(1)

(1)Vol. 12 No. 2 July 2001

Mark J.M. Sullman

Patrick M. Kirk

Liro Limited

New Zealand

The authors were, at the time of writing, Researchers, Liro Limited, Rotorua, New Zealand.

ABSTRACT

Hazards occurring to the fallers and chokersetters (breaker-outs) within cable yarder (hauler) crews working in windthr/ow salvage conditions were recorded. Fallers were exposed to considerably more and potentially more serious hazards than fallers working under normal conditions. The most hazardous parts of the faller's job were those of felling, clearing around the tree to be felled and clearing a path to the tree to be felled. The two most dangerous tree types to deal with were "hung-up" and "rootball trees". The choker setters were exposed to a similar number of hazards per cycle as choker setting in normal conditions, but a number of previously undocumented hazards were recorded. The majority of choking hazards (70%) occurred during the "wait" phase of choking with the most frequent hazard being "standing within one tree length of the turn". The information contained in this article may assist other contractors and forest companies faced with the difficult task of harvesting windthr/own trees.

Keywords: logging, cable yarder, choker setter, faller, windthr/ow, salvage, safety, hazard, New Zealand.

INTRODUCTION

Most of the previous research on windthr/ow salvage in New Zealand has focused on the development of fast and cost-effective ground-based extraction systems [1, 2, 3, 4, 8]. While safety has been a major consideration in the development of such systems, emphasis has traditionally been placed on the use of appropriate felling techniques, rather than the identification of specific hazards. In addition, most of the information to date on windthr/ow salvage has been based on ground-based extraction systems. Therefore, little information exists on the type and frequency of hazards encountered by loggers extracting windthr/ow using cable logging systems.

In windthr/ow recovery operations, it is often the faller who is perceived as having a substantial increase in hazard exposure [15, 16, 17]. It is the faller who has to fell standing trees, hung-up trees and spars (trees with the tops broken out), as well as removing the rootballs from toppled trees. All of these situations contain hazards such as excessive lean, tension, hang-ups and a substantial increase in both the quantity and size of debris retained in and around the trees. While it is commonly acknowledged that all of these factors add to the potential dangers of felling, the actual rate and type of hazard occurrence had not previously been investigated. Choker setters are also exposed to a large number of the hazards endemic to harvesting windthr/own trees using cable systems. For example, choker setters would be exposed to the same degree of extra debris as the fallers. The choker setters also have to deal with felled trees which are not presented (for extraction) in an orderly fashion, trees under tension still remain a problem and not all root balls are removed by the fallers.

The objective of this study was to assess the impact of windthr/ow salvage on the hazards encountered by both choker setters and fallers working within cable yarder windthr/ow recovery operations in a New Zealand production forestry environment. This study involved two experienced cable logging crews using different cable extraction systems, which are described below.

Crew 1

The first crew operated a Madill 171, equipped with a 28mm swaged skyline, 22mm swaged mainline (mainrope), 19mm haulback line (tail rope) and 13mm slack pulling line. During the study the cable systems used were Grabinski Running Skyline (Scab Skyline), Northbend and a Motorised Slack-Pulling Carriage. The stand contained 23 year old Pinus radiata stocked at 232 stems/hectare with an average; height of 32.5m, DBH (Diametre at Breast Height) of 49.4cm, 428m3/hectare, and an average piece size of 1.9m3. The setting contained a mixture of standing trees, standing spars (broken top trees), toppled full length trees with rootballs still attached (rootballs), partially toppled trees and an assortment of broken tops and pieces.

Two fallers, normally working separately, felled standing trees, spars and cut off rootballs where it was safe to do so, but did no delimbing. Two to four choker setters were used, depending on the number of chokers (strops) being used by the hauler. Both the fallers and choker setters were fully trained and had a minimum of four years experience with their current task. Crew 1 worked six days a week, beginning work (onsite) at 6:30am and finishing at 4:30pm, with a 30 minute break in the middle.

Crew 2

The second system involved a Madill 009 running a 28mm swaged mainline, 22mm haulback line and 22mm chokers. This crew used a Grabinski Running Skyline system thr/oughout the study. The stand contained 25 year old Pinus radiata stocked at 214 stems/hectare with an average; height of 33.9m, DBH of 54.9cm, 511m3/hectare, and an average piece size of 2.4m3. The setting contained mainly toppled full length trees with rootballs, as well as standing tall spars and full trees. Two fallers felled and delimbed in the bush and removed rootballs from toppled trees whenever safely possible. Two choker setters worked together on the extraction face. Both the fallers and choker setters were fully trained and had a minimum of six years experience with their current task. Crew 2 also worked six days a week and worked from 5:30am until 3:30pm, with a 30 minute break in the middle.

METHOD

Productivity

Activity sampling was carried out at one minute intervals for four complete shifts at each operation. One researcher observed the choker setters (observing all choker setters at once), while another observed the fallers (spending two full days with each faller). Both researchers carried Husky Hunter field computers running the activity sampling programme "SIFREQ". The programme caused the Husky Hunter to emit a `beep' at one minute intervals. At the beep the researcher would record which activity (shown below) the choker setters or fallers were engaged in.

The fallers' and choker setters' work cycles were broken down into the following tasks:

Fallers

| Clear Path | Clearing a path to the tree to be felled. |

| Clear Object | Clearing around base of tree to enable placement of felling cuts. |

| Walk/Select | Selecting and walking to the next tree. |

| Fell | Felling the selected tree. |

| Trim | Removing the branches and waste-wood from the felled tree. |

Choker setters

| Wait | Waiting for the return of the butt rigging or carriage. |

| Walk | Walking away to a safe point or to the next drag. |

| Hook-Up | Connecting chokers to the logs |

| Line Shift | Undertaking a line shift or a yarding road change. |

| Mechanical Delay | Delays caused by mechanical breakdowns |

| Operational Delay | Delays caused by operational interference. |

| Re-Hook | Re-hooking logs which have broken free during initial break out. |

As a part of the faller study, tree type was categorised into four groupings:

| 1. | Upright tree |

| 2. | Spar |

| · short <10 m, | |

| · medium 10 to 20 m | |

| · Tall > 20 m | |

| 3. | Hang-up |

| 4. | Rootball |

Hazards

For both fallers and choker setters, the type and frequency of hazards encountered were noted by each researcher, as were any obvious reasons for their occurrence. The hazard identification lists were based on those used by previous research [11, 14] and the New Zealand Department of Labour's Occupational Safety and Health Service's "Safety Code for Forest Operations" Part 2 (Cable Logging) and Part 3 (Logging). Unanticipated hazards were added to the list as they were identified.

Tables 1 and 2 list hazard definitions for the fallers and choker setters, respectively.

Hazard Ratios

Hazard ratios, in terms of hazards per stem, were calculated for the fallers using the following equation:

(1)

(1)

where: x = total number of hazards observed

y = total number of stems felled

Hazard incidence for the choker setters were calculated using the following equation:

(2)

(2)

where: A = % of total time spent undertaking the task

B = % of total hazards occurring while undertaking the task

Table 1. Hazard definition for fallers.

| Hazard | Description |

| Kickback | Kickback of such a severity that the chainbrake engages |

| Hang-Up | Working directly under a hung-up tree |

| Balance | Loses balance and falls off the object on which he was standing |

| Tension | While cutting the stem/tree, a sudden release of tension occurs |

| Saw Above | Using the chainsaw above shoulder height |

| Overcut | Overcutting the hinge wood |

| Sailer | Working directly under a sailer (large broken branch and/or pinecones hanging in a tree that can easily be dislodged and fall) |

| Butt Kick | Does not retreat a safe distance away from the tree once felled and is nearly struck by the butt |

| Lean | Tries to fell the tree against its predominant lean but loses control of it during felling |

| Flying Debris | Sudden release of tension thr/ows pieces of the stem into the air in the direction of the faller |

| Splitting | During felling, the butt of the tree suddenly splits violently |

| Eye | Object(s) are thr/own into the faller's eyes |

| Escape | Faller fails to establish and clear an escape route from the tree to be felled |

| Movement | Stem rolls while the faller is delimbing it |

Table 2. Hazard definitions for choker setters.

| Hazard | Description |

| Downhill Side | Hooking up drag from downhill side of the drag |

| Spragged/Jaggered | Hand punctured by sprag or jagger during hookup |

| Within one tree length | Being within one tree length of the drag and/or moving ropes |

| Bight of rope | Standing within the bight of a working rope |

| Swinging chokers | Standing less than one metre below swinging chokers |

| Slips/Trips | Choker-setter trips or slips over |

| Mainline caught | Mainline gets caught under a stem and violently breaks free |

| Under rigging | Standing or walking under elevated rigging |

| Near Moving Rope | Standing within one metre of moving rope |

RESULTS

Crew 1 - Fell Only

Fallers

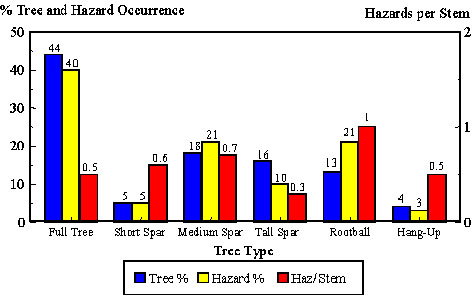

Figure 1. Tree type, hazard occurrence and hazards per stem for fallers in Crew 1.

As shown in Figure 1, the fallers in Crew 1 predominantly encountered full upright trees (44%). Correspondingly, this tree type generated the greatest proportion of total hazards (40%), yet only 0.5 hazards were encountered per stem (i.e. 1 hazard per 2 stems). The most hazardous tree type for the fallers were rootballs, which accounted for 21% of all hazards despite only accounting for 13% of all trees encountered. This resulted in rootballs having the highest hazard ratio of 1 hazard per stem. The two most frequently encountered hazards whilst cutting rootballs, as shown in Table 3, were tension and splitting.

The second most hazardous tree type for the fallers in Crew 1 were medium spars, which accounted for 18% of stems encountered and 21% of all hazards, generating a hazard ratio of 0.7 hazards per stem. Table 3 shows that the thr/ee most common hazards encountered while felling medium spars were overcutting the hingewood, butt kick and working under a hang-up (in that order). The third most hazardous operation was felling short spars, which accounted for 5% of the trees felled, generating 5% of the hazards, producing a hazard ratio of 0.6. Again, overcutting the hingewood was the most common hazard followed by working under a sailer and losing balance (tied for second place), with working under a hang-up and kickback being third equal (Table 3).

In terms of parts of the faller's job, by far the most hazardous, in terms of hazards/100 stems, were those of felling (50/100), clearing object (4/100) and clearing path to tree (3/100). The overall hazard/tree rating for the fallers in Crew 1 was 58 hazards per 100 trees felled.

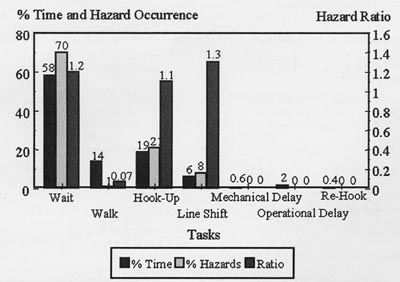

The percentage of all observed hazards that occurred within each phase of the breaking out cycle and their corresponding hazard ratio for Crew 1 is shown in Figure 2. Hazards observed during line shifts (yarding road changes) accounted for 8% of all hazards (Figure 2) observed during the study and generated the highest hazard ratio of all the chokersetters tasks (1.3). The most commonly occurring hazard during yarding road changes was standing within one metre of moving rope (Table 4). This was followed by standing/walking in the bight of the rope, and standing on the downhill side of a moving tractor (Table 4). The chokermen spent the majority of their time (58%) waiting (Figure 2). Correspondingly, the majority of total hazards (70%) occurred during this period, generating the second highest hazard ratio of 1.2. The most frequently occurring hazard was standing within one tree length of the turn (drag) and/or moving ropes followed by dragging thr/ough standing spars (Table 4).

Twenty-one percent of all hazards were observed during the hook-up phase of the operation, giving a hazard ratio of 1.1. The majority of the hazards involved hooking-up on the downhill side of the drag, being spragged or jaggered and walking along a stem over one metre above the ground. Overall, the number of hazards per cycle for this crew was 0.17, meaning that on average the choker setters encountered a hazard every six cycles.

Table 3. Most common hazard per task and tree type for Crew 1.

| Tree Type | Clear Path | Clear Object | Walk/Select | Fell | Trim |

|||

| Whole Tree | (1) Tension | (1) Hang-Up | (2) Tension | (1) Balance | (1) Butt Kick | (2) Hang-Up | N/A | |

| (2) Kickback | (2) Sailer | (2) Eye | (3) Lean | (3) Eye | ||||

| (2) Balance | ||||||||

| Short Spar | None | None | None | (1) Overcut | (2) Sailer | N/A | ||

| (2) Balance | (3) Hang-Up | |||||||

| (3) Kick-Back | ||||||||

| Medium Spar | (1) Kickback | (1) Tension | None | (1) Overcut | (2) Butt Kick | N/A | ||

| (2) Tension | (3) Hang-Up | |||||||

| Tall Spar | (1) Saw Above | (1) Balance | None | (1) Sailer | (2) Butt Kick | N/A | ||

| (1) Saw Above | (3) Tension | (3) Flying Debris | ||||||

| (3) Lean | ||||||||

| Rootball | (1) Tension | None | (1) Balance | (1) Tension | (2) Splitting | N/A | ||

| (3) Butt Kick | (3) Hang-Up | |||||||

| (3) Eye | ||||||||

| Hang-Up | None | (1) Tension | None | (1) Tension | (1) Butt Kick | N/A | ||

| (1) Balance | (1) Splitting | (1) Hang-Up | ||||||

| All Tree Types | (1) Tension | (1) Tension | ||||||

| Combined | (2) Kickback | (2) Balance | (1) Balance | (1) Tension | (2) Butt Kick | N/A | ||

| | (3) Saw Above | (2) Hang-Up | | | (3) Sailer |

| |

|

(1) = Most frequently occurring hazard; (2) = Second most frequently occurring hazard; (3) = Third most frequently occurring hazard

Choker setters

Table 4. Most common breaking out hazards per task for Crew 1.

| Hook-Up | Wait | Walk | Line Shift |

| (1) Downhill side of drag | (1)Within one tree length | (1) Within one tree length | (1) Within 1m of moving rope |

| (2) Spragged/Jaggered | (2)Dragging thr/ough standing spars | (2) Bight of rope | |

| (2) Walking on stem over | (3) Working directly below chute | (3) Downhill side of moving | |

| 1m above ground | (4) Rolling material | | tractor |

Key: (1) = Most frequently occurring hazard (2) = Second worst occurring hazard (3) = Third worst occurring hazard (4) = Fourth most frequently occurring hazard

Figure 2. Percentage and ratio of hazards observed during each task for choker setters in Crew 1.

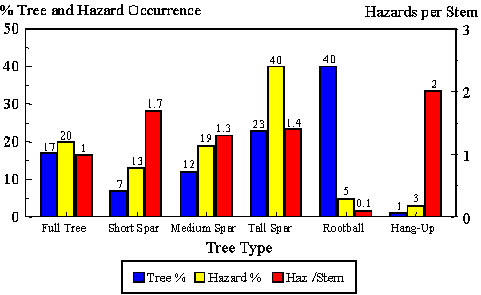

Figure 3 shows that the fallers mainly encountered rootball trees (40%) and tall spars (23%). In contrast to Crew 1 rootballs only accounted for a small percentage of hazards (5%) and produced a low hazard ratio of 0.1. The most hazardous tree type for the fallers in Crew 2 were hang-ups. Although hang-ups accounted for 1% of all trees encountered they produced 3% of all hazards, resulting in a hazard ratio of 2 (i.e. 2 hazards per stem). The most common hazard encountered when felling hang-ups was the unexpected release of tension (Table 5).

Crew 2 - Fell and Delimb

Figure 3.

Table 5. Most common hazards per task and tree type for Crew 2.

| Tree Type | Clear Path | Clear Object | Walk/Select | Fell | Trim |

|

| Whole Tree | (1) Saw Above | 1) Saw Above | None | (1) Butt Kick | None | |

| (2) Lean | ||||||

| Short Spar | (1) Sailer | (1) Saw Above | None | (1) Overcut | None | |

| (2) Sailer | ||||||

| Medium Spar | (1) Tension | (1) Saw Above | None | (1) Hang-Up | (1) Movement | |

| (2) Saw Above | (2) Sailer | (2) Kickback | ||||

| (3) Eye | (2) Eye | |||||

| Tall Spar | (1) Saw Above | (1) Saw Above | None | (1) Sailer | (2) Butt Kick | (1) Kickback |

| (2) Sailer | (2) Tension | (2) Escape | (3) Balance | (2) Tension | ||

| (3) Tension | (2) Sailer | (3) Kickback | (3) Lean | |||

| (3) Hang-Up | (3) Below | |||||

| Rootball | None | None | None | (1) Tension | (1) Kickback | |

| (1) Saw Above | ||||||

| Hang-Up | None | (1) Tension | None | (1) Tension | None | |

| All Tree Types Combined | (1) Saw Above | (1) Saw Above | None | (1) Sailer | (2) Butt Kick | (1) Kickback |

| (2) Tension | (2) Sailer | (3) Eye | (3) Overcut | (2) Tension | ||

| (3) Sailer | (3) Tension | (3) Tension | (3) Lean | (2) Saw Above | ||

| (2) Eye | ||||||

| | | | | | | (2) Movement |

Key: (1) = Most frequently occurring hazard (2) = Second most frequently occurring hazard (3) = Third most frequently occurring hazard

The second most dangerous tree type was felling short spars. These accounted for 7% of the trees encountered and 13% of all hazards, producing a hazard rating of 1.7 (i.e. 1.7 hazards per stem). The most frequently encountered hazard when felling short spars were overcutting the hingewood and working underneath a sailer. The third most dangerous tree type were tall spars, which accounted for 23% of all trees and 40% of all hazards. Tall spars produced a hazard ratio of 1.4. The most common hazards for felling tall spars were working under a sailer, followed by failing to identify/clear an escape path and butt kick (which were tied for second place) (Table 5).

The most hazardous parts of the faller's job, in terms of hazards per 100 trees, were those of felling (33/100), clearing object (24/100) and clearing a path to the tree (16/100). The overall hazard per tree rating was 83 hazards per 100 trees felled and delimbed.

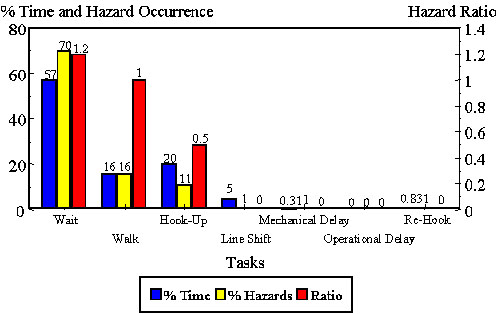

Choker setters

The hazards encountered by the choker setters in Crew 2 are shown in Table 6. All hazards have been ranked according to frequency of occurrence. As with Crew 1, the choker setters spent the majority of their time waiting (57%). Correspondingly, the majority of hazards (70%) occurred during this period, producing a hazard ratio of 1.2. The thr/ee most frequently occurring hazards while waiting were: waiting within one tree length of the drag being extracted, getting large pieces of logging debris caught on the haulback line, and being within one metre of a moving rope (Table 6).

Hazards observed during the walk phase of the operation accounted for 16% of all observed hazards and 16% of the choker setters time, which resulted in a hazard ratio of 1 (Figure 4). The most commonly occurring hazards during this phase of the operation were slips and trips followed by the mainline being caught under a stem and being violently released and walking under elevated rigging (Table 6).

Figure 4. Percentage and ratio of hazards observed during each task for choker setters in Crew 2.

Table 6. Most common breaking out (choking) hazards per task for Crew 2.

| Hook up | Wait | Walk | Line Shift |

| (1) Standing under | (1) Within one tree length | (1) Slips/trips | None |

| swinging chokers | (2) Slash caught on haulback line | (2) Main line caught under stem, | |

| (2) Downhill side of drag | (3) Near moving rope | violent release | |

| or turn | | (3) Walking under elevated rigging | |

Key: (1) = Most frequently occurring hazard (2) = Second most frequently occurring hazard (3)= Third most frequently occurring hazard

The choker setters spent 20% of their time hooking up the turn, while eleven percent of all hazards were observed during this part of the cycle (Figure 4). This produced a hazard ratio of 0.5. Standing under swinging chokers and hooking up the turn from the downhill side were equally common hazards recorded during the hook-up phase (Table 6). Overall, the number of hazards per cycle was 0.12, which means on average one hazard was observed every eight cycles.

DISCUSSION

The hazard ratios recorded for the fallers in this study (57/100 to 83/100) were considerably higher than those recorded for fallers working in non-windthr/ow stands (15/100) [12] and (3/100) [5]. It should be noted that although great care was taken to record every hazard encountered, due to the difficulty in identifying some hazards (e.g. standing trees with greatly weakened roots), a few hazards may have been missed. Therefore, the hazard ratios reported here may underestimate true hazard exposure.

The most common types of hazards encountered by the fallers in this study were different and potentially more serious than those encountered by fallers working in normal non-windthr/ow conditions. For example, research on the hazards encountered by fallers in non-windthr/ow conditions [12] found kickback was the most common hazard, while working under a hang-up was not observed and working under a sailer (a large broken branch or clump of pinecones hanging in a tree) was only the fifth most common hazard and accounted for 8% of all hazards (remembering that only 15 hazards were observed per 100 trees felled).

In the current study, working under a sailer and hung-up tree were in the top thr/ee (most common, second most common or third most common) hazards for 50% of the tree types (see Tables 3 and 5). This observation is of particular concern considering that a review of New Zealand logging fatalities found that 53% of felling fatalities were the result of either working underneath a sailer or a hung-up tree [7]. This same research found no fatalities due to kickback. Therefore, the fallers working in windthr/ow were exposed to considerably more hazards per 100 trees felled then fallers working in non-windthr/ow conditions and, to make matters worse, these hazards were potentially more serious than those encountered by fallers working in non-windthr/ow conditions.

The most dangerous tree types for fallers to deal with were hung-up trees, rootballs and short spars. One of the reasons short spars created such a large number of hazards was because they lacked the crown of the tree and its associated weight to assist with the initial movement of the tree during felling. Consequently, the most common hazard encountered while felling short spars was overcutting the holding wood (Table 5).

There were marked differences in the hazard ratios between the crews. The single biggest difference was the hazard ratio produced by rootballs. In Crew 1 one hazard was observed per rootball, while in Crew 2 the rate was 1/10 of that (1 hazard per 10 rootballs). The fallers in both crews were instructed to leave any trees which they considered too dangerous to handle. The prime reason for the low hazard ratio with rootball trees in Crew 2 was the fact that the yarder's cable sizes and power allowed rootball trees to be extracted whole. This meant that in most situations there was no need for the fallers to even attempt a split cut.

Although the yarder in Crew 1 possessed enough power to extract complete trees with attached rootballs, this was not often attempted due to the relatively small cable sizes being used. Consequently, the fallers would attempt to place some sort of split cut at the base of each rootball in order to at least help the rootball break off during extraction. Although leaving more of the rootballs uncut reduced the hazards the faller was exposed to, it resulted in the introduction of another hazard for the choker setters to deal with (rootballs standing up on break-out).

For the fallers, the hazard of "saw above" occurred frequently during the "clear path" and "clear object" elements for both crews. This was largely attributed to the particular windthr/own nature of the block. Consequently, there were large collections of broken heads (the broken off top part of the trees) and associated debris against the trunk and on the ground surrounding the base of the trees. In order to reach the base of the tree, the fallers often had to cut their way thr/ough this collection of debris. This resulted in frequent use of the saw above shoulder height, since much of the hindering debris was located at this level.

It became evident during the study that an individual's experience and attitude contributed considerably to their hazard exposure. Fallers entered into situations which, under "normal" felling conditions, they would not have attempted. Such a phenomenon is neither new nor restricted to the forest industry or windthr/ow salvage operations. Other researchers have found similar trends in different industries and attribute such behaviour to a state of mind known as "optimistic bias" [13]. That is, when discussing personal risks, people claim they are less likely to be affected than their companions. Weinstein [18] has found this exact phenomenon in numerous studies relating to different hazards. As a result, he found that the "it can't happen to me" syndrome is a common belief amongst workers continually undertaking hazardous jobs.

There are numerous explanations of why people take unnecessary risks, including boredom, sensationalism, poor risk perception (e.g. optimistic bias) and familiarity with the risk. In this case, all of these factors are valid explanations. Zimolong [21] states that a person's accepted risk level is established as a result of previous exposures to risk. In this particular case, constantly high daily exposure to a wide range of risks may have led to familiarity with certain hazardous situations and the development of poor risk perception. This phenomenon has been recorded in previous windthr/ow salvage operations [16].

Another factor which appeared to play a significant role in the development of poor risk perceptions by workers was fatigue. All the fallers and choker setters involved in the study mentioned feelings of moderate to severe fatigue. This was attributed to the combination of the extended working hours (10+ hours/day) and weeks (only one day off per week), and the extremely hot temperatures (35oC+) being experienced at the time.

During windthr/ow salvage operations there is a need to salvage the timber quickly to reduce deterioration. This usually results in crews working longer days and extended weeks during the salvage operation. If the effects of fatigue are not taken into account, there is a serious risk of increased engagement in hazardous situations. Such a development within an inherently hazardous working environment can have dire consequences in terms of worker safety and health and not least of all, the productivity of the operation.

For the chokersetters, there was only a very small difference in hazard ratios between the crews, with Crew 2 again having a lower hazard/cycle ratio (0.12) than Crew 1 (0.17). The type and frequency of hazards the choker setters encountered during the study did not differ greatly from those observed in non-windthr/ow conditions [11]. Although not contained within the article, analysis of the original data from the previous research produced hazard rates of 0.61 and 0.17 for choker setting in normal conditions [11]. This indicates that the hazard rates found in the current study were similar, or lower, than those found in normal logging conditions.

There was, however, a difference in the types of hazards experienced between the two crews observed here, and a number of hazards which were not documented in the previous research. These included dragging thr/ough standing spars (broken top trees), large pieces of slash (logging debris) being lifted by the haulback line and rootballs standing up during break-out. As the rootballs were often heavier than the stem, stems with rootballs still attached often `stood up' during break-out and then fell to one side. This hazard was only observed in Crew 2 where the fallers were able (because of the large rope sizes) to leave more of the rootballs attached. Rootballs standing up during break out is particularly concerning when it is considered that the single most commonly observed hazard was standing within one tree length. This again could have been due to a number of reasons, including; hazard familiarity, optimistic bias, and the physical fatigue experienced by the choker setters' working long hours and weeks in very high temperatures.

Fallers leaving spars standing resulted in the addition of another hazard for the choker setters when the yarding road went thr/ough the standing spars. When the turn reached the spars, invariably one of the stems would catch on a spar resulting in the whole drag flicking around uncontrollably and breaking, creating the potential for broken material to roll downhill towards the choker setters. Having a yarding road thr/ough standing spars was not prohibited by the logging code of practice. However, under New Zealand's health and safety legislation, it would not be allowed due to the potential for material to break off, roll downhill and injure the choker setters.

The extra logging debris produced by logging in windthr/ow conditions produced two additional hazards. Firstly there were the large pieces of logging debris which occasionally got caught on the haulback line and were flung off when the ropes lifted. Secondly, the extra logging debris created another potential hazard in the form of material (rootballs and other debris) being accidentally pushed over the edge of the landing. In such circumstances the material could roll downhill and injure the choker setters working directly below the landing.

The use of systematic sampling at one minute intervals is a valid [6] and frequently used method [9, 10, 19, 20] for activity sampling. The most important factor to consider while using this technique is to ensure that the sampling interval does not correspond with any natural cycles in the work being studied. As the one minute intervals did not correspond with any natural cycles in the work being studied, this technique of activity sampling was considered valid.

CONCLUSIONS

The frequency of hazards the fallers were exposed to were considerably higher than those recorded for fallers working in non-windthr/ow conditions. Further, two of the most commonly encountered hazards had potentially more serious consequences than the hazards most commonly encountered in non-windthr/ow conditions.

The type and frequency of hazards encountered by the choker setters did not differ greatly from those experienced in non-windthr/ow conditions, although a number of previously undocumented hazards were observed in this research.

Hazard exposure was affected by the suitability of the hauler. The yarder set up most suitable for the conditions had lower hazard ratios for both the fallers and choker setters. Also, reducing the hazards one worker is exposed to can introduce another hazard to a different task, as found here.

Constantly high daily exposure to a wide range of hazards appeared to lead to familiarity with certain hazardous situations and the development of poor risk perception by the choker setters and fallers.

RECOMMENDATIONS

When planning the recovery of windthr/ow, great care should be taken to select the most suitable machinery for the task.

Felling aids, such as felling jacks or winches, should be used to reduce hazard exposure while felling spars or hung-up trees.

It is important that increased production pressure and/or longer working hours are not imposed on the fallers or choker setters. Their daily tasks are already extremely hazardous without such additional pressures.

Only fully trained and very experienced logging crews should be selected to work in windthr/ow conditions.

AUTHOR CONTACT

Mr. Sullman can be reached by email at --

M.Sullman@massey.ac.nz

ACKNOWLEDGMENTS

The authors wish to acknowledge the contractors and their crews, and Carter Holt Harvey Forests.

REFERENCES

[1] Childs, B.H. 1966. Salvage of Windthr/own Forest. New Zealand J. For., 11, (1).

[2] Donovan, V.F. 1982. Windthr/ow Recovery Operations at Tarawera Forest. In proceedings of LIRA Windthr/ow Salvage Seminar.

[3] Eager, G.D. 1976. Windthr/ow Logging in Canterbury. New Zealand Loggers Association Conference.

[4] Eager, G.D. 1982. A Summary of 1982 Windthr/ow Recovery Operations. In proceedings of LIRA Windthr/ow Salvage Seminar.

[5] Fraser, D. and Kirk, P. 1996. Hazard Assessment of the Vertical Wing Cut Felling Method. Unpublished LIRO Report for Fletcher Challenge Forests.

[6] Galloway, R.L. 1993. Principles of Operations Management. Routledge: London.

[7] Gaskin, J. 1988. Analysis of fatal logging accidents - 1968 - 1987. LIRA Report 13, (20).

[8] Gleason, A.P. 1983. Guidelines for Windthr/ow Salvage. LIRA Report, 8, (4).

[9] Kirk, P.M., and Parker, R.J. 1994. The Effect of Spiked Boots on Logger Safety, Productivity and Workload. Applied Ergonomics 25 (2), 106-110.

[10] Kirk, P.M. and Parker, R.J. 1996. An Ergonomic Evaluation of Douglas Fir Pruning in New Zealand. J. For. Eng., 7(2), 51-58.

[11] Kirk, P. M., and Sullman, M.J.M. 2001. Heart rate strain in cable hauler choker setters in New Zealand logging operations. Applied Ergonomics 32(4):389-398.

[12] Kirk, P., Sullman, M. and Parker, R. 1996. Fatigue Levels in Motor-Manual Tree Felling and Delimbing Operations. LIRO Report 21, (18).

[13] Lark, J 1991. Risk Taking: Perspective's and Intervention. Professional Safety, November, 36-39.

[14] Parker, R and Kirk P. 1993. Felling and Delimbing Hazards. LIRO Report, Vol. 18 No. 22.

[15] Prebble, R.L. 1982. LIRA Accident Reporting Scheme. In proceedings of LIRA Windthr/ow Salvage Seminar.

[16] Sperry, G. 1982. Summary of Tauhara Forest Windthr/ow Salvage Operations. In proceedings of LIRA Windthr/ow Salvage Seminar.

[17] Vincent, B. 1982. Felling Techniques for Windthr/own Trees. In proceedings of LIRA Windthr/ow Salvage Seminar.

[18] Weinstein, N.D. 1989. Optimistic Biases about Personal Risk. Science, 246:1232 - 1233.

[19] Vitalis, A. 1981. An investigation of the relationship between pulse rate, environmental heat and work output of cane cutters in Fiji, unpublished Ph.D. Thesis, London University.

[20] Vitalis, A., Pournaras, N.D., Jeffrey, G.B., Tsagarakis, G., Monastiriotis, G., and Kavvadiast, S. 1994. Heart rate strain in Greek steelworkers. Ergonomics 21(5), 845 - 850.

[21] Zimolong, B. 1985. Hazard Perception and Risk Estimation in Accident Causation. Trends in Ergonomics and Human Factors II, 463 - 470.