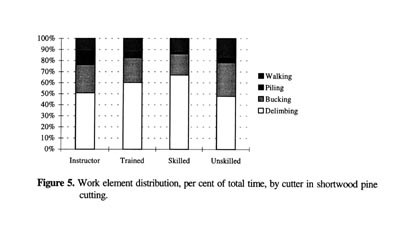

The relative proportion of the parts of Main and Complementary work time, such as delimbing, bucking, piling, and walking, differs between the cutters. Figure 5 presents the relative proportion of some work elements for the studied cutters when cutting pine with the shortwood method. The differences are typical throughout the material. Video-grammetric analyses of the work patterns of the respective cutters revealed marked differences in working tactics.

The instructor took great care in planning his work. He repeatedly studied the 'next' five to ten trees carefully. His tactics included felling over bench trees so that the felled tree would rest on a pivot point after delimbing, enabling him to 'pile by balance'. This work tactic made frequent slash handling necessary, i.e., removing branches from the log piles. On the other hand, he did not have to spend a lot of effort on lifting and carrying logs and yet he produced the most concentrated wood piles among the studied cutters. He worked efficiently and calmly and seemed quite relaxed after work.

The trained cutter also took great care in piling but did not master felling and 'piling by balance' to the same degree. The end result was a well prepared strip road including good concentration of pulpwood within reach of the crane. He was very careful not to cover piles with slash while delimbing but was forced to strain himself by lifting logs instead. He worked hard, but recovered quickly during breaks.

The skilled cutter had a special work pattern. He was directing felling in such a manner that when one tree was processed, he would be close to another tree designated to be felled. In Figure 5, the effect of this tactic is clearly shown as an extremely small proportion of walking time. Another notable feature is the small proportion of time spent on piling. The end result was a scattered layout including small piles and strings of wood, often intermingled with slash. The skilled cutter also worked hard, but recovered quickly during breaks.

The unskilled cutter experienced problems with felling and very often had to push the trees hard. He also had difficulties with his delimbing technique and often had to complete delimbing in connection with piling. The relative proportion of piling was not very high, but in absolute figures he had to spend a lot of time carrying and skidding pulpwood into piles. The completed striproad was probably better prepared for forwarding than the striproad of the skilled cutter, but at a high price in terms of time and energy consumption. He clearly worked at the maximum of his short term physical ability and did not recover fully during breaks. He was very tired at the end of the day and, probably, exceeded his long term working capacity.

Figure 5. Work element distribution, percent of total time, by cutter in shortwood pine cutting.

All cutters expressed that differentiated processing was an ergonomically attractive method inducing less work load.

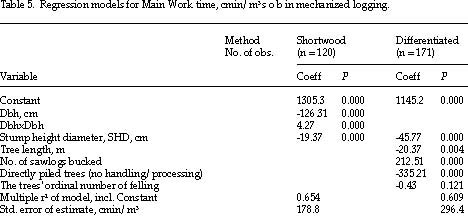

Mechanized logging

The material of the study of mechanized harvesting was submitted to analyses using the same approach as described for motor manual logging. Results from the analysis of Main Work time consumption (crane positioning, felling, processing, and handling/piling) are summarized in Table 5. Again, the diameter proves to 'contain' many time influencing factors connected to the size of the tree. The variable 'tree species' did not influence the consumption of time in a statistically significant way (r=0,133 in a Pearson correlation test) - once the covariation between species and stem volume was controlled. Of the 171 trees included, almost a third (55 trees, mainly small spruce) were felled and piled directly, without processing. The correlation between this procedure and time consumption is indicated (r=-0,506). The inclusion of the tree's ordinal number suggests that the work pattern of differentiated processing improved during the course of this study.

Table 5. Regression models for Main Work time, cmin/m3 o b in mechanized logging.

The comparison of shortwood and differentiated processing methods in mechanized logging with single grip harvester gives entirely different results from what has been described for motor manual logging. As can be seen in Table 6, time consumption was higher for differentiated processing. Contrary to the case of motor manual logging, the advantage of not having to process small diameter wood does not increase productivity. This is not only an effect of the difference in the average tree size. By simulating the same average tree size, using the developed regression functions, the comparison between the methods can be made more relevant. Even after this adjustment, differentiated processing is more time consuming than the shortwood method, as shown in Table 6.

Display large image of Table 6

Table 6. Time consumption, cmin Productive time per m3 s o b, for the shortwood and differentiated logging methods respectively. Adjusted time consumption figures are standardized with regard to tree size for both methods.

DISCUSSION

Motor manual logging

Comprehensive data on the workpiece (tree, log) were collected, assuming that such detailed data would increase the explanatory power of the models concerning differences in time consumption between the tested methods, an approach suggested e.g., by Ager, [1]. A notable result is that the detailed data did not pay off in the expected way. In spite of the attempts of dethronization through a number of combinations of other variables, dbh remained the 'king of forestry predictors'. Dbh is easy to collect, and seems much more stable in relation to the overall characteristics of the tree than any of the other investigated variables. The hypothesis that dbh would have to yield for more detailed data when analyses were performed on different stands is not supported by this study. No statistically significant differences between the two stands were found, nor can the hypothesis be declared false. Although only one stand type is included in the study, the performance of the investigated methods in other stands is probably possible to simulate, using the extensive data collected within the Nordic comparative studies tradition. There is a rich source of material on the relative influence of different stand and terrain variables on time consumption in motor manual logging [2, 19].

The individual efficiency gain by differentiated processing was found to be negatively correlated to the relative performance level in conventional shortwood processing. Differentiated processing is a less complicated and physically less demanding method. The unskilled workers gain relatively more when operations are simplified while the skilled workers find less opportunity to engage their superior ability to plan and carry out complex working patterns. This conclusion may have great implications for the development of working methods and for the recruitment and training of forest workers. At least in Scandinavian forestry, this has probably not been given enough consideration. Although differentiated processing is a method suited for less skilful cutters, it is necessary to point out that planning and directional felling are still important skills. Correcting the effects of poor felling techniques can hardly be done by manual skidding of tree sections, as is possible in the case of pulp wood. In addition, these skills are essential in order to get an ergonomically sound working position in delimbing by way of using a bench tree. This is more difficult in differentiated processing since the method requires that all tree sections are felled into a tree section zone separated from the sawlogs. Thus, felling directions are more restricted and the use of bench trees more complicated.

A weak point of the study is that the exertion of the workers was only subjectively rated. Hansson [14] found that studied forest workers worked harder when studied than during normal logging, but with a stable physiological intensity. Since the objective of the study was to establish the relative productivity of differentiated processing compared to shortwood logging, no pulse rate measurements or other physiological data over the intensity of work were collected. A simple pulse rate registration or similar objective measurements would, however, have increased the possibilities to extract valid conclusions [20]. This is particularly the case concerning the decreased work load experienced by the cutters, although this opinion is supported by other, ergonomically oriented studies of the tree section method [10].

This study measured quantity of work, not the quality. This does not mean that the qualitative side of work is not important. A full comparison of the cutters' respective performance within or between the methods requires that the quality of work be taken into account. In this study, only a rough estimate was done based on the layout of the logging plot after completed felling. This subjective assessment indicated rather large differences between the cutters. The ability to implement the 'new' method (to interpret the method description) varied.

It is probable that the cutters had different rates of extracting sawlog value from the trunk of the tree. There are differences, e.g., in the average length of sawlogs produced. The Instructor bucked sawlogs with a great variability of length. The Skilled worker made many sawlogs of maximum length. For the course of the study, it was assumed that the rates of sawlog length and value were the same for each cutter in both methods. Thus, no theoretical analysis of the deviation of the sawlogs actually produced from the optimum length distribution was made, but it is evident that it may influence the comparison of the methods.

It must be pointed out that the performed work studies and analyses do not establish an absolute or 'normal' level of productivity. The material is too limited and the cutters were not chosen to represent the 'normal' population of loggers. Instead, the aim was to establish the relative difference in time expenditure between the two methods. Further, as no real repetitions are made for the 'cutter' variable, the observations on, e.g., impact of formal training cannot be regarded as conclusive until they have been supported by additional studies.

Mechanized logging

The results are discouraging with respect to the efficiency of a single grip harvester applying differentiated processing in thinning. The positive correlation between ordinal tree number and performance was not statistically significant but strongly indicates that the method may be made more efficient. A much longer study would be needed however, to substantiate this 'learning effect'. The level of productivity observed in this study is probably not doing the method justice. Even so, it does not seem likely that the method can be justified by increased productivity alone. If the value of harvested forest fuel is taken into account, there may be a margin for the method. Thus, it is essential that little biomass is lost [12]. Handling was, however, observed to result in substantial unintended delimbing of tree sections.

This undesired delimbing of tree sections is a strongly negative factor. About 1/3 of the branch and top biomass that could have been left attached to the tree sections was severed and left in the stand. The larger trees, yielding sawlogs, had to be delimbed at least one metre past the small end of the sawlog. Processing would sometimes continue several metres on the pulpwood section before the operator decided where to buck the sawlog. Heavy tops were easier to feed to the balance point for handling rather than releasing the grapple to take a new hold. The feeder rolls were used to transport the tree section for piling, resulting in additional delimbing. The obstruction by the remaining stand added to the need for such transverse 'stitching' with tree sections in order to produce good sized piles. These problems are smaller in final felling. Studies, of differentiated processing in final felling also show better results for the method [13, 16]. Here, the cost of logging is reported to break even for the two methods.

Another reason for discounting thinnings as a potential source of energy is that the residual stand would prosper from the

nutrients contained in the slash. In final felling, there is no residual stand and the volumes of additional biomass are much

higher per hectare. The piles of slash constitute obstacles to scarification and planting and the leakage of nutrients is

diminished if energy assortments are harvested [18]. There rests

a strong case for concentrating the harvest of forest fuel to final fellings.

The considerably smaller tree size of the differentiated processing tree batch is not the only effect of stand variation. The operator tried to add as much material as possible to the tree section piles. Even very small trees (dbh 6 to 4 cm) that would have been overlooked or felled to waste in conventional shortwood logging were carefully sought, felled, and piled. This, of course, added to the time consumption.

Why does mechanized logging not draw the same benefits from the simplified processing method? The answer may lie in the fundamental differences in working patterns between Nordic harvesters and motor manual cutters. The 'positioning' of motor manual cutters are time and cost efficient parts of work while delimbing alone normally draws more than half the work time, and bucking and piling together another third. Thus, the differentiated processing method simplifies the heaviest and most time consuming parts of motor manual work (processing and piling). These work elements happen to be the most time efficient parts of mechanized work. Processing is extremely time efficient (a few seconds per log) with 'piling' as a bonus. At the same time, the method adds to the need for crane handling (piling tree sections) which is a weak point of mechanized harvesting. A large part of machine work is made up by crane and machine movements in order to get access to the tree.

REFERENCES

[1] Ager, B. 1970. Tidformler för huggning. (Time functions for logging). The Forest Operations Institute of Sweden, Ekonomi 1970:1.

[2] Andersson, S. and B. Sprängare. 1967. Sortimentshuggning i Norrland. (Shortwood cutting in the north of Sweden). The Forest Operations Institute of Sweden, Report No. 14.

[3] Björheden, R. 1988a. Differentierad upparbet-ningsteknik vid motormanuell upparbetning. (Differentiated processing in motor manual logging). Garpenberg: SLU, Department of Operational Efficiency. Uppsatser och Resultat 112.

[4] Björheden, R. 1988b. Increased output of bio-mass through differentiated processing. In: Proceedings of the IEA/BA Task III, Project A1 work shop in Garpenberg.

[5] Björheden, R., 1988c. New work study methods help to decide processing technique in logging. Scand. J. For. Res. 3: 569-574.

[6] Björheden, R., 1990. Detailed and accurate logging studies - an example of the use of videorecording in work study. Proceedings of the IUFRO WP 3.04.02 Symposium on recent developments in work study, Thessaloniki.

[7] Anonymous. 1995. Forest Work Study Nomenclature, IUFRO WP 3.04.02. Test Edition valid 1995-2000, Garpenberg.

[8] Dahlin, B. 1989a. Cradle type multi-stem delimber. SLU, Department of Operational Efficiency. Garpenberg: Uppsatser och Resultat 162, 1989.

[9] Dahlin, B. 1989b. The influence of tree dimension on production capacity for different delimbing principles. Scand. J. For. Res. 4:267-272.

[10] Eriksson, E. 1987. Arbetsmiljön vid träddel-savverkning - granskning och åtgärdsförslag. (Health and safety aspects of tree-section logging for energy wood survey and measures of improvement). Garpenberg: SLU, Department of Operational Efficiency. Uppsatser och Resultat 89.

[11] Frohm, S., G. Svensson and C. Wigren. 1991. Uttag av de klena stammarna som träddelar i dimensionsuppdelad slutavverkning. (Harvesting small trees as tree sections in 'clearfelling-by-dimension'). Special report, dated 1991-05-22). The Forest Operations Institute of Sweden.

[12] Gabrielsson, L. and Karlsson (Gullberg), T. 1987. Träddelar i slutavverkning. (Tree sections in final felling). Garpenberg: SLU, Institutionen för skogsteknik. Intern Stencil nr 23/85.

[13] Granström, T. 1985. Skördaren gör träddelar. (The harvester in production of tree sections). SLU, Norra Skogsinstitutet, Specialarbeten 4.

[14] Hansson, J.-E. 1965. Samband mellan personvariabler och prestation vid huggningsarbete. (The relationship between individual characteristics of the worker and output of work in logging operations). Studia For. Suec. 29.

[15] Hildeman, A., G. Rutegård and G. Tibblin. 1986. Träddelsmetoden-integrerad pro-duktion av skogsbränsle och massaråvara. (Tree sections - integrated harvesting of forest fuel and pulp wood). Ultuna: SLU, Institutionen för Skog-Industri-Marknad-Studier. Uppsat-ser nr 19.

[16] Jakobsson, R. 1984. Dimensionsuppdelad slutavverkning. (Final felling by dimension). SLU, Institutionen för skogsteknik, Stencil 252.

[17] Lönner, G. and M. Parikka. 1985. Trädbränslen. (Wood Fuels). Uppsala: SLU, Department of Operational Efficiency. Uppsatser och Resultat 18/85.

[18] Rosén, K. and A. Lundmark-Thelin. 1987. Increased nitrogen leaching under piles of slash - a consequence of modern forest harvesting techniques. Scand. J. For. Res. 2:21-29.

[19] Samset, I. 1950. Cutting studies in Norwegian Spruce Forests. Medd. Norske Skogforsoeks Ves. 14.445-498.

[20] Åstrand, L. 1986. Arbetsfysiologi (Work physiology). Norstedts, Stockholm.