"Something More Durable. . .":

The British Military’s Building of Wellington Barracks and Brick Construction in 19th-Century Halifax

Cameron Pulsifer

1 FOR MORE THAN A CENTURY AFTER ITS FOUNDING in 1749, Halifax was built mostly of wood. Some brick and stone buildings were constructed over the years, especially along the waterfront. Most of these were stone, as were a few prominent public buildings, such as the lieutenant-governor’s residence (completed in 1808), the legislature (completed in 1819), and St. Mary’s Cathedral (completed in 1827).1 The majority of the city’s buildings, however, were constructed of relatively cheap, plentifully available wood and covered with wooden shingles. Crowded along the downtown streets, these buildings were subject to deterioration due to the weather and liable to destruction by fire, though Halifax escaped the sweeping conflagrations that devasted Quebec, Saint John and St. John’s.2

2 Building construction changed in the second half of the 19th century as the city expanded and the economic base diversified following a period of unprecedented prosperity in the 1850s and 1860s. Expansion required more and larger buildings and, as Susan Buggey has noted, growing civic pride and social conscience resulted in efforts "to upgrade the quality of the urban fabric".3 A series of devastating fires in the downtown between 1857 and 1861 was, perhaps, of most immediate impact. This impelled civic authorities to pass stringent new fire regulations requiring builders to use fire-resistant materials such as cast iron, stone and brick. The latter proved the most popular.4

3 Bricks became increasingly common as a building material in mid-19th-century North America; Halifax, as well as Nova Scotia generally, was about to join the mainstream. First, though, it needed an adequate supply of brick at reasonable prices. This occurred in the 1850s, as a direct result of the British military’s decision to build the massive brick Wellington Barracks. Its construction was important to the spread of brick architecture in Halifax and highlights the impact of the military garrison on the material culture of Halifax and the lives of Haligonians.5

4 Some locally-made bricks were available in Halifax soon after European settlers landed in June 1749. The governor, Edward Cornwallis, reported to London a year later that across the harbour at Dartmouth "30,000 bricks have been produced . . . which proved very good", and some bricks were made there over the course of the next century.6 Wood, however, remained the chief construction material; builders used bricks primarily for the relatively minor work of building foundations, chimneys and fireplaces.

5 From the beginning, Halifax was the home of a sizable British naval and military presence, first as a counterweight to the French presence at Louisbourg and then as an important naval outpost protecting British interests in the western North Atlantic. Ships and their sailors were usually at sea or else at Bermuda, the other important western Atlantic naval station. At least two regiments of infantry, plus artillery and engineers, however, were always stationed in Halifax. They had the greatest ongoing interaction with, and impact upon, the local community and required infrastructure such as storage, buildings and barracks, which were sometimes of stone but usually of wood. As well, the military constructed defensive works, which were usually of earth and were most often thrown up during periods of war or when war threatened. Typically, they were left to deteriorate after these periods passed.

6 A lengthy consideration of the prospects of fortifying Halifax produced by the British in 1761 noted: "Brickwork is of shorter duration than masonry [stones and mortar] and much more Expensive, it is therefore seldom used where stone can be got, but for some uses it is absolutely necessary, such as fire-places and Partitions in Dwelling-houses, arches of Powder-Magazines, Casemates and other subterraneans that are used for stores or occasionally for lodging places".7 The first permanent defensive works constructed of stone and intended to last were five "Martello Towers" the British erected between 1797 and 1827. Only one of these structures, the relatively elaborately designed Sherbrooke Tower at the tip of Mauger’s Beach on the western side of McNab’s Island, was designed to be bomb-proof, requiring a large number of bricks for its interior walls. It would appear that these were obtained locally.8

7 In 1828, when the British began planning for a huge new stone fortification atop Citadel Hill as part of a large-scale upgrading of British North American defences, officers of the Royal Engineers had different ideas about the suitability of local bricks. This was to be by far the largest military work ever undertaken in Halifax whether temporary or permanent. The walls were to be of ironstone and granite, but the fortification contained numerous structures requiring bricks. These included at least 58 casemates under the ramparts and eight, two-storey casemates in a separate building, and other structures such as powder magazines, water tanks, passages from the parade to the ditch and a lengthy musketry gallery bordering the ditch that required bombproofing. Huge numbers of bricks would be needed for their arches and walls, indeed the largest number required for any structure yet erected in Halifax.9

8 The Commanding Royal Engineer in charge of the Citadel Hill project was Lieutenant-Colonel Gustavus Nicholls. During an earlier posting he had worked on Sherbrooke Tower. In December 1825, he sent London his plans for "re-erecting in masonry, Fort George on Citadel Hill" and raised concerns about relying on local brick supplies. "In regard to bricks for turning the arches", he wrote, "I would suggest the advantage of sending them as ballast in any ship taken up for the transport to this place of Troops or Ordnance Stores, as the bricks here are of a very poor quality". Later, in October 1828, he wrote: "There are only two brickmakers in Halifax and it would never do to depend entirely on them as besides enhancing the price they would not be likely to supply the number of bricks required".10

9 Despite Nicholl’s reservations, the Board of Ordnance directed in July 1829 that 517,000 "small" bricks and 283,000 "large" ones be purchased on the spot; 280,000 "large" bricks were to be sent from England.11 English bricks measured nine by three by four inches; Nova Scotia-made bricks, as regulated by a statute of 1792, were eight by two by four inches, although English size bricks could be made in Nova Scotia.12 Nicholls persevered as he considered English-made bricks "in every way superior" to local ones. In 1831 he urged his superiors to send out an additional 200,000 "gray [sic] stock" bricks on top of those already sent out in 1829.13 His arguments must have succeeded, as large numbers of English-made bricks continued to arrive in Halifax. Despite being called "grey stocks", these bricks were almost exclusively of a yellowish colour, except possibly for a few among the earliest shipments, which were red. Precisely how many English bricks arrived is not known, but hundreds of thousands arrived during Nicolls’ tenure as Commanding Royal Engineer. Many more were shipped subsequently, with half a million arriving in 1842 and a similar number in 1843.14 Indeed, yellow-coloured, British-made bricks make up most of the Citadel’s visible brickwork.15

10 By 1843, however, with work on building the Citadel casemates probably at its most intense, another Commanding Royal Engineer, Lieutenant-Colonel Patrick Calder, reversed purchasing policy. After the arrival of the 1843 shipment of bricks from England, Calder indicated he was displeased with their quality and convened a Board of Survey to investigate. Not surprisingly, this Board, under Captain Molesworth of the Royal Engineers, reported the bricks to be "the very worst description of mixed stocks and common place bricks and not fit for the purpose they are chiefly required for viz. for the arches and the brick lining of the walls on which it is intended to plaster".16

11 Calder sent the report to his superiors in London, offering his opinion that "Bricks of a much better quality than has been sent out for several years are made in this Province, and that by a timely arrangement with the makers could be obtained in quantity at a price under that charged against the work for English bricks". He even included some samples so that they could see for themselves. The local products, he noted, were "rather smaller than English bricks [but the] manufacturers say if required [they could] be made of the full size".17

12 Calder’s complaints seem to have had an impact on purchasing policy. All the brickwork in the casemates built after 1846, Calder’s last year in Halifax, was constructed with large, red-coloured bricks, which almost certainly were locally-made; use of British-made, yellow bricks practically ceased after that date. There is no evidence of a dramatic improvement in the quality of Halifax bricks in the decade between Nicholls’ forthright condemnation of local bricks and Calder’s ringing endorsement. Nor do the British-made bricks in place at the Citadel seem to be in especially bad shape after more than 160 years. Calder, pressed by construction deadlines, may have been more concerned about all too frequent delays in shipping from England than about quality.18 And references to "bricks made in this province" (not city) and to "a timely arrangement with the makers" suggest he intended to obtain them outside Halifax. Certainly, for the next major military construction project begun in 1852, a huge new barracks in the city’s north end to be constructed mostly of bricks, the Royal Engineers specified that the bricks come from yards either in Annapolis Royal or in New Brunswick.

13 This new barracks was to be erected in a field off Gottingen Street owned by the Ordnance Department. The site was just north of the dockyard and immediately south of a knoll called Fort Needham; in the 18th century a fort of that name occupied the knoll. The Royal Engineers first proposed building a barracks in this field in 1835 to relieve congestion in Halifax barracks. At that time, the infantry in Halifax lived in two major complexes. One, North Barracks, was on the northeast tip of the Citadel’s glacis, at the intersection of Brunswick and Cogswell Streets. It consisted of four wings. Two were four and a half storeys high and had been built in 1800. The other two, which stood two and half storeys, dated from 1759. The latter were the first infantry barracks built in Halifax independent of a pre-existing fort.19 The other complex, South Barracks, stood southeast of the Citadel across Sackville Street and east of Royal Artillery Park (where today Brunswick Street cuts through to Spring Garden Road). It consisted of two wings, both of wood. One, to the west, stood a storey and a half and was built in 1786; the other, to the east, stood two and a half storeys and was completed in 1802.20 North Barracks accommodated 38 officers and 699 rank and file, and South Barracks two officers and 548 other ranks.21

14 The Commanding Royal Engineer, Lieutenant-Colonel Rice Jones, reported to London that these two complexes had "become so decayed from age and long use as with difficulty to be Kept in a fit state for occupation by Troops, and that only at a very great Annual expense which must go on increasing as the buildings get older and more decayed".22 As the Halifax Garrison at this time consisted of three regiments of infantry, and the Citadel, then under construction, was expected to accommodate only one, he proposed the expenditure of £40,325 for a building capable of housing 37 officers and 1,059 men on the Ordnance Land near Fort Needham. The ground was sufficiently flat to facilitate construction and "conveniently near to and covering the Magazines, Dock Yard, and other Public Establishments". This location was preferable to building at Point Pleasant at the southern tip of the Halifax peninsula, which earlier had been mentioned as a possible building site, as quick access to the major military establishments from Point Pleasant would be more difficult in winter. Unlike previous barracks built in Halifax, the new one would be permanent as its walls would be "Masonry faced with roughly wrought Granite". Rice Jones specifically ruled out brickwork, which, he wrote, "is found to suffer from the effects of Weather in this country".23

15 Authorities in London replied in April 1836 that, while they intended someday to erect a barracks "for one battalion" on this site, they still wanted to receive plans for a barracks to be built for another battalion "in the rear of the batteries" at Point Pleasant. Rice Jones supplied these plans in September, noting his own preference for the site "near Fort Needham".24 Still, nothing was done toward building on either site for another decade and a half.

16 In April 1845, the British military took a step that significantly advanced the cause of a new barracks in Halifax. Responding to growing concern about the state of barracks accommodation at the regimental level, authorities in London imposed new regulations that guaranteed a minimum space allocation of 450 cubic feet to every soldier in barracks. Although this was still 30 cubic feet less than that assured to inmates in Scottish workhouses, it was nonetheless much more than soldiers had ever been officially allotted before.25 The new space allocations were supposed to apply only to new construction, but local barracks officials were required to report on the extent that their existing barracks conformed to the new regulations. This helped emphasize the degree to which most barracks fell well below the new standard. In October 1848, when authorities in Halifax finally examined their situation, they found the North Barracks, with 697 rank and file occupants, should, under the new rules, only have 442. South Barracks, which held 457, should hold only 285.26 The Citadel which was expected to accommodate 649 men, had space for only 445.27 Overall, the garrison had 1,109 more men in its existing barracks than the new space regulations authorized.28 Realizing the extent of the housing problem in Halifax, the Board of Ordnance agreed on 25 January 1849 that "at present no alterations in Barrack accommodation need take place". But it also directed that "as the Citadel . . . or other barracks come into use, accommodation should be regulated" by the new orders.29

17 In October, the inspector general of fortifications, General John Fox Burgoyne, drafted a minute for the benefit of the secretary of state for war and the colonies intended to clarify a "Demand for rebuilding a Barracks at Halifax". The demand to which Burgoyne refered is missing from the available documentation, but his minute drew attention to the deplorable state of existing military accommodation in Halifax. With particular reference to the North Barracks, he wrote that it "is now in a thorough state of dilapidation so as to require being shored up to prevent its falling, and to be beyond repair except at a most wasteful expenditure; while its state for a considerable time has been attended with great discomforts and suffering by troops".30 Overall expenditure on British barracks was rising during this period, partially as compensation for a pronounced drop during the decades immediately following the end of the Napoleonic wars in 1815.31 Probably this and the support of strong advocates such as General Burgoyne led to new barracks being finally approved for land near Fort Needham.32 Vice-Admiral, the Earl of Dundonald, living in Admiralty House, just south of the intended construction site, pleaded that the new barracks would result in his residence being surrounded "by Grog shops and Brothels, and that the quarter will be converted into the Wapping of Halifax" and that "No Admiral with a family could possibly reside here". But his protests were of no avail.33

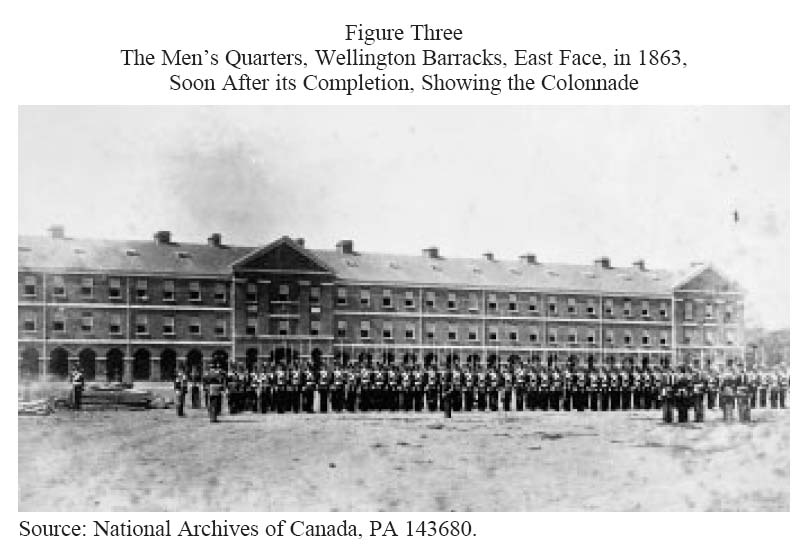

18 The new barracks was initially intended to accommodate 26 officers and 555 rank and file, together with hospital space for 40 patients.34 There were to be two buildings on opposite sides of a parade square, the men’s quarters just off Gottingen Street and the officers’ across the square towards the harbour. Designed by officers of the Royal Engineers, the buildings were similar in design and bore many traits in common with any number of military barracks built in Britain over the previous 70 years.35 Both were of neoclassical design with gable roofs and pedimented pavilions at the ends and in the centre. Each stood three and a half storeys high, although the bottom storey of the officers’ quarters was below ground, bordered by a sunken areaway. The bottom interior facade of the men’s barracks was colonnaded, while access to the parade from the street was by means of an arched arcade through the centre of the building. Both buildings were to be of brick, making them the largest brick structures in Halifax to date. According to the contract, the bricks were to be from "New Brunswick or the best quality from this province".36 What influenced the decision in favour of brick, when only 15 years earlier Lieutenant-Colonel Rice Jones had dismissed bricks as inappropriate for the Halifax climate is unclear. Possibly experience in the meantime had convinced the Royal Engineers that bricks could weather as well as stone.

19 The Commanding Royal Engineer, Lieutenant-Colonel Henry Savage, recommended the new barracks in July 1850. In December, the Board of Ordnance approved the construction. Despite destruction of the North Barracks by fire in December 1850, the contract was not awarded until 30 July 1852.37 It went to a firm of Quebec contractors, headed by Simon and Henry Peters and George Blaicklock. The work was to be completed by 31 March 1856 for a sum of £43,271.38 Simon Peters was a well-established master joiner and general contractor. The self-taught son of an Irish sergeant in the British Army, he had rounded off his qualifications with architectural drawing lessons in New York and night school in Quebec. The year after taking the contract for the new barracks in Halifax, he opened a profitable steam-powered sash, door and blind factory in Quebec and, over the following decades, became one of its major building contractors. His younger brother, Henry, had learned the business as an apprentice under Simon’s tutelage.39 George Blaicklock was the son of Henry Musgrave Blaicklock, a draftsman with the Royal Engineer Civil Establishment in Quebec City, who had helped design that city’s Citadel and later branched out into civilian contracting. George’s specialties were those of "master mason, stone cutter, masonry contractor . . . and brick supplier". For three years in the 1840s he held the contract for masonry work on the Quebec Citadel. In addition, he had been involved in extensive civilian stone and brick building.40

20 This was the three contractors’ first venture outside the immediate Quebec City area. There is no documentation indicating their motivation in bidding for the Halifax contract, but it seems likely that they saw potential opportunities in the city which went well beyond the building of the new barracks. Although still backward in many ways, Halifax was nonetheless, since 1840, the first port of call for the westbound Royal Mail ships of the Cunard line and an electric telegraph had been opened from Halifax to Saint John and from there to Boston. Optimism had replaced the initial gloom with which Nova Scotians had greeted the British abandonment of imperial preference and adoption of free trade in 1846, and there was hope that unrestricted trade might well result in a new age of prosperity. Intense negotiations were underway between local politicians and the imperial government to obtain financing to build the railways that would allow Halifax to tap resources in outlying areas such as the Annapolis Valley and Truro and establish a connection with Quebec. Also, there was serious discussion of free trade or reciprocity with the United States. Halifax was indeed entering a period when, as historian David Sutherland has written, "the shape of the future was becoming clear enough to inspire confidence".41

21 That Halifax was expected to benefit from these developments could well have helped spark the decision of the three Quebec entrepreneurs to locate in the city, perhaps in anticipation of a local building boom. Whatever the case, one of their first steps after securing the contract for the new barracks was to ignore its direction regarding where to obtain the bricks. Instead, they forged ahead with establishing their own brickyard across the harbour from Halifax at Eastern Passage in Dartmouth. This they equipped with American-made, steam-operated, brick-making machinery, which appears to be the first such equipment in the Halifax area. The introduction of these new processes and the consequences for the future of brick construction in Halifax ran counter to the original intentions of the British military. Thus, military authorities were responsible for initiating a new era of brick construction in the city despite their original plans.

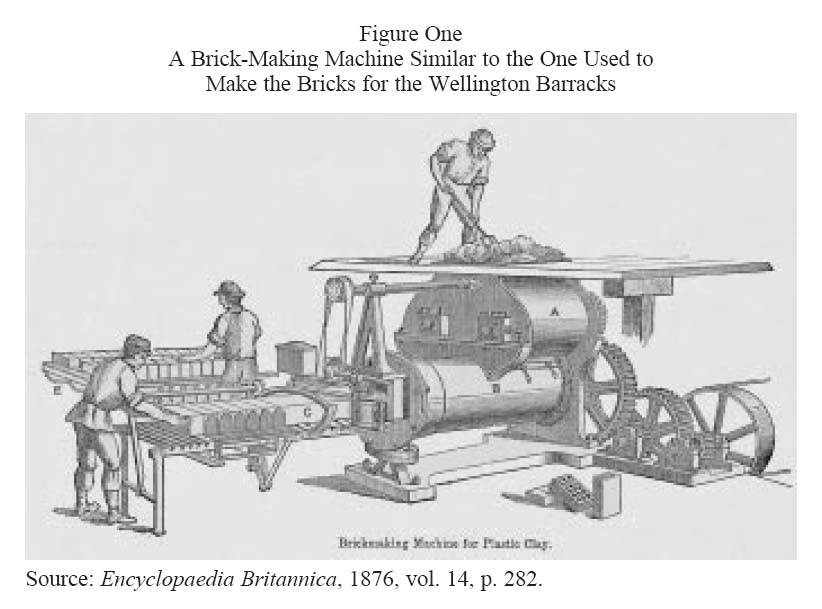

22 An understanding of brickmaking technology helps to put those developments in context. Five basic steps have always been required in manufacturing bricks. First, the brickmaker obtains clay, removing large stones and other objects and, if necessary, adding sand and sometimes shale. The second step is to temper, or mix, the clay with water. The third step is to mould the bricks into their customary rectangular shapes. In the fourth step, the brickmaker lays the bricks out to dry in preparation for burning. Lastly, the bricks are burnt at a very high temperature, which makes them hard and durable (Figure One).

23 Tempering was the first step to become mechanized. Early mechanization involved use of a pit, where the clay, water and other ingredients were mixed with a large wheel rotated by a horse or ox. Early in the 19th century, the ring pit was replaced with the pug mill, an inverted cylindrical box with a number of rotating blades on the inside. The clay, water and sand mixture was introduced at the top of the mill, thoroughly churned and mixed up inside, and then emitted at the bottom. Pug mills were rotated by either horse or steam power.42

24 Although pug mills mechanized the tempering process, virtually all bricks continued to be moulded or shaped by hand until the middle of the 19th century. The tempered clay mixture was manually pressed into rectangular moulds with four sides but no top or bottom. After the clay was thoroughly packed into the mould, the excess was scraped from the top with a flat stick and the moulds removed. Then the rectangular-shaped masses of clay were dried and baked at high temperatures to form the hard, durable brick product. At first this was done by a "clamp-firing" process, a complicated outdoor procedure. Walls of brick were stacked on each other and interspersed with flamable materials called "breeze", which were then set on fire. Increasingly over the course of the 19th century, this process was replaced by the use of dome-shaped ovens (kilns), in which the heating process could be more finely regulated.43

25 The term "machine-made bricks" refers primarily to machine-moulded bricks. There were two basic methods of moulding bricks by machine. One was to force the clay directly from a pug mill into moving metal moulds. The other, more common, method was to emit the clay through the mouthpiece as a continuous rectangular band along rollers, where it was cut into individual bricks by means of mechanically operated wires.44

Figure One : A Brick-Making Machine Similar to the One Used to Make the Bricks for the Wellington Barracks

Display large image of Figure 1

26 Although patents on machines for the moulding of bricks were taken out as early as the last decade of the 18th century, effective brick-making machines did not begin to appear until the mid 19th century and it was probably not until then that their products began to dominate the market. According to Ronald Brunskill and Alec Clifton-Taylor, after 1858 "most bricks [in England] were made by machinery in metal moulds either in power-operated, belt-driven presses, or by squeezing a band of clay through a mill and along strong rollers to a cutting table along which it was sliced by vertical wires suspended from a mechanically operated frame".45 British labour and social historian, Raphael Samuel, though, has emphasized the survival of conservative, manual methods of production in the British brickmaking industry into the 1880s, particularly in the London area.46 The 9th edition of the Encylopedia Britannica, published in 1878, prefaced a discussion of brickmaking by noting that "of recent years there has been no little activity in the invention of brick-making machines", suggesting that although machine methods were becoming more common they did not yet dominate the industry.47 Nonetheless machine methods of production were gaining ground in Britain by mid century. Raphael Samuel claims that because of the relative scarcity of labour in North America, manufacturers adopted machine methods of production in the United States much earlier than in Britian.48 The American brick specialist, Harvey McKee, notes that although "a few bricks were being made by machine" beginning in the early 1830s, "until around 1870 the percentage was small. Machine-made bricks appear to have gained favour in England sooner than in the United States".49 McKee may be correct for the American brick industry as a whole, but some areas of the country were more advanced than others. Brick-making machinery of some sophistication was successfully imported into Halifax from Boston in the mid 1850s and machine-made bricks probably began to dominate the Halifax market from that point on. Since it is improbable that this technology would have gained favour in Halifax earlier than at its place of origin, it seems likely that the production of bricks by machine was well-established in the Boston area of the New England states by this time.

27 Peters, Blaicklock and Peters set to work on the new barracks immediately after winning the contract. They began excavating on 5 August 1852 and the masonry foundations were begun in September. They set the granite plinth in the summer of 1853.50 They had, however, seriously underestimated the problems involved in getting their brickyard established. It began production in 1853, but the Royal Engineers rejected its products before they left the yard. There was little improvement the next year. Major brickwork was due to start on the officers’ portion of the barracks in April, but because of production difficulties at the yard, no bricks were delivered until the end of July. Then the work went so slowly that by the time the construction season ended in November, the walls were only three and a half feet high. Worse, a Royal Engineers Board of Survey reported in September that the bricks were "inferior in quality, roughly manufactured and badly shaped".51

28 Despite these problems, the Board agreed that the work be allowed to stand in hope that it would serve as a usable foundation for better work the next year. The winter of 1854-55, though, was especially severe and by the spring of 1855 the existing brickwork had deteriorated badly. Another Royal Engineers Board of Survey reported on 18 April that "notwithstanding their selection" many of the bricks had "perished owing to their softness from imperfect burning and most of those appearing in the face of the walls are more or less damaged from pieces having become detached from their angles and sides from the bursting of the numerous stones contained in their composition".52 These problems could have been avoided, the Board argued, if the contractors had procured the bricks "by purchase from established manufacturers in Annapolis or New Brunswick", as had been specified in the contract.53

29 The Board of Survey noted that the major problem with the bricks was the number of stones remaining in the clay used to form them, a situation doubtless not helped by the hard soil of the Eastern Passage. Too many of the bricks were gritty and misshapen, and they tended to break under pressure. In his report, the chief Royal Engineer at the building site, Lieutenant Edward Loftus Bland, noted that the "contractors are now putting up new machinery for the purpose of further separating the stones from the clay". But "no new bricks can be expected from their yard until about the 1st of July". The patience of the Royal Engineers was stretched to the breaking point. The Commanding Royal Engineer at the time, Lieutenant-Colonel Richard Stotherd, remarked later that if, by July, he had "had no hope of improvement on the part of the contractors", he was prepared to seek measures to enable the Royal Engineers to take over the work themselves.54

30 As for the three contractors, they had become desperate and were willing to spend money if that is what it took to finish the work. By April, with the clock ticking towards the expiration of their contract, they had installed new machinery at the site, especially imported from the United States, and they had arranged to bring in trained workmen from the Boston area familiar with the equipment. The Board of Survey of 18 April observed that the contractors were even building a residence to house the brickmakers, "who are to be constantly employed on the spot in further of the manufacture of the bricks".55 The first group of about 40 American brickmakers arrived at the yard by the first week of August, 1855. The Novascotian noted on 22 August: There are about forty hands on the premises who are provided for by the proprietors in a building fitted for the purpose. A long room running the entire length of the house with a fixed table and capable of seating about sixty persons, is the dining room, while immediately overhead are sleeping apartments, of similar dimensions, airy and comfortable, and containing about thirty double bed steads, sufficient to lodge the same number of hands.56Besides being familiar with the new machinery, these men were able to help with other troublesome aspects of the enterprise, such as the operation of two new kilns.

31 The clearest description of the machinery used at the brickyard comes from another Royal Engineer Board of Survey of 26 August:The different processes of brickmaking were proceeding on the most improved principles practiced in the United States aided by steam machinery of superior description which screens, grinds and pugs the clay and moulds the bricks (according to the statement of the contractors) at the rate of 20,000 per day. The machine made 200 in 7 minutes. . . . [Also] the pressed brick was of a superior description.57From this it would appear that in addition to the new machinery for screening the clay, there was a pug mill and a moulding apparatus, probably of the type that squeezed the clay into moving moulds. It is not clear whether these were three separate machines, or whether one machine performed all tasks. As well, there were facilities for making pressed bricks, which were to be used for the face of buildings. Lieutenant Bland reported after a visit to the yard on 11 August that he had been told that it was capable of producing 12,000 ordinary bricks and "4,000 pressed bricks per day".58 The brickyard had two kilns, one capable of burning about 170,000 bricks, the other about 187,000.59 "Although not an expert in the art of brick procreation", wrote the reporter for the Novascotian,we can easily foresee that the abundance of mechanical facilities on the ground must make the kiln of Messrs. Peters & Blaicklock the great brick-producing machine of the day. A quantity of face bricks lately burnt attracted particular attention. These are for the new barracks at Fort Needham and for beauty of finish, smoothness of surface, and evenness of color are superior to anything of the kind ever seen in this city. A new American invention but lately in operation and calculated to turn out an almost incredible number of bricks daily is the principle [sic] feature of the premises.60

32 The problems facing the brickmakers in meeting their deadline for finishing the building in less than a year’s time were outlined in reports by Lieutenant Bland. He noted in April, for example, that none of the joiners’ work for doors and windows was ready, nor was the carpentry work for floors and roofing, which "must be stacked to season for nine months after being worked".61 Nor did the newly-arrived brick-making machinery necessarily inspire him with confidence. Simon Peters had told him on 3 August that the contractors would be able to manufacture 12,000 stock and 4,000 pressed bricks per day for a total of 16,000 bricks. But to complete just the officers’ barracks required about 1,300,000 bricks. With 300,000 bricks made to date, a further 1,000,000 were required. Indeed, Bland strongly urged that the builders’ contract be revoked.62

33 The first shipment of bricks made with the new machinery arrived at the building site on 11 August. A Royal Engineers’ Board of Survey inspection at Magazine Wharf, where the vessel carrying the material had tied up, produced a favourable report. "Although not equal to the pattern bricks in the office", the bricks "were with few exceptions fit for use in the work". Furthermore, it observed a greater efficiency in the operations of the brickyard and was optimistic about the speed of future deliveries, testifying to the "energy and perseverance of the Contractors . . . this season". Since the new machinery came into operation, it reported, "about 500,000 have been moulded".63

34 These were all large, British-size, bricks, although the colour was the prevailing local red shade. There was also hope for the work of the joiners and carpenters, as Simon Peters had earlier revealed "a contract he had entered into for being supplied with machinery for the preparation of the Carp[ente]rs and Joiners work which he proposed setting up at the Barracks to facilitate the execution of that portion of the work". Moreover, Bland had been assured that slates and patent felt for the roofing had been ordered and that the "framing for the roof would be ready on time". He noted cautiously, however, that "as this is being prepared a distance from Halifax, we have not seen it".64 The contractors later claimed that they put £12,000 to £13,000 of their own money into such necessary undertakings.65 Stotherd, perhaps relieved to see his way clear of the legal and scheduling complexities of withdrawing from the contract, was similarly positive. He had anxiously awaited the arrival of the first shipment of bricks and was prepared to terminate the three builders’ contract should they prove unsatisfactory. But he wrote, "for the present this does not appear necessary". When the first shipment of bricks arrived on 11 August, he "was glad to find so great an improvement in their manufacture, with a prospect of continuous supply, that nothing but the lateness of the season would prevent the contractors from completing the roofing in the block of Officers Barracks this year, of which they express themselves still confident".66

35 Stotherd’s hopes were disappointed; the contractors did not meet the deadline. Five days after its expiration, on 5 April 1856, Major-General Sir Gaspard Le Marchant, Commander-in-Chief in Nova Scotia, received a petition from the three contractors requesting to have their contract reinstated after Colonel Stotherd had refused to do so. They explained that sometime before the 31 March deadline they had realized that due to "various unforeseen causes" they could not meet their deadline and applied for an extension. Knowing that some sort of security would be required, they asked Stotherd to accept the large sums of money spent on the project as a "Material Guarantee . . . in lieu of personal security". They thought that Colonel Stotherd had accepted this proposal, but in the meantime they acquired the requisite personal security as well from Archibald Campbell, an old Quebec business partner. Yet on 28 March they received news that their application was unsuccessful due to a lack of personal security, which they claimed not to have registered as they were awaiting the outcome of their first request for the offer of material security. When they made this claim to Stotherd, he had simply reiterated to them that "their contract must cease". They argued that they had made every provision for "the rapid completion of the Contract. They have all the Material that is needed; they have numbers of men engaged from the United States for the various operations, and they are prepared to push the work on with all speed and on this head they Court the Strictest Enquiry". The matter was, they claimed, "one of Life or Death to them and their Families".67

36 Possibly worried about even further delays, Le Marchant upheld their appeal. The Novascotian of 21 April reported that a suggestion in a previous issue that the British intended to complete the work on the new barracks was wrong. Peters, Blaicklock and Peters were now under contract to finish the barracks by 30 September 1858. "The Brick-yard at Eastern Passage is now in an admirable state of efficiency", it claimed, "and an augmentation of skilled labor, a portion of which came down in the Packet brig America from Boston will enable them to fulfill their contract without further difficulty or detention".68 The new brickyard had been granted the chance it needed to become firmly established. The contractors also missed their deadline of 30 September 1858 by a couple of months and had to pay a late fee of £5 a day for 64 days, or a total of £320. However, the new Commanding Royal Engineer, Lieutenant-Colonel Richard Nelson, was more sympathetic, writing in March 1859, "The very limited and indifferent resources of this place have . . . told with great severity on the enterprise – for enterprise it was in a Colony notoriously backward in matters of every kind connected with advancement and civilization". Furthermore, "the contractors had no established market with competitive advantages for brick lime etc. & they had to find out the very land for the clay, and set up a special manufactory and so on".69

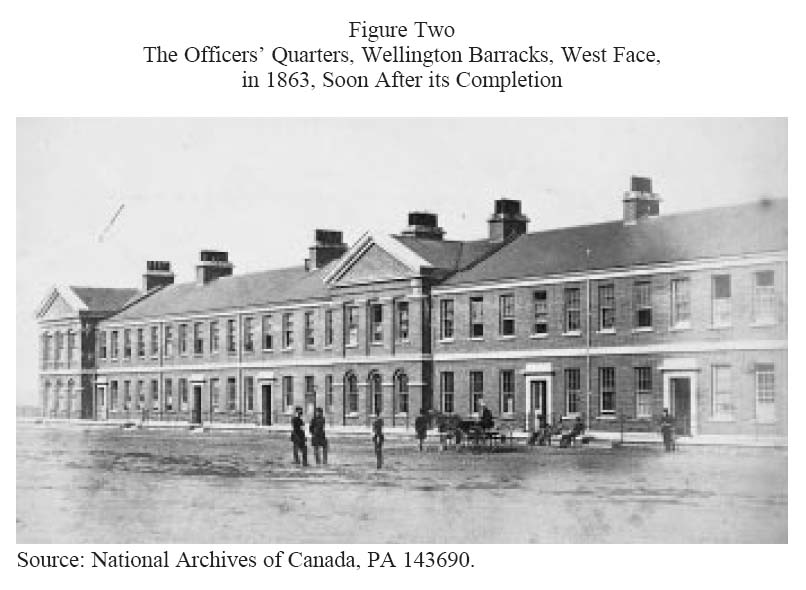

37 The Royal Engineers finally handed over the new barracks to the Barrack Department on 13 April 1860 (Figure Two).70 The 62nd Regiment of Foot began to leave the Citadel and South Barracks on 18 April and on the 21st, as reported by the Acadian Reporter, South Barracks was "all but vacated and the new ‘Wellington Barracks’ – we do not know who is accountable for that name – is the place in this city where soldiers ‘most do congregate’".71 The new barracks accommodated more men than first envisioned in 1850. According to Lieutenant-Colonel Nelson, it comfortably housed 35 officers and 794 rank and file with 458 cubic feet per man, eight cubic feet more than the regulations dictated. In the meantime, however, barrack authorities were confronted with new decrees from London requiring 600 cubic feet for every soldier. In response, Nelson argued,"Taking the general airiness and healthy aspect of the Wellington Barrack rooms at 458 feet per man, I cannot but conceive that this is ample for a North American climate – leaving 600 cubic feet for our tropical colonies".72 Nelson’s arguments were not accepted in London, and over the coming years barrack officials in Halifax had to grapple with the problem of providing every soldier with 600 cubic feet of space, but the new building was at least now fully occupied (Figure Three).

38 The reporter from the Novascotian who visited Peters’, Blaicklock’s and Peters’ new brickyard in August 1855 had commented: "With such facilities bricks cannot any longer command the high rates they have hitherto held, and our citizens . . . we have no doubt will in future erect their buildings of something more durable than the crazy rotten fabrics so prevalent with the present generation of Haligonians".73 Leaving aside the question of whether these comments were prompted by the brickmakers themselves, the observations proved prophetic for the building history of downtown Halifax over the next decades. The new brickyard was purchased by a local businessman, William Hare, soon after the completion of the Wellington Barracks. Named, appropriately enough, Wellington Brickyard, it offered its product for sale in the city. On 31 July 1861 an advertisement appeared in the Halifax Evening Express newspaper for "No. 1 First Class Large Sized Bricks manufactured at the Wellington Brickyard, Eastern Passage", which could be "landed at any wharf in the city, in any quantities that may be required, and . . . sold at the lowest market prices". Quantities of between 1,500,000 and 2,000,000 were available.74 A shift was underway in Halifax at this time from the almost exclusive use of wood for buildings to the adoption of more durable and fire-resistant building materials; indeed, city council had legislated it for the downtown area.75 The plentiful, high-quality and inexpensive products available from the Wellington Brickyard no doubt helped to ensure the success of this transition.

Figure Two : The Officers’ Quarters, Wellington Barracks, West Face, in 1863, Soon After its Completion

Display large image of Figure 2

39 Peters, Blaicklock, and Peters never received another military contract. Instead, the Royal Engineers subsequently favoured the Yorkshire immigrant, John Brookfield, who received contracts from them totaling more than half a million dollars. It was Brookfield who undertook the extensive rebuilding projects of the 1860s and 1870s at places such as York Redoubt, George’s and McNab’s Islands and Point Pleasant, readying their defences for the new age of rifled artillery. While large numbers of bricks were required for these and later buildings, the work benefited from the developments made earlier in local brickyards and it did not have the revolutionary impact on the local building scene as had the construction of Wellington Barracks.76

40 After the completion of the new barracks, Simon Peters returned to Quebec where he continued to prosper. Henry Peters and George Blaicklock became major Halifax builders.77 Susan Buggey, borrowing the typology of the British building historian E.W. Cooney, puts them in the category of "master builder", of which there were then only a half dozen in Halifax. These were builders who undertook the "erecting of complete buildings . . . employing more or less permanently a relatively large body of labourers and workmen in all the principal buildings crafts", as opposed to other lesser types who performed some, but not all, of these operations.

41 In 1857, even before Wellington Barracks was finished, Peters, Blaicklock, and Peters obtained the contract to build the new St. Matthew’s Presbyterian Church on Barrington Street, still there today.78 Independently, Blaicklock constructed numerous buildings in the prosperous south end suburbs, and in 1869, completed the large brick structure of St. David’s Presbyterian Church on Grafton Street, also still standing.79 Henry Peters was even more successful, receiving the contracts for, and completing, such imposing brick structures as: the Halifax Poor Asylum, on the South Common between Morris and South Streets, erected in 1869, "the highest building in Halifax and the second largest in the province"; the North Street Intercolonial Railway Depot at the foot of North Street, built in 1879; and St. Patrick’s Church on Brunswick Street, which opened in 1885.80 Obviously, despite the disenchantment of the British military with their work on Wellington Barracks, and the military’s refusal to give them any more contracts, Peters’ Blaicklock’s and Peters’ determination to secure the contract for Wellington Barracks and to push ahead with the development of a brickyard had paid off handsomely. After Wellington Barracks was completed in 1858, there was a huge expansion of brick-making activity in Halifax, and the three contractors benefited greatly from this.81 Indeed, one might argue that despite the large losses that they incurred in building the Wellington Barracks, their entry into the world of Halifax contracting had been subsidized by the British military.

42 For economic reasons, the "crazy rotten fabrics" referred to by the reporter for the Novascotian in 1855 remained an unfortunate characteristic of much Halifax working-class housing well into the 20th century, if indeed it has been completely eradicated even today. Also, most middle-class housing and even much of that of the elite remained of wood, leaving Halifax as probably more extensively wood-built than most North American cities to this day. Nonetheless, the establishment of the Wellington Brickyard initiated significant brick-making in the Halifax area and fostered changes in construction especially in business and public buildings. To meet demand, bricks were, for a time, also made on the Halifax side of the harbour, at Freshwater in a yard equipped with a "Mellings Brick Making Machine".82 Later, in 1885, the yard at Annapolis Royal, which the Royal Engineers initially wanted to supply the bricks for Wellington Barracks, was greatly expanded. Equipped with a "double-headed plunger machine, made by Noseworthy of St. Thomas, Ontario", bricks from it were used in the construction of the new Dalhousie College in the southwest of the city.83

Figure Three : The Men’s Quarters, Wellington Barracks, East Face, in 1863, Soon After its Completion, Showing the Colonnade

Display large image of Figure 3

43 Another area, about 30 miles west of Halifax towards Truro on the Shubenacadie River, also gained prominence in the manufacture of bricks. In April 1862 an advertisement appeared in the Halifax Morning Chronicle for a "Stone and Earthenware Manufactory" at Elmsdale. It sold stoneware, glazed drain pipes, pots of various sorts, fire bricks and had "700,000 superior stock and pressed bricks, large and small sizes".84 Enfield, a few miles away, also had a brickyard. It was first established in the 1850s and was enlarged and improved in 1870 with a number of steam-operated brickmaking machines. In 1875 it produced 2,000,000 bricks, most of which were shipped to Halifax on the Intercolonial Railway. This important link, although not completed in its entirety until 1876, was finished as far as Truro in 1857. The Enfield yard’s chief products were pressed and common stock bricks, but it also made chimney crocks, sewage pipes, flower vases and earthenware of various sorts.85 Other brickyards were established in the Shubenacadie area later in the century. Probably it was the quality of their product that finally resulted in the demise of facilities such as the Wellington Brickyard in Dartmouth, where the conditions of manufacture were not quite so favourable. It closed in the late 1880s.86 The Elmsdale-Enfield region remains the centre of the Nova Scotia brickmaking industry to this day.

44 While the widespread adoption of brick as a construction material in Halifax almost certainly would have happened eventually with or without the British military or the three contractors, the ready availability of the products of the Wellington Brickyard allowed this to take place more quickly than it would have otherwise. Certainly, the new Wellington Brickyard was able to supply Halifax builders with large supplies of locally-made bricks, and do so cheaply. Its success probably helped to instigate the founding or modernizing of rival brickyards which were better situated and capable of producing a superior product. Although slightly further afield, these yards had easy access to Halifax, either by ship or by railway, and were able to supply the increasingly voracious demands of the Halifax market during the remaining decades of the century. There can be little doubt that this process of industrial growth and urban structural transformation began in a major way with the building of the Wellington Barracks and the success of its associated brickyard.

45 For the first century of Halifax’s existence, the British military played a critical part in the city’s formation and development. This was perhaps especially so in wartime, but it continued during peace as well, as large numbers of troops went about their duties garrisoning the city and maintaining its defences. Over the years, numerous civilian trades and industries flourished through the receipt of military contracts and patronage. In the period of prosperity that marked the 1850s and 1860s, the population became double that of the 1820s, and Halifax developed a thriving, independent civic and economic life. In this context, the importance of the military proportionately declined, although it continued to play an important part in the life of the city, as it does to the present day.87 The construction of Wellington Barracks and its impact on the adoption of brick as a building material in Halifax is an important example of the significance of the military garrison to the city’s civilian urban sphere.

Notes