Series

Great Mining Camps of Canada 5.

Britannia Mines, British Columbia

SUMMARY

Britannia was discovered in 1888, began production in 1905, and after nearly 70 years of underground operation produced more copper than any other mine in British Columbia. At one time it was the largest copper mine in the British Empire. Britannia survived the Great Depression, labour shortages brought on by two world wars, and several natural disasters. For most of its life Britannia was owned by the Howe Sound Company of New York, which was formed in 1903 for the purpose of financing the development of the mine. In 1963 it was purchased by Anaconda Canada Limited, which operated the mine until closure in 1974.

The Britannia camp encompassed eight separate ore zones located approximately 5 km inland from Britannia Beach. The deposits occurred within a large shear zone in a roof pendant of Mesozoic sedimentary and volcanic rocks enclosed by the Coast Plutonic Complex. Until a few years before mining ceased, the deposits were believed to have been emplaced in structurally favourable sites by hydrothermal fluids; the most recent interpretation of the deposits invokes a VMS model.

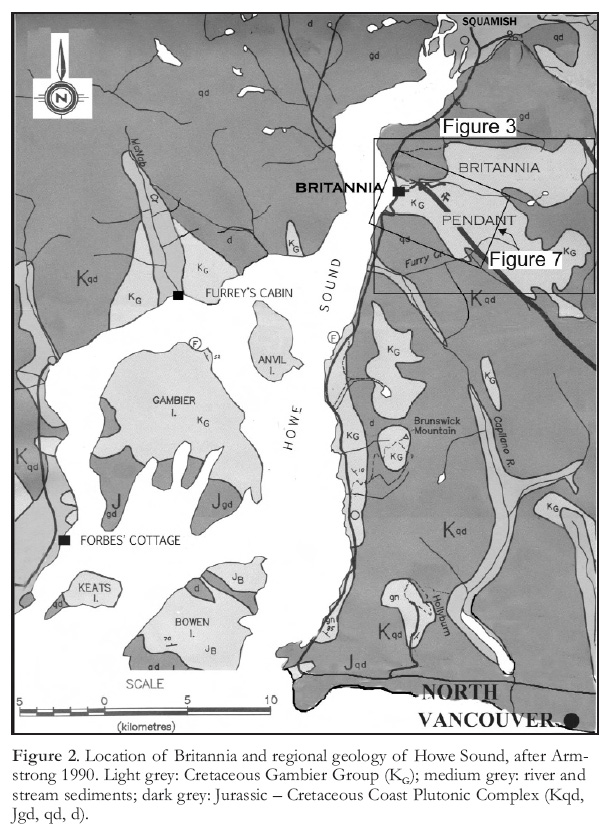

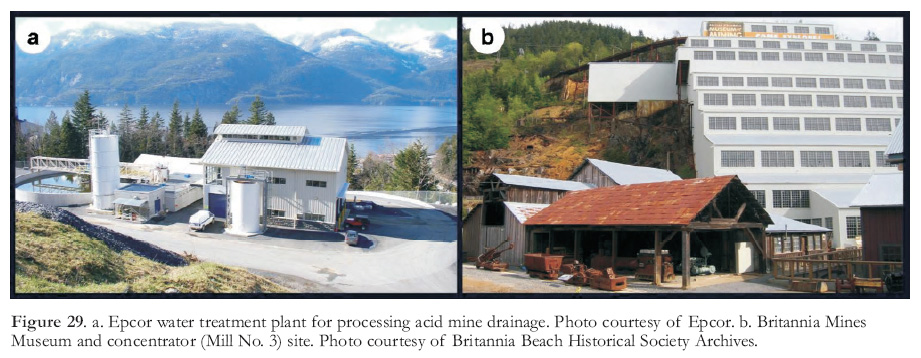

During the mine’s lifetime, thousands of people worked at Britannia, and they and their families lived in one of two company towns that, until 1956, were accessible only by coastal steamer. After closure, the community of Britannia Beach faced the prospect of becoming a mining ghost town, and the distinction of being the site of an environmental hazard created by acid mine drainage. A solution to the pollution problem was found, and road access to Vancouver combined with the success of the Britannia Mine Museum, a highlight of which is the surviving and spectacular mine concentrator that has been designated a National Historic Site, have given Britannia Beach a promising future.

Britannia is historically important from a mining technology viewpoint because it was the first mine in BC to successfully employ froth flotation. It was economically significant because it was an important element in BC’s emerging economy and it is culturally significant because the Britannia communities represented a way of life that was typical of many Canadian mining towns in the first half of the 20 th century. Moreover, Britannia Beach has survived and has become a well established community. Additionally, the recent history of Britannia Beach illustrates the importance of environmental considerations related to mine closure.

SOMMAIRE

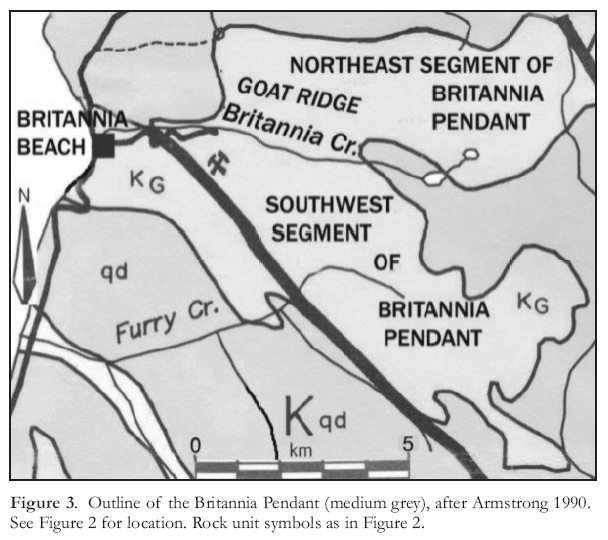

La mine Britannia a été découverte en 1888, elle a débuté sa production en 1905 et, en près de 70 ans d'exploitation souterraine elle a produit plus de cuivre que toute autre mine en Colombie-Britannique. À une époque c’était la plus grande mine de cuivre de l'Empire britannique. Britannia a survécu à la Grande Dépression, aux pénuries de main-d’œuvre provoquée par les deux guerres mondiales, ainsi qu’à plusieurs catastrophes naturelles. Pour la majeure partie de son existence, Britannia a été la propriété de la société Howe Sound de New York, laquelle a été formée en 1903 dans le but de financer la mise en valeur de la mine. En 1963, elle a été achetée par Anaconda Canada Limited, laquelle a exploité la mine jusqu'à sa fermeture en 1974.

Situé à environ 5 km de la côte de Britannia Beach, le camp minier de la Britannia était constitué de 8 zones minéralisées distinctes. Les gisements étaient situés dans une grande zone de cisaillement située dans le toit d’une unité de roches volcano-sédimentaires mésozoïques du Coast Plutonic Complex. Quelques années avant la fin de l’exploitation, on croyait encore que les gisements avaient été mis en place par la migration de fluides hydrothermaux dans des pièges structuraux favorables, mais l'interprétation la plus récente suggère plutôt une mise en place selon le modèle des SMV.

Tout au long de son exploitation, des milliers de personnes ont travaillé à la mine Britannia et ces travailleurs et leurs familles demeuraient dans l’une des deux villes de compagnie; notons que l’endroit n’était accessible que par un vapeur côtier jusqu’en 1956. Après la fermeture de la mine, la ville de Britannia Beach a bien failli devenir une ville fantôme avec la réputation de constituer une menace pour l’environnement étant donné les effets du drainage acide des résidus miniers. Mais grâce à la solution qui a été appliquée, à la route qui a été construite jusqu’à Vancouver et au succès du musée de la mine Britannia avec son spectaculaire concentrateur, lequel a pu être préservé et qui a été désigné lieu historique national, Britannia Beach peut maintenant être confiante en l’avenir.

Du point de vue technologie minière, la mine de Britannia est importante historiquement en ce qu’elle fut la première mine de C.-B. qui ait employé avec succès le procédé de séparation de flottation par mousse. Économiquement elle fut un élément majeur de l’économie émergente de la C.-B. Les communautés de la Britannia sont importante culturellement aussi en ce qu’elles représentent un mode de vie typique des villes minières canadiennes de la première moitié du 20e siècle. Qui plus est, la ville de Britannia Beach a subsisté au-delà de son épisode minier et est devenue une communauté autonome. L’histoire récente de Britannia Beach montre bien qu’il est important de tenir compte des questions environnemen-tales liées à la fermeture d’une mine.

INTRODUCTION

Location, Access and Historical Background

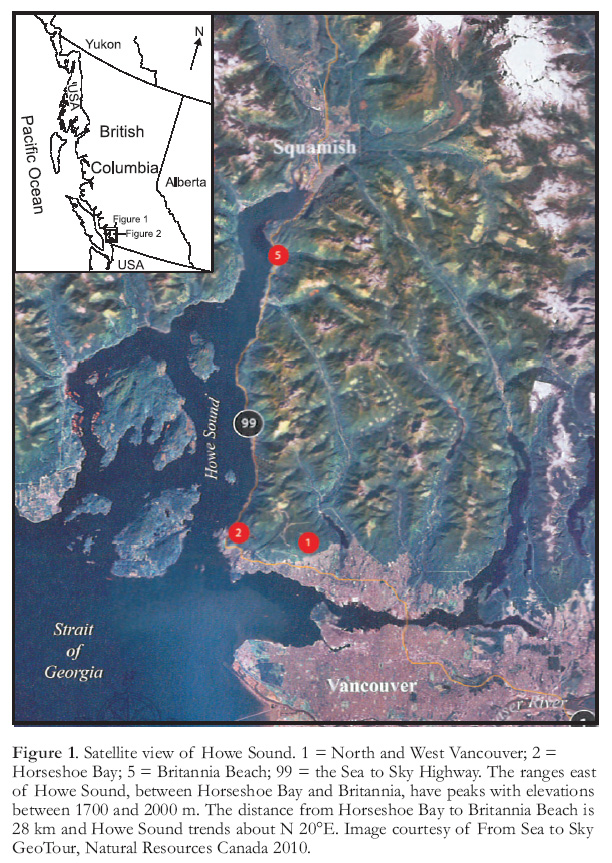

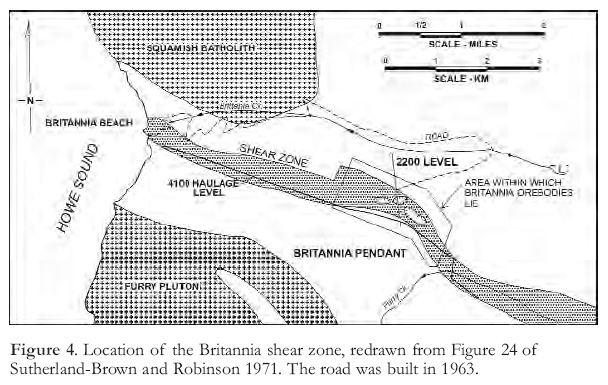

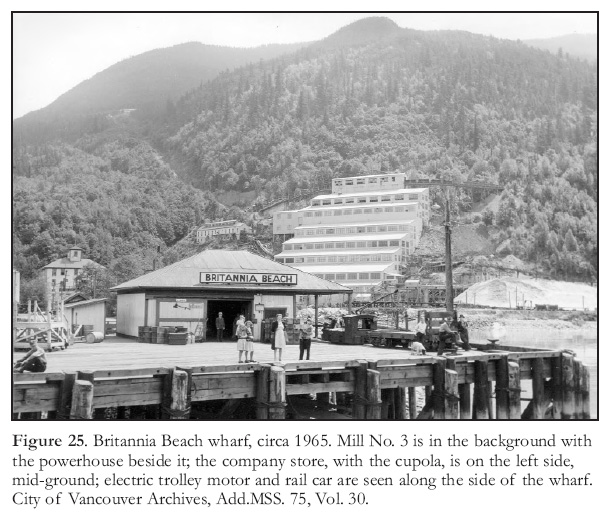

1 Britannia Beach and the mine sites lie 40 km north of Vancouver, British Columbia (BC), on the eastern side of Howe Sound, a fiord-like inlet set in rugged, heavily timbered mountainous terrain (Fig. 1). Britannia Beach, on the shore of Howe Sound, was the administration centre and the location of the concentrators. Today, the Sea-to-Sky highway and a branch line of the Canadian National Railway run from Vancouver, through Britannia, Squamish and Whistler to the interior of BC. The highway forms the backbone of a growing residential and recreational corridor that offers a variety of water and alpine activities set in spectacular scenery. However, during the period from 1888 to 1904, when Britannia was discovered and developed, Howe Sound was remote and sparsely populated.

Display large image of Figure 1

Display large image of Figure 1

2 In the late 1880s, settlers who began farming in the Squamish Valley, at the head of Howe Sound (Fig. 1), sent their crops to the Vancouver market by ship. By 1891 the Union Steamship Company, which serviced isolated logging camps, salmon canneries and farms along the BC coast, had established a twice weekly service to the community of Squamish, 10 km north of Britannia, but at that time there was no road connection between Squamish and Britannia. The population of Vancouver in 1900 was only about 12 000. It was not until 1956 and 1957 that rail and road, respectively, connected Britannia to the ‘outside’, thereby severing the dependency of the isolated and close knit Britannia communities on the Union Steamship Company.

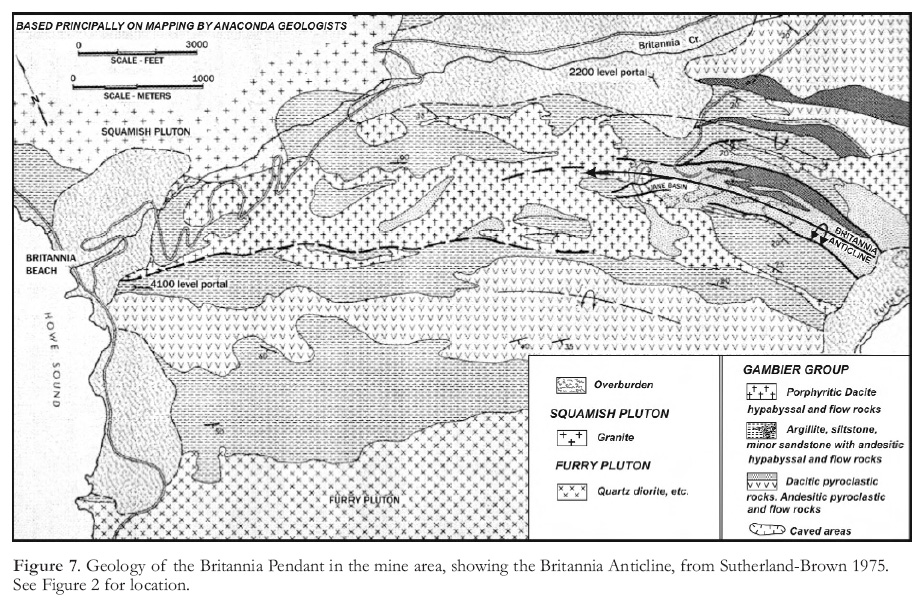

3 Britannia was discovered and developed early in the history of mining and economic growth in BC. The Fraser River and Cariboo gold rushes (1858 – 1863), the discovery of silver and lead in the Kootenay area of southeastern BC during the 1880s, and the development of the Rossland and Phoenix mining camps in 1893 and 1900, respectively, drew international attention to the potential mineral wealth of BC. Many of the participants and much of the investment capital involved in the subsequent growth of the mining industry, including Britannia, came from the United States. A factor that likely influenced the financing and development of Britannia was the rapid increase in demand for copper that began around 1890 as industries and homes in the industrial world became electrified.

Information Sources

4 Information regarding the regional geological setting of the Britannia deposits is available in Geological Survey of Canada (GSC) publications. Much of the information regarding the operations at Britannia was obtained from the annual reports of the British Columbia Ministry of Mines and Petroleum Resources and its predecessor the BC Ministry of Mines (referenced throughout this article as ARBCMM), and from several reviews that appeared in Geology, Exploration and Mining, also published annually by the BCMM (the Ministry is now named the BC Ministry of Energy and Mines). Numerous articles on the geology, mining and milling at Britannia Mines have been published in professional journals, especially in the transactions and bulletins of the Canadian Institute of Mining and Metallurgy. Significant collections of archival material relating to Britannia are held by the British Columbia Provincial Museum and by the Special Collections department of the University of British Columbia. The Britannia Mine Museum document and photo archives are a rich source of information and Mullan (1992), former Executive Director of the Britannia Mine Museum, wrote an informative review article.

GEOLOGICAL SETTING

Regional Geology

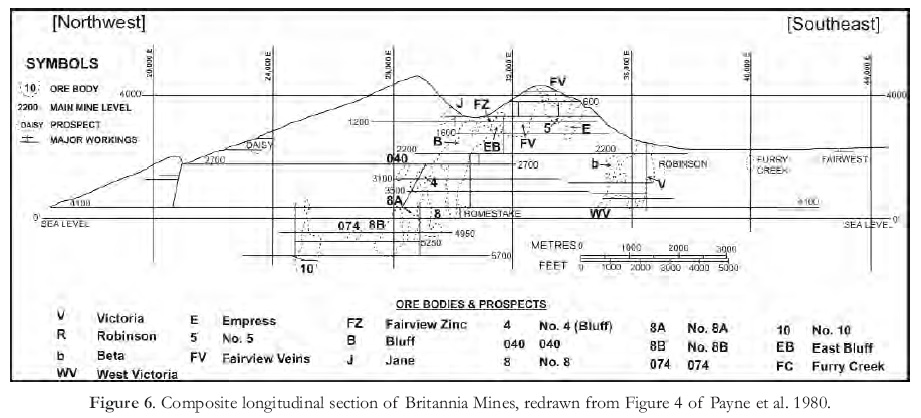

5 The earliest geological descriptions of the Britannia area were general reports by LeRoy (1908), McConnell (1915) and Schofield (1919) of the Geological Survey of Canada. Bostock (1963) and Roddick (1965), also of the GSC, mapped areas adjacent to the Britannia area and Lynch (1991) and Monger (1993) conducted studies of the Gam-bier Group, the host rocks to the Britannia deposits.

Display large image of Figure 2

Display large image of Figure 2

6 The Gambier Group is preserved within and adjacent to the Mesozoic to Cenozoic Coast Plutonic Complex (Fig. 2). It lies unconformably on early phases of the complex, and is intruded by later phases, within which it occurs as roof pendants. Gambier Group exposures extend from near the southern end of the complex northwestward for about 550 km, where they terminate south of the Skeena Arch (Massey et al. 2005). Strata of broadly similar lithology and age occur within the Skeena Arch and northwestward into the Alaska Panhandle. These northern assemblages are included in the Gambier Group on the Tectonic Assemblage Map of the Canadian Cordillera (Wheeler and McFeely 1991). In southwestern BC, roof pendants of Gambier Group are spread across the width of the Coast Plutonic Complex, from Howe Sound in the west to Harrison Lake in the east, a distance of approximately 100 km. Over a dozen roof pendants of Gambier strata are present in the Vancouver North and adjacent map areas , which includes Howe Sound (Roddick 1965).

7 The Gambier Group in southwestern BC comprises arc-related marine and non-marine volcanic and clastic sedimentary rocks that were deposited along the eastern margin of Wrangellia during the Early Cretaceous, and deformed in response to subduction during the Late Cretaceous (Lynch 1992, 1995). In the Brunswick Mountain pendant, about 15 km south of Britannia (Fig. 2), Roddick (1965) divided the Gambier Group into three assemblages, an upper, dominantly volcanic assemblage, a middle sedimentary assemblage dominated by argillite and slate, and a lower, dominantly volcanic assemblage. This division of the Gam-bier Group is generally applicable in southwestern BC. Both the lower and upper volcanic assemblages are generally calc-alkaline and include units of basalt, andesite, dacite and rhyolite. Gambier strata locally lie unconformably on Jurassic rocks of the Coast Plutonic Complex, or on basement metamorphic rocks; in the Vancouver North map area, the base of the lower volcanic assemblage is characterized by conglomerate containing cobbles of granodiorite lithologically identical to rocks of the local Coast Plutonic Complex (Roddick 1965). Fossils collected from eastern exposures of Gambier strata, near Harrison Lake, indicate a Hauterivan age (136 – 130 Ma; Arthur et al. 1993). In the Howe Sound area, fossils collected by W.H. Mathews from strata near the base of the lower volcanic assemblage north of Britannia also indicate a Hauterivan age (Monger 1993). A cephalopod fossil collected by W.H. Tipper 10 km south of Britannia was determined to be of Albian age (112 – 99.6 Ma; Lynch 1995).

8 Roddick (1965) cautioned that a useful stratigraphic description of the Gambier Group in the Vancouver North and adjacent areas is impossible because of the discontinuous nature of outcrops, large variations in lithology over short distances, and because nowhere in the area are all the units in the sequence well exposed.

Geology of the Britannia Pendant

9 Several prominent topographic features are present in the Britannia area: Britannia Creek flows westward to Britannia Beach from mountain lakes about 9 km east of Howe Sound. Goat Ridge (elevation over 1500 m) lies north of Britannia Creek, and Britannia Mountain (elevation 1463 m) lies south of it (Fig. 3). On the south side of Britannia Mountain, Furry Creek flows westward into Howe Sound (Figs. 2, 3).

Display large image of Figure 3

Display large image of Figure 3

10 The area is underlain by Gam-bier Group strata, which form a roof pendant, commonly referred to as the Britannia Pendant, within the Coast Plutonic Complex (Fig. 3). The Britannia Pendant consists of two lobes or segments, a northeast segment lying east of Goat Ridge and a southwest segment lying south of Goat Ridge. The Britannia deposits underlie Britannia Mountain within the southern segment, which is about 2 to 4 km wide and extends 14 km in an east-south-easterly direction from Britannia Beach (Fig. 3).

11 Lynch (1990, 1991) described the stratigraphy of the Gambier Group within the Britannia Pendant and elsewhere in the Howe Sound area as "...two broad volcanic complexes, separated by a predominantly clastic sedimentary unit. These effectively correspond to the ‘Lower’, ‘Middle’ and ‘Upper’ subdivisions of Roddick (1965)." Broadly speaking, Lynch’s ‘lower volcanic complex’ underlies the northeast segment of the Britannia Pendant, his middle clastic interval underlies parts of Goat Ridge and parts of the southern segment, and his ‘upper volcanic complex’ underlies much of the southern segment and parts of Goat Ridge. Lithotypes within the lower and upper volcanic assemblages are similar, except for the presence in the lower assemblage of basal conglomerate and arkose (Lynch 1991). The middle clastic interval is characterized by shale, siltstone, wacke, and lesser sandstone and breccia, and is tuffaceous in places. Upper members of the middle interval are intercalated with subaqueous basaltic and andesitic members of the upper volcanic assemblage.

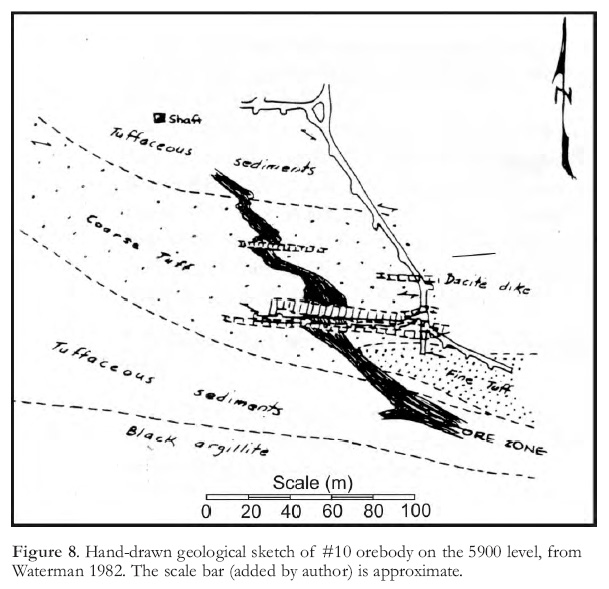

12 The upper volcanic assemblage comprises basalt and andesite flows, felsic and heterolithic volcanic breccia, bedded tuff, argillite, chert, and bodies of porphyritic dacite. The flows are variably massive, vesicular, pillowed and autobrecciated, and in places contain interbeds of tuff and argillite. Some porphyritic dacite bodies are sill-like and others have no discernable shape. The detailed stratigraphy within the Britannia Pendant has not been established because of abrupt changes in thickness, lack of continuity, and deformation. Lynch (1991) estimates the stratigraphic thickness of the Gambier Group in the Howe Sound area to be over 4500 m. He estimates the thickness of the middle interval to be about 500 m but does not offer an estimate of the thickness of the upper and lower volcanic assemblages. James (1929) and Payne et al. (1980) estimate the stratigraphic sequence in the southern segment of the Britannia Pendant alone to be over 1525 m thick.

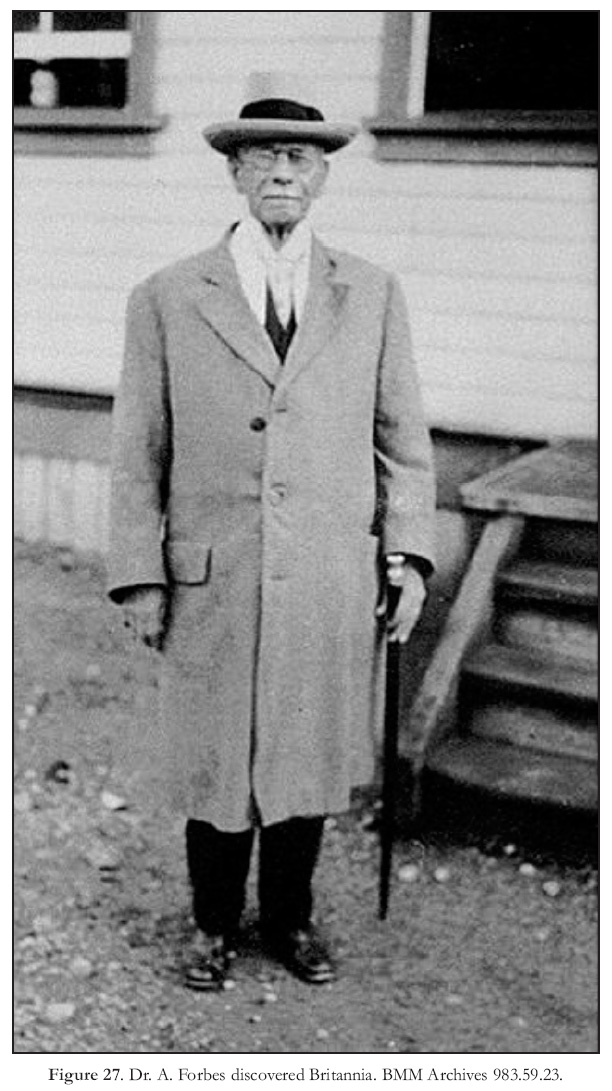

13 The age of Gambier strata in the Britannia Pendant is loosely bracketed by Late Jurassic granodiorite on which the lower volcanic assemblage in the northeast segment rests unconformably (Lynch 1990), and by Early Cretaceous to Early Tertiary granodiorite of the Squamish Pluton, which intrudes the upper volcanic assemblage in the southern segment (Bostock 1963). The Squamish Pluton returned a tentative K–Ar age of 92 ± 4 Ma (White 1968), and a U–Pb zircon age determination on rhyolite from the lower volcanic assemblage in the northeast segment yielded an age of 112.0 ± 0.3 Ma (i.e. Albian; Lynch 1995).

14 Strata in the Britannia Pendant have been folded, faulted and altered by regional greenschist facies metamorphism and local contact metamorphism. Rocks display cleavage, schistosity and small-scale folds, most of which have northwesterly trending axes (Lynch 1990). Large-scale folds have not been identified, except in the mine area. Both segments contain north-westerly trending, steep southwesterly dipping thrust faults that can be followed for several kilometres. Shorter normal faults trend northwesterly or northeasterly across the structure.

15 The Britannia Shear Zone (Fig. 4), within which the Britannia orebodies lay, extends the length of the southwestern segment (Payne et al. 1980), from Britannia Beach southeast-erly, more or less parallel to the structural grain. It varies in width from about 0.6 to 1.3 km.

Display large image of Figure 4

Display large image of Figure 4

Mine Geology

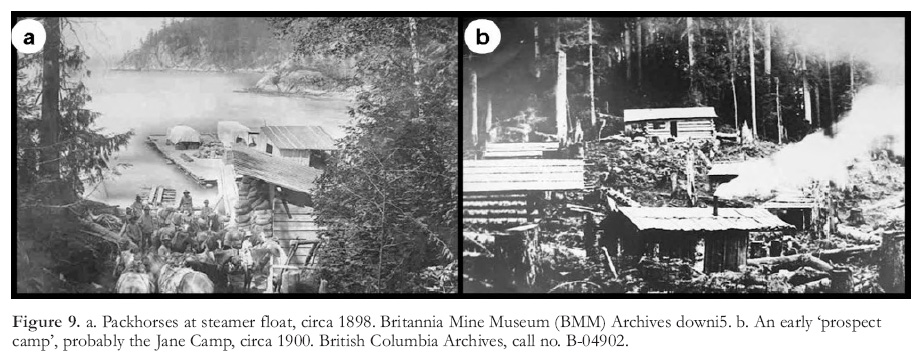

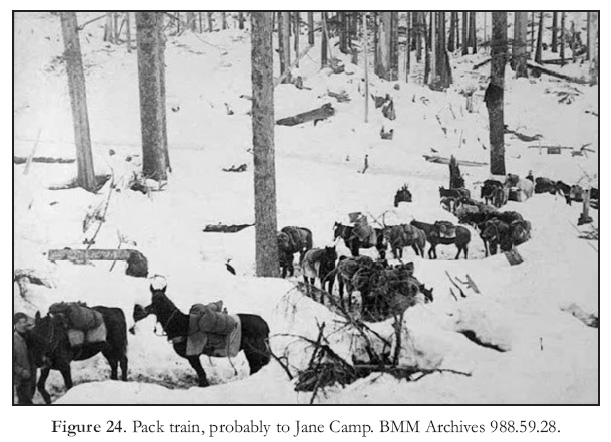

16 Schofield (1926) published a detailed account of the mine geology, and James (1929) authored a GSC Memoir that provided detailed geological descriptions of the Britannia Pendant and the mine. James (op. cit.) had been employed by the Britannia Mining and Smelting Company (BM&S Co.) for several years before he joined the GSC, and consequently he was able to draw upon data gathered by mine geologists as well as by the provincial and federal geological surveys. The result was an account that served as a framework for subsequent investigations for decades to come. Papers by Sutherland-Brown and Robinson (1971), Sutherland-Brown (1972, 1975), and Payne et al. (1980) provide the most recent descriptions and interpretations of the Britannia deposits. Numerous company geologists have contributed directly and indirectly to these and other publications, as have geology students, mostly from UBC, who have written theses on the Britannia deposits. A capsule report on the geology of Britannia appears in the Britannia link of the BC Ministry of Energy and Mines MINFILE website [ http://minfile.gov.bc.ca/].

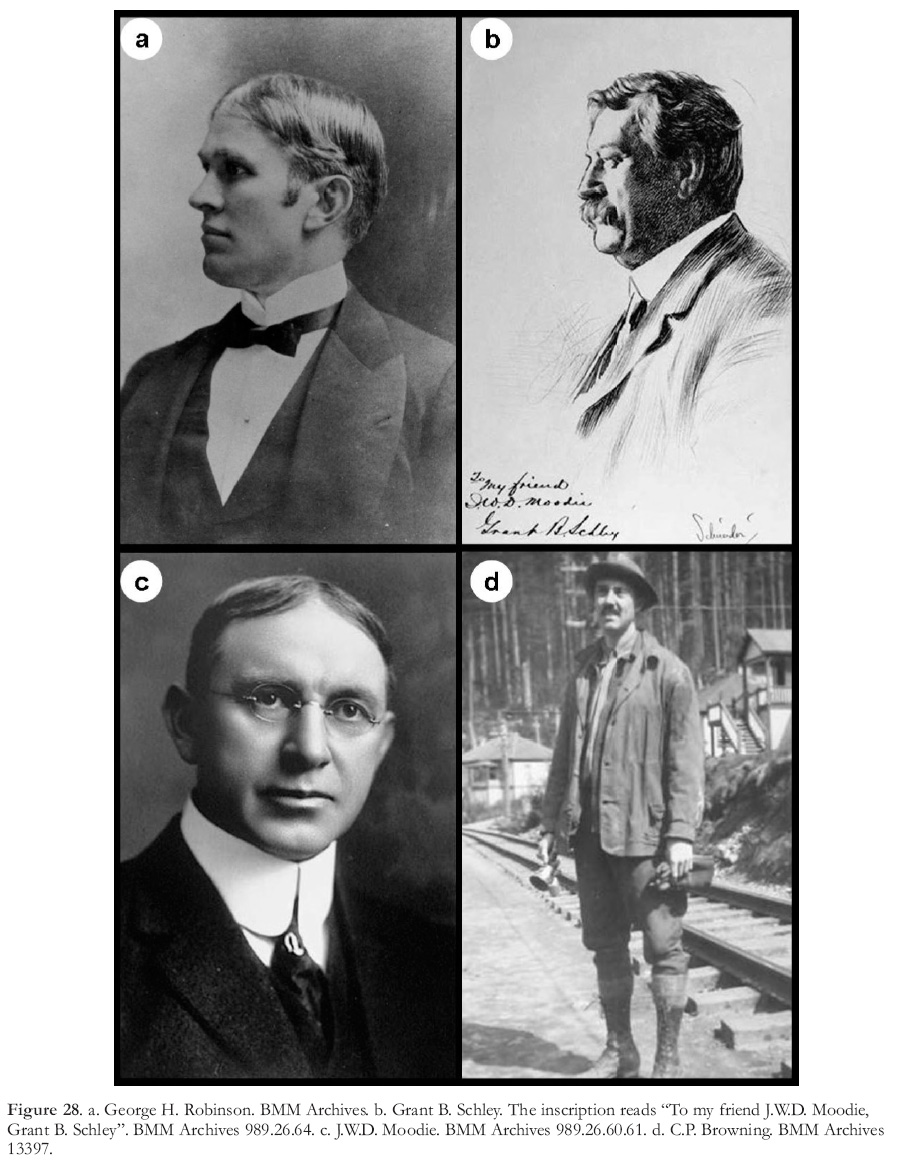

Lithology and Structure

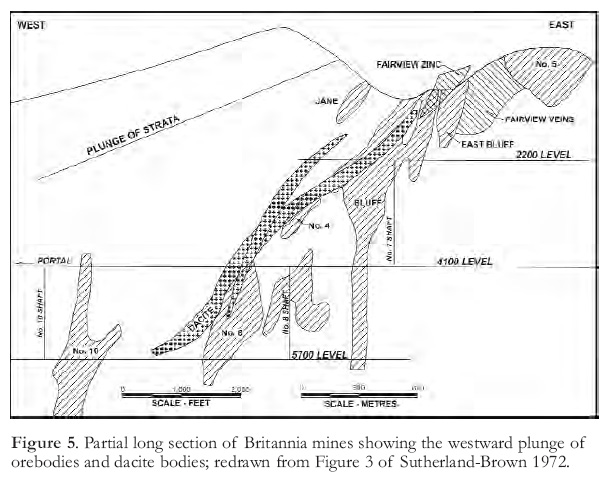

17 Lithological units recognized at the mine scale of mapping and the names given them have varied over the decades, as have interpretations of structure and origin of the deposits. In part this is because the stratigraphy, even at the mine scale, is discontinuous, but also because regional and dynamic metamorphism have masked and disrupted the original appearance and composition of the rocks. However, certain general aspects of the geology are commonly accepted; for example, (a) the rocks in which the shear zone formed and the strata in the hanging wall and footwall of the shear zone were laid down in an active volcanic region that for major intervals was partly submerged; (b) the Britannia Shear Zone is a product of ductile shear deformation; and (c) most of the orebodies occur in green mottled schist and show a spatial relationship with bodies of dacite (Fig. 5).

18 The stratified succession in the mine area comprises two sequences, a dominantly pyroclastic sequence and an overlying argillite and siltstone sequence containing minor tuff (Sutherland-Brown and Robinson 1971; Sutherland-Brown 1975; Fig 5). A transitional interval between the sequences is characterized by mixed crystal tuff and well-bedded grey and green argillite. The upper part of the pyroclastic sequence is composed largely of dacitic, lapilli-rich pyroclastic flows and minor argillite beds, interbedded with and overlain by plagioclase crystal tuff. Andesitic dykes (and possibly some flows) were emplaced early in the evolution of the mine sequence. They are deformed and in places mineralized. Sill-like bodies of porphyritic dacite were emplaced later; they are locally slightly deformed along their margins, and weakly mineralized, probably by remobilized sulphides. Schofield (1926) and James (1929) described masses of anhydrite and gypsum in the Fairview Mine (Fig. 6), located apart from the sulphide bodies. They lie in the plane of foliation, contain no other minerals and are up to 5 m thick and 30 m long in a down dip direction. One year Britannia mined and shipped several hundred tons of gypsum from these bodies. Barite is described as a common gangue mineral in zinc-rich parts of the Jane and Fairview orebodies.

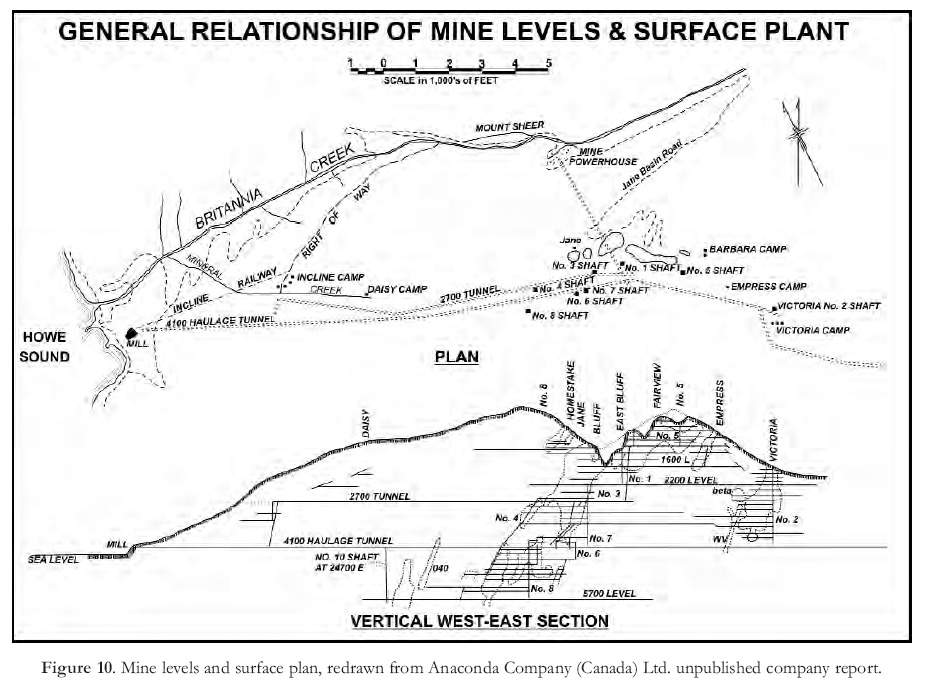

Display large image of Figure 5

Display large image of Figure 5

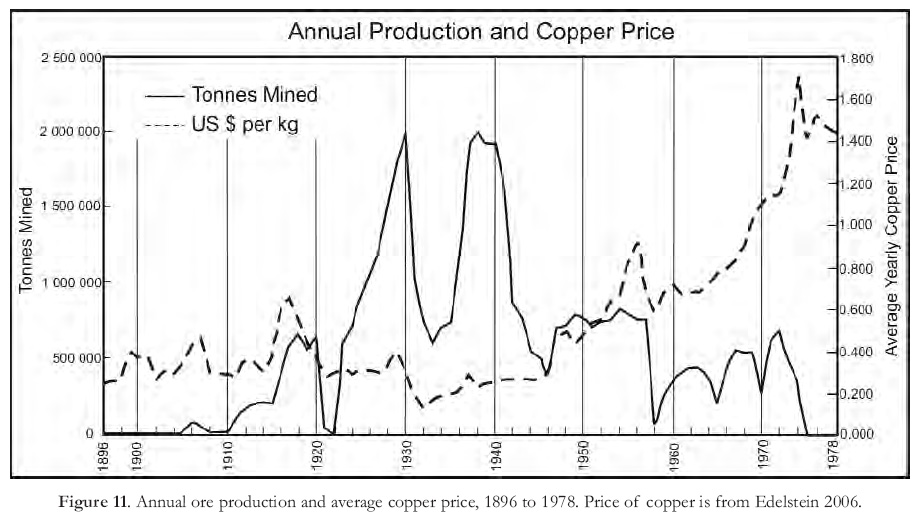

19 The Britannia Anticline (Fig. 7) and the Britannia Shear Zone (Fig. 4) are the principal structures in the mine area. The anticline trends north-westerly to westerly, is overturned to the northeast, and is flanked on the northeast by a sub-parallel syncline. West of the Jane Mine, where schistosity is less strongly developed than elsewhere in the shear zone, the nose of the Britannia Anticline can be observed to plunge about 20° westward (Sutherland-Brown and Robinson 1971). The Britannia Shear Zone, which also, in general terms, trends northwesterly, was superimposed on the Britannia Anticline. In the mine area, the shear zone ranges in width from 400 to 800 m and is not confined to one rock type. It is characterized by a strong southward-dipping schistosity and is bounded on both sides by southward-dipping faults, which Sutherland-Brown and Robinson (1971) suggest are en-echelon in character.

20 Original mineral assemblages and textures in the mine area have been altered, first by regional metamorphism to lower-greenschist facies, and then by dynamic metamorphism and metasomatism. Primary bedforms in the zone have been obliterated, except for small fragments of beds that lie sub-parallel to schistosity. Any mineral assemblages that formed as alteration haloes related to postulated pre-deformational sulphide deposition, or that formed during regional metamorphism, were modified during the episodes of dynamic metamorphism described below (Payne et al. 1980).

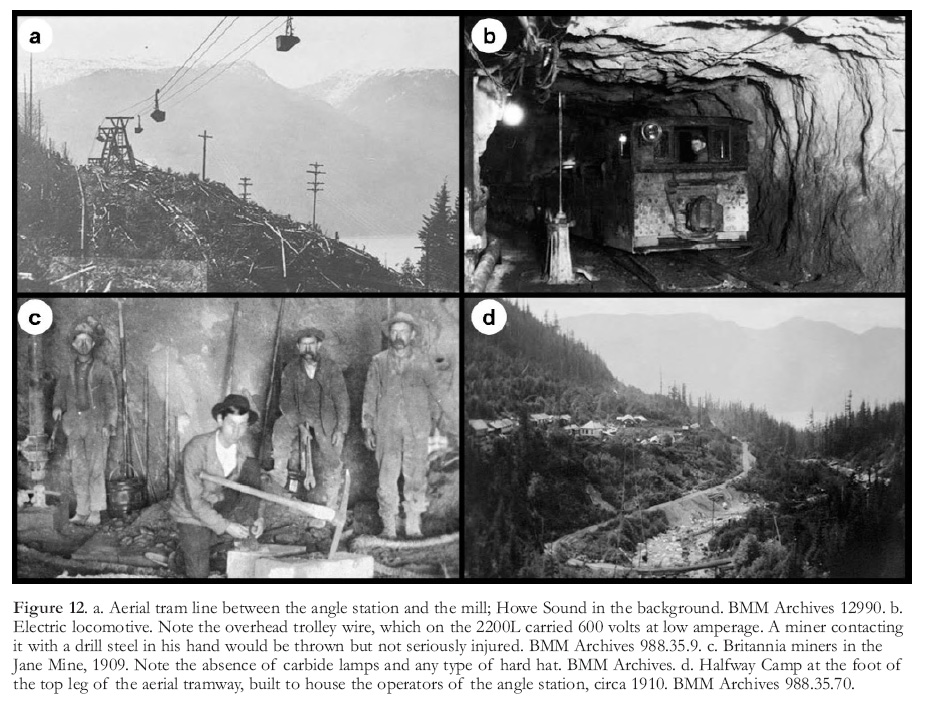

21 In mine geology terminology, the main components of the shear zone are chlorite mottled schist, quartz-sericite (chlorite) schist, bodies of schistose and fragmental andesite, and dacite dykes and sills. Chlorite mottled schist, in which most orebodies are found, is believed to be the schistose equivalent of dacitic tuffbreccias. Quartz-sericite (chlorite) schist (the ‘silver schist’ of former geologists), which does not contain orebodies, is thought to have formed from argillite by isochemical metamorphism (Sutherland-Brown and Robinson 1971).

22 Payne et al. (1980) recognized five stages of deformation in the mine area. The first (D 0) produced the Britannia Anticline and other flexural-slip folds (F 0) with sub-horizontal to gently plunging axes trending west-northwest. Following the development of the Britannia Anticline, successive episodes of shear deformation produced the Britannia Shear Zone and the multiple generations of textures within it. The first episode (D 1) produced a strong west-northwest trending, steeply southward dipping schistosity (S 1), defined by parallel chlorite and sericite plates and flattened lithic fragments. Small isoclinal folds with axial planar S 1 schistosity were formed during this episode. Outside the shear zone and in competent blocks within the zone that are thought to be andesitic intrusions, S 1 is present but is much less intensely developed. A subsequent episode of shear deformation produced another schistosity (S 2) that is sub-parallel to S 1 and deforms it. Late deformation (D 3 and D 4) produced a locally developed schistosity (S 3) that is parallel to northeast-trending faults, and a widespread fracture cleavage (S 4) that is locally prominent, for example, in No. 10 mine.

23 The shear zone is transected by a number of late faults, many of which are subparallel to the schistosity and margins of the shear zone. In the eastern part of the area a series of these faults branch off a major foot-wall fault, and in the western part of the mine area, oblique faults converge westward and upward to form a single major fault (Payne et al. 1980).

Ore Bodies

24 The most distinctive feature of the Britannia orebodies is that they all lay within the Britannia Shear Zone. They were distributed over a horizontal distance of approximately 3700 m and a vertical range of 1800 m (Fig. 6). The horizontal extent of known mineralization, which includes non-economic sulphide deposits northwest and southeast of the mined deposits, is about 6000 m. As the Britannia deposits were developed, the opinion formed that orebodies occurred at or near the footwall of the shear zone. However, Glen Waterman, the Anaconda geologist who examined the geological data before Anaconda purchased Britannia, concluded that seams, stringers and veins of mineralization were widespread in the shear zone (Waterman 1970). He reported that "the study clearly indicated that ore was not only localized along the footwall of the shear zone but occurred in intermediate positions between the hanging wall and footwall". The subsequently discovered 040 and No. 10 ore bodies lay some 800 feet (244 m) into the shear zone from the footwall. Orebodies occurred as massive and stringer deposits. Both types lay approximately in the plane of schistosity (S 1), although in detail they crossed the schistosity at small angles (Sutherland-Brown and Robinson 1971).

Display large image of Figure 6

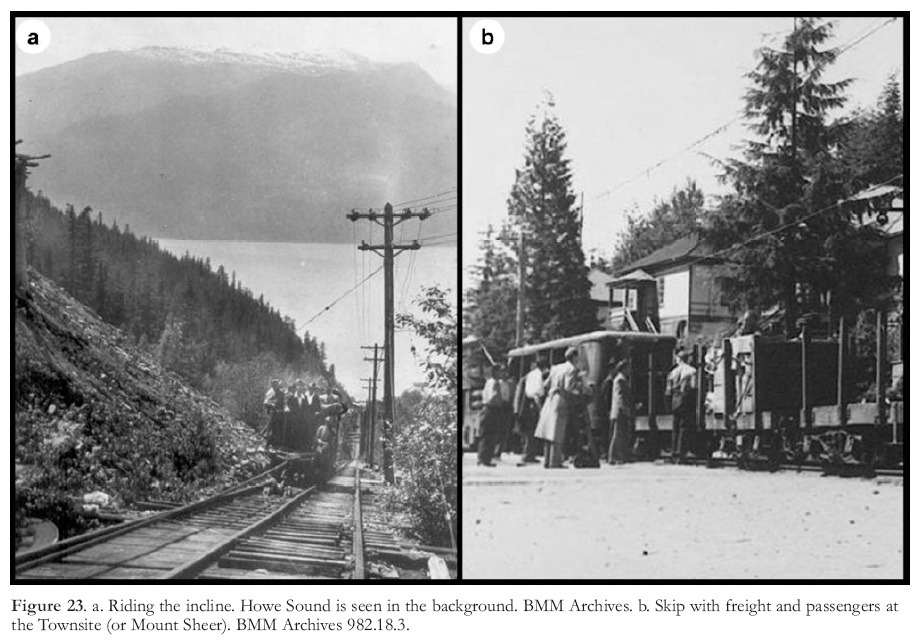

Display large image of Figure 6

Display large image of Figure 7

Display large image of Figure 7

25 Within the deformed and altered rocks of the shear zone, possibly near the top of the pyroclastic sequence described by Sutherland-Brown and Robinson (1971) and reported above (Lithology and Structure section), Payne et al. (1980) recognized a unit of dacitic tuffs and breccias (their ‘Bluff tuff-breccia’) overlain by andesitic sedimentary and tuffaceous rocks (the term ‘possibly’ is used here because descriptions of rock units by different authors are comparable only in a general sense, not in detail). They reported that massive deposits occur along or slightly above the top of the dacitic Bluff tuff-breccia, commonly in or near cherty andesitic rocks, whereas stringer deposits occur mainly in silicified tuff-breccias below the contact of the two units. Sutherland-Brown (1975) reported that mineralization of some type is common at or near the contact between "crystal-rich dacitic pyroclastic rocks and the green andesitic siltstones" (i.e. the contact between the dacitic pyroclastic rocks and overlying argillite–siltstone sequence of Sutherland-Brown and Robinson 1971). Seemingly, Sutherland-Brown (1975) and Payne et al. (1980) were referring to the same stratigraphic interval when describing the location of mineralization.

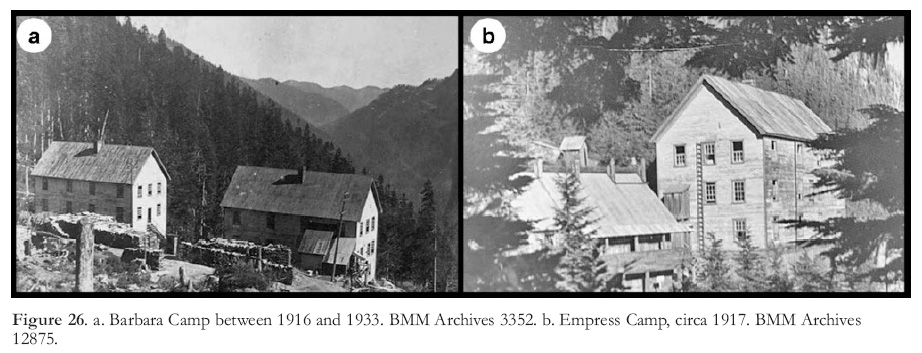

26 Sutherland-Brown and Robinson (1971) described both massive and stringer orebodies as heterogeneous mixtures of sulphides, remnant host rocks and discrete veins. Near or adjacent to some orebodies, as well as elsewhere in the shear zone, sulphides occur as disseminations, bedding plane concentrations and small stringers. Horses (relict masses) of host rock recognizable as chlorite mottled schist or andesite commonly occurred within orebodies (Sutherland-Brown and Robinson 1971).

27 Pyrite was the main sulphide mineral in both types of orebodies, and was accompanied by much less abundant chalcopyrite and erratically distributed sphalerite and galena. Tennantite, tetrahedrite, argentite, pyrrhotite and native gold occurred sporadically and sparingly. Associated non-sulphide minerals were principally quartz, muscovite and chlorite, and in some orebodies barite and anhydrite were present.

28 Massive ore bodies, namely the Bluff, No. 5, No. 8 and No. 10, had a zoned structure consisting of a chalcopyrite-rich core surrounded by a lower grade copper zone and overlapping pyrite- and silica-rich zones (Sutherland-Brown and Robinson 1971). Zinc-rich ore was present in the upper central parts of some massive orebodies and gold was clearly most abundant in the massive zinc–copper bodies. Galena formed irregular inter-growths with sphalerite and was abundant in a few thin layers in zinc and copper–zinc ore (Payne et al.1980). Andesitic, tuffaceous sedimentary rocks flanking and above massive ore bodies locally contained abundant disseminated pyrite as well as anhydrite, barite and cherty zones (Payne et al. 1980).

29 The only ‘truly stratified’ sulphide-bearing zones were found in the Fairview Zinc orebody and in pyritic green siltstones overlying it (Sutherland-Brown 1974). The Fairview Zinc orebody was a metre-thick, sheet-like body of massive ore containing pyrite, chalcopyrite, sphalerite and thin beds and disseminations of barite. Stringer orebodies, such as the Empress and Victoria zones, consisted of veins of chalcopyrite, pyrite, and lesser quartz. They were typically associated with broad zones of silicified rock containing quartz and quartz–pyrite veins (Payne et al. 1980).

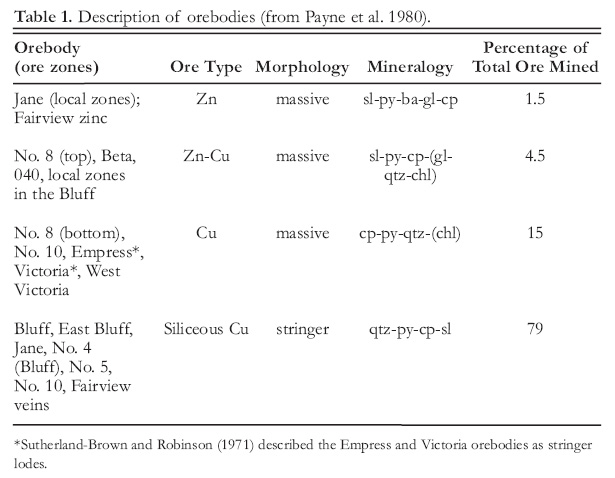

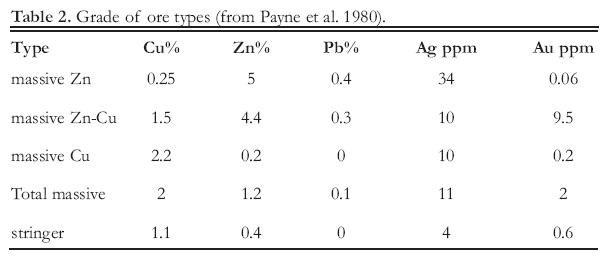

30 Table 1 is a compilation of some generalized features of Britannia orebodies. Some orebodies were not uniform in character; for example, No. 8 orebody graded from zinc–copper ore at the top down into copper ore, and the Bluff orebody contained both massive and stringer ore. The Beta, West Victoria, East Bluff and No. 4 orebodies (Table 1; Fig 6) were either small or else were subdivisions of principal orebodies; they are not discussed in this paper. Table 2 reports the average tenor of the different types of ore mined. It shows that, by far, most of the ore at Britannia was stringer ore. The average grade of all ore mined was approximately 1.2% Cu, 0.6% Zn and 0.6 g/t Au. Variations in tenor were sufficient to allow selective mining in response to variations in metal prices. For example, in 1943, ore reserves were divided into 3 classes, copper ore, with an average grade of 1.22% Cu, copper–gold ore, with a tenor of 0.67% Cu and 0.097 oz/ton Au, and copper–gold–zinc ore with a tenor of 1.72% Cu, 5.49% Zn and 0.04 oz/ton Au (BM&S Co. Ltd. Annual Report 1943).

Structure and Origin of Deposits

31 Between 1963 and 1974, when Anaconda Canada operated Britannia Mines, Anaconda geologists re-logged old drill core, remapped old mine workings and mapped new mine workings that were opened during this period. They collected much more data than were previously available, and contributed significantly to the previously cited publications by Sutherland-Brown and Robinson (1971), Sutherland-Brown (1972, 1975) and Payne et al. (1980). These publications span the period during which the perceived origin of the Britannia deposits changed from a structurally controlled epigenetic model to a volcanogenic massive sulphide model.

32 Prior to 1970, the Britannia deposits were generally believed to have formed from hydrothermal fluids that emanated from an underlying pluton, migrated upwards through permeable zones in the shear zone and replaced susceptible rocks within the shear zone. Schofield (1926) proposed that the Bluff, Empress and Victoria deposits were located in wedges of shear zone rocks that had been faulted into black slate in the footwall of the shear zone. The impermeable slate thereby formed ‘hoods’ that trapped ore fluids rising through the permeable schist. Ebbutt (1935) suggested that fracture zones in northwesterly plunging drag folds that had developed during movement along a major fault in the footwall of the shear zone provided the loci for sulphide deposition from ore fluids that had risen along the fault zone from a deep-seated igneous source. Irving (1948) proposed that fracturing of competent green mottled schist in the hangingwall of a fault in the footwall of the shear zone allowed ore fluids to ascend along the fault to favourable loci for deposition. The spatial relationship between orebodies and dacite sills (Fig. 5) has led many authors to suggest a genetic relationship between the dacite and ore deposition.

33 The pre-purchase geological review and the early investigations by Anaconda mine geologists led them to support a structurally controlled model for ore deposition. When describing this early work, Waterman (1970) wrote "Ore controls appeared to be structural, with relative rock competence of greater importance than particular rock units".

34 Sutherland-Brown and Robinson’s (1971) paper was based on detailed surface mapping in the mine area and on data acquired by Anaconda geologists. They concluded that although there was insufficient information to ascertain the process of ore deposition, the evidence suggested that, apart from the sheet-like Fairview Zinc deposit, the orebodies were formed by replacement after the development of schistosity. They commented, however, that the deposits had "great similarity to the Keiko ore of Japanese Kuroko deposits" and suggested that the source of mineralizing fluids might have been a solfataric field. In subsequent publications, Sutherland-Brown (1972, 1975) described Britannia orebodies as massive sulphide deposits and noted that some of the massive orebodies contain, in places, textures indicative of deformation, flow and annealing.

35 Payne et al. (1980) pointed out that "a critical factor regarding the origin of the Britannia sulphide deposits is whether they are pre- or post-D 1 (and D 2)". In other words, which came first, sulphide deposition or the development of the first and most intense episode of shear deformation? Aided by considerably more mine geological information than was previously available, including textural and chemical data, they concluded that host rocks were initially altered by volcanogenic hydrothermal solutions associated with pre-deformation sulphide deposition. Alteration patterns that developed during subsequent deformation were imposed upon and reflect the pre-existing ore-stage alteration. In summary, they stated that the "deposits formed from hydrothermal and exhalative solutions related to contemporaneous dacitic volcanism and then deformed during later shearing and faulting." Most of the orebodies are either cut by or have contacts at or near late faults. Based on a pre-deformation reconstruction across fault zones, they suggested that the various Britannia orebodies may represent segments of two original massive sulphide deposits.

36 The publication by Payne et al. (1980) generated a discussion initiated by Waterman (1982) and responded to by Stone and Payne (1982). Waterman expressed the opinion that deposition occurred in structures that developed during the formation of the shear zone. In support of his opinion, he cited geological mapping on the 5900 level of No. 10 mine that showed the ore zone cutting across lithological boundaries (Fig. 8), a feature that is at odds with a model that invokes syn-genetic ore formation. Stone and Payne (1982) responded by referring to data collected by Anaconda geologists during the 1970s, most of which, in their opinion, supported a model of ore deposition in which the massive sulphide bodies were genetically related to certain felsic volcanic units in the mine sequence, and were deformed during deformation of the enclosing rocks. Both papers referred to data that were collected by Anaconda geologists and never published; they are now probably buried in Anaconda’s archives. It is unfortunate that Britannia closed before these data were published and subjected to discussion. However, regardless of how the Britannia orebodies were formed, the mining operation that they supported was a significant event in BC and Canadian mining history, and it is that subject with which the rest of this article is concerned.

Display large image of Figure 8

Display large image of Figure 8

DISCOVERY AND EARLY DEVELOPMENT

Discovery

37 The discovery of Britannia is credited to Dr. A. A. Forbes, a medical doctor with a keen interest in prospecting, although Forbes himself gives partial credit to a fisherman named Granger. In 1888 Forbes was a medical officer for the small communities around the western entrance to Howe Sound. He occupied a cottage approximately 30 km from the mouth of Britannia Creek near what is now Hopkin’s Landing (Fig. 2). His attention was drawn to Britannia Mountain by a fisherman named Granger who showed him a copper stained rock and offered to show him its source for a fee of $400. Granger took Forbes to a site near the summit of Britannia Mountain, but the area was mostly covered with snow and the visible outcrops contained nothing of interest. The next day, while prospecting lower on the mountain, Forbes spied and shot a buck. In its death throes the buck kicked moss off an outcrop and exposed some mineralization. Forbes uncovered what he described as a "good showing" and, upon a promise of secrecy, paid Granger $400. Granger bought a boat and sailed for Alaska, never again to be associated with Britannia.

38 The above account was recorded some 40 years later by Cecil Scott, a reporter with The Vancouver Province (Scott 1931). Forbes summarized the discovery for Scott with the following comment: "So the first discoverer of copper at Britannia was Mr. Granger, the second was Mr. Buck and the third was Dr. Forbes". While the story seems implausible, it certainly is not the only colourful account of an accidental mineral discovery.

39 Forbes worked on his showing periodically for eight years but did not stake it because he believed that since gold, not copper, was the commodity of interest at the time there was no danger of the showing being staked by someone else. In 1893, he unsuccessfully sought aid from the provincial government to explore his discovery. He lost interest in his find and, according to the interview recorded by Scott (1931), in 1897 he gave a chart showing the location of his Britannia showing to a Mr. Turner, a man with interests in mining whom he had befriended. Forbes told Scott that he believed the chart he gave Turner was later used by Oliver Furry, who first staked claims on Britannia Mountain.

40 In 1898, the Britannia and Empress claim groups were staked by Oliver Furry, a trapper who had a cabin on the west side of Howe Sound, 18 km by water from the mouth of Britannia Creek (Fig. 2). All the Britannia orebodies were discovered within these claim groups. Furry staked the Britannia Group as agent for friends and family of Thomas T. Turner, and the Empress Group as agent for Joseph Boscowitz and his sons Leopold and David. For example, the declaration of staking of the Jane Claim contains the wording "Initial post No.1, ‘Jane’ Mineral Claim located by Oliver Furry for Thos. T. Turner" (BC Ministry of Energy and Mines, Mineral Titles Branch 1898). Furry staked only one claim (the Mineral Creek) in his own name. Leopold Boskowitz, of the fur trading firm of Boscowitz and Sons in Victoria, purchased half of Furry’s interest in the Empress Group, and in 1899 Boskowitz bought the Britannia Group claims either from the people in whose names Furry staked the claims or from Turner, who had already acquired some of the claims from their owners. According to the Bills of Sale, which are included in the above mentioned staking declarations, the total price paid by Boscowitz for the Britannia Group of five claims was $20 200. To summarize, the actual staking of the Britannia and Empress groups was done by Furry acting as agent for others, and T. T. Turner organized the staking on behalf of Leo Boscowitz, who, with other members of his family, subsequently obtained control of the claims. In a legal challenge, the Boscowitz family alleged that Furry’s share of the claims he had staked on their behalf (the Empress Group) should be reduced from 50 to 20%, due to certain signing irregularities. The case was decided by the Supreme Court of Canada in favour of Furry.

Display large image of Figure 9

Display large image of Figure 9

41 One wonders what led Furry, a trapper by vocation and not a prospector, to the Britannia showing located high in the mountains on the opposite side of Howe Sound from his cabin, if he did not have directions. Thomas Turner was a Vancouver furrier with whom Furry might have done business. If the Mr. Turner to whom Forbes gave a chart of his Britannia discovery was Thomas Turner, it is probable that, with chart in hand, Turner hired Furry to stake Forbes’ discovery. Alternatively, it is possible that Furry discovered Britannia without guidance. If he had, by chance, wandered through the area he would very likely have noticed a prominent, copper-stained bluff that subsequently became known as Mammoth Bluff. The bluff is located on one of the claims Furry staked. Regardless of the roles played by Forbes, Turner and Furry, it is remarkable that the claims staked by Furry should have covered all the main ore deposits of Britannia Mines (Figs. 4, 6).

42 It has been reported (Haggen 1923; Ramsey 2004, p. 17-18) that a Vancouver merchant from whom Furry obtained supplies, Mr. W.A. Clark, grubstaked Furry on a 50–50 basis to stake claims on mineralization that Furry might come across. Clark obtained miner’s licenses in the names of his family and friends that Furry could use to record any claims he staked. Clark then left Vancouver to investigate recent placer gold discoveries in Atlin, BC, but when he returned some months later he found that Furry had staked the Britannia Group of claims, but had not recorded them using the miner’s licenses he had purchased for Furry. Unfortunately the grubstaking agreement between Clark and Furry is not documented and it is not known in what way, if at all, Clark benefited from grubstaking Furry.

Early Development and Corporate Organization

43 The Boskowitz group began development work in 1899. During that year, a 6.5 km horse trail was built from the mouth of Britannia Creek to the Jane claim in the Britannia Group, where the Jane Camp was established at about 1000 m above sea level (Fig. 9a, b). The results of tunneling and trenching were encouraging, and suggested the presence of a significant body of ore. However, the Boscowitz group was not experienced in the mining business, and they decided to seek a stronger partner to share the expense and management of continuing development. After visiting the property in late 1899, Howard Walters of Libby, Montana, an experienced mining investor, purchased a 70% interest in the venture for $35 000, leaving the Boscowitz group with a 30% interest (Haggen 1923). To raise development capital, Walters enlisted ten Vancouver business partners, with whom he immediately formed the Britannia Copper Syndicate Ltd.

44 As work progressed under the management of Walters it became apparent that a large amount of capital would be required to bring the Jane deposit into production. The syndicate was refinanced several times, largely with Vancouver money, and at one point shares were offered to the public at $800 to $1000 per share (Ramsey 2004, p. 20). However, additional financing was required. Although the property attracted wide interest, no purchasers came forward, possibly because the price being asked by the syndicate was reported to be in the $750 000 to $1 000 000 range (ARBCMM 1900, p. 930). In 1901, with the syndicate facing bankruptcy, George Robinson, a mining engineer from Butte, Montana, acquired an interest in the syndicate by paying off its liabilities.

45 Robinson obtained control of the syndicate in 1902 by purchasing Walters’ share and in 1903 he bought out the Boskowitz group (Ramsey 2004, p. 21). Robinson then reorganized the directorship and capital of the syndicate. The Hon. E. Dewdney (a future Lieutenant-Governor of BC) was appointed President of the new Board of Directors and financier Henry Stern of New York underwrote a new offering of Britannia Copper Syndicate shares. Stern incorporated the Howe Sound Company under the laws of the State of Maine, with a share capital of $2 000 000 (Ramsey 2004, p. 23). Grant B. Schley, a business associate of Stern’s who was a partner in the banking firm of Moore and Schley, invested heavily in the new company. Robinson, Stern and a future prominent manager of Britannia, J.W.D. Moodie, had been associated with the Tintic Mining Company or its subsidiaries in Utah, a company of which Schley was President (Strack 2011; O’Brien 1987). The Howe Sound Company acquired all the shares of the Britannia Copper Syndicate in 1904 in return for 200 000 Howe Sound shares worth $1 000 000. Howe Sound financed the further development of Britannia by floating a $1 000 000 convertible bond issue. Meanwhile, Schley acquired a controlling interest in the Howe Sound Company and a position on the Board. Robinson, who apparently had excellent management skills, took over management of the developing mine from Walters in early 1904 (Robertson 1905). Under Robinson, mine production began in 1904, but shipment of ore to a smelter did not begin until 1905. Unfortunately, Robinson’s untimely death in 1906 prevented him from participating in the growth of the mine he had brought into production.

Display large image of Figure 10

Display large image of Figure 10

46 In 1905, the Howe Sound Company created the Britannia Smelting Company to purchase the Crofton smelter on Vancouver Island; the Crofton smelter had been commissioned in 1902 to process ore from a nearby copper mine. The Britannia Power Co. Ltd. was formed to operate a hydroelectric power plant and dam, the first of several such installations that would enable Britannia to generate its own power for several decades to come. The final step in the corporate evolution of Britannia occurred in 1908, when the Howe Sound Company folded the assets of the Britannia Copper Syndicate, the Britannia Smelting Company and the Britannia Power Co. Ltd. into a single company, the Britannia Mining and Smelting Company (BM&S Co.), which was incorporated in BC. The Howe Sound Company, which was controlled by G.B. Schley, thus became the holding company of the Britannia operation and related assets. Much credit is due Schley for his steady and supportive guidance during the troubled financial times that were to follow.

THE BRITANNIA OPERATIONS

Mining

47 Mining at Britannia took place in a number of separate ore zones that were discovered at different times and initially developed and mined via different adits or internal shafts. Crews often lived in semi-temporary camps somewhat remote from the community and mill site at Britannia Beach (e.g. see Fig. 10). Consequently, it became customary in corporate documents and the literature to refer to these ore zones as ‘orebodies’ and ‘mines’ in their own right, e.g. the Bluff Mine and Victoria Mine or orebody. In terms of relative geographic position within the Britannia shear zone, from northwest (closest to Britannia Beach) to southeast, the mines were: No. 10 (discovered by Anaconda), No. 8, Jane (the first producer), Bluff, Fairview, No. 5, Empress and Victoria (Figs. 6, 10). Several lesser orebodies that were close to or extensions of principal ore zones were also given names, for example the East Bluff orebody, which could be considered part of the Bluff ore zone, and the small Beta orebody in the Victoria mine. In this article the terms ‘ore zone’, ‘mine’ and ‘orebody’ are used interchangeably. The Britannia operations are referred to as ‘Britannia Mines’, ‘Britannia Mine’ or simply ‘Britannia’, as was the custom. Britannia Beach was commonly referred to as ‘the Beach’.

Display large image of Figure 11

Display large image of Figure 11

48 The numerous mine levels (Figs. 6, 10) were named according to their approximate vertical distance in feet below a datum established on Britannia Mountain, early in the mine’s development, at an approximate elevation of 4300 ft (1310 m) above sea level.

49 The composition and grade of ore differed somewhat from mine to mine, and also between parts of a single orebody. Consequently, the cut-off grade and rate of production from a given mine (orebody) was not necessarily uniform, but varied in response to metal prices and other factors. Figure 11 shows the annual average copper price and annual ore production throughout the life of the mine.

50 Mine and mill production are expressed in this article as metric tons (mt), and copper prices are quoted in US¢/lb, uncorrected for inflation (except in Fig. 11). Mine levels and level intervals are referenced in feet, in accordance with the original designations.

51 A significant cost advantage at Britannia was that, except for No. 8 and No. 10 mines, the vertical component of ore transportation was largely gravity driven. During the first decade of production ore was transported to the mill at Britannia Beach from the Jane, Bluff and Fairview mines far above by aerial tram lines (Fig. 12a). The ore transportation system, which was a significant factor in mining cost, evolved through stages that increasingly relied on underground track (Fig. 12b) and ore-pass routes to avoid the inconvenience and expense of surface transportation.

52 The interplay between management skills, economic factors and unforeseen events was clearly responsible for Britannia’s remarkable 69 years of production and the attendant social history of the communities. For this reason the following account highlights significant operational activities and developments during the life of the mine. Much of the information regarding the operational aspects of Britannia was obtained from the annual reports of the BC Ministry of Mines (ARBCMM) and Ministry of Mines and Petroleum Resources.

1905

53 Production from the Jane Mine (Fig. 12c), as recorded by smelter returns, began in 1905, although ore-grade material encountered during exploration and development work prior to 1905 was stockpiled for later processing. Shipments to the company-owned Crofton smelter in 1905 included both mill concentrates and direct shipping ore, from which 285 mt of copper were recovered. The price of copper at the time was 15.6¢/lb (34.4¢/kg), which equates to $3.08/lb ($6.79/kg) in 2010 dollars. The managing director of operations in 1905 was George Robinson.

Display large image of Figure 12

Display large image of Figure 12

54 The Jane Mine was 4.5 km east of Britannia Beach at an elevation of about 1020 m (Fig. 10). Ore was transported to the newly completed 200 tons-per-day (tpd; 180 metric tpd) mill at the Beach by a two-stage, aerial tramway 5150 m long, with a vertical drop of 980 m. The top leg of the tramway carried ore from the Jane Camp to a transfer station (the angle station) at the Halfway Camp, 435 m below (Fig. 12d). There it was transferred to the lower leg of the tramway (the legs of the tramway travelled in different directions).

1906 – 1915

55 This was a promising but difficult period for the young mine. Start-up problems naturally arose, the copper market was volatile, and the parent Howe Sound Co., with offices in New York, was periodically dissatisfied with operating results. In 1906, mine production and mill recovery of copper were not up to expectations because of problems with the tramway and the mill. Fortunately the mine was able to produce over 32 000 mt of direct-shipping ore that year, which partially compensated for the mill problem, and the operation remained marginally profitable. During 1907 the mill was redesigned in an attempt to improve recovery, but with disappointing results. Between 1907 and 1909 production fell to startup levels as a result of the continuing inability of the mill to produce a satisfactory concentrate, and the low price of copper (Fig. 11). Britannia was in danger of closing. However, in 1909 an exploration tunnel intersected what was to become the Fairview ore zone, and by 1911, development work, under the direction of mine manager R.H Leach, had outlined almost a million mt of 2.5 to 3% copper ore that was more amenable to concentration than the Jane ore. In 1911 Britannia was mining on six levels, and J. W. D. Moodie, who had assumed management late in 1911, was authorized by New York to make extensive improvements to the mine. One of these improvements, already started in 1909 by Leach, was a cross-cut adit that would become the 2200L haulageway, 1150 feet (350 m) below the lowest production level.

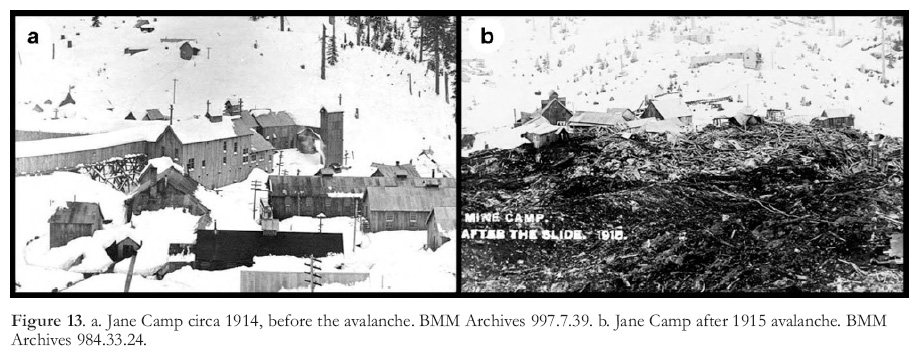

56 The encouraging performance of a new flotation circuit that was added to the mill in 1912 was undoubtedly a significant factor in the renewed confidence shown by the Howe Sound Co. (see the section on milling for recovery details). Production rose sharply to 212 500 mt in 1913, with ore coming from the Bluff and Fairview mines. However, in response to a sudden drop in the price of copper during late 1913 and early 1914, the Howe Sound Company ordered mining operations at Britannia to be cut back by about 50% and surface construction work to be suspended. During the month in which these cut backs were implemented – August of 1914 – World War I broke out. The price of copper suddenly rebounded and Britannia was again saved from possible closure. With the price of copper rising, a considerable volume of ore blocked out and the first phase of a new mill (No. 2) nearing completion, the future at Britannia must have appeared bright. However, in March of 1915 the Jane Camp was hit by a disastrous and deadly debris avalanche that claimed 57 lives and destroyed the top leg of the aerial tramway and many buildings (Fig. 13a, b).

Display large image of Figure 13

Display large image of Figure 13

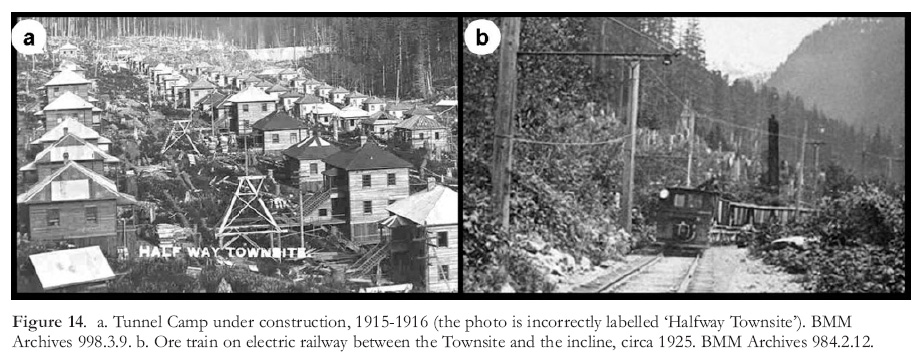

Display large image of Figure 14

Display large image of Figure 14

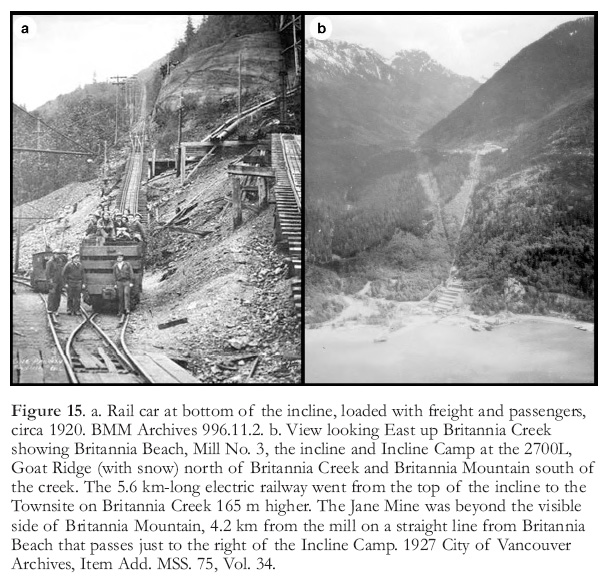

57 A new system of ore transportation had to be put in place quickly. Fortunately, plans to close the Jane Camp and to revamp the ore transportation system had already been made, and construction was already underway. At the Tunnel townsite (Fig. 14a), so named because it was located near the portal of the recently driven 2200L adit, construction of bunkhouses and mine facilities was almost complete. An interior working shaft and an ore pass with a crushing and loading station at its bottom were raised from the 2200L adit to the Fairview mine 1148 feet (350 m) above (primary crushing continued to be done underground until the 1940s). The ore pass and the 2200L adit, which became the main haulageway, replaced the destroyed top leg of the aerial tramway. A two-stage system for transporting crushed ore from the 2200L underground loading station to the concentrator at the Beach, thereby reducing dependency on the lower leg of the tramway, was nearing completion. The first stage, a 5.6 km narrow-gauge surface electric railway between the 2200L loading station and the top of an incline 180 m below, was finished (Fig. 14b). The incline, designed to carry ore from the end of the railway down a steep slope to the mill, formed the second stage and was almost complete (Fig. 15a, b). The ‘Incline’ as it came to be known, consisted of a rail bed on which ore cars were lowered 1645 m by cable down a 27% grade to ore bins at the top of the recently completed No. 2 mill. At the top of the Incline a small camp was established that was later expanded to house miners driving the nearby 2700L adit. Near the top of the undamaged lower leg of the aerial tramway a new loading terminal was built and connected by rail to the 2200L loading station. The tramway was kept in service to deliver ore to the still operating No. 1 mill, which had been upgraded to handle 725 metric tons per day (mtpd). The damaged Jane Camp was abandoned and production resumed in June of 1915, only 3 months after the debris avalanche. The new system eliminated the high costs and inconveniences of operating the Jane Camp and the former upper leg of the tramway; it also provided better and safer accommodation at the Tunnel Camp, and facilitated the increase in production that was to follow.

Display large image of Figure 15

Display large image of Figure 15

58 However, production was interrupted again from September to December of 1915 by a shortage of hydroelectric power caused by falling water levels in the reservoirs that supplied the power plants. This necessitated steps to provide a more reliable source of power. The power facilities are described in a later section.

1916 – 1919

59 The WW I demand for copper, which was used in the production of brass shell casings, pushed the price of copper to an average of 29.2¢/lb by 1917. The Britannia mill came under the jurisdiction of the Imperial Munitions Board, a British agency charged with providing adequate supplies of metals for the war effort by overseeing supply and production facilities within the British Empire. Ore from the Fairview and Empress mines and from five ‘glory holes’ (open pits) in the upper Fairview mine was being carried by the new transportation system to mills 1 and 2 at the Beach. Production increased from about 200 000 mt in 1915 to 663 000 mt in 1918 and remained close to this level during the next two years, in spite of falling copper prices after the war ended. In 1916 Britannia became the largest copper mine in the British Empire (Mining and Engineering Record 1923).

60 Two adits that would become major haulageways beneath the main ore zones (namely the Jane, Bluff, Fairview and Empress mines; the Victoria orebodies had not yet been discovered) were begun in 1916 below the 2200L. One was collared at the 2700L adjacent to the top of the incline, and the other at the 4100L near the top of No. 2 mill (Figs. 6, 10). These adits and their associated ore passes would eventually replace the surface railway and the incline in the ore transportation system.

61 In 1916, construction of the Barbara Camp (Fig. 10) began at the 500 level on the southeast side of Britannia Mountain, and the Fairview and Empress mines were connected, thereby providing a second passageway through Britannia Mountain. At least four other levels would break through to the Furry Creek side of Britannia Mountain in subsequent years. Also, in 1916, the second 900 mtpd unit of Mill No. 2 was finished. The Tunnel town site became known as the Tunnel Camp about 1918.

62 Although mine production reached a new high in 1918, operations were hampered by the Spanish Flu pandemic, which had a tragic effect on the Britannia community (see section titled Disasters).

1920 – 1922

63 W. D. Moodie, who had been General Manager since 1911, retired in August, 1920. Many of the operational decisions that enabled Britannia to become such a successful mine were made under his leadership. B.B. Niedling was manager for a brief period, and later in 1920 E.J. Donohue was appointed manager. C.P. Browning became manager in 1922.

64 The 1920s were years of post-WW I recession. The average price of copper in 1921 was only 12.6¢/lb, a drop of 57% from its 1917 price of over 29¢/lb. The outlook for copper seemed dim, and under orders from the Howe Sound Company, production at Britannia was sharply reduced. In November of 1920 the concentrator, tramway, electric railway and incline were shut down, except to transport supplies and passengers to the Town-site. The payroll was reduced by approximately 40% and operations were confined to essential development work. Mineralization in what would become the Victoria Mine had been intersected by surface diamond drilling in 1918 and the decision to develop the deposit was made in 1921. The Victoria Camp was established on the Furry Creek side of Britannia Mountain and preparation of the Victoria deposit for production accounted for much of the limited development work that was done in 1921 and 1922. The small amount of ore extracted by development operations was stockpiled.

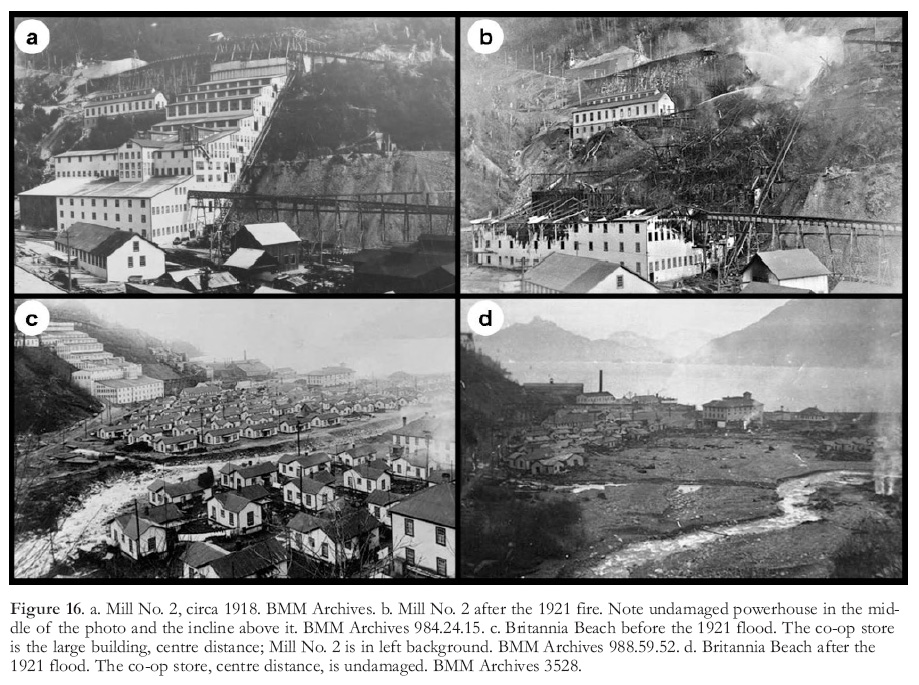

Display large image of Figure 16

Display large image of Figure 16

65 Elsewhere in BC, mines in the Phoenix and Copper Mountain camps, both major copper producing areas, suspended operations. The copper smelters at Greenwood, Boundary Falls and Grand Forks closed in 1918 and 1919 and, as it turned out, never reopened.

66 In 1921, as the price of copper was bottoming, Britannia was dealt two more serious blows. In March, the concentrator (Mill No. 2), which had been idled by the production cut-back, was destroyed by fire (Fig. 16a, b) and in October a flash flood in Britannia Creek wiped out part of the Beach community, with significant loss of life (Fig. 16c, d) (see section titled Disasters).

67 Production was suspended for the whole of 1922, as every effort was devoted to recovery and rebuilding under Browning’s direction. New family homes were built on a bench well above the level of Britannia Creek and a new concentrator, to be known as No. 3 mill, was constructed adjacent to the previous mill site. A significant improvement to the ore transportation system was completed in 1922, namely a 446 m long ore-pass from near the 2700L portal to the 4100L. Rather than being lowered down the incline, ore carried from the 2200L by the railroad could now be dumped through the 2700L – 4100L ore-pass and trammed on the 4100L haulage-way out to the mill storage bins (Figs. 6, 10).

1923 – 1929

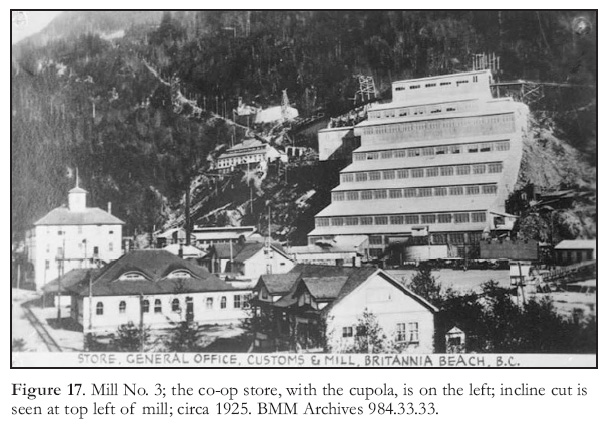

68 Mill No. 3 (Fig. 17), with a rated capacity of 2300 mtpd, was commissioned early in 1923 and production resumed after a year of rebuilding. Although all the ore was now handled through the 2700L – 4100L ore pass, the incline was kept in operation to service the Townsite. The Victoria mine began production in 1923, but the ore travelled a circuitous route that included a short aerial tramway lift to the 1600L portal on the Furry Creek side of Britannia Mountain. However, in 1924 the 2200L adit was extended to the Victoria workings (making it 3 km long), thereby connecting the Victoria mine directly to the ore transportation system. In late 1925 or early 1926 the lower leg of the old aerial tramway that had carried ore to mills 1 and 2, and recently to No. 3 mill, was abandoned.

Display large image of Figure 17

Display large image of Figure 17

Display large image of Figure 18

Display large image of Figure 18

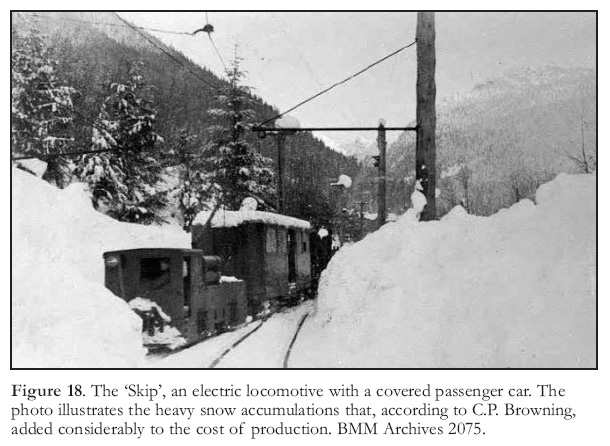

69 The surface electric railway, the last component of the ore transportation system still above ground, was eliminated from the system in 1928. During the previous two years the 2700L adit had been extended to below the Bluff and Fairview mines (making it 3.4 km long) and near its end it was linked to the 2200L by a major orepass. Ore from all the mines, which had previously been hauled out the 2200L haulageway and down to the 2700L – 4100L orepass near the 2700L portal by the surface railway, was now dumped through the new 2200L – 2700L orepass to near the end of the 2700L (Fig. 6) and then hauled about 3.3 km to a crushing chamber at the top of the 2700L – 4100L ore-pass. There it was crushed, fed down to the 4100L and hauled out to the mill. This improvement reduced costs and production delays related to snow removal on the railway (Fig. 18) and made the 2700L and 4100L adits the two main haulageways. The surface railway and the incline remained in service for transporting supplies and passengers between the Beach and the Townsite.

70 In 1929, the price of copper exceeded 18¢/lb, after being range-bound between 12 and 14¢/lb for 8 years. It was a good year for the mining industry. Approximately 1100 men were employed at Britannia mines, 625 underground and 470 on surface. About half the men on surface worked at the Beach and the remainder worked in the various camps. Most of the underground crew lived at the Town-site, although miners also lived at the Barbara, Empress, Victoria and Incline (2700L) camps.

1930 – 1934: The Great Depression

71 In 1930 ore production at Britannia reached an all-time high of just over two million mt. The Fairview, Bluff, Empress and Victoria mines were all in production. About 20 500 mt of copper and 392 000 grams of gold were recovered. However, towards the end of 1930, Britannia, and the mining industry as a whole, began to be affected by the Great Depression.

72 The economic downturn that followed the Wall Street stock market crash in October 1929 quickly spread throughout the industrialized world. The demand for metals, and metal prices, plummeted. In 1930 the price of copper fell 40% in six months, and continued to fall from an average of 13¢/lb in 1930 to an average of only 5.8¢/lb in 1932. Compounding the price squeeze were protectionist trade barriers erected by Britain and the United States that affected sales of Britannia copper. As a result, production at Britannia fell from over 2 million mt in 1930 to a depression low of 598 000 mt in 1933. Elsewhere in BC, the Copper Mountain mine near Princeton, BC, which was a significant copper producer before the depression, closed in 1930. The Anyox mine, the only other important copper producer still operating in BC, maintained production but became depleted and closed in 1935.

73 The most difficult years of the depression for Britannia were 1932 and 1933. Operations were severely restricted but the mine survived. In 1932 the tonnage mined was 30% of that mined in 1930 and in 1933 the mill operated at only 20% of capacity. By mid 1933 the payroll had dropped to about 400, compared to an average of over 1000 in 1930. In order to minimize layoffs, men were employed in staggered shifts and were allotted a number of days of employment per month, with a degree of preference given to married men. In this way, most men with families, as well as some of the single men, kept their jobs.

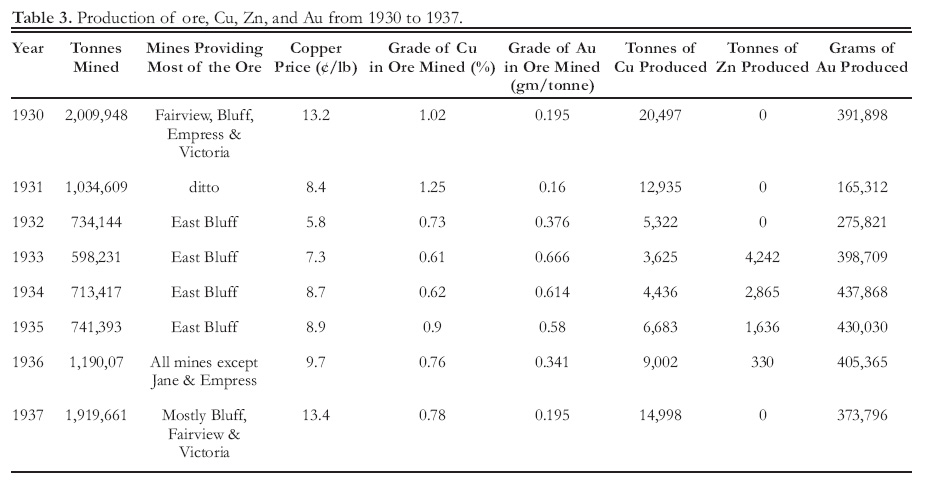

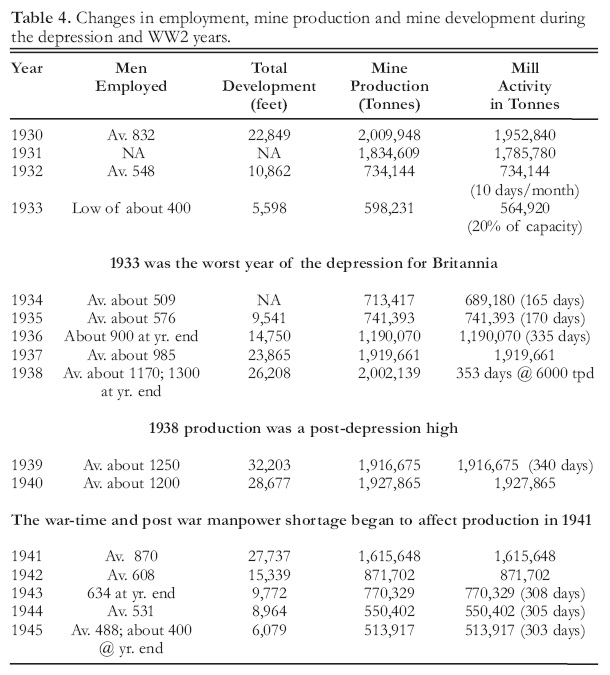

74 Britannia adapted during the depression by mining orebodies that contained relatively high gold and zinc credits. Britannia became a copper– gold–zinc producer, and in 1933 the mill added a zinc circuit to produce zinc concentrate. While the price of gold increased from an average of US$20.72 per ounce in 1930 to US$35.00 in 1935, the price of copper decreased. Britannia responded by drawing most of its ore between 1931 and 1936 from the East Bluff orebody, which contained only 0.5% copper but had higher gold and zinc values than other orebodies. Table 3 shows the dramatic decrease in copper and the increases in gold and zinc produced between 1931 and 1937. Metal prices began to recover in 1933, and in 1936 it was decided to resume mining beyond the East Bluff and to increase both mine and mill production. Tables 3 and 4 show these changes and the accompanying changes in employment.

1935 – 1946

75 By 1938 production had recovered from the depression-era lows almost to the peak level of 1930, and the average payroll had increased to pre-depression levels (Table 4). But in 1941 production began to drop sharply to a 23 year low in 1946 of only 400 000 mt (Fig. 11). This large fluctuation was not caused by metal prices, which gradually increased during this period, but from labour issues. Whereas the upswing from 1934 to 1938 reflected a period of increasing employment, active mine development, the beginning of production in 1938 from No. 5 and No. 8 mines, and a high level of continuing production from the Bluff, Fairview and Victoria mines, the decline from 1941 to 1946 reflected a war-time shortage of experienced miners. Table 4 reflects these operational changes.

76 During the post-depression period several important changes were made to the ore transportation system. Extension of the 4100L adit had continued periodically through the depression and by 1938 the face was 4.1 km from the portal. An ore-pass raised from near the end of the 4100L adit to a point on the 2700L near the bottom of the 2200L – 2700L orepass (Fig. 6) provided a more direct route to the 4100L haulageway for all ore handled on and above the 2200L, including ore from the recently discovered No. 5 orebody. A primary crushing station was built near the bottom of the new 2700L – 4100L ore-pass. The 2700L adit was no longer a principal haulageway because ore was no longer hauled from the bottom of the 2200L – 2700L ore-pass to the old 2700L – 4100L ore-pass near the 2700L portal.

77 No. 8 orebody was discovered in 1937 by a diamond drill program along the 4100L. An internal shaft (#8) was collared a short distance west of the new 2700L – 4100L ore-pass to access the No. 8 orebody, most of which lay below the 4100L. By 1941, the 4100L adit had been extended to the Victoria shaft (6.1 km from the portal) and ore from all the mines could now be hauled to the mill on the 4100L. The 4100L had become the only principal haulageway, and it would remain as such to service the yet to be discovered No. 10 Mine. The 4100L adit was subsequently extended beyond the Victoria shaft to approximately 8 km from the portal (Fig. 6).

78 By 1941 the labour shortage attributable to WW II had become serious. Not only had enlistment reduced the workforce during the war but so too had the lure of better paying jobs with companies engaged in the war effort. Few returning veterans had mining experience and few wanted to obtain it. In a single post-war year, Britannia lost 1152 employees, mostly recently hired men who were unqualified or who became dissatisfied. "Britannia was hiring just about anything that walked" (anonymous staff member). New ore was not being developed and production and profits fell. Toward the end of 1945, Britannia was operating with fewer than 400 employees and, in the opinion of one operations staffer, it was "living in a state of hand to mouth". In 1946 the situation was exacerbated by a strike by the Britannia local of the International Union of Mine, Mill and Smelter Workers (Canada) that closed Britannia for 3.5 months. The closure was partly responsible for the drop in production in 1946 to less than 400 000 mt, the lowest level since 1920.

Display large image of Table 4

Display large image of Table 4

79 In 1945 or 1946, the New York office of Howe Sound Co. decided to close Britannia if newly set production quotas could not be met (Ramsey 2004, p. 100). Fortunately, metal prices improved and closure was avoided.

1947 – 1962

80 In 1947 C. P. Browning retired and E. C. Roper was appointed manager. In 1956 G.C. Lipsey was appointed manager and E.C. Roper moved to the New York to become President of BM&S Co. and the Howe Sound Co. Late in 1957, Lipsey retired and J.S. Roper (no relation to E.C. Roper) was appointed temporary manager.

81 With the resumption of work after the 1946 strike, the mine was still under threat of closure, but spurred by a sharp rise in the prices of copper, zinc and lead and an improving labour situation, production more than doubled from 1946 to 1947. During the decade from 1947 to 1957, annual production at Britannia remained fairly constant, between 721 000 and 831 000 mt. Metal prices increased, supported in part by the Korean War (1950 to 1953). During this period most of the ore came from the Bluff, Fairview, No. 8 and Victoria mines. The Jane, East Bluff, Empress and No. 5 mines were active but produced only small tonnages intermittently; in 1954 No. 5 mine was depleted. Development consisted mainly of following downward extensions of known ore-bodies such as the Bluff.

82 Base metal and silver prices fell sharply during 1957 and both 1957 and 1958 were difficult years for the North American mining industry. At Britannia, the payroll at the end of 1957 was 523 compared to 859 the previous year, and production was falling. The Howe Sound Company lost a significant sum of money during 1957, and late in the year it announced that Britannia would close in December, ostensibly because of the low price of copper. However, direct subsidies from the provincial and federal governments enabled Britannia to continue operations on a reduced scale until March, 1958, when operations were temporarily suspended. A mere 60 600 mt of ore were produced and milled in 1958.

83 After a financial reorganization of the Howe Sound Company (see section titled ‘Demise of the Howe Sound Company’) D.W. Pringle was appointed general superintendent, and then manager at Britannia. Underground operations resumed in January 1959, and the mill reopened the following month. Until 1963 total employment ranged between 300 and 400, with 200 to 250 men working underground.

84 Production increased as metal prices improved, reaching slightly over 450 000 mt in 1962. Development work underground returned to a normal level and limited exploration was conducted in the Victoria and No. 8 mines, which suggests that the operations staff expected production to continue. However, the strategy of the reorganized Howe Sound Company was to divest itself of its mining assets. Accordingly, the instructions to A.D. McCutcheon, Britannia operations manager during 1961 and 1962, were to operate the mine as long as it was making money and then to shut it down (Waterman 1970). To this end the Britannia operation was put up for sale.

85 Following an invitation by McCutcheon to J.B. Knaebel, General Manager of Anaconda Canada Ltd., Knaebel visited the mine in 1962. Knaebel and Glen C. Waterman then conducted a formal evaluation of the Britannia operation. Knaebel examined the economics of the operation and Waterman studied the geology and recalculated the ore reserves. The result of their study was a recommendation that Anaconda purchase the Britannia property.

1963 – 1974: The Anaconda Years

86 In January 1963, the Anaconda Company (Canada) Ltd., a wholly-owned subsidiary of Anaconda American Brass Limited, purchased the Britannia operations from the Howe Sound Company for $5 000 000. Britannia was incorporated as Anaconda Britannia Mines Ltd., and B.B. Greenlee was appointed resident manager. Anaconda Canada Ltd. used Britannia as an operations base for exploration activities in western Canada, although it also maintained an office in Vancouver, which became the registered office of Anaconda Canada in 1965.

87 From an operations perspective, Anaconda had a poor start at Britannia. In August, 1964, the Britannia local of the Mine, Mill and Smelter Worker’s Union called a strike, and in September the company removed all equipment from underground except the main hoists and transformers. The strike lasted five months and production did not resume until May, 1965.

88 Anaconda initially developed and mined limited reserves in the No. 8, Victoria and Bluff mines. In 1965, roads were built to the old Jane Basin to access the previously mined ‘glory holes’ (see section titled ‘Mining Methods’) and during the summer of 1967, a 20-man open-pit crew produced about 77 000 mt from the Jane pit (7.5% of the year’s production). By the end of 1971 all the ore zones above the 4100 haulageway level had been mined out, namely the Jane, Bluff, Fairview, Empress, Victoria, No. 4 and No. 5 zones.

89 After assuming control of Britannia, Anaconda established a well equipped geological research laboratory, and a large staff of geologists was employed to re-log existing drill core and to re-map the mine workings. The program also involved considerable diamond drilling, which resulted in the discovery in 1964 of the 040 orebody lying 760 m west of the No. 8 mine.

90 Unlike other orebodies, which lay close to the footwall of the shear zone, the 040 was found some 240 m into the shear zone from the footwall. It was a small orebody, but its discovery led to the development of the important No. 10 mine. A drill hole from the 5700L in No. 8 mine, the deepest level in the mine at the time, had intersected 12 m of 040 mineralization the day before the August, 1964, strike began, and G. C. Waterman, Vice President and Chief Geologist of Anaconda Britannia Mines Ltd., later observed that if the 040 intersection had not been made before the strike began it is probable that the 5700L would not have been reclaimed after the strike, and hence the 040 and No. 10 ore bodies would not have been discovered (Waterman 1970). No. 10 shaft was collared on the 4100L, 2435 m from the portal, and extended to below the 5700 level. Production began in October of 1970, using trackless mining. The No. 10 ore body contained approximately 2.7 million mt grading 1.9% copper, and accounted for about half of Anaconda’s Britannia production.

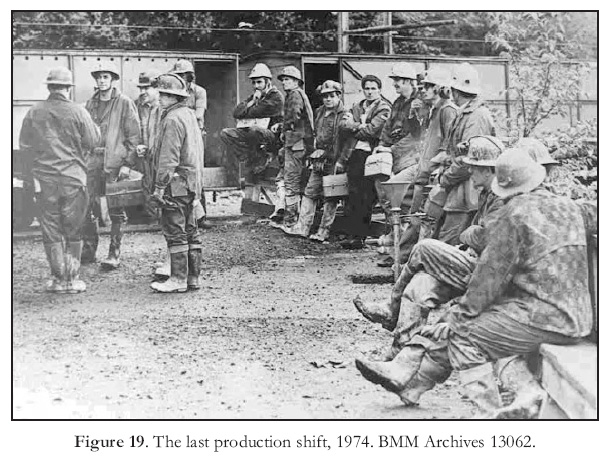

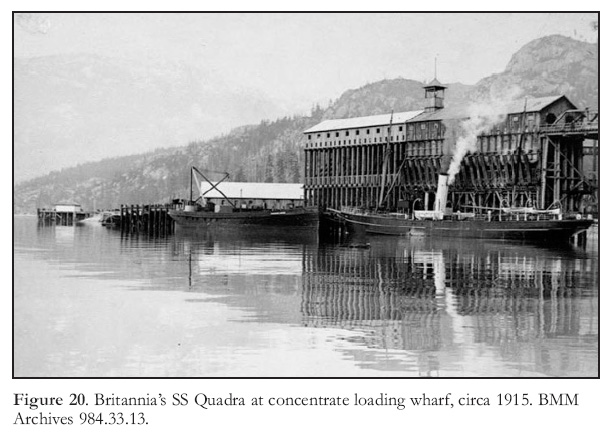

91 During 12 years of operation, Anaconda mined 5.7 million mt and produced 66 700 mt of copper, which was almost 13% of the total copper recovered from Britannia Mines. When Anaconda closed Britannia in 1974, No. 8 ore zone was depleted and the remaining ore reserves in No. 10 Mine, mostly below the 5700L, were about 1.4 million mt grading approximately 1.9% copper (MINFILE), which represented just under three years mill feed at the 1973 production rate. The price of copper was an historic high of 77¢/lb. The last production shift went underground in November of 1974 (Fig. 19).

92 During nearly 70 years of almost continuous operation, Britannia Mines produced 517 000 mt of copper, 125 290 mt of zinc and lesser, but economically important, quantities of gold, silver, lead and cadmium. The network of tunnels, shafts, raises and development drifts connecting the workings extended more than 1.8 km vertically and 7 km horizontally, and is estimated to have exceeded 200 km total length.

Mining Methods

93 Mining methods at Britannia were mainly adaptations of square-set, cutand-fill and shrinkage stoping techniques (Brennan 1935; Stewart 1968). Muck handling during stope development was by scraper drifts and mucking machine draw-points, supplemented by bulldoze chambers in blocky ground. Longhole ring drilling, both horizontal and vertical, was utilized during the 1930s and 1940s in large, wide stopes. Parts of the Bluff and Fairview orebodies were mined by induced caving. At various times, notably from 1916 to 1922, upper parts of the Jane, Fairview and Bluff deposits were mined by a combination of open pits (‘glory holes’) and shrinkage stoping. The glory-hole system of mining was developed by driving raises from underground to the surface; the tops of these raises were then enlarged. Five such open pits were developed (Fig. 10), from which broken ore was directed through ore-passes to the underground ore transportation system. The snow accumulation at high elevations limited open-pit production to about seven months of the year.

94 Ground in the Britannia mines was sufficiently competent that extensive timbering was not required. However, in the Victoria and Empress mines, square-set stoping was required, in places with immediate back-filling. A sawmill was established near the Victoria camp in 1924 to supply the required timber.

95 A significant production advantage at Britannia was that, except for No. 8 and No. 10 orebodies (which lay below the 4100L), and early production from the Victoria mine, the vertical component of ore transportation was largely gravity driven. The No. 8 and No. 10 shafts were sunk from the 4100L and ore was hoisted to the 4100L haulageway. In No. 10 mine, ore was mined by blasthole stoping and sub-level caving with trackless haulage to No. 10 shaft. When mining operations ceased near the end of 1974, the trackless haulage system reached below the 5950L, which was more than 518 m below sea level. Although the bottom of the mine was below sea level it did not extend out beneath Howe Sound.