January, 2000, vol.11 no.1

Lars Eliasson

Swedish University of Agricultural Science

Umeå, Sweden

ABSTRACT

An increased use of shelterwoods in regeneration has generated a demand for knowledge of how single-grip harvester performance is affected by shelterwood treatments. Time consumption and productivity of a large single-grip harvester working in shelterwood establishment and thinning was studied using work sampling. Five treatments were studied, 1) shelterwood establishment, thinning of 2) sparse, 3) medium and 4) dense shelterwoods and 5) clear-cutting. Each treatment was replicated three times. Results shows that time consumption for the average harvested tree increased with tree volume and declining number of harvested trees per ha. Productivity was higher in clear-cutting than in any of the shelterwood treatments. Harvesting costs in the shelterwood system thus becomes higher than in the clear-cutting system. These costs must be carefully weighted against the ecological and silvicultural benefits of the shelterwood, including the possible reductions of the regeneration costs.

Keywords: single-grip harvester, productivity, clearcut.

The author is a Researcher in the Forest Technology Division of the Department of Silviculture.

INTRODUCTION

Interest in natural regeneration has increased in Sweden during the last decade. Regeneration under shelterwood is seen as one of the alternatives to clearcutting and planting, especially on sites with good conditions for natural regeneration, and sites where artificial regeneration may be prone to failure. Norway spruce (Picea Abies, (L) Karst.) dominated stands on wet soils is one of the stand types where regeneration is faced with a number of obstacles, e.g. frost, high ground water level, competition from other plants, and insect damage [5]. From an environmental standpoint shelterwoods have advantages as they lead to moderate changes of physical site conditions [12], and smaller changes in ground vegetation compared to clear cutting [3, 6]. However, use of shelterwood systems increases the number of logging treatments at the end of the rotation from one to two or three [11]. The shelterwood has to be established and this is done through a high intensity thinning. To improve growth of the regeneration, it may be necessary to reduce the shelterwood density through another thinning before the shelterwood is finally removed.

The increased interest in shelterwoods for regeneration of spruce has led to an interest in how single-grip harvester performance is affected by different types of shelterwood treatments. Harvester productivity in shelter-wood establishment and shelterwood thinning should not differ from harvester productivity in other forms of thinning, i.e. it should decrease with increased residual stand density (cf [1, 8]) and thus be lower than in clear-cutting. Westerberg et al. [15] found no effect of increased shelterwood density on single-grip harvester productivity in shelterwood establishment in pine and spruce stands, whereas increased residual stand density decreased productivity in studies of shelter-wood establishment in spruce stands [2, 9].

The objective of the present study was to investigate which work elements of a single-grip harvester are affected when establishing or thinning a shelterwood stand, and how single-grip harvester productivity in shelter-wood establishment and shelterwood thinning compares to single-grip harvester productivity in clear cutting.

MATERIAL AND METHODS

The study was carried out at Gideåbruk (63°29' N, 19°7' E), 10 km NNE of Örnsköldsvik airport in Sweden, in a shelterwood trial that was established in 1988 to study regeneration in Norway spruce dominated shelterwood stands [4]. The shelterwood trial was located in one stand and had a randomised block design with three blocks and four treatments. Treatments in 1988 were shelter-woods with residual stem densities of 140, 200, and 300 stems ha-1, and an unharvested control. Plot size varied from 0.40 to 1.82 ha. In 1997 it was decided to do a shelterwood thinning in the shelterwood plots and to establish a shelterwood on the control plots. To be able to include a clear-cutting treatment three more plots were established in a previously untreated part of the stand. In the present study five treatments were thus studied;

| R140 | Reduction of shelterwood density from 140 to 70 stems ha-1 |

| R200 | Reduction of shelterwood density from 200 to 100 stems ha-1 |

| R300 | Reduction of shelterwood density from 300 to 150 stems ha-1 |

| DS | Establishment of a dense shelterwood stand with approx. 300 stems ha-1 |

| CC | Clear-cutting. |

Total enumeration of all plots was carried out before logging and stem diameter at breast height (dbh) was recorded for and marked on all trees with dbh³ 8 cm. Plot boundaries were marked with tape. Plot area and harvested plot area was measured after logging. According to a revision of the regeneration experiment made in 1996 the amount of spruce regeneration higher than 1 m in treatments R140, R200, R300 and DS was 3900, 900, 2500 and 900 trees per ha, respectively [17].

The study was done under daylight conditions during six days in early April 1997. Snow depth varied from a few dm in dense forest to almost one meter in sparse shelterwoods. Plots were harvested in a randomised order, and harvesting was done with a large single-grip harvester (FMG 1870) equipped with a large harvester head (Timberjack 762B) mounted on a boom with 8.3 m reach (FMG 184E). The operator had used the harvester for six years, mostly in clear cutting. The harvester operator selected what trees to harvest in the treatments, and where to place the strip road. He was instructed to reduce the number of commercial trees in the shelterwood plots by 50 per cent, to cut 30 per cent of the trees in the previously unharvested control plots to establish a shelterwood stand, and to fell all trees in the clear-cut plots. Trees to cut should normally be selected from the co-dominant shelterwood trees. In addition, damaged or suppressed trees had to be cut, and trees with a dbh exceeding 45 cm should be cut to avoid unacceptably large logs in the final felling of the shelterwood. Timber harvested was sorted into four assortments, spruce sawlogs, pine sawlogs, softwood pulpwood, and hardwood pulpwood. In the shelterwood treatments care should be taken to avoid damage to the regeneration. Whenever possible, trees were felled into the strip road to minimise the disturbed area of the stand (cf. [15]).

The study was done as a work sampling with 8 s interval between observations. Thirteen work elements were studied (table 1) and if more than one work element was performed at the time of an observation the element with the highest priority was recorded. For each harvested tree species, dbh and damage were noted. Total time consumption per plot was measured with a stopwatch. A total of 11017 observations were done during a total study time of 88868 s, and the true sample interval was 8.060 ± 0.127s.

Of 1766 trees harvested, 1361 were undamaged spruce trees. All observation data was converted to time consumption through multiplication of the number of observations with the true sample interval.

For each plot, average time consumption per tree was calculated for all work elements, and for work elements that has no logical connection to the single tree (move, branch movement, cleaning, and miscellaneous) time consumption per hectare was also calculated. Although delays were included in the work elements studied, they were not included in the analyses. All statistical analyses were done on plot data and mean and standard deviation were calculated for all treatments. A more thorough statistical analysis was done using ANOVA in SPSS with the model:

yij = m + ti + bj + eij

where m is the grand mean, ti the treatment main effect, bj the block main effect, and eij the error term. The clear-cutting treatment was excluded from the ANOVA, as it was not a part of the original randomised block design.

table 1. Defination of the work elements.

| Work Element | Definition | Priority |

| Move | Machine movement, the wheels are turning. | 3 |

| Boom out | When the boom is moving towards a tree until the harvester head has reached it. | 2 |

| Position | Starts when the harvester head has reached the tree and stops when the chain saw starts. | 2 |

| Felling | When the chain saw sewers a standing tree. | 1 |

| Tree fall | Starts when the chain saw stops and ends when the tree reaches the ground. | 2 |

| Delimbing | When the feeding wheels of the harvester head are turning | 1 |

| Cross cutting | When thefeeding wheels of the harvesterhead have stopped and the chain saw cross cuts the stem. | 1 |

| Other processing | Work necessary to process damage trees, trees with double tops, etc. | 2 |

| Boom in | When the boom is moving towards the machine prior to a change of conversion site. | 2 |

| Branch | When the operator moves branches or tree tops | 3 |

| Cleaning | Felling of non-commercial trees | 1 |

| Miscellaneous | Other elements that contributes to the work, e.g. moving or sorting of logs. | 4 |

| Delays | operational, mechanical, and personal delays that interrupt the normal work activity of the harvester. | 4 |

To avoid disturbances caused by species mixture or damaged trees, a second analysis was done for undamaged spruce trees. The spruce trees were divided into 5 cm dbh classes. Trees with a dbh³ 40 cm were excluded from the analysis due to being to few. In each plot average time consumption per tree was calculated in each dbh class for elements that have a logical connection to individual trees.

RESULTS

Treatment R140 and DS differed in harvested dbh and harvested mean stem volume compared to each other and the other treatments (table 2). There were no such differences between R200, R300 and CC. Harvested dbh for block 1, 2 and 3 was 22.3, 22.8 and 27.2 cm, respectively. There was more strip roads per ha in CC than in the shelterwood treatments. Due to this, swath width in treatments R140, R300 and DS was approximately the double compared to the swath width in CC, and R200 had 50 per cent wider swaths than CC. (table 3).

table 2. Stand data for the stand prior to treatment and extraction data.

| Treatment | R140 | R200 | R300 | DS | CC |

| Before harvest | |||||

| Stems ha-1 8-20 cm | 27.4 | 56.7 | 71.1 | 237.0 | 172.2 |

| Stems ha-1 > 20cm | 140.6 | 182.8 | 209.6 | 313.7 | 402.9 |

| Stems ha-1 Total | 168.0 | 239.5 | 280.8 | 550.8 | 575.1 |

| Volume ha-1 (m3) | 101.9 | 122.0 | 133.6 | 190.7 | 270.3 |

| Average dbh (cm) | 29.1 | 27.1 | 26.3 | 22.3 | 25.6 |

| Extracted | |||||

| Stems ha-1 8-20 cm | 17.0 | 34.5 | 44.4 | 142.4 | 172.2 |

| Stems ha-1 > 20 cm | 55.0 | 75.3 | 74.4 | 98.1 | 402.9 |

| Stems ha-1 Total | 72.0 | 109.9 | 118.7 | 240.5 | 575.1 |

| Volume ha-1 (m3) | 45.4 | 52.8 | 57.0 | 60.1 | 270.3 |

| Average dbh (cm) | 28.6 | 24.8 | 24.1 | 18.8 | 25.6 |

| Mean stem volume (m3) | 0.63 | 0.48 | 0.48 | 0.25 | 0.47 |

table 3. Strip road length, swath width and machine speed. Data for treatments not followed by the same letter are significantly different (p>0.05)

| R140 | R200 | R300 | DS | CC | |

| Strip road length (m ha-1) | 510a | 661ab | 467a | 500a | 1034b |

| Theoretic swath width (m) | 19.7a | 15.2ab | 21.8a | 21.0a | 10.3b |

| Machine speed (m minute-1) | 34 | 31 | 26 | 22 | 23 |

Move was the only work element that was significantly affected by treatments (table 4, 5) on average tree level. Branching and cleaning were significantly affected by treatments (table 6, 7) per ha. The total time for positioning, felling, treefall, cross-cutting, delimbing and other processing (felling and processing time) did not differ for R200, R300 and CC, i.e. were the harvested mean stem volume was comparable. Delimbing was the dominating element and accounts for 55 to 60 per cent of the felling and processing time. Nearly all observations of other processing was caused by spruce trees broken by snow 30 years ago that have developed multiple tops or a severe bend on the stem.

table 4 Time consumption(s) per tree seterated on work elements

| Treatment | R140 | R200 | R300 | DS | CC | |

| Work Element | Mean | SD | ||||

| Move | 12.84 | 10.61 | 8.89 | 5.47 | 4.77 | 1.61 |

| Boom out | 4.06 | 3.67 | 3.86 | 4.35 | 3.21 | 0.12 |

| Positioning | 5.45 | 5.09 | 5.60 | 4.14 | 5.52 | 0.93 |

| Felling | 4.13 | 3.35 | 3.74 | 2.36 | 3.03 | 1.01 |

| Treefall | 2.68 | 2.30 | 2.29 | 1.60 | 1.76 | 0.59 |

| Crosscut | 5.57 | 4.24 | 3.97 | 2.11 | 3.74 | 1.45 |

| Delimbing | 24.60 | 18.38 | 18.80 | 13.24 | 17.17 | 3.58 |

| Oth. proc. | 0.47 | 0.49 | 0.91 | 0.11 | 0.43 | 0.51 |

| Boom in | 1.15 | 0.89 | 0.73 | 0.80 | 0.30 | 0.15 |

| Branching | 0.49 | 0.25 | 0.43 | 0.45 | 0.32 | 0.13 |

| Cleaning | 0.11 | 0.17 | 0.18 | 0.27 | 0.43 | 0.30 |

| Misc. | 0.52 | 0.62 | 0.41 | 0.64 | 0.51 | 0.44 |

| Total time | 62.08 | 50.04 | 49.82 | 35.54 | 41.20 | |

table 5. Results of ANOVA on time consumption per tree for each work element. Treatment DF=3, block DF=2, residula DF=6 and total DF=11 in each case.

| Work element | Treatment p-value |

Blocak p-value |

| Move | .010 | .608 |

| Boom out | .309 | .233 |

| Positioning | .209 | .562 |

| Felling | .086 | .049 |

| Treefall | .177 | .256 |

| Crosscut | .061 | 0.33 |

| Delimbing | .103 | .201 |

| Oth. proc. | .369 | .214 |

| Boom in | .649 | .528 |

| Branching | .328 | .116 |

| Cleaning | .113 | .175 |

| Misc. | .943 | .877 |

For the elements Boom out, Boom in, positioning, felling, treefall, cross-cutting, and delimbing no differences in time consumption per tree was found between treatments when comparisons were done on undamaged spruce trees and within diameter classes. Time consumption per tree for work elements positioning, felling, treefall, cross-cutting, and delimbing increased significantly with dbh.

table 6. Time consumption per ha (s/ha) for elements not clearly associated with the single tree.

| R140 | R200 | R300 | DS | CC | ||

| Mean | SD | |||||

| Move | 902 | 1286 | 1090 | 1381 | 2721 | 814 |

| Branching | 36 | 33 | 53 | 114 | 189 | 89 |

| Cleaning | 8 | 21 | 23 | 67 | 252 | 195 |

| Misc. | 37 | 67 | 48 | 163 | 284 | 246 |

table 7. ANOVA of time consumption per ha for elements not clearly associated with the single tree. Treatment DF=3, block DF=2, residual DF=6 and total DF=11 in each case.

| Work element | Treatment p-value |

Block p-value |

| Move | .095 | .360 |

| Branching | .010 | .075 |

| Cleaning | .001 | .035 |

| Misc. | .102 | .891 |

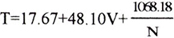

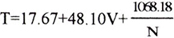

Average effective time consumption per tree (T, s) increased with mean harvested stem volume (V, m3u.b.) and the inverse of number of harvested trees (N). A multiple linear regression resulted in:

where adjusted r2 is 0.94, beta values are 0.698 and 0.390 for the coefficient for V and 1/N respectively, and all coefficients are significant. However, note that the regression is based on only 15 observations.

Harvester productivity was 25.7 m3u.b. E0h-1 for DS, 36.3, 34.6 and 34.4 m3u.b. E0h-1 for R140, R200 and R300, respectively, and 41.3 m3ob E0h-1 for CC.

DISCUSSION

When the shelterwoods were established in 1988, shelterwood trees were selected among the dominant and co-dominant trees, i.e. the largest trees [4]. However, trees that had not reached commercial size, were neither felled nor recorded as part of the shelterwood. As a result the number of commercial trees in some treatments was higher in 1997 than in the original shelterwoods (table 2). As the harvester operator, during the 1997 study, selected which trees to cut among the suppressed and co-dominant trees many of these previously uncommercial trees were cut, resulting in less reduction of the overstorey than targeted. From a silvicultural point of view it is doubtful whether trees with a dbh lower than 10 cm belong to the shelterwood or are a part of the advance regeneration, in which case they should be retained. The small difference between treatment R200 and R300 in pre-harvest and extracted number of shelterwood trees and average harvested tree size made meaningful comparisons between these treatments difficult.

As final felling of shelterwoods often damage a large proportion of the regeneration [15, 16], damage to regeneration must be restricted to the extent possible, when thinning in shelterwoods. This can be done by minimisation of the strip road area per ha [14], by directional felling of large trees so that they fall into the strip roads, and by careful positioning of log piles and slash (cf. [10]). These measures are time consuming, and thus reduce the harvester productivity. They will however increase forwarder productivity through higher wood concentrations and better piling [10]. Due to the operators� desire to retain as much regeneration as possible undamaged, swath width was increased in the shelterwood treatments. The use of a larger swath width in shelterwood thinning treatments R140 and R 300 than in treatment R 200 can be explained by the fact that the operator had to consider a larger number of spruce saplings in treatments R140 and R300 than in R200. Logically, time consumption per tree for boom out should increase with swath width due to an increased mean distance for boom movements, and it seems to be the case in this study.

It may look illogical that the shortest time consumption for treefall occurs in treatment DS where the number of residual trees was highest. However this is an effect of the fact that time consumption for tree fall increases with increasing tree size and that the harvested trees in DS was smaller than the harvested trees in any of the other treatments.

In order to increase productivity and reduce wear on the harvester the operator avoided utilising the full boom reach when clear-cutting. However, strip road length was longer than necessary in one of the clear-cutting plots, due to a bad shape of the plot. When the �unnecessary� driving is deducted strip road length per ha decreases to approximately 900 m in clear-cutting, i.e. with 10%. The large change is mostly an effect of the small plots. Striproad length in CC after deduction of this �unnecessary� driving is still statistically different from R140, R300 and DS. This suggests that time consumption for move in clear-cutting was overestimated with 10%.

The harvester had difficulties felling and processing trees with a dbh larger than 50 cm. During felling the machine had to reposition the harvester head to be able to severe these trees from the stump. And during processing of the first logs, the harvester head was moved along the stem by the boom, as it was difficult to pull the tree through the harvester head using only the feed rollers. This latter technique was often used by the operator when delimbing large trees with many and/or large limbs.

Time consumption for the average harvested tree was found to increase with average tree volume, and declining number of harvested trees per ha. The former effect is well known and Richardson & Makkonen [13] stated that the average tree volume is the most significant factor influencing single-grip harvester productivity. The latter effect is caused by two factors. Firstly, a declining number of trees harvested leads to an increased inter-tree distance that increase the distance for machine movements per tree and thus the time consumption for move (cf. [7]). Secondly, time consumption for elements not related to individual trees will be distributed on a smaller number of trees.

Single-grip harvester productivity was higher in clear-cutting than in any of the selective fellings. Although distance between harvested trees was largest in R140, productivity was higher than in the other shelterwood thinnings due to the larger trees harvested. Productivity in shelterwood establishment and clear-cutting was lower than in a study by Eliasson et al. [2], although the same type of harvester was used. However, the relation between clear-cutting and shelterwood establishment was the same. In both studies productivity when establishing shelterwood of similar density was 36 - 37 per cent lower than in clear-cutting. Due to the lower harvester productivity both establishment and thinning of shelterwoods are considerably more costly than clear-cutting. This effect is increased by the fact that a lower wood concentration per ha will decrease forwarder productivity in the shelterwood treatments (cf. [8]). It can furthermore be expected that harvester productivity in final felling of the shelterwoods will be some-what higher than in the thinning of the shelter-woods, as the number and average volume of the residual stems are higher than of the extracted stems. The higher costs for the harvesting operation must be carefully weighted against the ecological and silvicultural benefits of the shelterwood, including the possible reductions of the regeneration costs.

ACKNOWLEDGEMENTS

The study was partly funded by the Swedish Council for Forestry and Agricultural research. MODO skog AB had established the shelter-wood trial in cooperation with Associate Professor Björn Hånell, dept. of Silviculture, SLU. I also thank Professor Iwan Wästerlund, and Associate Professor Lars Lundquist at the dept. of Silviculture, for valuable comments on the manuscript.

REFERENCES

[1] Brunberg, T. 1997. Basic data for productivity norms

for single-grip harvesters in thinning. The For. Res. Inst. of Sweden,

Uppsala. Report 8, 18 p. ISSN 1103-4580 (In Swedish with English summary.)

[Return to text]

[2] Eliasson, L., Bengtsson, J., Cedergren, J., and Lageson,

H. 1999. Comparison of single grip harvester productivity in clear- and

shelterwood cutting. J. For. Eng. 10(1) :43-48.

[Return to text]

[2] Eliasson, L., Bengtsson, J., Cedergren, J., and Lageson,

H. 1999. Comparison of single grip harvester productivity in clear- and

shelterwood cutting. J. For. Eng. 10(1) :43-48.

[Return to text]

[3] Hagner, S. 1962. Natural regeneration under shelterwood

stands. An analysis of the method of regeneration, its potentialities and

limitations in forest management in middle North Sweden. Reports of the

forest research institute of Sweden, 52(4). Thesis. 263 pp. (In Swedish

with English summary.)

[Return to text]

[4] Hånell, B. 1988. Försök med själv-föryngring

på högproduktiv, dikad torv-mark. Swed. Univ. Agr. Sci., dept.

of Silviculture, Umeå. Paper dated 1988-06-14. (In Swedish)

[Return to text]

[4] Hånell, B. 1988. Försök med själv-föryngring

på högproduktiv, dikad torv-mark. Swed. Univ. Agr. Sci., dept.

of Silviculture, Umeå. Paper dated 1988-06-14. (In Swedish)

[Return to text]

[5] Hånell, B. 1993. Regeneration of Picea abies forests

on highly productive peat-lands - clearcutting or selective cutting? Scand.

J. For. Res. 8:518-527.

[Return to text]

[6] Hannerz, M. and Hånell, B. 1993. Changes in the

vascular plant vegetation after different cutting regimes on a productive

peatland site in central Sweden. Scand. J. For. Res. 8:193-203.

[Return to text]

[7] Klunder, R.A. and Stokes, B.J. 1994. Productivity and

cost of three harvesting methods. South. J. Applied For. 18(4):168-174.

[Return to text]

[8] Kuitto, P-J., Keskinen, S., Lindroos, J., Oijala, T.,

Rajamäki, J., Räsänen, T. and Terävä, J. 1994.

Mechanized cutting and forest haulage. Tiedotus Metsäteho, Helsinki.

Report 410: 38. ISBN 951-673-139-2. (In Finnish with English summary.)

[Return to text]

[8] Kuitto, P-J., Keskinen, S., Lindroos, J., Oijala, T.,

Rajamäki, J., Räsänen, T. and Terävä, J. 1994.

Mechanized cutting and forest haulage. Tiedotus Metsäteho, Helsinki.

Report 410: 38. ISBN 951-673-139-2. (In Finnish with English summary.)

[Return to text]

[9] Meek, P. and Legere, G. 1998. Trials of two harvesting systems for

shelterwood cutting in softwood stands. For. Eng. Res. Inst. of Canada,

Pointe-Claire, Technical note TN-269. ISSN 0381-7741.

[Return to text]

[10] Meek, P. and Plamondon, J.A. 1996. Effectiveness of cut-to-length

harvesting at protecting advance regeneration. For. Eng. Res. Inst. of

Canada, Pointe-Claire, Technical note TN-242. ISSN 0381-7741.

[Return to text]

[10] Meek, P. and Plamondon, J.A. 1996. Effectiveness of cut-to-length

harvesting at protecting advance regeneration. For. Eng. Res. Inst. of

Canada, Pointe-Claire, Technical note TN-242. ISSN 0381-7741.

[Return to text]

[11] Nyland, R.D. 1996. Silviculture: concepts and applications.

McGraw-Hill, New York. ISBN 0-07-056999-1

[Return to text]

[12] Ottosson-Löfvenius, M. 1993. Temperature and radiation

regimes in pine shelterwood and clearcut area. Swed. Univ. Agr. Sci., Dept.

of Forest ecology. Thesis. 29pp. ISBN-91-576-4677-5.

[Return to text]

[13] Richardson, R. & Makkonen, I. 1994. The performance of

cut-to-length systems in eastern Canada. For. Eng. Res. Inst. of Canada,

Pointe -Claire. Technical Report TR-109: 16. ISSN 0318-7063.

[Return to text]

[14] Wales, H.B. 1926. A study of damage by tractor skidding.

J. For. 27: 495-499.

[Return to text]

[15] Westerberg, D., Sikström, U., von Hofsten, H. and Gustafsson,

L. 1996. Shelterwood systems. IN Frumiere, G. Ed. Research and development

conference 1996. The For. Res. Inst. of Sweden. Report no. 1:112-122. (In

Swedish with English summary.)

[Return to text]

[15] Westerberg, D., Sikström, U., von Hofsten, H. and Gustafsson,

L. 1996. Shelterwood systems. IN Frumiere, G. Ed. Research and development

conference 1996. The For. Res. Inst. of Sweden. Report no. 1:112-122. (In

Swedish with English summary.)

[Return to text]

[15] Westerberg, D., Sikström, U., von Hofsten, H. and Gustafsson,

L. 1996. Shelterwood systems. IN Frumiere, G. Ed. Research and development

conference 1996. The For. Res. Inst. of Sweden. Report no. 1:112-122. (In

Swedish with English summary.)

[Return to text]

[16] Youngblood, A.P. 1990. Effect of shelter-wood removal methods on

established regeneration in an Alaska white spruce stand. Can. J. For.

Res. 20: 1378-1381.

[Return to text]

[17] Holge´n, P. 1999. Regeneration data Gideåbruk.

Swed. Univ. Agr. Sci., Dept. of Silviculture. Personal communication

[Return to text]