Vol. 11 No. 2 July 2000

Silvicultural Result of One-Grip Harvester Operation

M. Sirén

The Finnish Forest Research Institute

Vantaa, Finland

Abstract

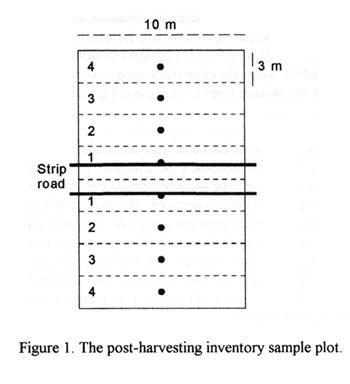

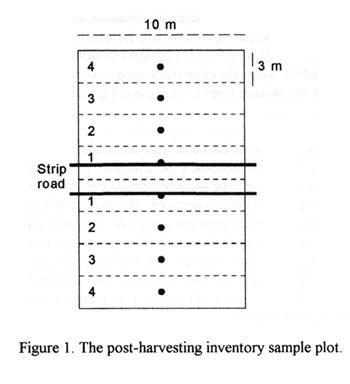

A new method for measuring the silvicultural result

of thinning is presented in the study. The measuring

method was based on rectangular sample plots measured

parallel to strip roads. An individual sample plot consisted of

eight zones, each 30 m2 in area. Due to its considerable

importance in Finland, the one-grip harvester operation was

the harvesting system examined. The research material

was collected from 15 stands amounting to a total area of

14.7 ha.

The post-harvesting inventory provided good

information on the removed and standing trees, their size and

distribution. The number and distribution of standing and

removed trees were according to Finnish thinning

instructions, and thinning was typical low thinning, in

which smaller trees and trees of low quality are removed.

The average tree damage percentage, 4.6, is acceptable.

However, the proportion of damage varied from 1.1% to

9.1% with different operators. The damage was highest

during the summer. Small, superficial damage was typical.

The average strip road width was 4.8 m, the distance

between strip roads 19.8 m and the rut depth 0.6 cm.

The economic consequences of the damage was

estimated using a calculation model. The model estimates

the losses caused by strip roads, tree and soil damage.

The economic consequences of harvesting damage during

the rotation period was 1158 FIM (1 U$ = 5.60 FIM).

Strip roads make a significant contribution to the amount

of costs.

Due to the high variation in the harvesting quality,

both the continuing supervision of the silvicultural thinning

result and the training of machine operators are

necessary. Thinning spruce stands during the sap period should

be avoided due to the high risk of tree damage, and

decay following damage. Generally, it is possible to obtain a

good silvicultural thinning result with one-grip harvester

operation.

Keywords: Thinnings, tree damage, one-grip

harvester, strip roads.

The author is a Research Scientist at the Vantaa

Research Centre.

INTRODUCTION

Studies of the impact of harvesting operations are

well represented in the scientific literature. More than

2500 studies of the environmental consequences of

harvesting operations have been made since 1980 [28].

Harvesting damage was studied in 12 European countries by 28

research institutions during the period 1991 - 1997

[27]. Tree and soil damage were the most common topics.

The economic consequences of damage were generally

not addressed. Less than 2% of the reports included

economic considerations [28].

The field of study has been rich, but the research

principles and methods applied have been diverse. In

Scandinavia, where damage inventory methods have differed

between countries and even within countries, there has

been a trend to harmonize research methodology.

Measuring the width of the strip road and combining the results

with economic impacts seems to be one the most difficult

problems. In Finland, the measurement and effects of strip

roads have been widely studied [10,11].

The most widely used damage inventory method in

Scandinavia was developed in Sweden [1]. The method is

based on circular sample plots measured along inventory

lines, and it has been used both in Sweden and Finland. In

the United States, three sampling methods for measuring

tree damage were compared. Circular sample plots

measured from systematic measuring lines were the best way to

study tree damage [24].

A very important question when estimating

the silvicultural harvesting result is the number, quality

and distribution of removed and remaining trees. Trees

near the strip roads have an important role in the future

development of stands. The edge trees of strip roads have

more room, light and nutritients than the trees far away

from strip roads, and positive growth effects have been

reported in many studies [3, 4, 6, 9, 11, 21]. The condition for

this positive effect is that the edge trees are not damaged

and that there are enough trees to utilize good growth

conditions.

Damage inventories based on comprehensive data

are expensive. They are necessary, nonetheless, when

information on amount of tree and soil damage caused by

different harvesting systems is required. The amount of

damage varies considerably between stands and operators,

and a limited study can give false results. Circular sample

plots measured on inventory lines give good information on

the quantity and quality of damage. However, information

on the quality and distribution of removed and remaining

trees is not the best possible.

The present study has three objectives; to present

a method for measuring the silvicultural thinning result,

to clarify the thinning result of one-grip harvester

operations, and to estimate the cost of damage level found in

measuring with a Kovalama calculation model [14].

In 1997, the mechanization rate of thinnings in

Finland was 77%, an increase of 9% over the previous year

[29]. Thinnings are carried out using one-grip harvesters

and forwarders. The amount of tree damage in one-grip

harvester operations has generally been acceptable, but

there has been a great variation between the stands studied.

Due to considerable importance, the one-grip harvester

operation was selected as the harvesting system examined.

MATERIALS AND METHODS

Description of the inventory method

For this investigation, a new method for measuring

the silvicultural result of harvesting was developed.

The method was based on rectangular sample plots

measured parallel to the strip roads. At the beginning of an

inventory, an interval of 1 - 10 m was selected at random

and the starting point of the first sample plot placed

within this interval on the strip road. Sample plots were

subsequently placed at intervals of either 30 m for areas <

1.5 ha or 40 m for areas > 1.5 ha.

The sample plots were determined by first measuring

a distance of 10 m along the strip road. After this, four

zones of 10 m x 3 m were defined on either side of the

strip road. Thus each individual sample plot consisted of

eight 30 m2 zones. The post-harvesting sample plot and

measurements are shown in Figure 1.

|

Measurements on 3 m wide zones

- basal area (•)

- tree species relations

- number and average diameter of trees and stumps

- number of removed trees

- number of silviculturally removable trees

- number, quality and location of damage

Measurements on the strip road

- strip road width

- rut depth

- soil information

- amount of logging stash

- distance to the nearest strip road

|

Cost calculation of harvesting damage

A literature review on studies concerning the

consequences of harvesting damage and a Kovalama

calculation model using MS Excel software for estimating

the losses caused by damage was presented in Finland [14].

The model is based mostly on Scandinavian research

results concerning impacts of tree and soil damage.

The model presents the losses in

m3 and in Finnish Marks (1 US $ = 5.60 FIM) and estimates the costs caused

by tree damage, soil damage and strip roads. Both

growth and quality losses are estimated. Losses by thinning

intensity or tree selection cannot be estimated by the

model, but losses can be estimated between thinnings or

during the whole rotation period. The variables used in the

model are number, quality, size and location of damage, strip

road width and spacing, rut formation, tree species and

forest type.

Study material and machine

The research material was collected from 15

stands amounting to a total area of 14.7 ha. A total of 178

sample plots consisting of 1398 zones were measured.

The total area of sample plots was 4.2 ha, 28.6 % of the

inventoried area. A total of 8192 stems with the volume

of 1085 m3 was cut from the study stands, of which 586

m3 was cut in winter, 288 m3 in spring or autumn and 211

m3 during the sap period.

The initial growing stock in the stands studied

averaged 1169 stems/ha, while the corresponding figure after

thinning was 634 stems/ha. The stands were

spruce-dominated under going first and second thinning. The machines

employed were Valmet 901 one-grip harvesters

equipped with Valmet 942 harvester heads. Four operators

were included in the study. Pulpwood was cut to 5 m

lengths. The study stands were located on easy terrain. A

post-harvesting inventory was made prior to forwarding.

The results include only the damage caused by the

one-grip harvester.

RESULTS

Time consumption of the damage inventory

The time consumed by the damage inventory

method employed was studied. Moving between sample

plots, marking the boundaries of the plot, and collecting

stand, damage and strip road data was included in time

accounting. The average effective time/sample plot with a

two-man crew was 43 minutes, and varied between 32 - 60

minutes. With a three-man crew, the average time

required was 30 minutes/plot, and varied between 25 - 40

minutes. As about 15 sample plots were measured on a 1 ha

stand, a three-man crew needed 7.5 hours to make the

measurements.

The residual stand and removals

Figure 2 shows the initial growing stock, the

residual stand, the numbers of felled and cleaned trees and the

basal area per zone. An important feature is the form of

thinning. Figure 3 shows the size of standing and

removed trees with different operators.

Display large image of Figure 2

The number, quality and location of tree damage

The amount of damage/ha and damage percentages

by operator are presented in Table 1. Table 2 shows the

proportion of damage in different measuring zones.

Display large image of Figure 3

Table 1. The amount of damage and proportion of damage by different operators and in average (standard error of the mean presented within parenthesis).

| Operator |

Damaged trees, n/ha |

Damage-% |

|

Average |

Variation |

Average |

Variation |

| A |

9.4 (3.1) |

6.7 - 15.2 |

1.8 (0.6) |

1.2 - 3.0 |

| B |

58.5 (6.4) |

26.5 - 96.4 |

9.1 (1.1) |

3.1 -14.0 |

| C |

38.2 (10.9) |

25.0 - 47.6 |

7.9 (2.6) |

6.1 - 9.4 |

| D |

6.2 (2.0) |

0.0 - 8.7 |

1.1 (0.4) |

0.0 - 2.3 |

| Average |

27.7 (2.7) |

0.0 - 96.4 |

4.6 (0.5) |

0.0 -14.0 |

Table 2. Proportion of damage within different measuring zones. Distances of zones from the centre of the strip road: zone 1: 0 - 3 m, zone 2: 3 - 6 m, zone 3: 6 - 9 m, zone 4: 9 - 12 m.

| Damage- % |

| Operator |

Zone 1 |

Zone 2 |

Zone 3 |

Zone 4 |

All |

| A |

0.9 |

2.2 |

2.0 |

0.4 |

1.8 |

| B |

7.9 |

9.2 |

9.9 |

9.2 |

9.1 |

| C |

20.6 |

1.1 |

10.9 |

1.6 |

7.9 |

| D |

1.2 |

0.4 |

1.5 |

1.4 |

1.1 |

| Average |

4.8 |

4.0 |

5.6 |

4.1 |

4.6 |

Damage was classified as superficial, when the bark

was loosened, but the wood fibres were not damaged.

With deep damage the fibres were also damaged. If a tree

was broken, the damage was classified as break damage.

Of the damage, 91.3% was superficial, 7.8% deep

damage and 0.9% break damage. Some 79% of damage was

located in stems and 21% in root collars. In the

wintertime, the average size of damage was 34

cm2, in spring and autumn 53

cm2 and in the summer 48 cm2. On average

the damaged trees were located 5.3 m from the centre of

the strip road and stem damage was located 2.8 m from

the root collar. Falling trees (41% of damage), trees

under processing (25%) and the harvester head (22%) were

estimated to be the most common causes of damage.

Strip road width, distance between strip

roads and rut formation

The average strip road width, measured by the

SLU-method [1], was 4.8 m, the distance between strip

roads was 19.8 m and the rut depth 0.6 cm. On 48% of

sample plots there was plenty of slash on the strip road.

The distance between strip roads was measured in

two ways. From every sample plot, the perpendicular

distances to the nearest strip roads were measured. The total

strip road length and the area of every study stand were

measured to find the calculatory strip road spacing. Strip

road widths and spacing are presented in Table 3.

Cost of harvesting damage

The economic consequences of the damage was

estimated using a Kovalama model [14]. The model

estimates the losses caused by strip roads, and tree and

soil damage. In the calculation, a typical spruce stand in

Southern Finland was thinned twice during the rotation

period. The 1997 price levels used for different assortments

were: 220 FIM/m3 for spruce sawlogs, 130

FIM/m3 for spruce pulpwood and 100

FIM/m3 for pine pulpwood. The damage level in the present study was used in the

calculation for mechanized cutting, while for forwarding a

damage percentage of 1 % was employed. This level is typical

in forwarding in Finland [15,26] Rut depth after

forwarding was assumed to be 5 cm. The same strip road

network was used in both first and second thinnings. The

economic consequences during the rotation period are presented

in Table 4.

Table 3. Measured and calculated distances between strip roads and strip road widths.

| Distance between strip roads, m |

| Operator |

Measured |

Calculated |

Strip road width, m |

| A |

20.6 |

20.8 |

4.88 |

| B |

18.9 |

19.5 |

4.83 |

| C |

18.9 |

21.7 |

4.86 |

| D |

20.4 |

19.2 |

4.60 |

| Average |

19.8 |

19.9 |

4.76 |

Table 4. The economic consequences of harvesting damage

(m3/ha and FIM/ha) during the rotation period. The

discount percentage used is 3 %. 1 US $ = 5.60 FIM.

|

Losses, m3/ha |

Discounted value, FIM/ha |

|

Cutting |

Forwarding |

Total |

Cutting |

Forwarding |

Total |

|

Growth losses |

| Strip roads |

|

|

10.80 |

|

|

711.58 |

| Rutting |

0.34 |

1.00 |

1.34 |

25.61 |

76.83 |

102.44 |

| Tree damage |

0.51 |

0.21 |

0.72 |

39.55 |

16.52 |

56.07 |

| Quality losses |

| Decay |

3.43 |

1.78 |

5.21 |

136.84 |

150.96 |

287.80 |

| Total |

|

|

18.07 |

|

|

1157.89 |

Discussion

The measuring method presented provides good

information concerning the removed and standing trees,

their size and distribution. The time required for the

measuring method is high, about 30 min/sample plot with a

three-man crew. Measuring 10 sample plots/ha takes 5

hours. Due to the high cost, the use of this method in large

scale inventories is limited.

The time requirement for measuring circular sample

plots from inventory lines in stands smaller than 2 ha is

about 80 min/ha [1]. In Finland, a time consumption of 120

min/ha has been reported [25]. Thus, in large scale

inventories, circular sample plots provide an efficient way to

measure thinning quality. However, when comparing

different working methods or strip road spacings with

different machinery, exact knowledge on thinning quality is

needed. In this case the method presented in this paper may

provide a practical solution.

The number and distribution of standing and

removed trees were according to Finnish thinning instructions,

and thinning was typical low thinning. Thinning

instructions are based on the number of remaining trees after

first thinnings, in later thinnings a certain basal area,

m2/ha, is obligatory after thinning.

The average level of 4.6% damage of residuals is

acceptable. However, the proportion of damage varied

from 1.1% to 9.1% with different operators. The risk for

damage was highest during the summer. The power needed

to loosen root bark of pine and spruce was 40

N/cm2 in the summer and 60 - 80

N/cm2 in the autumn [30]. This means that damage risk is highest in the summer.

The damage percentages in this investigation were

close to those found in large scale inventories. In Sweden,

the average damage percentage using a one-grip

harvesters and forwarders was found to be 5.9 [7]. In Finland in

inventories between 1993 - 1996 the damage levels

have been around 4% [8]. These numbers are low when

compared with damage levels found after mechanized

harvesting in North-America. Damage proportions greater

than 20% after feller-bunchers and skidders have been

reported [20,23]. In thinning of deciduous stands as much as

62% of remaining trees were damaged [17].

Small, superficial damage was typical in the study

material. In a large scale inventory, 80% of damage in

one-grip harvester operations (forwarding damage

included) was found to be smaller than 100 cm2

[8a]. In forwarding there seems to be more deep damage, and damage is

also larger in size [7,26].

The average strip road width, measured with the

SLU-method [1], was 4.8 m, the distance between strip

roads was 19.8 m and the rut depth 0.6 cm. According to

Finnish thinning instructions [19], the distance between

strip roads should be at least 20 m. The average strip road

width is quite high, but the result also depends on the

measuring method. The average number of remaining trees in

the study stands was 634 trees/ha, and this results in

quite large distances between the trees even outside the

strip road zones.

Rut formation by the one-grip harvester was small.

Small rut formation by one-grip harvesters, compared with

forwarders, has also been reported in Sweden [12,13]. On

a half of the sample plots there was plenty of slash on

the strip road. Many studies [2,5,18], have

demonstrated that branch mats reduce soil damage. If the operator

processes trees on the strip road, more branches and tops

are available for protecting both soil and roots.

The discounted value of the total losses, 1158

FIM/ha, is acceptable when related to the advantages arising

from thinnings. Strip roads make a significant contribution

to the amount of costs. A calculation model for damage

losses in which the model structure and the results are similar

to those presented in this paper has been presented in

Sweden [22].

A questionnaire-based study concerning the

demands placed on good harvesting machinery was made in

Finland [16]. According to the study, forest owners

considered that a good silvicultural result is the most

important criterion to be placed on harvesting machinery in the

future. Good silvicultural thinning results also play an

important role in the certification processes of forest

companies. Due to the high variation in the harvesting

quality, both the continuing supervision of the silvicultural

thinning result and the training of machine operators are

absolutely necessary. Thinning spruce stands during

the sap period should not be allowed due to the high risk

of tree damage, and decay following damage. Generally, it

is possible to obtain a good silvicultural thinning result

with a one-grip harvester operation.

AUTHOR CONTACT

Matti Sirén can be reached by email at --

matti.siren@metla.fi

[1] Björheden and Fröding, A. 1986. Ny rutin

för praktisk gallringsuppföljning. A new routine

for checking the biological quality of thinning in

practice. Sveriges lantbruksuniversitet, Institutionen

för skogsteknik. Uppsatser och Resultat 48. 14 p.

[2] Brunberg, T. and Nilsson, N. 1988. FMG

0470 Lillebror, beståndsgående engreppsskördare

för klena gallringar. Skogsarbeten, Resultat 13. 4 p.

[3] Bucht, S. and Elfving, B. 1977.

Gallringsreaktion och tillväxt i ett korridorgallrat bestånd.

Summary: Thinning response and increment in a

strip-thinned stand. Sveriges Skogsvårdsförbunds Tidskrift 4:

323-345.

[4] Eriksson, H. 1982. Stigvägsbreddens inverkan

på tillväxten i unga granbestånd - några nya resultat

från ett sameuropeisk forskningsprojekt. Summary:

The effect of the width of the increment of young

Norway spruce stands - some new results from a common European research project.

Sveriges Skogsvårdsförbunds Tidskrift 6: 47-56.

[5] Fries, J. 1974. Thinning - why and how? Thinning

in the forestry of the future. Reprint of the papers

from the international conference at Elmia 1973. Skogshögskolan, Institutionen för

skogsteknik, Rapporter och uppsatser 69:1-19.

[6] — 1976. Körskador och

produktionsförluster. Skogshögskolan. Institutionen för

skogsproduktion. Rapporter och Uppsatser 40. 64 p.

[7] Fröding, A. 1992. Gallringsskador - En studie

av 403 bestånd i Sverige 1988. Summary:

Thinning damage - A study of 403 stands in Sweden in

1988. Sveriges lantbruksuniversitet, Institutionen

för skogsteknik. Rapport 193. 45 p.

[8] Hartikainen, S. 1996.

Harvennushakkuiden korjuujälki. Tulokset koneellisista

harvennuksista 1996. Metsätalouden kehittämiskeskus

Tapio. Moniste.

[9] Isomäki, A. 1986. Linjakäytävän

vaikutus reunapuiden kehitykseen. Summary: Effects of

line corridors on the development of edge trees.

Folia Forestalia 678. 30 p.

[10] — 1994. Ajouran leveyden

määritys. Metsäntutkimuslaitoksen tiedonantoja 501. 66 p.

[11] — and Niemistö P. 1990. Ajourien

vaikutus puuston kasvuun Etelä-Suomen

nuorissa kuusikoissa. Folia Forestalia 756. 36 p.

[12] Karlsson, L. and Myhrman, D.

1990a. Spårdjupsprov, engreppsskördare.

Skogsarbeten, Resultat 22. 4 p.

[13] — and Myhrman, D. 1990b.

Spårdjupsprov, skotare. Skogsarbeten, Resultat 22. 4 p.

[14] Kokko, P. and Sirén, M. 1996.

Harvennuspuun korjuujälki, korjuujäljen seurausvaikutukset ja

niiden arviointi. Metsäntutkimuslaitoksen tiedonantoja

592. 70 p.

[15] Lilleberg, R. 1984. Kasvatushakkuiden

korjuujälki. Summary: The state of harvested thinning

stands. Metsätehon tiedotus 388. 16 p.

[16] Matilainen, J. 1995. Tulevaisuuden

puunkor-juukoneen suunnitteluvaatimukset. Oulun

yliopisto. Prosessitekniikan osasto. Työtieteen jaos.

Hanke 93314. Loppuraportti työsuojelurahastolle. 102 p.

[17] Meadows, J.S. 1993. Logging damage to

residual trees following partial cutting in a green

ash-sugarberry stand in the Mississippi delta.

In: Gillespie, A.R., Parker, G.R., Pope, P.E. & Rink,

G. (eds.). Proceedings of the 9th central hardwood

forest conference. March 8-10. West Lafayette, IN.

Gen. Tech. Rep. NC-161. St. Paul, MN: U.S.

Department of Agriculture, Forest Service, North Central

Forest Experiment Station:248-260.

[18] McMahon, S. and Evanson, T. 1994. The effect

of slash cover in reducing soil compaction

resulting from vehicle passage. LIRO Logging Industry

Research Organization Report. Vol. 19 (1). 8 p.

[19] Metsänhoitosuositukset 1989.

Keskusmetsälaut-akunta Tapio. 55 p.

[20] Nichols, M.T., Lemin Jr.,R.C. and Ostrofsky,

W.D. 1994. The impact of two harvesting systems on

residual stems in a partially cut stand of

northern hardwoods. Canadian Journal of Forest

Research. 24:350-357.

[21] Niemistö, P.1989. A simulation method for

estimating growth losses caused by strip roads.

Scandinavian Journal of Forest Research 4: 203-214.

[22] Olsson, P. 1984. Beräkning av tillväxt-

och kvalitetsnedsättning orsakad av skador i

gallring. Skogsarbeten, Stencil. 16 p.

[23] Ostrofsky, W.D., Seymour, R.S. and Lemin, Jr.,

R.C. 1986. Damage to northern hardwoods from

thinning using whole-tree harvesting technology.

Canadian Journal of Forest Research 16:1238-1244.

[24] Pilkerton, S.J., Han, H.-S. and Kellogg, L.D.

1996. Quantifying residual stand damage in partial

harvest operations. In: Blinn, C.H.& Thompson, M.A.

(eds.). Planning and implementing forest operations

to achieve sustainable forest. Proceedings of papers

presented at the Joint meeting of the Council of

Forest Engineering and International Union of Forest

Research Organisations. Marquette, Michigan, USA. July 29 - August 1, 1996:62-72.

[25] Poikela, A. 1992. Selvitys

harvennushakkuun korjuujälki-inventoinnin tarkkuudesta.

Metsäkeskus Tapio. Raportti 9.9.1992. 12 p.

[26] Sirén, M. 1981. Puuston

vaurioituminen harvennuspuun korjuussa. Summary: Stand

damage in thinning operations. Folia Forestalia 474. 23 p.

[27] Spinelli, R. 1995. Ongoing research on the

environmental consequences of forest harvesting in 14

European countries: how it matches the needs of

the forester. In: Kellogg, L. & Milota, G. (eds.).

The way ahead with harvesting and transportation

technology. Proceedings of IUFRO P3.07 meeting in Tampere, August 6-12, 1995:163-170.

[28] — 1996. The environmental consequences

of harvesting operations: A bibliography. A report

from Concerted Action "Cost-Effective Early

Thinnings" (AIR2-CT93-1538). Publisher: Ministry of

Environment and Energy. Danish Forest and Landscape

Research Institute. 193 p.

[29] Säteri, L. and Örn, J. 1998. Puunkorjuun

ja puutavaran kaukokuljetuksen kustannukset vuonna 1997. Summary: Timber harvesting and

long-distance timber transportation costs in 1997. Metsätehon katsaus 1. 4 p.

[30] Wästerlund, I. 1986. The strength of bark on

Scots pine and Norway spruce trees. Sveriges lantbruksuniversitet, Institutionen för

skogsteknik. Rapport 167. 100 p.